Edge pressing mechanism for overcoming glass warpage

It is a technology of edge pressing and warping, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve problems such as warping and poor glue coating of products, and achieve the advantages of preventing warping, obvious edge pressing effect, and convenient driving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

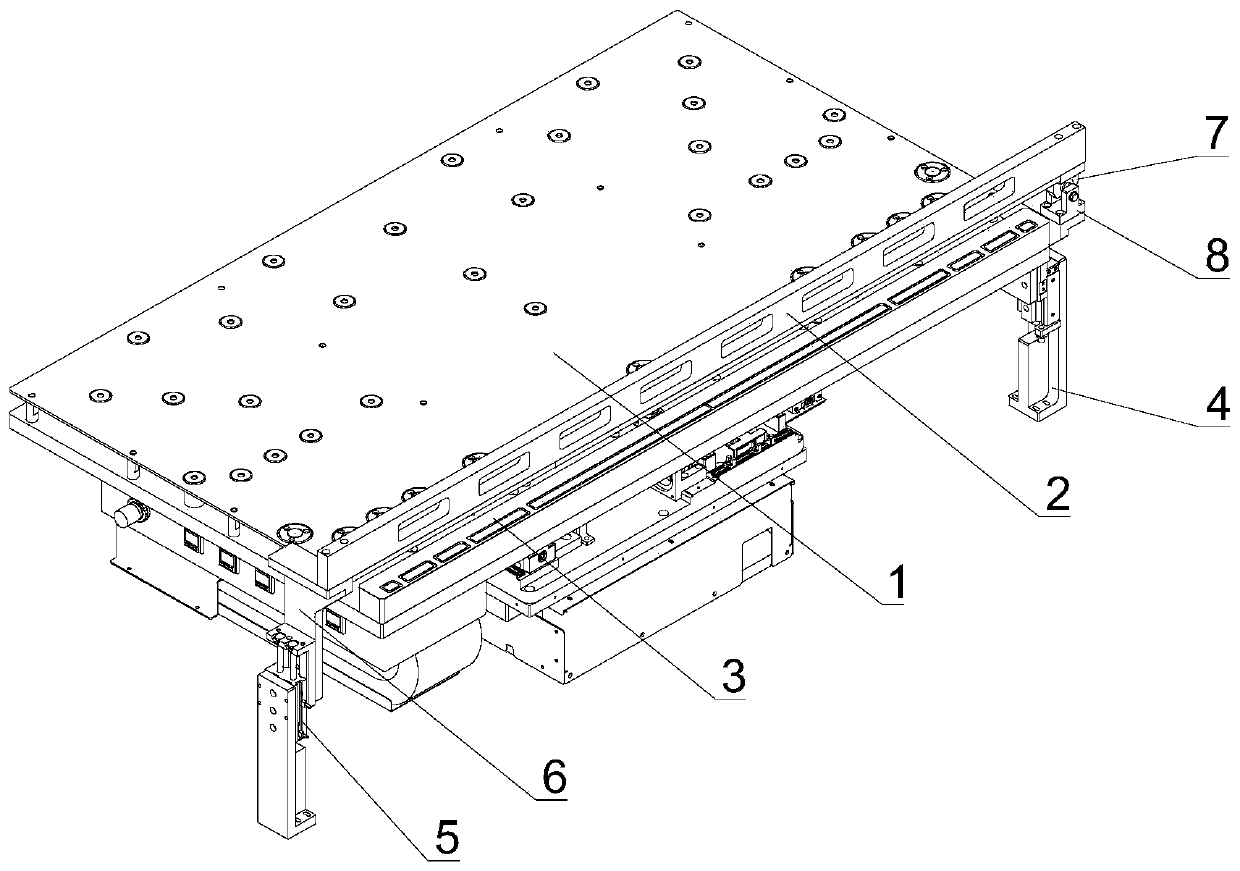

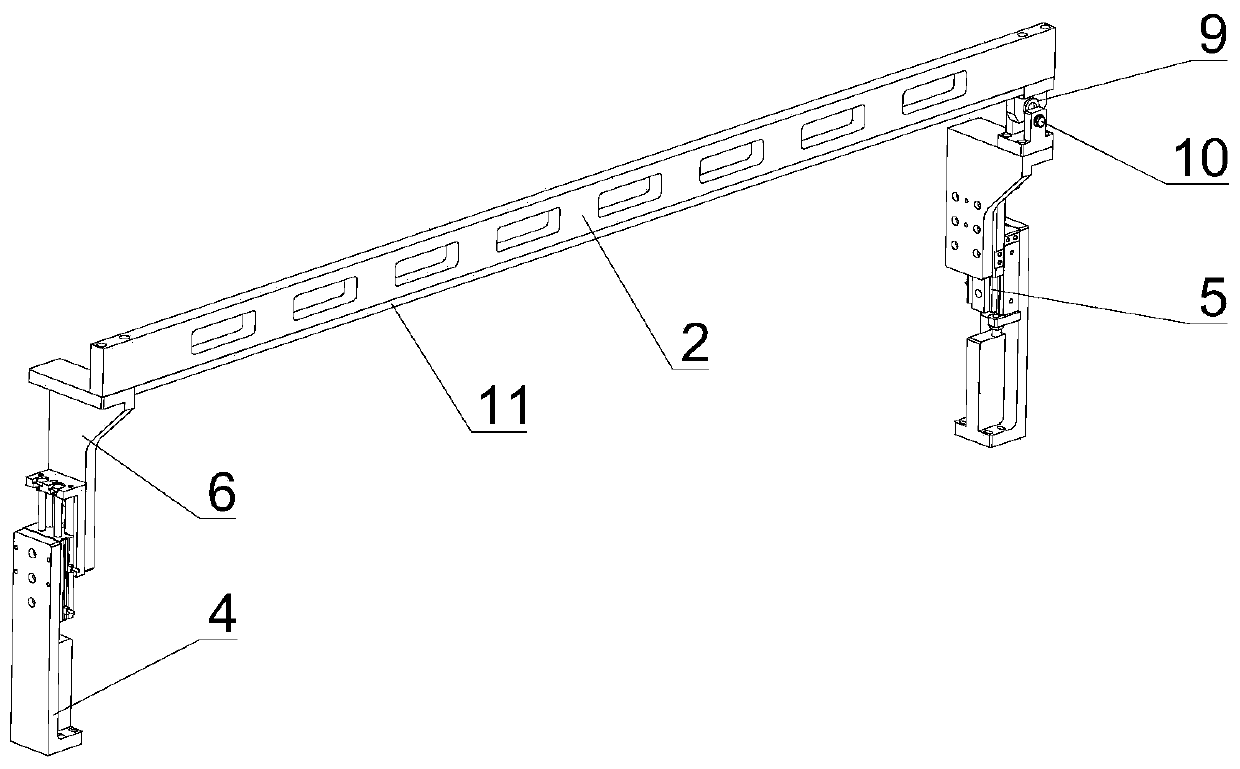

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0013] see figure 1 and 2 As shown, this embodiment provides a crimping mechanism for overcoming glass warpage, which includes a glue-applying carrier 1 and a crimping beam 2 .

[0014] The gluing platform 1 is provided with a positioning column 3, and the product to be glued is placed on the gluing platform 1, and its edge is limited by the positioning column 3.

[0015] The crimping beam 2 is located above the gluing carrier 1 and is arranged parallel to the positioning bar 3 , and the edge of the product is pressed by the downward movement of the crimping beam 2 .

[0016] The two ends of the crimping beam 2 are respectively provided with fixing seats 4, and the two fixing seats 4 are provided with slide table cylinders 5. One end of the crimping beam 2 is provided with a support block 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com