Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

A manufacturing method and wear-resistant coating technology are applied in the manufacturing field of wear-resistant workpieces and their wear-resistant coatings, which can solve the problems of limited external control means, unfavorable process stability control, and high consumption of additives, so as to suppress side reactions and reduce The content of impurities and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

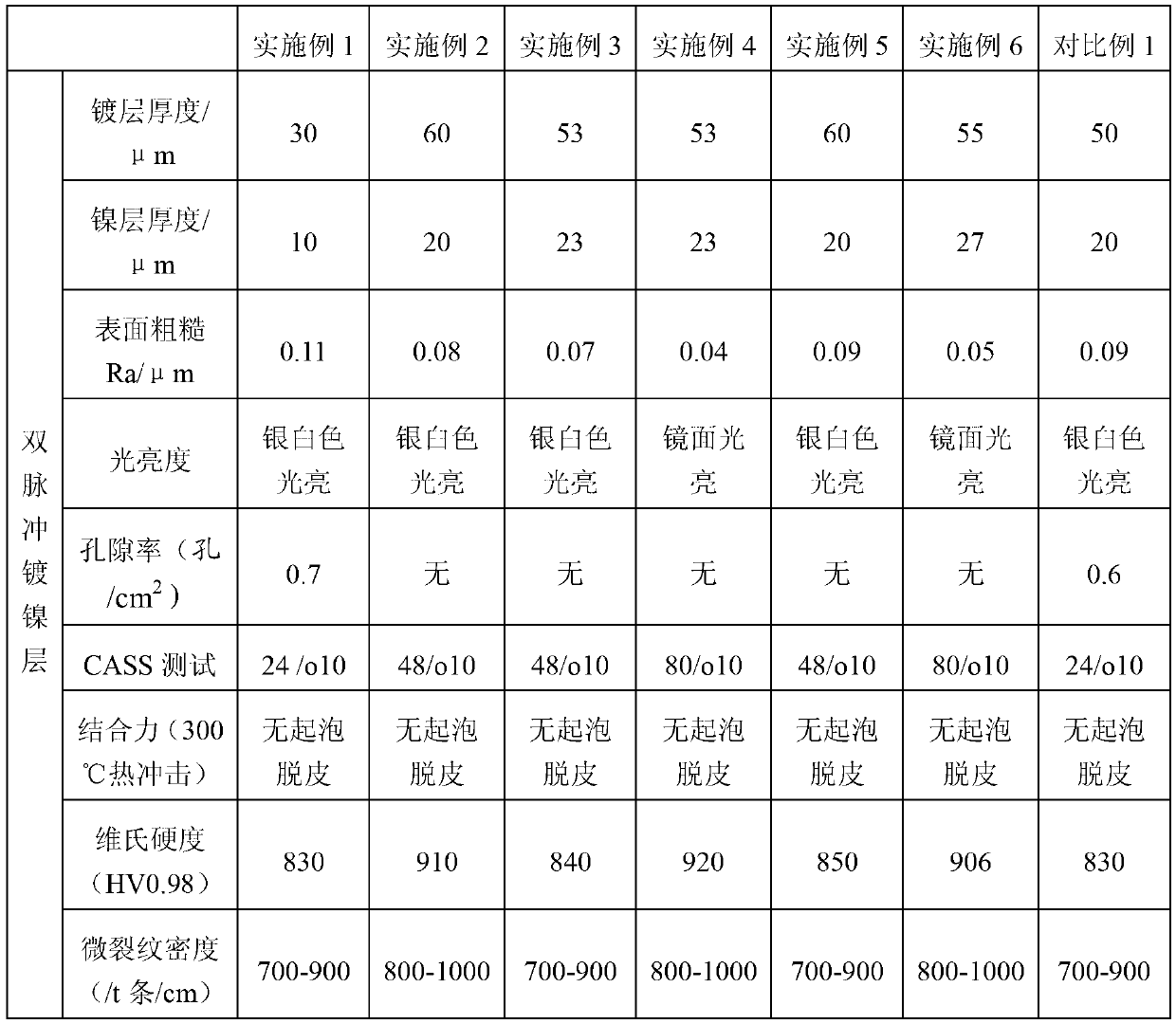

Examples

Embodiment 1

[0058] Example 1: (Double pulse nickel plating + chromium electroplating process)

[0059] (1) Make spare parts according to the required piston rod structure.

[0060] (2) Degrease the prepared spare parts:

[0061] Dip the prepared spare parts into a 50℃ hot-dip chemical degreasing agent (UNICLEAN-154 produced by Atotech) for 10 minutes; immerse the chemically degreasing spare parts into the anode electrolytic degreasing agent at 60℃ 2A / dm in the solution (UNICLEAN ELECTRO ES2 produced by Atotech) 2 The anode current density is electrolytic oil for 120s;

[0062] The electrolytic degreasing spare parts are washed with three-stage water to remove the surface degreasing agent solution.

[0063] (3) Carry out pickling activation treatment on spare parts after degreasing treatment:

[0064] Soak the prepared parts after degreasing treatment in a hydrochloric acid solution with a volume concentration of 10%, soak for 60 seconds; after taking it out, rinse with water to remove the hydrochlo...

Embodiment 2

[0077] Example 2: (Double pulse nickel plating + double pulse chromium electroplating process)

[0078] (1) Make spare parts according to the required piston rod structure.

[0079] (2) Degrease the prepared spare parts:

[0080] Immerse the prepared spare parts into the hot-dip chemical degreasing agent solution at 60℃ for chemical degreasing for 5 minutes; immerse the chemically degreasing spare parts into the anode electrolytic degreasing agent solution at 70℃ for 5A / dm 2 The anode current density is electrolytic oil for 60s;

[0081] The electrolytic degreasing spare parts are washed with three-stage water to remove the surface degreasing agent solution.

[0082] (3) Carry out pickling activation treatment on spare parts after degreasing treatment:

[0083] Soak the prepared parts after degreasing treatment in a hydrochloric acid solution with a volume concentration of 20% for 30s; after taking it out, rinse with water to remove the hydrochloric acid solution on the surface.

[0084] ...

Embodiment 3

[0096] Example 3: Double pulse nickel plating + bright nickel + chromium electroplating process

[0097] (1) Make spare parts according to the required piston rod structure.

[0098] (2) Degrease the prepared spare parts:

[0099] Immerse the prepared spare parts into the hot-dip chemical degreasing agent solution at 55℃ for chemical degreasing for 8 minutes; immerse the chemically degreasing spare parts into the anode electrolytic degreasing agent solution at 65℃ for 4A / dm 2 The anode current density is electrolytic oil for 100s;

[0100] The electrolytic degreasing spare parts are washed with three-stage water to remove the surface degreasing agent solution.

[0101] (3) Carry out pickling activation treatment on spare parts after degreasing treatment:

[0102] Soak the prepared parts after degreasing treatment in a hydrochloric acid solution with a volume concentration of 15% for 50s; after taking it out, rinse with water to remove the surface hydrochloric acid solution.

[0103] (4) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com