Dehumidifying room for drying glue impregnated bamboo curtain

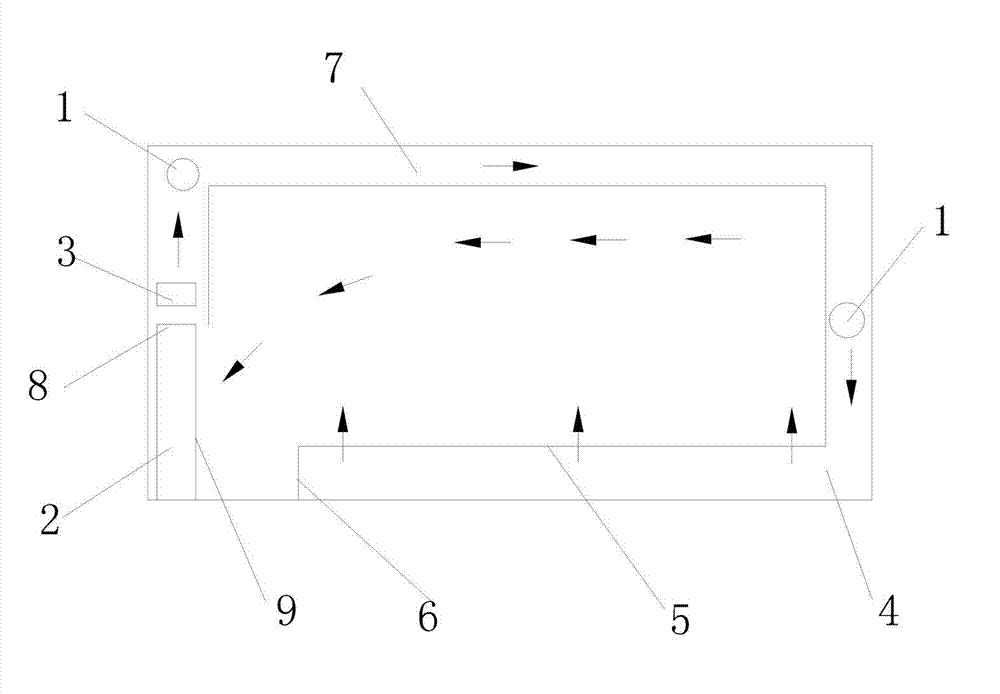

A wet room and bamboo curtain technology, which is applied in the directions of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of slow drying, poor gluing performance of bamboo plywood, and reduced glue survival rate, etc. Reduce labor intensity, improve productivity, and ensure the effect of gluing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0031] Adopt the following steps to prepare bamboo plywood:

[0032] (1) Dry the bamboo curtain until the moisture content is below 10%, to ensure that the bamboo curtain has a uniform and sufficient glue absorption;

[0033] (2) Glue dipping, the glue is phenolic resin glue, and the solid content of the glue is 30-40%;

[0034] (3) Put the soaked bamboo curtains into the dehumidification room, dehumidify and dry at a low temperature below 38 degrees, so that the moisture content of the bamboo curtains can reach below 15%;

[0035] (4) Billet formation: According to the characteristics and requirements of the product, the billet formation is prepared, and the product density is controlled by feeding with an electronic scale;

[0036] (5) Hot pressing and solidification into a board.

[0037] According to the product bonding performance test method and standard requirements in the national building materials industry standard JC / T2124-2012 of "Bamboo Glue Pallets for Concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com