Preparation process for high-purity low-oxygen copper powder and water atomizing device thereof

A preparation process and low-oxygen copper technology, which is applied in the preparation process of high-purity low-oxygen copper powder and its water atomization device, can solve the problems of low bulk density, low atomization efficiency, agglomeration and segregation of copper powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

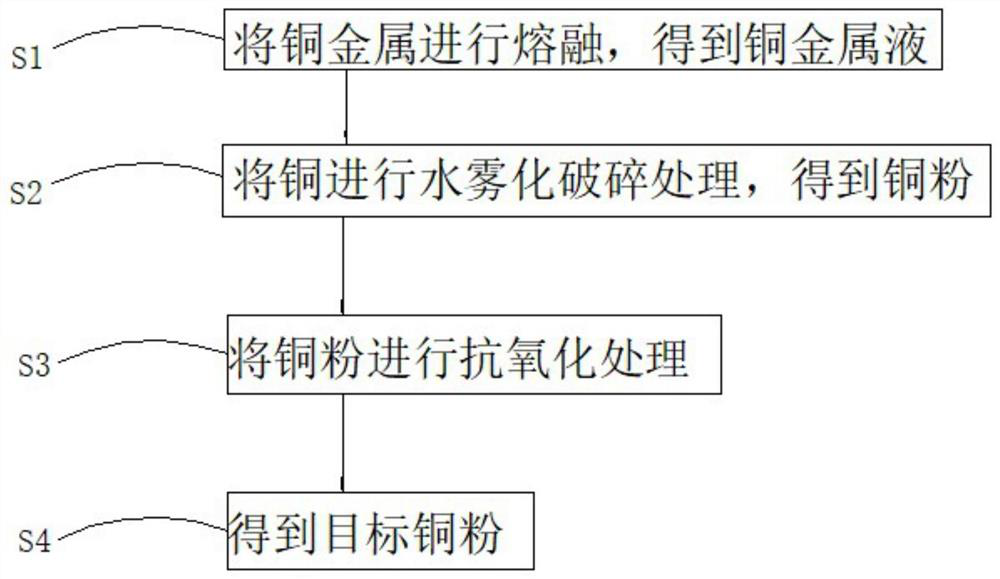

[0042] refer to figure 1 A preparation process of high-purity low-oxygen copper powder comprises the following steps:

[0043] S1: Melting solid copper metal to obtain molten copper metal;

[0044] S2: performing water atomization and crushing treatment on copper to obtain copper powder;

[0045] S3: performing anti-oxidation treatment on the copper powder;

[0046] S4: Obtain the target copper powder.

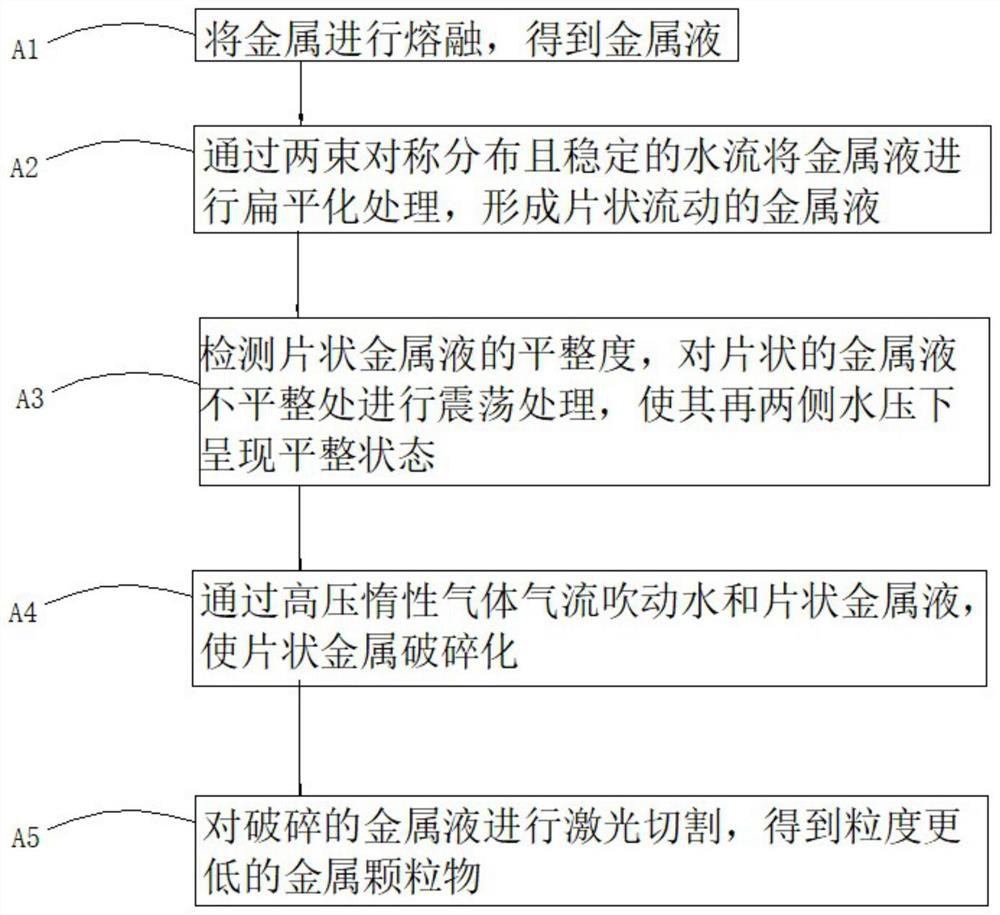

[0047] refer to figure 2 , the water atomization method in this copper powder water atomization system comprises the following steps:

[0048] The water atomization method in step S2 comprises the following sub-steps:

[0049] A1: Melting solid copper metal to obtain molten metal;

[0050] A2: The molten metal is flattened by two streams of symmetrically distributed and stable water flows to form a sheet-like flowing molten metal;

[0051] A3: Vibrate the flake molten metal to make it flat under the water pressure on both sides;

[0052]A4: Blow water and flake metal ...

Embodiment 2

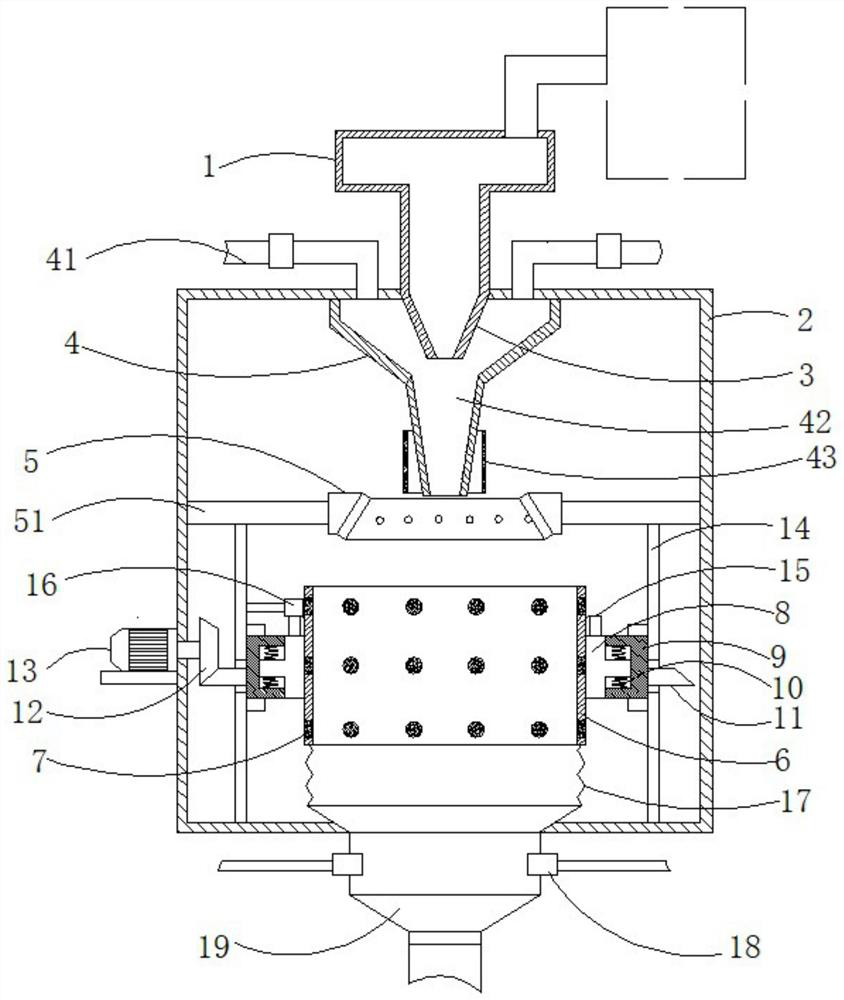

[0062] Different from the embodiment, the atomization device in this embodiment also includes a cutting assembly for re-cutting the crushed metal powder, refer to figure 1 , the cutting assembly includes a cutting cylinder 6, the cutting cylinder 6 is located below the high-pressure gas ring 5, the cutting cylinder 6 is coaxially arranged with the high-pressure gas ring 5, and a plurality of laser generators are embedded in the inner wall of the cutting cylinder 6 7, the laser generator 7 can emit laser light, and the broken metal particles move inside the cutting cylinder 6 due to gravity and the promotion of high-pressure gas. The laser generator 7 cuts the broken metal particles inside the cutting cylinder 6 again, reducing the The particle size of the metal droplet enhances the atomization effect of the metal liquid.

[0063] Further, refer to figure 1 and 6 , the outer wall of the cutting cylinder 6 is fixedly provided with a mounting ring 8, the outside of the mounting...

Embodiment 3

[0065] Different from Example 2, refer to figure 1 and Figure 5 , the outer wall of the cutting cylinder 6 in this embodiment is fixedly provided with a wave ring 15, and the inner side of the spacer 14 is provided with a roller 16 that is rotatably connected with the spacer 14 and adapted to the wave edge on the wave ring 15; An elastic member 10 is arranged between the spline end surface and the spline groove wall of the rotating sleeve 9 . While the cutting cylinder 6 in this embodiment is rotating, the wave ring 15 is in contact with the roller 16. Since the position of the roller 16 is fixed, the cutting cylinder 6 will move up and down following the wave edge on the wave ring 15 to speed up the cutting efficiency. In the example, the rotation and the up and down movement of the cutting cylinder 6 share a power source, and the structure is compact.

[0066] In this embodiment, in order to cooperate with the up and down movement of the cutting cylinder 6, the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com