Fixing device

A fixing device and mounting hole technology, applied in the directions of threaded fasteners, thin plate connections, connecting members, etc., can solve the problems of intrusion, poor operability, increase the insertion resistance of the pin 104, etc., to increase the pull-out force, Good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

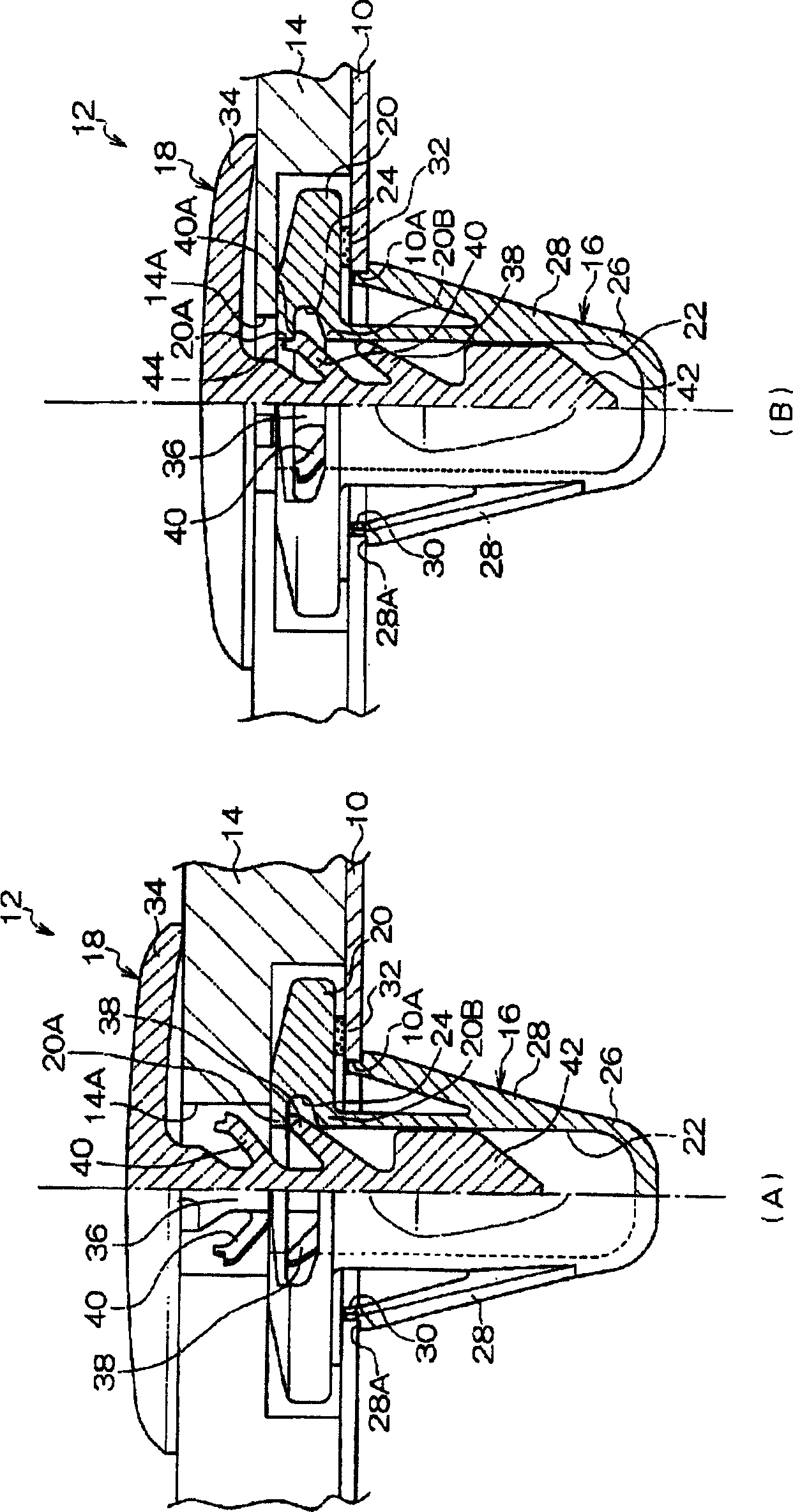

[0035] Hereinafter, a fixing device according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0036] Such as figure 1 and image 3 As shown in (A), a carpet 14 is laid on the upper surface of the vehicle floor 10 with a fixing device 12 .

[0037] The fixing device 12 is composed of a cylindrical grommet 16 that can be inserted through the installation hole 10A formed on the vehicle floor 10 , and a pin 18 that is inserted through the installation hole 14A formed on the carpet 14 and is fastened in the grommet 16 .

[0038] The grommet 16 is provided with a thick-walled flange portion 20 , and the flange portion 20 is formed with a width dimension D in a direction perpendicular to the axial direction of the grommet 16 . 2 than the inner diameter dimension D of the insertion hole 22 1 Larger generally rectangular through hole 24 (see Figure 5 ). The through hole 24 divides the flange portion 20 into two parts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com