Composite flame-retardant paperboard and preparation method thereof

A composite flame retardant and cardboard technology, applied in chemical instruments and methods, paper/cardboard layered products, synthetic resin layered products, etc., can solve the problems of high cost, low material hardness and easy wear, etc. Cost reduction and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Preparation of Composite Flame-Retardant Cardboard

[0042] Material preparation:

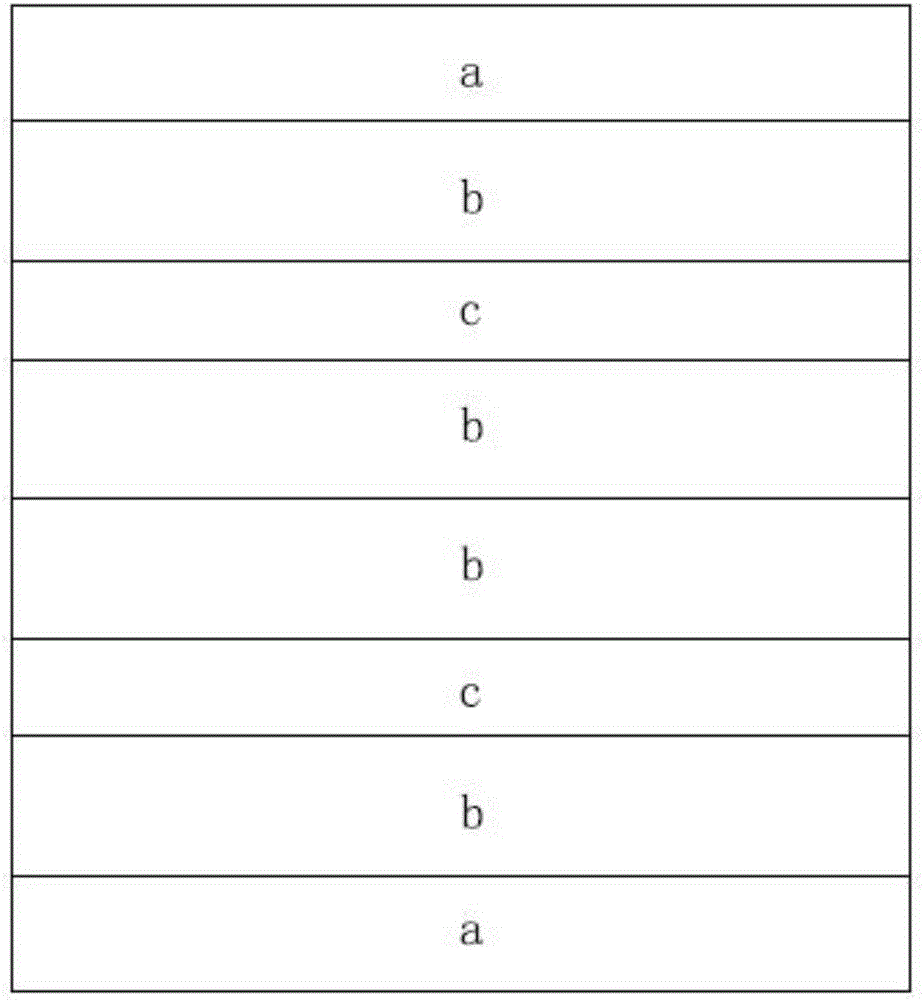

[0043] Put 1 layer of MP layer, 1 layer of CEM1 layer, 1 layer of PP layer, 2 layers of CEM1 layer, 1 layer of PP layer, 1 layer of CEM1 layer, 1 layer of MP layer in the structural order, code them, and send them into the laminator.

[0044] The initial temperature is 30-35°C, the pressing pressure is 60-90bar; the tonnage of the press is 1250T, and the product width is 1050x1250mm. At this time, the glue is in a semi-solid state;

[0045] Then it rises to 50-60°C, the pressing pressure is 140-170bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0046] Continue to raise the temperature to 80-90°C, the pressing pressure is 170-210bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0047] Then keep the pressure and heat up to 150°C; at this time, the glue is in a semi-cured state and turns into a solid st...

Embodiment 2

[0050] Embodiment 2: Preparation of composite flame-retardant paperboard

[0051] Material preparation:

[0052] 2 layers of MP layer, 1 layer of CEM1 layer, 3 layers of PP layer, 2 layers of CEM1 layer, 3 layers of PP layer, 1 layer of CEM1 layer, and 2 layers of MP layer are coded and sent to the laminator.

[0053] The initial temperature is 30-35°C, the pressing pressure is 60-90bar; the tonnage of the press is 1250T, and the product width is 1050x1250mm. At this time, the glue is in a semi-solid state;

[0054] Then it rises to 50-60°C, the pressing pressure is 140-170bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0055] Continue to raise the temperature to 80-90°C, the pressing pressure is 170-210bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0056] Then keep the pressure and heat up to 150°C; at this time, the glue is in a semi-cured state and turns into a solid state;

[0057] Then cool ...

Embodiment 3

[0059] Example 3: Preparation of Composite Flame Retardant Cardboard

[0060] Material preparation:

[0061] 1 layer of MP layer, 2 layers of CEM1 layer, 2 layers of PP layer, 4 layers of CEM1 layer, 2 layers of PP layer, 2 layers of CEM1 layer, and 1 layer of MP layer are coded and sent to the laminator.

[0062] The initial temperature is 30-35°C, the pressing pressure is 60-90bar; the tonnage of the press is 1250T, and the product width is 1050x1250mm. At this time, the glue is in a semi-solid state;

[0063] Then it rises to 50-60°C, the pressing pressure is 140-170bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0064] Continue to raise the temperature to 80-90°C, the pressing pressure is 170-210bar, and the heating rate is 1-2°C / min; at this time, the glue is in a liquid state;

[0065] Then keep the pressure and heat up to 150°C; at this time, the glue is in a semi-cured state and turns into a solid state;

[0066] Then cool down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com