Dry-hanging wall slab structure

A wallboard, dry-hanging technology, applied in building construction, covering/lining, construction, etc., can solve the problems of grout, wallboard thickness cannot be guaranteed, wall surface leveling accuracy is low, construction time is long, etc., to reduce the number of on-site Operation time, simple structure, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

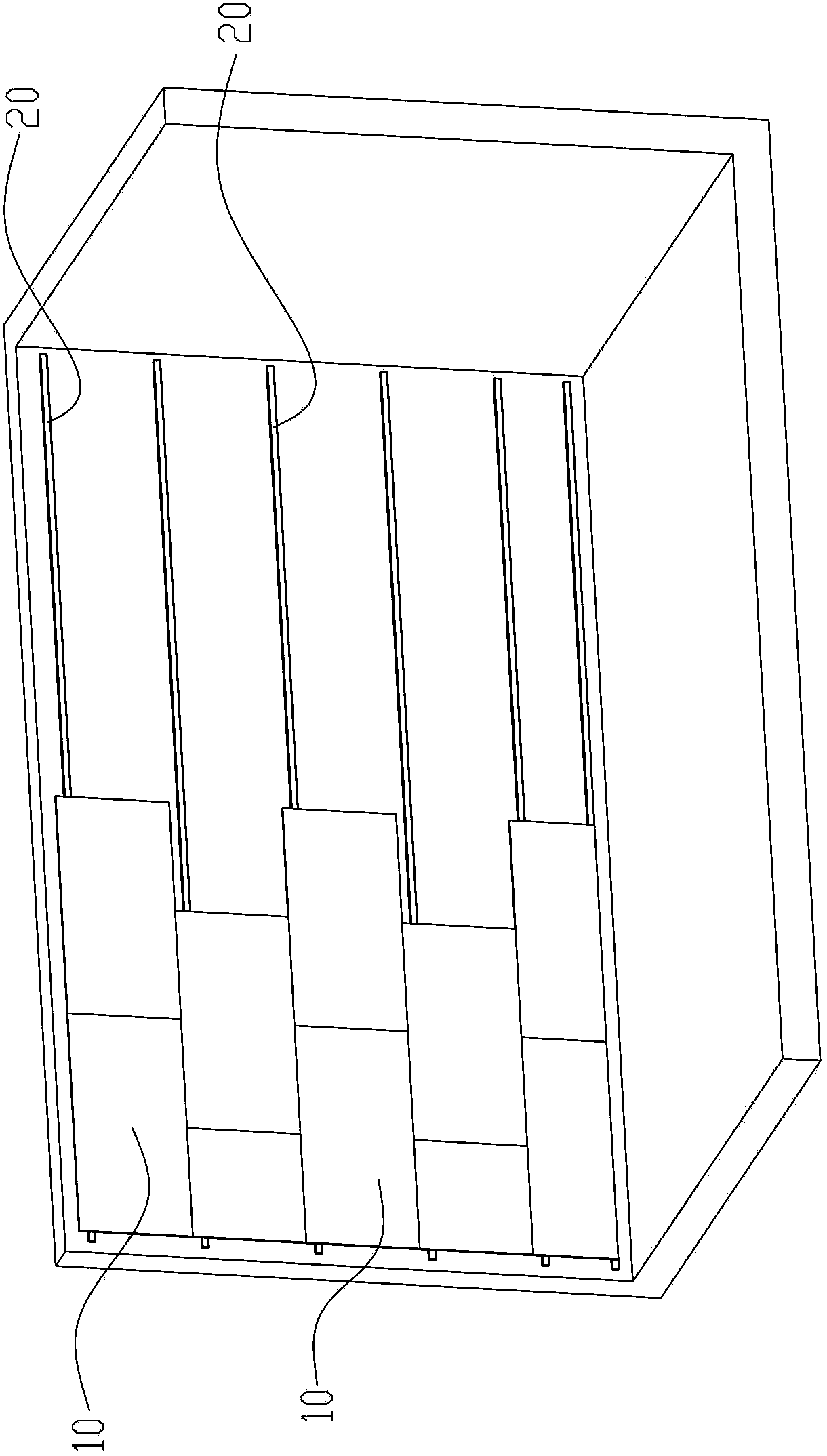

[0040] Please refer to figure 1 , a dry-hanging wallboard structure of the present invention includes a plurality of composite panels 10 and a plurality of keel frames 20 . The keel frames 20 are arranged in parallel on the wall at intervals, and the composite panels 10 are hung on the keel frames 20 evenly.

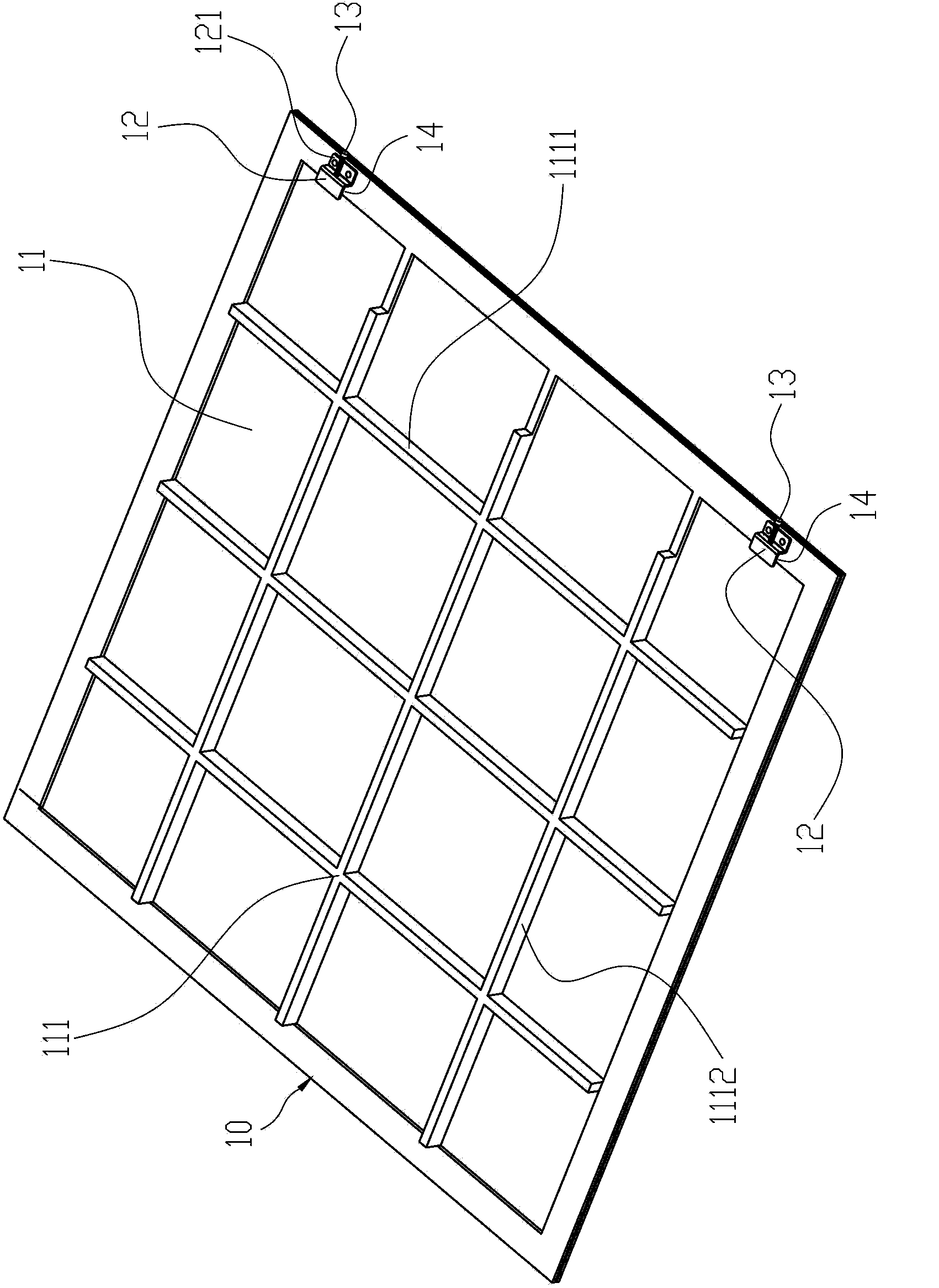

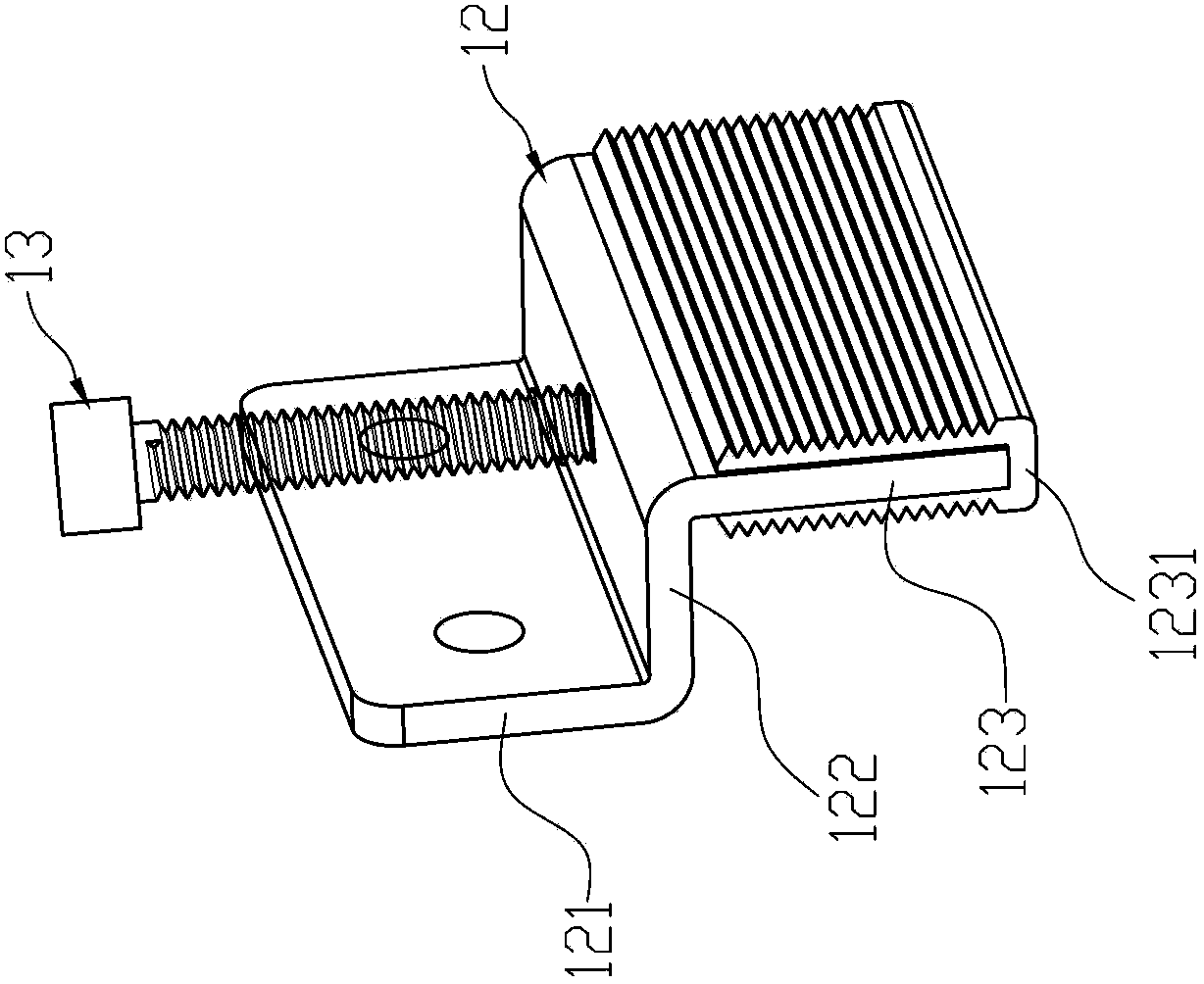

[0041] Please refer to figure 2 and image 3 , the composite panel 10 includes a support plate 11 , two buckles 12 and two adjusting bolts 13 . The support plate 11 has a square shape. The supporting board 11 is a wooden board such as MDF, plywood or particle board. The back side of the support plate 11 is provided with clamping plates 111 distributed in a mesh shape. The clamping plate 111 includes several transverse ribs 1111 arranged in parallel and spaced apart, and several longitudinal ribs 1112 arranged in parallel and spaced apart. The transverse ribs 1111 are parallel to the upper edge of the support plate 11, and the distance between two adjacent transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com