Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Solve the warping problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive paste for solar cell and preparation method thereof

ActiveCN101820002ASimple preparation processLow costFinal product manufacturePhotovoltaic energy generationConductive pasteHigh volume manufacturing

The invention provides conductive paste for a solar cell, comprising metal powder, glass powder and an organic carrier, wherein, the metal powder comprises aluminum powder and one ore more of tungsten powder, molybdenum powder and gold powder. The conductive paste solves the problem that the solar cell is easily warped after sintering; the solar cell finally prepared from the conductive paste of the invention has higher photoelectric conversion efficiency; and the conductive paste has easily obtained raw material sources and less element pollution, thus lowering the cost to some extent. The invention further provides a preparation method of the paste. In the method, the tungsten powder, the molybdenum powder and the gold powder are simply added to the conductive paste or uniformly mixed with the glass powder after simple ball-milling and then added to the conductive paste to obtain the finished product through simple process without smelting and large-sized equipment. The invention has simple preparation process and low cost, thus being beneficial to mass production.

Owner:BYD CO LTD

Nylon composite material and preparation method thereof

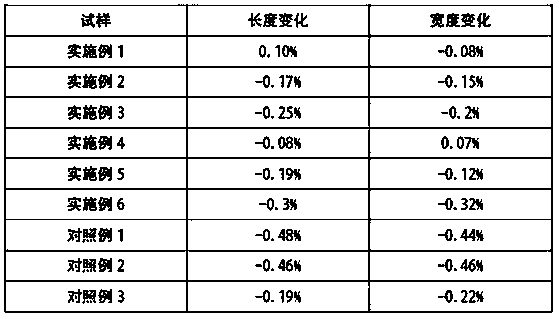

The invention discloses nylon composite material and a preparation method thereof. The material is composed of nylon 66 slices, thermotropic liquid crystalline polymer, needle-like mineral fiber, coupling agent and antioxidant. The weight ratio of the nylon 66 slices, the thermotropic liquid crystalline polymer, the needle-like mineral fiber, the coupling agent and the antioxidant is 60-70: 10-15: 20-30: 4.5: 0.5. The preparation method comprises the following steps: the nylon 66 slices, the thermotropic liquid crystalline polymer, the needle-like mineral fiber, the coupling agent and the antioxidant with weight ratio of 60-70: 10-15: 20-30: 4.5: 0.5 are mixed evenly under the agitating condition, and then extruded, drawn and granulated at 280 DEG C or 295 DEG C, and molded by injection into the sample to obtain the nylon system composite material. The nylon system of the invention can attain the remarkable enhancement effect under the circumstance of a little thermotropic liquid crystalline, and can have the effects on lightening the warping of the product, reducing the roughness of the product surface and reducing the cost.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

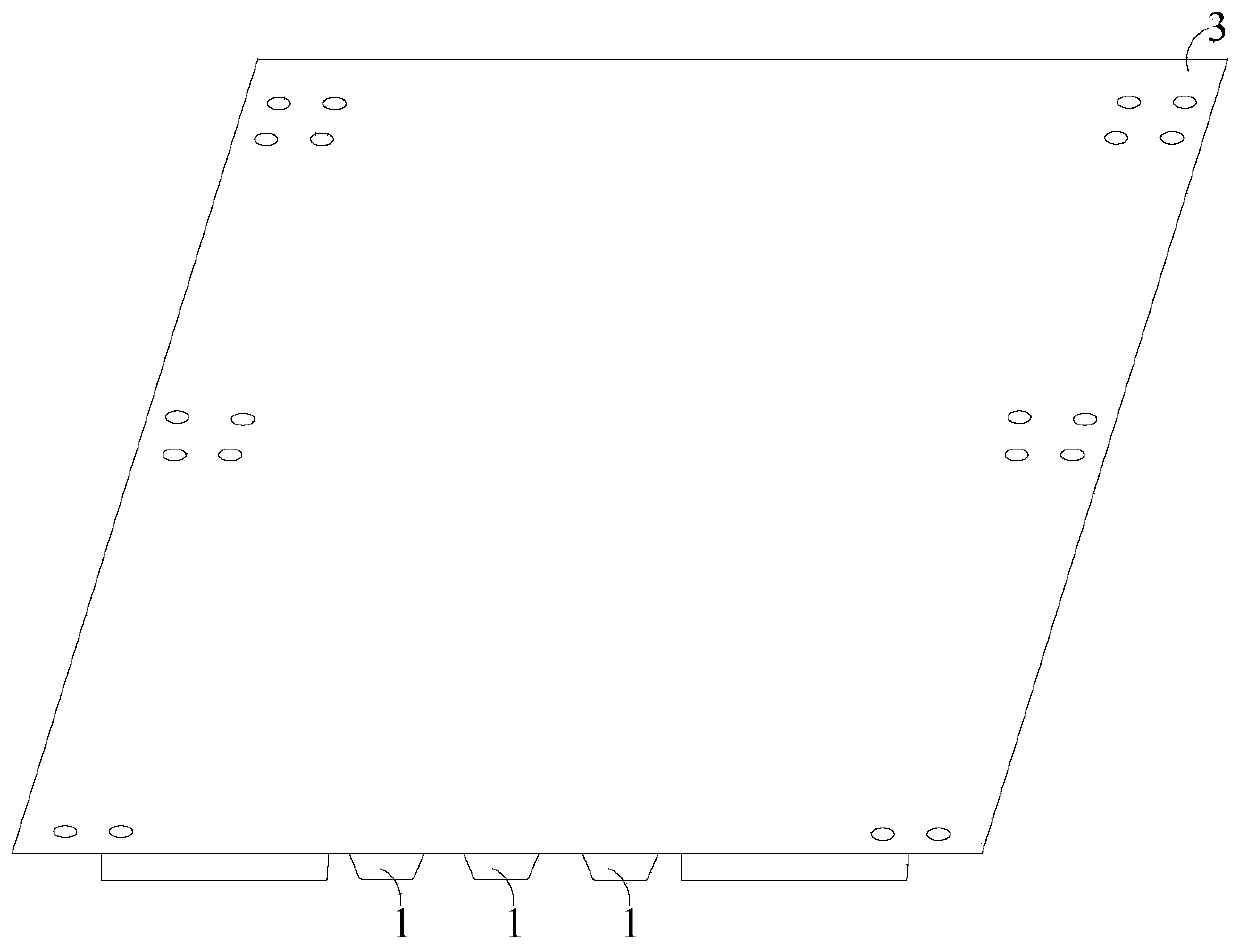

SiC ceramic thin-layer bullet-resistant material for laminated armor, and preparation method of material

The invention relates to a SiC ceramic thin-layer bullet-resistant material for a laminated armor and a preparation method of the SiC ceramic thin-layer bullet-resistant material. The SiC ceramic thin-layer bullet-resistant material is a gel-casting sheet prepared from the following raw materials: silicon carbide micro powder, boron carbide micro powder, acrylamide monomer, N'N-methylene bisacrylamide, tetramethyl ammonium hydroxide, tributyl phosphate, deionized water and ammonium persulfate. The invention also provides the preparation method of the SiC ceramic thin-layer bullet-resistant material. According to the SiC ceramic thin-layer bullet-resistant material, a silicon carbide ceramic sheet which is large in size, compact and smooth can be prepared; the SiC ceramic thin-layer bullet-resistant material is adjustable in size, good in hardness and good in fracture toughness, and is high in protective capability as a bullet-resistant material for the laminated armor.

Owner:SHANDONG UNIV

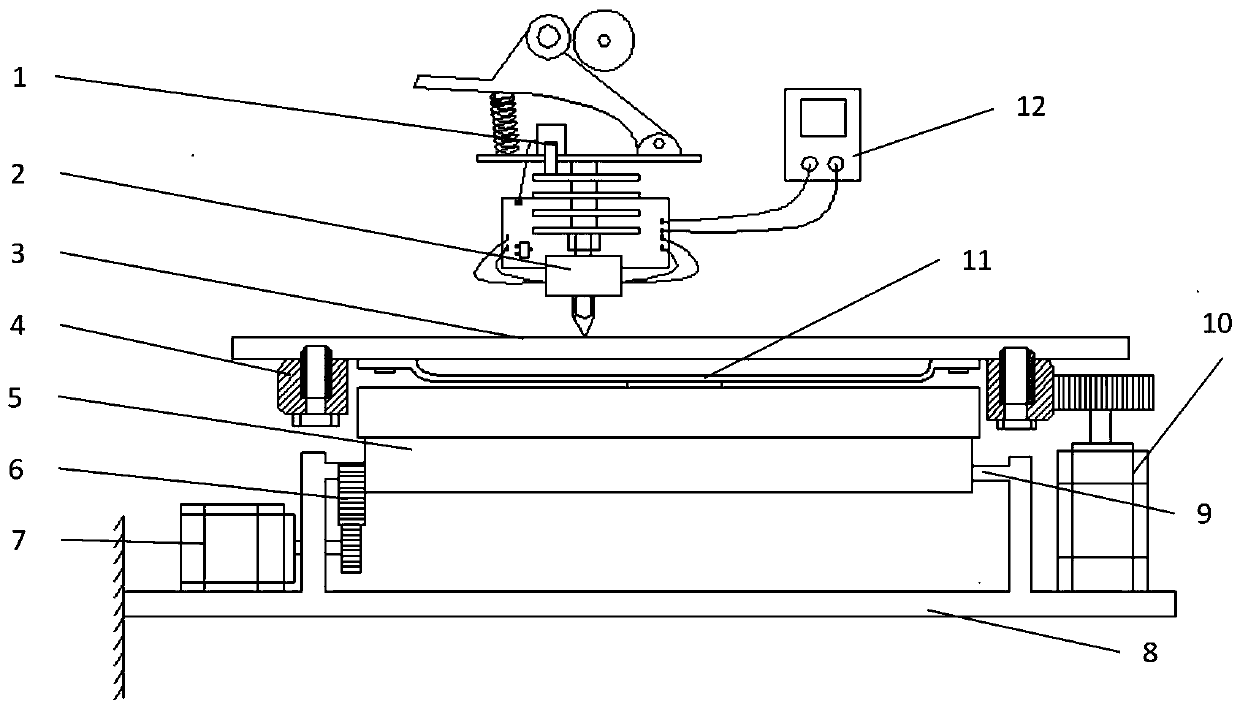

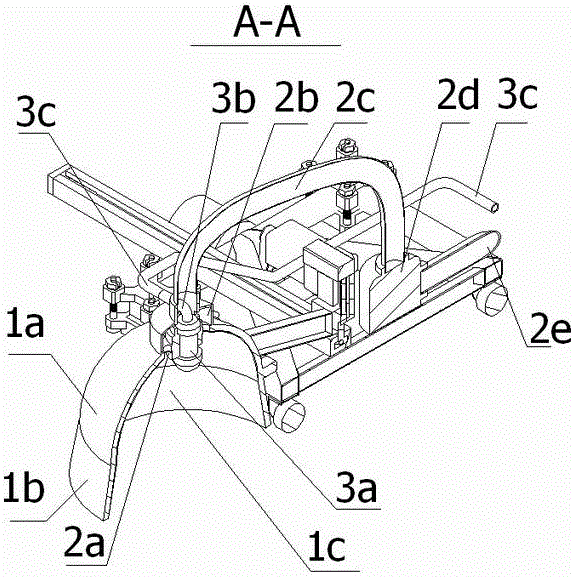

Automatic leveling method and leveling device for hot bed of 3D printer

InactiveCN107672172AAvoid scratchesHorizontal state real-time monitoringManufacturing heating elementsAngular degreesHeight difference

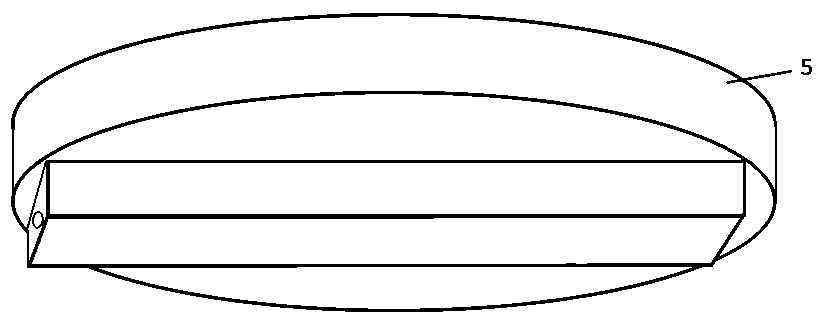

The invention discloses an automatic leveling method and leveling device for a hot bed of a 3D printer. Spatial coordinates of arbitrary three points which are not located on the same straight line onthe hot bed are measured; spatial coordinates N(x,y,z) of all points on a spatial circle determined by the three points are calculated through the algorithm of determining a circle by threepoints; the highest point M and the lowest point m on the spatial circle are determined according to the z value, and a vector Mm connecting M and m and passing through the center of the spatial circle is obtained; the included angle lambda of the vector Mm and the X axis and the half height difference H of the vector Mm in the Z axis direction are calculated; the hot bed is driven to rotate bythe angle lambda along a vertical rotating shaft perpendicular to the XOY plane, and a horizontal rotating shaft is driven to drive the hot bed to swing by the height H; and the steps are repeated till measured H meet the precision requirement. According to the leveling method and the leveling device, automatic detection and leveling of the hot bed of the 3D printer can be achieved, and the quality of a 3D printed product is improved.

Owner:ZHONGBEI UNIV

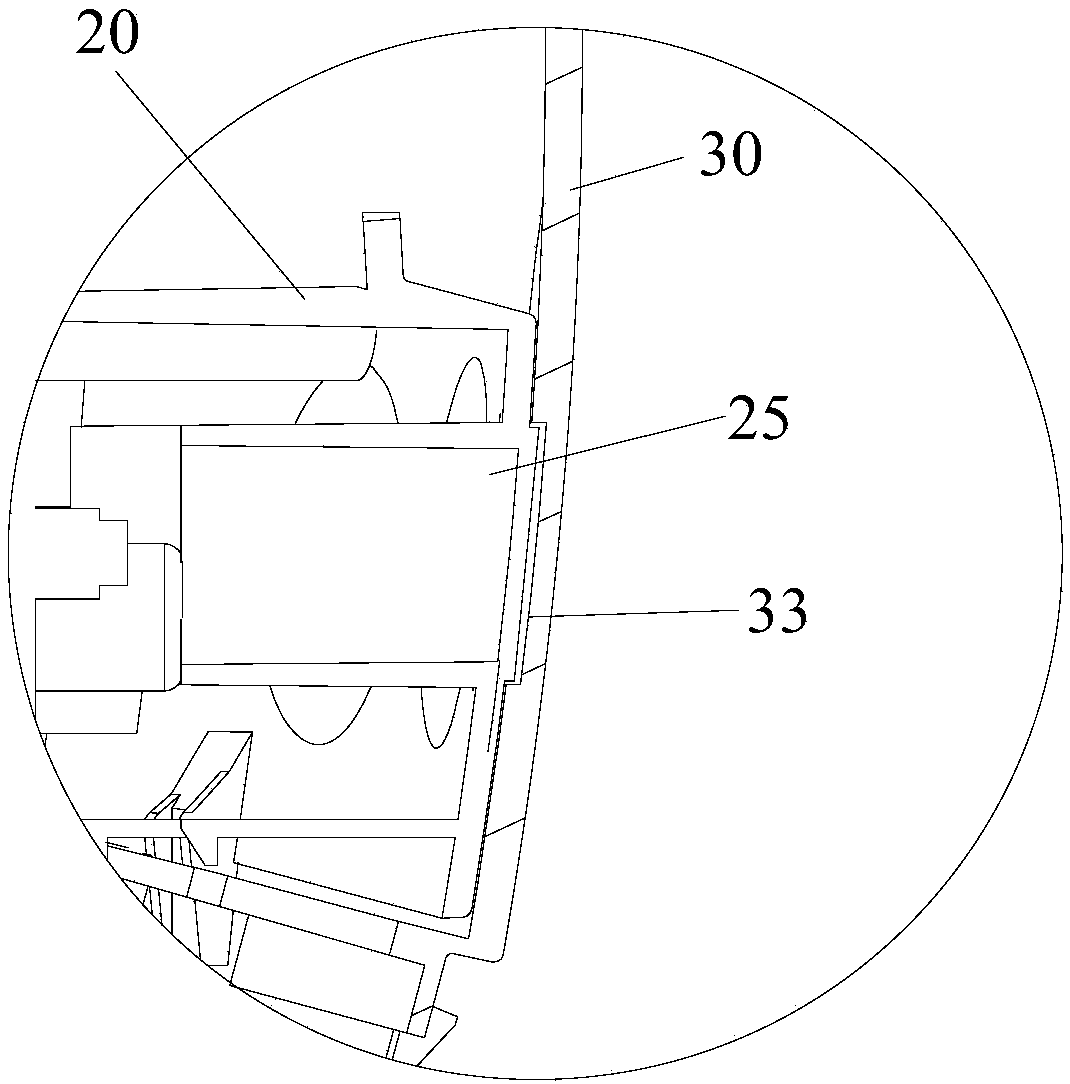

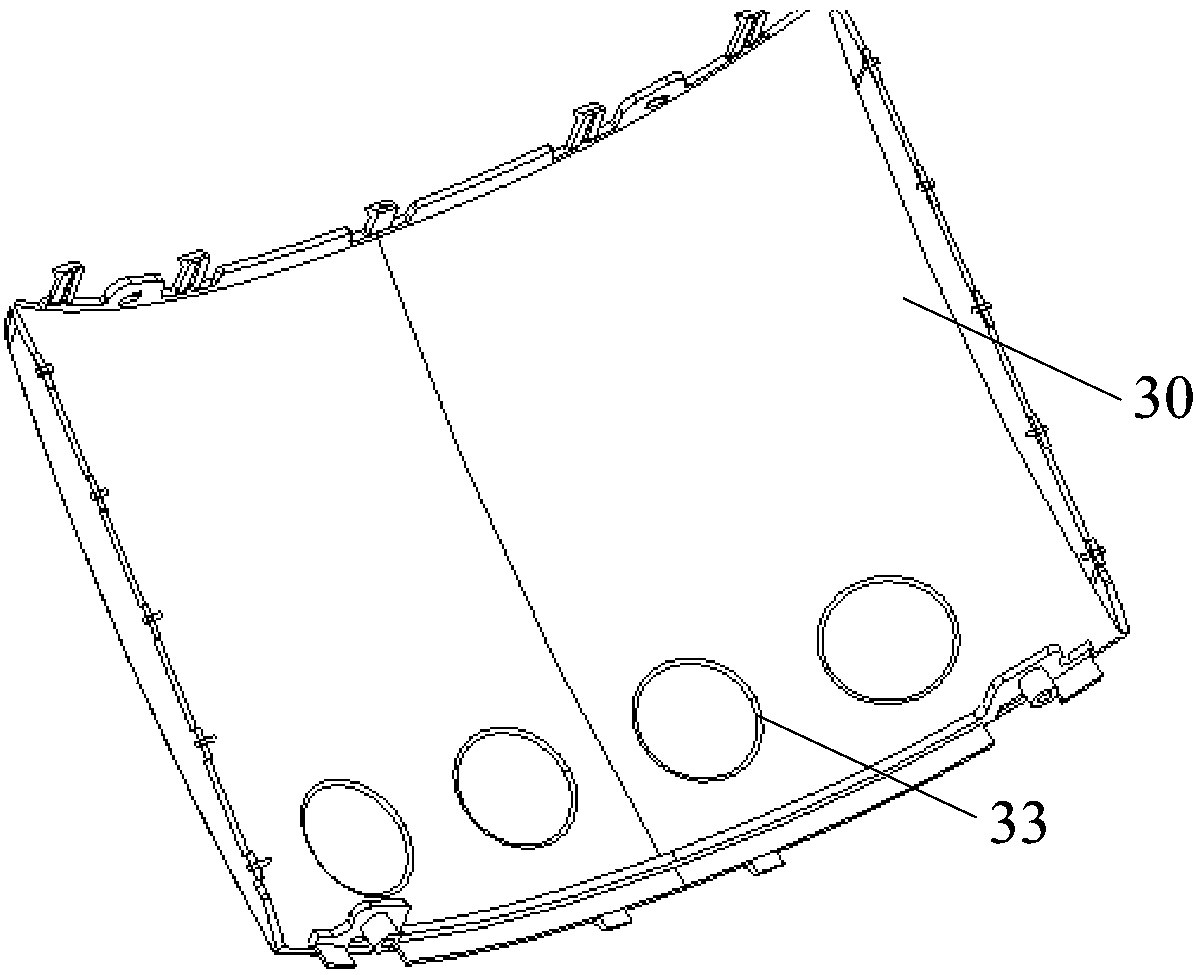

Rotating shaft supporting structure, display device and assembling method thereof

ActiveCN111536144AGood flexibility and stretchabilityEasy to matchShaftsDetails for portable computersStructural engineeringMechanical engineering

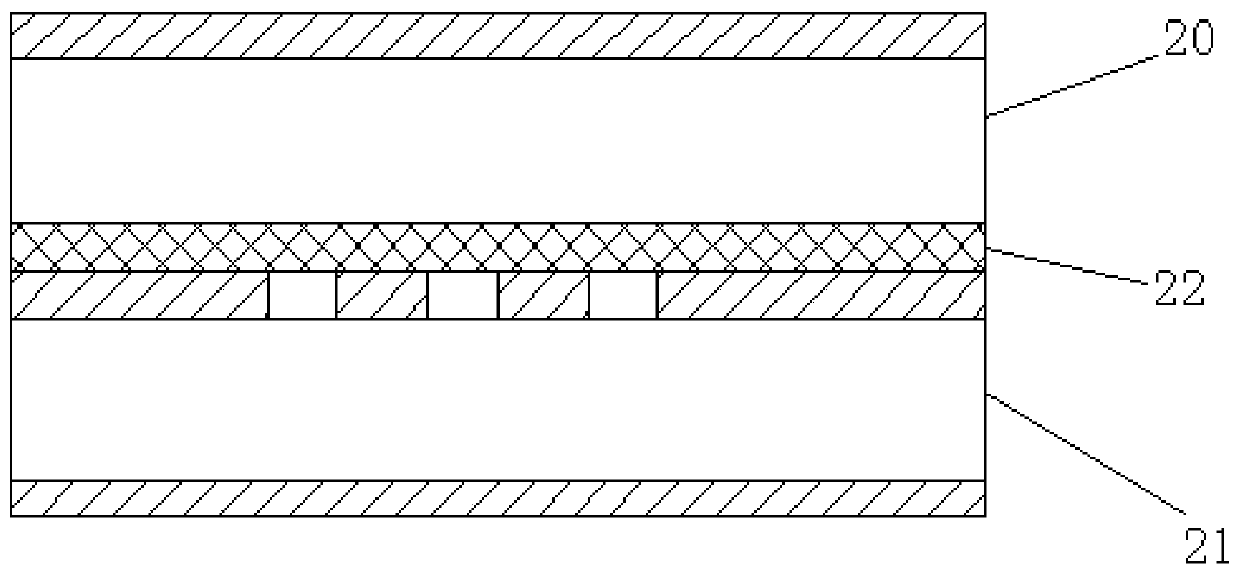

The invention relates to the technical field of display, and provides a rotating shaft supporting structure, a display device and an assembling method. The rotating shaft supporting structure comprises a rigid supporting part. The rigid supporting part comprises a plurality of rigid supporting strips arranged in parallel. A first gap is arranged between every two adjacent rigid supporting strips.The length direction of the rigid supporting strips is perpendicular to the bending direction of a flexible display panel. The orthographic projection of the rigid supporting part on the flexible display panel is located in the bending area. Two first supporting plates are arranged in parallel with the rigid supporting strips and are correspondingly located on the two opposite sides of the rigid supporting part. A second gap is arranged between the first supporting plates and the rigid supporting part. The orthographic projection of the first supporting plates on the flexible display panel islocated in a straight area. A flexible coating layer wraps the rigid supporting part and the supporting plates. One side, close to the flexible display panel, of the rigid supporting part is connected with one side, close to the flexible display panel, of the supporting plate into a whole. The bending area of the flexible display panel is not prone to warping.

Owner:BOE TECH GRP CO LTD

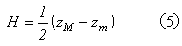

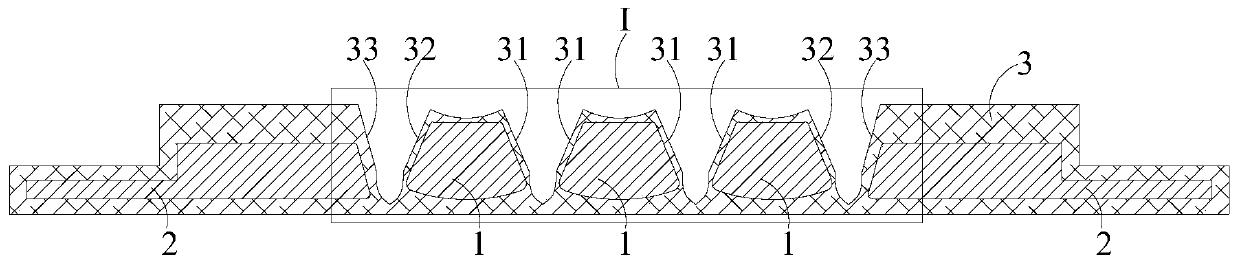

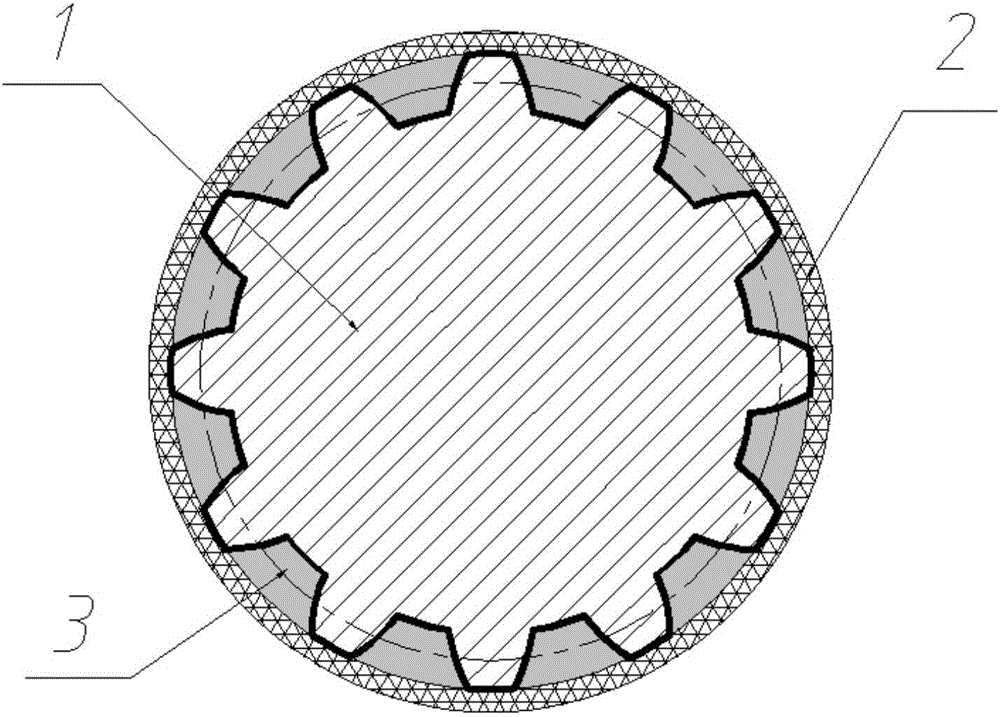

Laser shock strengthening method for small-pitch gear surface

InactiveCN105936974AEasy to cleanFacilitate large-area overlapping laser shock treatmentFurnace typesHeat treatment furnacesShock treatmentsGear tooth

The invention relates to a laser surface shock strengthening technology, and in particular to a laser shock strengthening method for a small-pitch gear surface. The method can be expanded into surface strengthening of a small-pitch spline male die and a fine-pitch thread. The method is characterized in that clearances among teeth of a gear are filled with transparent fillers prepared by mixing materials in ratio, and the clearances are full of the transparent fillers in order to form a column body by the gear and the transparent fillers; then an aluminum foil is adhered to the column surface to be used as an energy absorbing layer; the gear surface can be subjected to large-area overlapping laser shock treatment under the condition that running water is used as a limiting layer. The method has the advantages that the clearances among the teeth of the gear are fully filled with the transparent fillers, and the tops of the teeth of the gear and the transparent fillers can form a smooth column surface, thus the large-area overlapping laser shock treatment can be conveniently carried out for the gear, and as a result, the laser shock strengthening effect can be greatly improved; and after the shock treatment, the transparent fillers in the clearances among the teeth of the gear can be easily removed, so that the demand of mass production can be met.

Owner:JIANGSU UNIV

Feeding and paint mist recovery protective cover system of ship shell plate towing spraying type robot and operation method of feeding and paint mist recovery protective cover system

ActiveCN106378274AEasy to atomize and recycleAvoid accumulationSpraying apparatusThin walledBending moment

The invention discloses a feeding and paint mist recovery protective cover system of a ship shell plate towing spraying type robot and an operation method of the feeding and paint mist recovery protective cover system and belongs to the technical field of ship shell plate spraying intelligent devices in ship and ocean engineering. The feeding and paint mist recovery protective cover system mainly comprises a spraying and protective cover part, a spraying feeding part, a paint mist vacuum recovery part, a towing pipeline bending moment and winding prevention part and the like and has the technical characteristics that by fully considering the practical engineering application requirements and the economy, the structure is simple and novel, the functions are perfect, and the operation is convenient; by utilizing a robot to carry a spraying gun and a thin-walled hemispherical protective cover which carry out large-span operation with always left-and-right movement and a towing pipeline bending moment and winding prevention connection device, the problems of atmospheric pollution due to paint mist, robot carrying body protection, warping or winding of a towing pipeline and damage of a sprayed region are well solved; and the feeding and paint mist recovery protective cover system has the advantages of safety, reliability, high efficiency and the like and has a high engineering application value.

Owner:DALIAN UNIV OF TECH

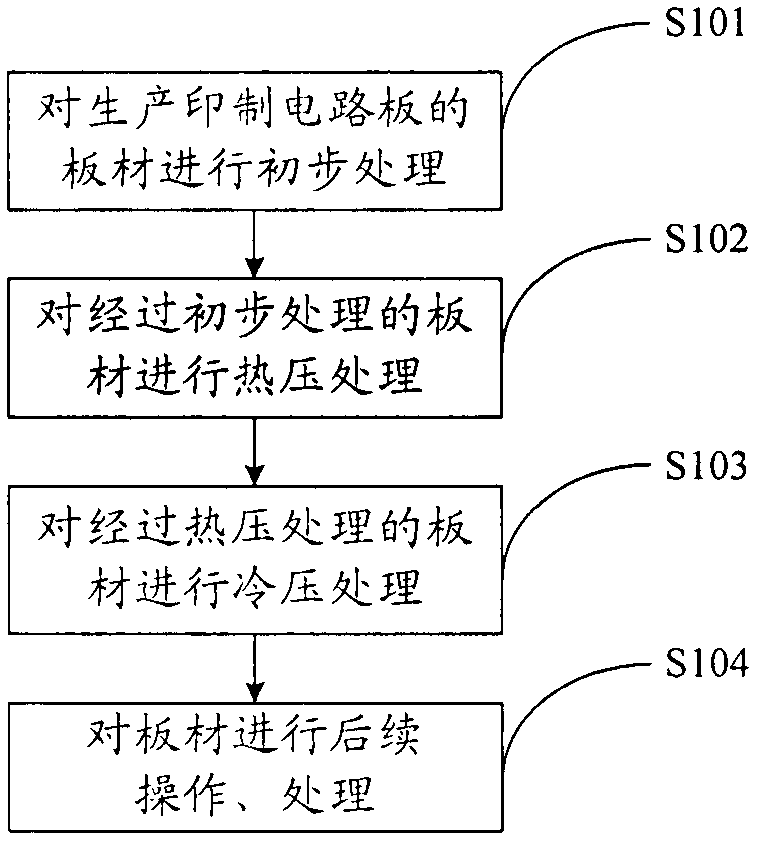

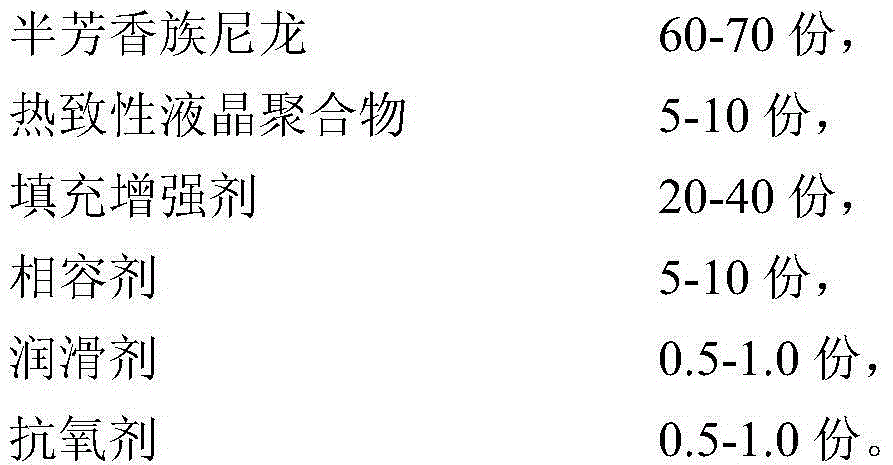

Method for producing asymmetrically laminated printed circuit board

InactiveCN102548259ASimple preparation processHigh hardnessMultilayer circuit manufactureOn boardHardness

The invention belongs to the field of printed circuit boards, and provides a method for producing an asymmetrically laminated printed circuit board. Hot pressing treatment is performed on boards in six stages by modifying lamination parameters, pressure, temperature and time are rationally controlled according to production requirements, and the boards are gradually and uniformly heated and pressurized in stages, so that a manufacturing process for the printed circuit board is optimized. A layer of core board is sandwiched between the boards, so that the hardness of the boards is improved, the boards are difficult to bend and deform, the problem that the board is warped towards a thin surface in the production of a subsequent procedure after the lamination is effectively solved, the production difficulty of the subsequent procedure is reduced, a leveling step after forming is avoided, production cost is decreased, and production efficiency is improved.

Owner:苏州艾迪亚电子科技有限公司

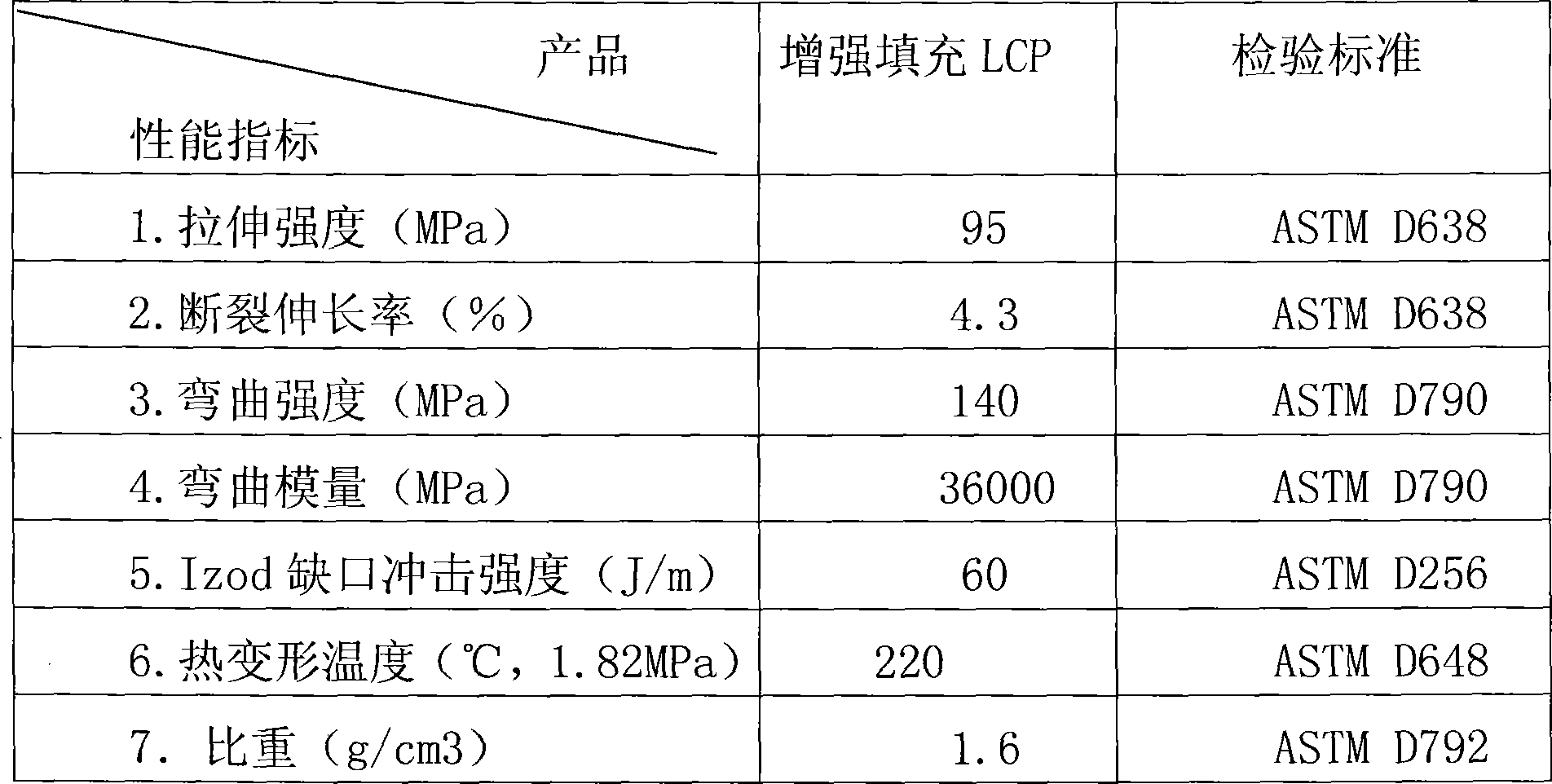

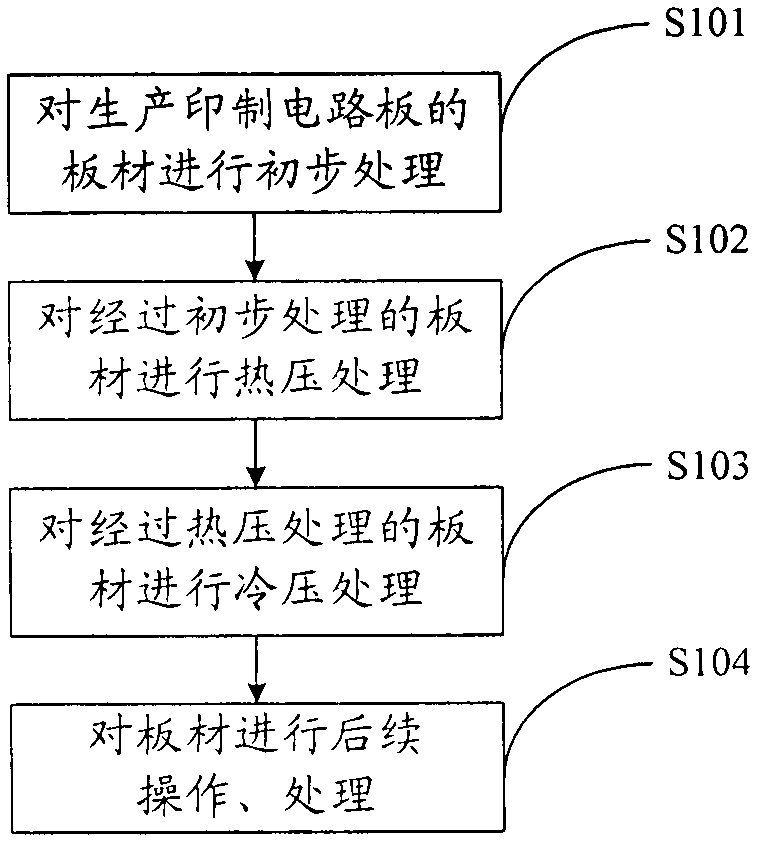

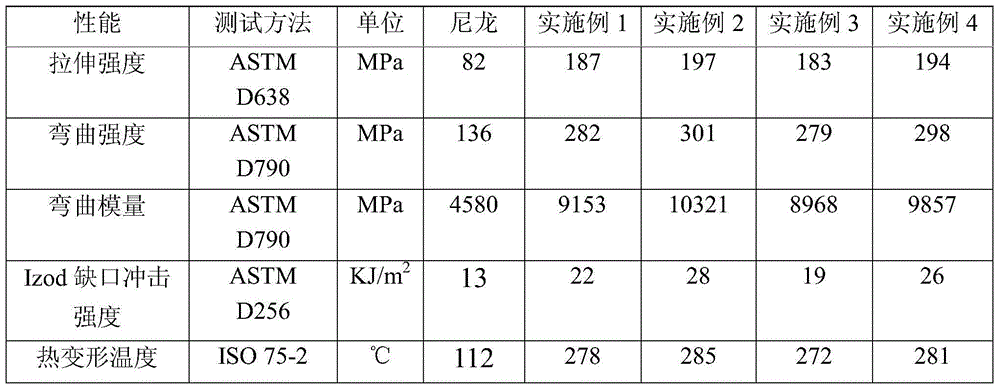

Enhanced semi-aromatic nylon/liquid crystal polymer alloy material and preparation method thereof

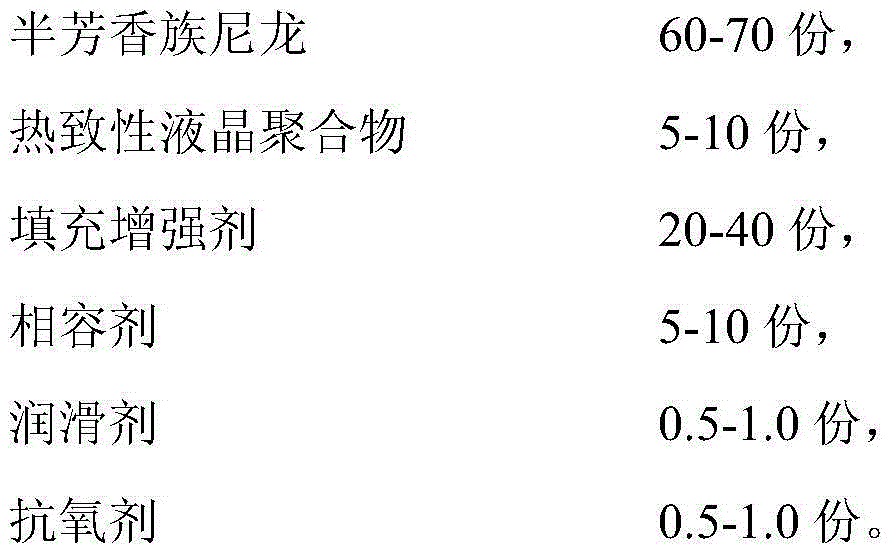

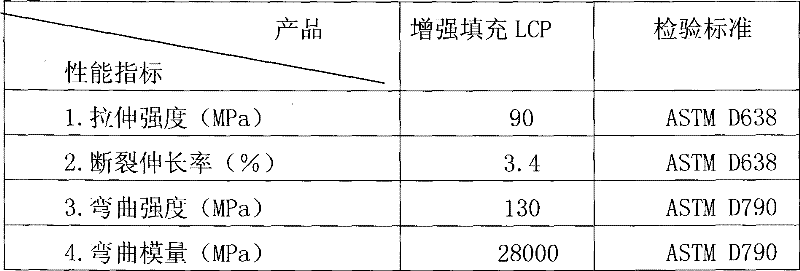

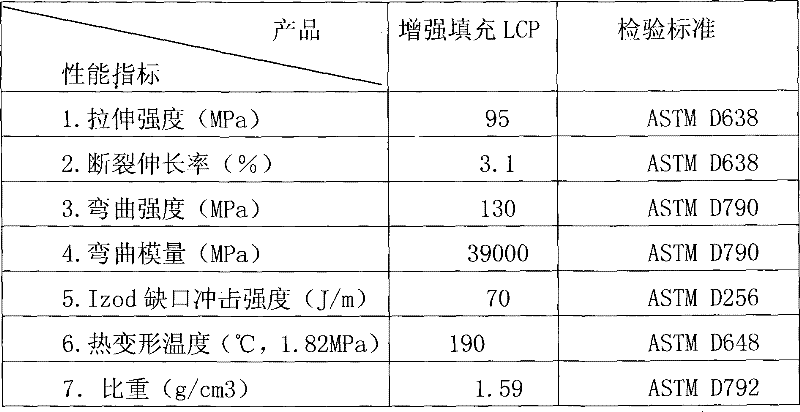

Belonging to the technical field of engineering plastics, the invention relates to an enhanced semi-aromatic nylon / liquid crystal polymer alloy material and a preparation method thereof. The material is prepared from the following components by weight: 60-70 parts of semi-aromatic nylon, 5-10 parts of a thermotropic liquid crystal polymer, 30-40 parts of a filling reinforcer, 5-10 parts of a compatilizer, 0.5-1 part of a lubricant, and 0.5-1 part of an antioxidant. The enhanced semi-aromatic nylon / liquid crystal polymer alloy material provided by the invention has the characteristics of high strength, high rigidity and high temperature resistance, simple preparation process and low cost, and the preparation method for the semi-aromatic nylon / liquid crystal polymer alloy material can achieve good economic benefits.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

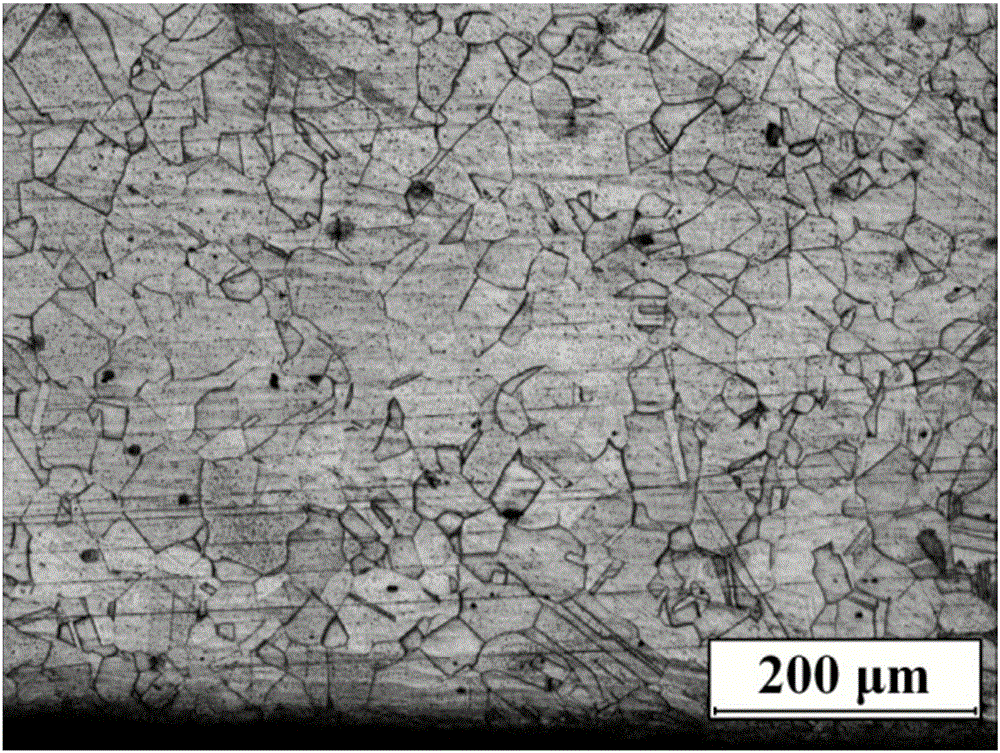

Method for rapidly measuring quenching machine slot nozzles

InactiveCN108180816ASolve the warping problemIncrease expansionAngles/taper measurementsTimerQuenching

The invention discloses a method for rapidly measuring quenching machine slot nozzles. The method comprises steps that (1), three square timbers with the consistent thickness are selected, and red lubricating oil is uniformly coated on surfaces of the square timbers; (2), the three square timers are displaced on an outlet roller way of a quenching machine and are arranged at the assigned positionfrom left to right; (3) the roller way of the quenching machine is started, the three square timbers are poured back to the position of the slot nozzle of the quenching machine, distances between quenching machine slots and the square timbers are reduced, the upper and lower slot nozzles are started up and down, and the water supply pressure, the valve opening degree and the continuous water supply time are guaranteed; (4), the roller way of the quenching machine is lifted to 600mm, and the three square timbers are taken out of the quenching machine and are lifted down from the roller way; and(5), an included angle formed by surfaces of the square timbers after water washing is measured through a steel plate ruler, if the tip portion of the included angle is at 1 / 2 of the thickness direction and errors are in the assigned range, requirements are satisfied, if not, the slot nozzle angle is adjusted. The method is advantaged in that a problem of warping of a quenching plate can be completely solved.

Owner:NANJING IRON & STEEL CO LTD

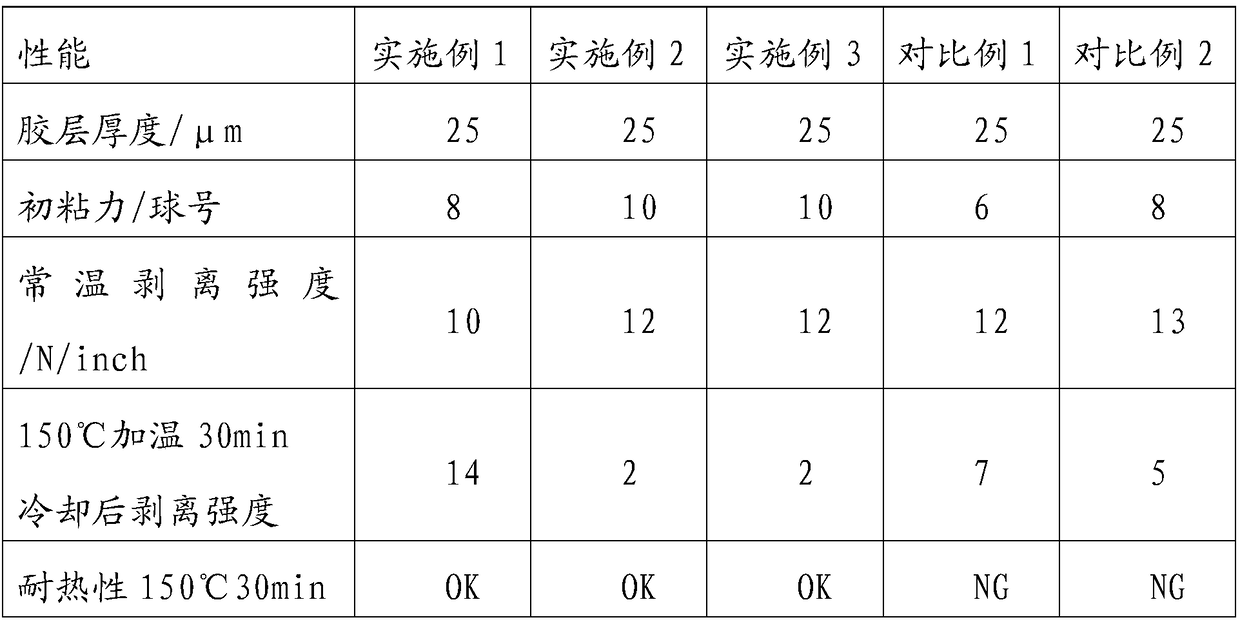

Viscidity-reducing adhesive tape for lamination edge seal of solar double-glass photovoltaic module and preparation method of viscidity-reducing adhesive tape

InactiveCN108102571ASolve the warping problemImprove initial viscosityPressure sensitive film/foil adhesivesCross-linkAdhesive

The invention belongs to the technical field of solar double-glass photovoltaic modules and in particular relates to a viscidity-reducing adhesive tape for lamination edge seal of a solar double-glassphotovoltaic module and a preparation method of the viscidity-reducing adhesive tape. The viscidity-reducing adhesive tape adopts a flexible substrate, the used composite membrane is not needed to bereleased, the prepared viscidity-reducing adhesive tape for the lamination edge seal of the solar double-glass photovoltaic module is not cross-linked at normal temperature, high in initial viscosityand good in compliancy, no residual adhesives exist when the adhesive tape is stripped after heating lamination, the adhesive tape is easy to strip and incapable of breaking, and the problem that theadhesive tape is easy to warp during construction under a low-temperature condition is solved. The adhesive tape disclosed by the invention has no burrs when being processed and slit, and the viscidity of the adhesive tape is reduced when the adhesive tape is stripped after high-temperature lamination, so that the adhesive tape is relatively easy to strip, no residual adhesives exist, and the condition of breaking can be avoided; and compared with an ordinary high-temperature-resistant silica gel adhesive tape, the viscidity-reducing adhesive tape is capable of reducing the production cost and increasing the production efficiency.

Owner:YANTAI DARBOND TECH

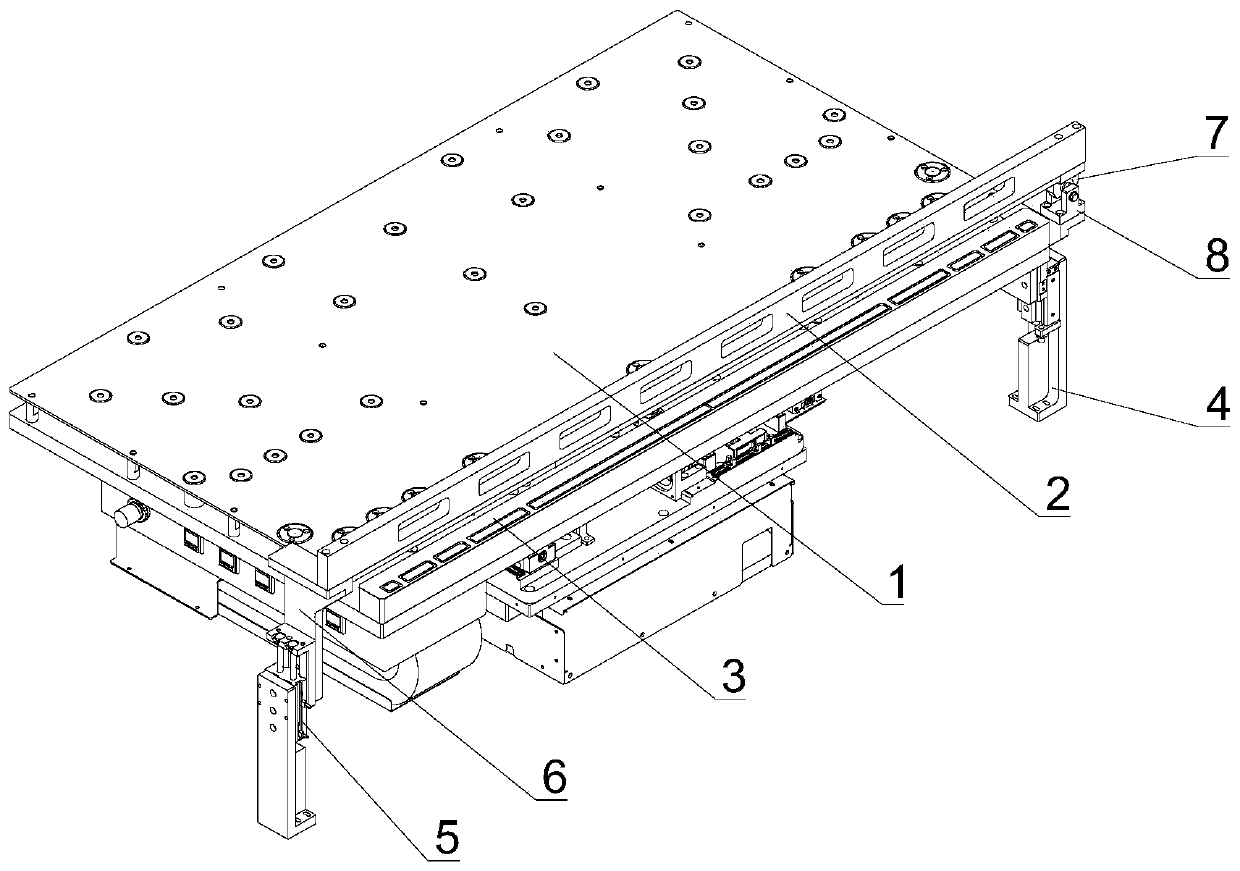

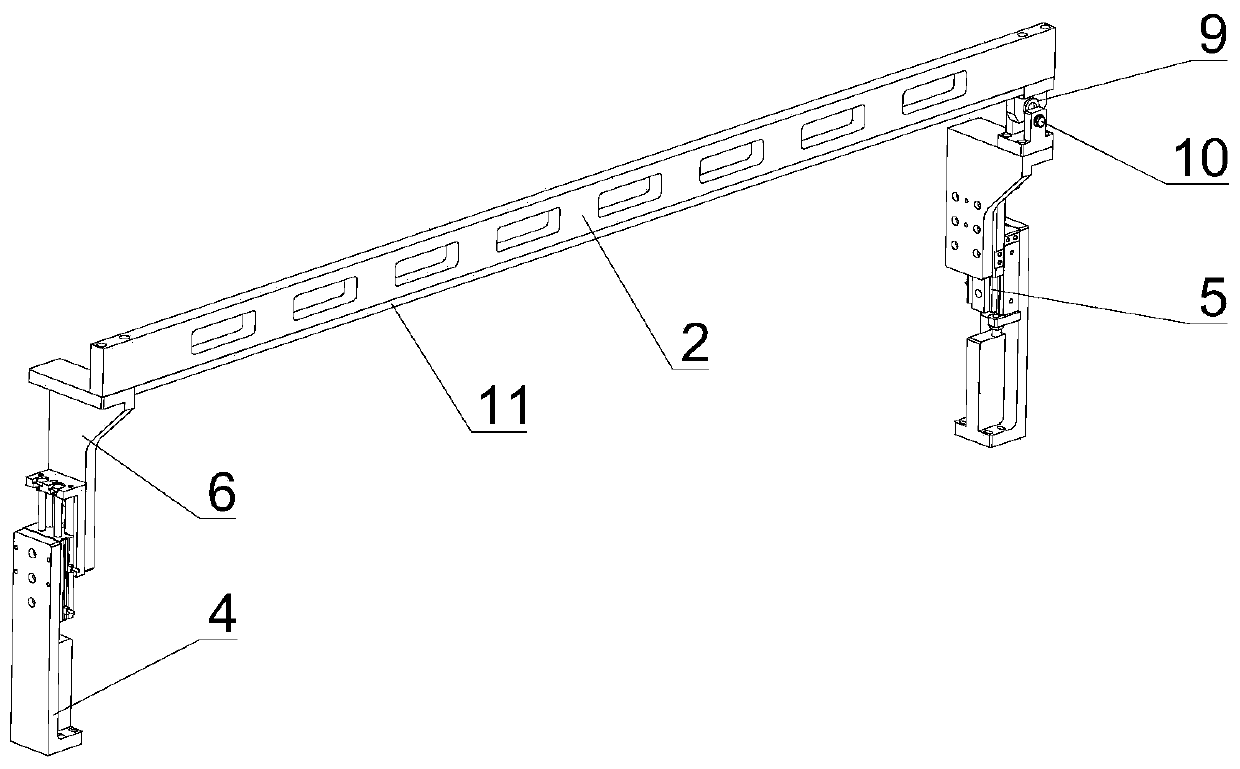

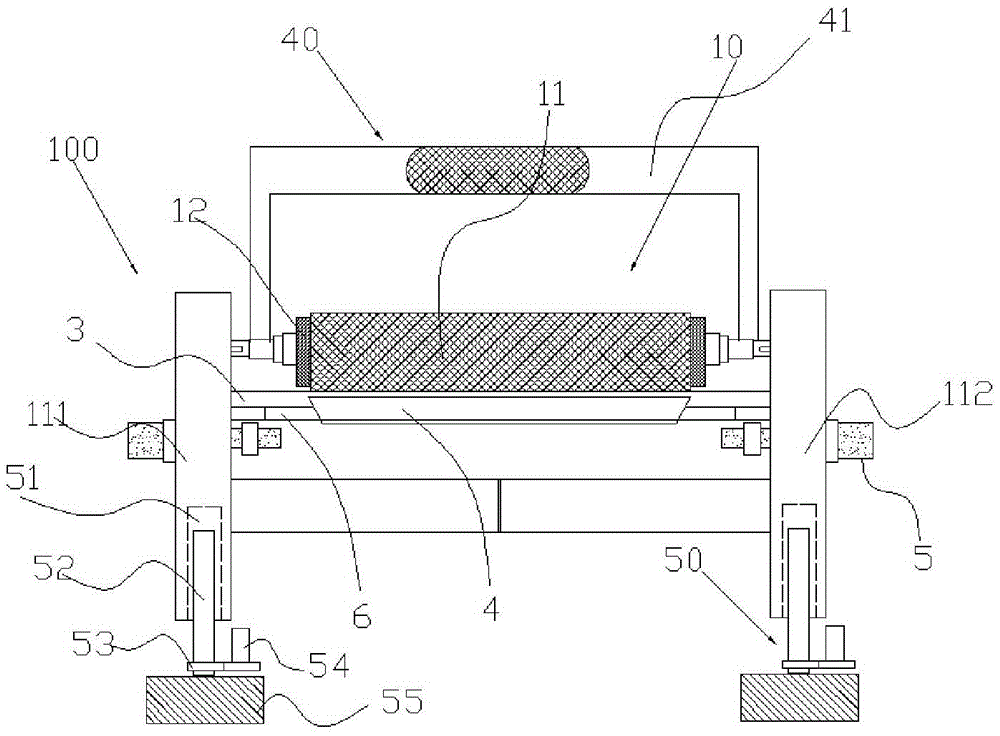

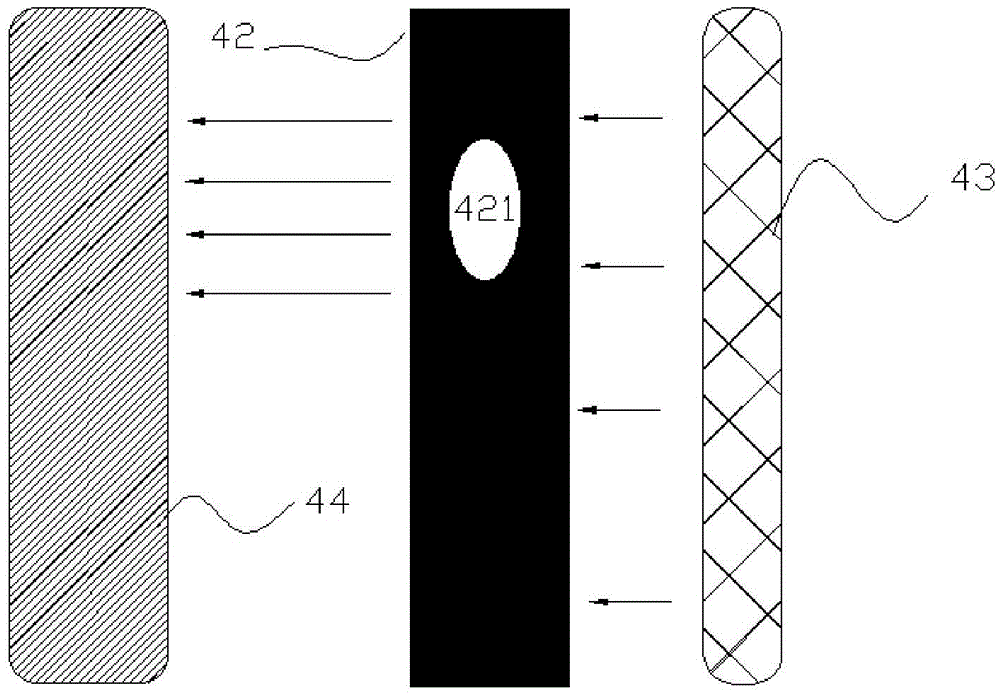

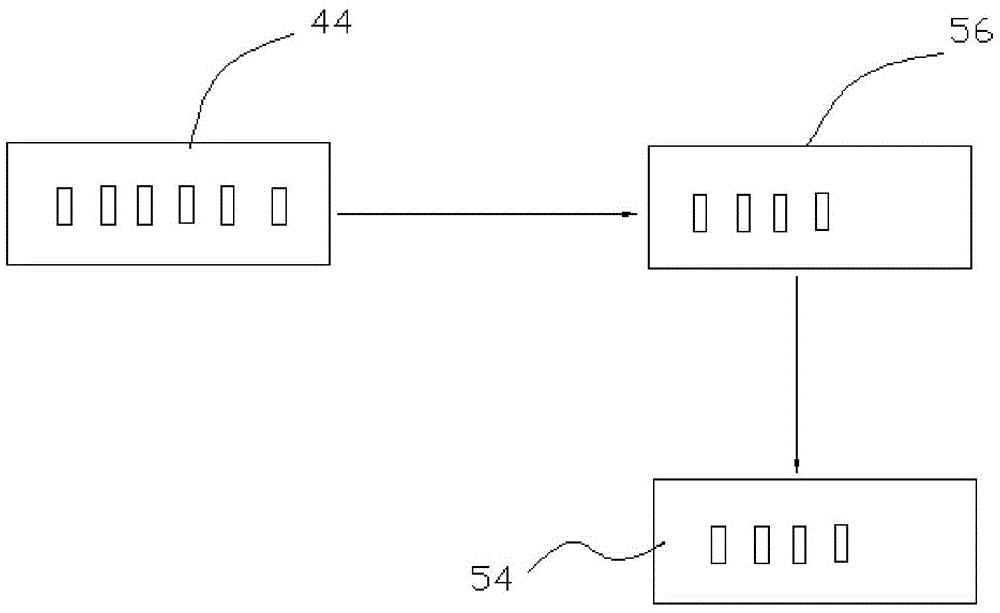

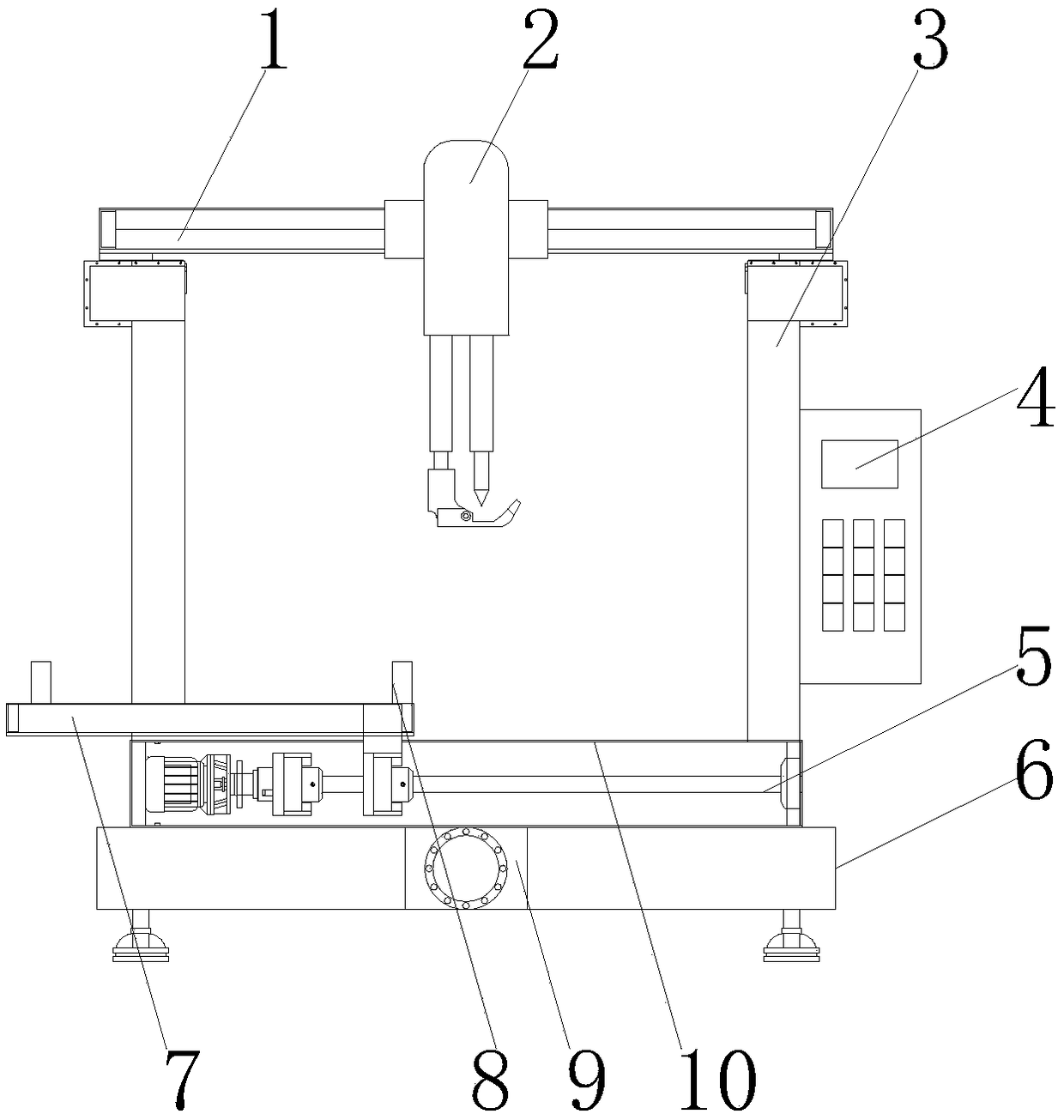

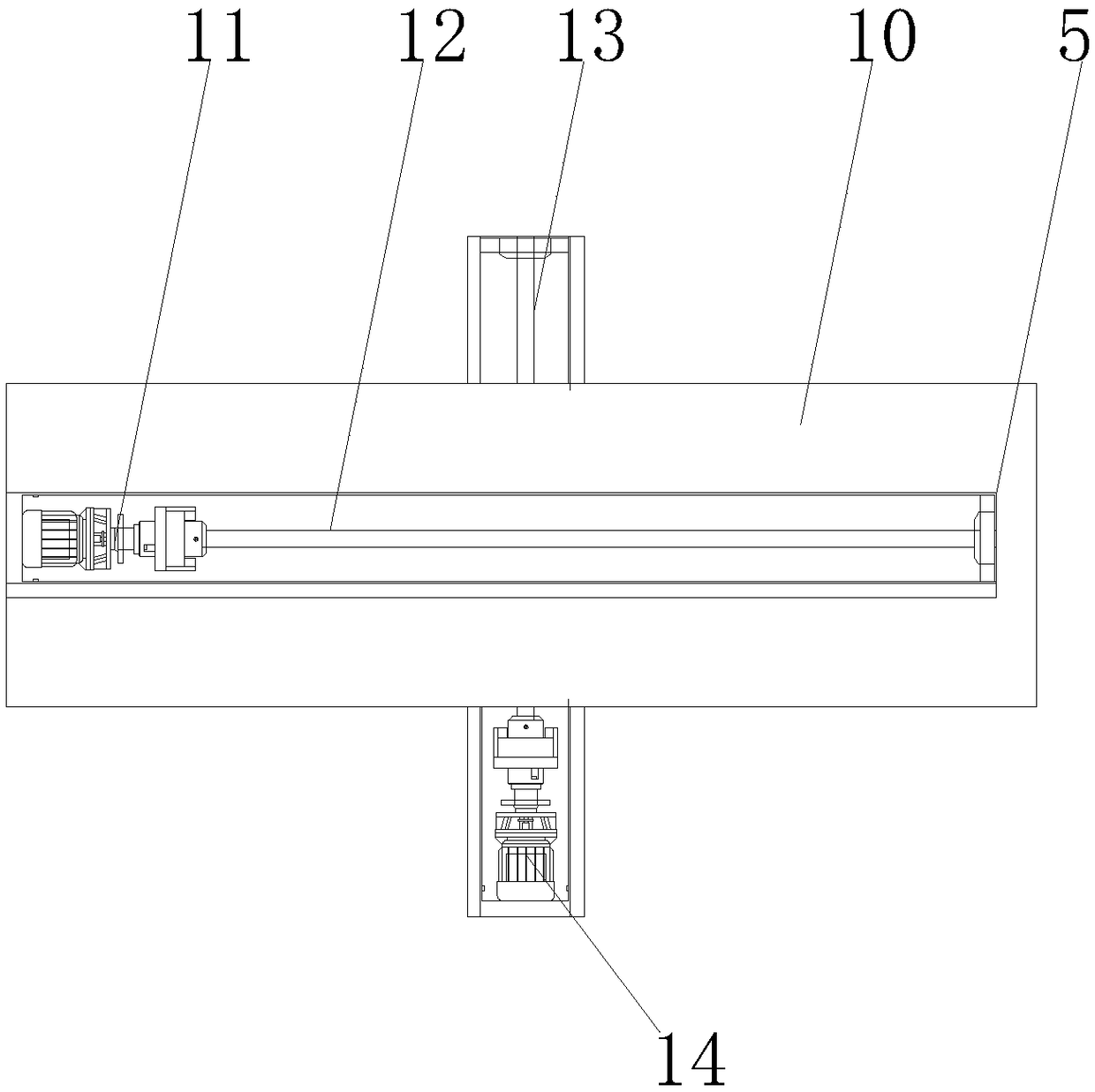

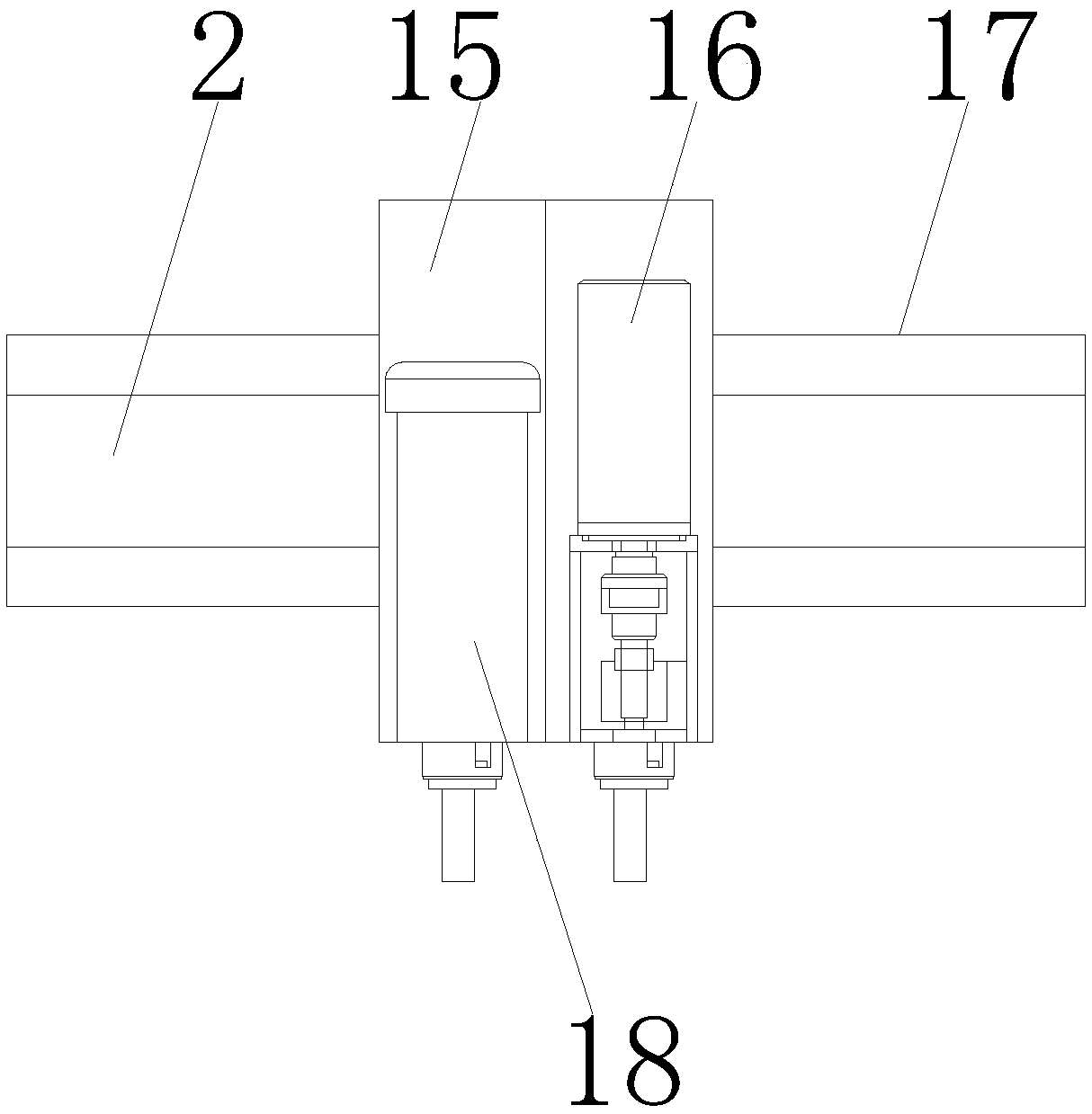

Edge pressing mechanism for overcoming glass warpage

PendingCN110252613AAvoid warpingGuaranteed flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:KUNSHAN SAMON AUTOMATION TECH

Circular screen printer device with antiskid roller

The invention discloses a circular screen printer device with an antiskid roller. The circular screen printer device comprises a circular screen and a printing conduction band and further comprises a long-strip-shaped trough arranged below the circular screen and the printing conduction band. Fixed frames are fixedly connected to the outer sides of the two ends of the long-strip-shaped trough in the longitudinal direction correspondingly. The fixed frames are fixed to a first vertical pillar and a second vertical pillar which are vertically arranged correspondingly. A roller printing device is fixed to the first vertical pillar and the second vertical pillar. The two ends of the roller printing device are rotationally connected with the first vertical pillar and the second vertical pillar correspondingly. The roller printing device is of a step type. The two ends of the roller are each provided with a small segment of step. The diameter of the middle area segment of the roller is larger than that of the area segments of the two ends of the roller. An antiskid structure used for increasing friction force is arranged on the part, located in the milled area segment, of the outer surface of the roller. The antiskid structure is antiskid lines formed on the outer surface of the roller printing device. The circular screen printer device is simple and reasonable in structure and ingenious in design concept.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

A manufacturing method for an ITO auxiliary thin-type multi-junction gallium arsenide solar cell bottom electrode

ActiveCN105702754AReduced Metal Coverage AreaSolve the warping problemFinal product manufacturePhotovoltaic energy generationMetal gridEngineering

The invention provides a manufacturing method for an ITO auxiliary thin-type multi-junction gallium arsenide solar cell bottom electrode, and belongs to the technical field of solar cell manufacturing. The manufacturing method of the invention comprises the steps of gluing, cleaning, metal grid line evaporation, IOT film layer evaporation, etc. The method is applicable to a large-size III-V-group solar cell, of which the thickness reaches below 145 [mu]m; metal grid lines and the ITO film layer are combined to be used as the bottom electrode; a bottom electrode metal covering area of the cell is reduced; a problem of warping of the thin-type cell are effectively solved; and the weight of the cell is reduced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

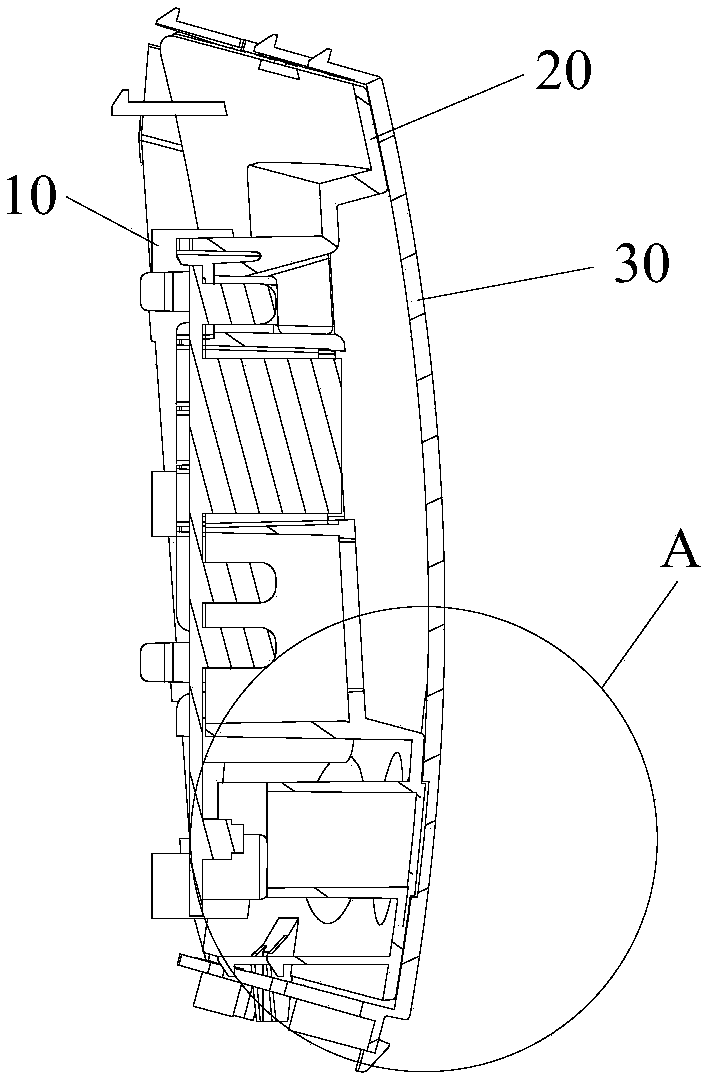

Cooking appliance and operating panel thereof

The invention provides a cooking appliance and an operating panel thereof. The operating panel of the cooking appliance comprises a lamp panel, a lamp holder, a plurality of indicating marks and a panel, wherein one or more indicator lights are arranged on the lamp panel; the lamp panel is arranged at the front side of the lamp holder; a plurality of function display parts, which correspond to theindicator lights, are arranged on the lamp holder, and light-permeable holes are each arranged in the function display part; the plurality of first indicating marks are arranged at the side, away from the lamp panel, of the lamp holder, and the plurality of indicating marks are arranged in a mode of corresponding to the plurality of function display parts one by one; the panel is arranged at thefront side of the lamp holder and shelters the function display parts; and the panel is made from a semi-transparent material. According to the technical scheme, problems of the prior art that an operating panel is not beautiful and can get turned easily in surface mounting.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

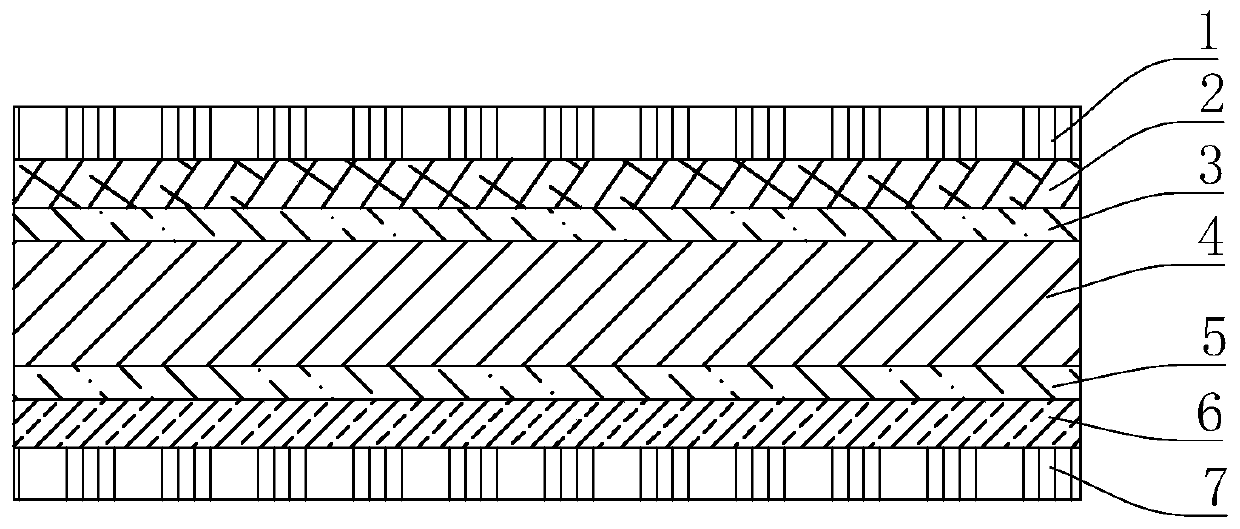

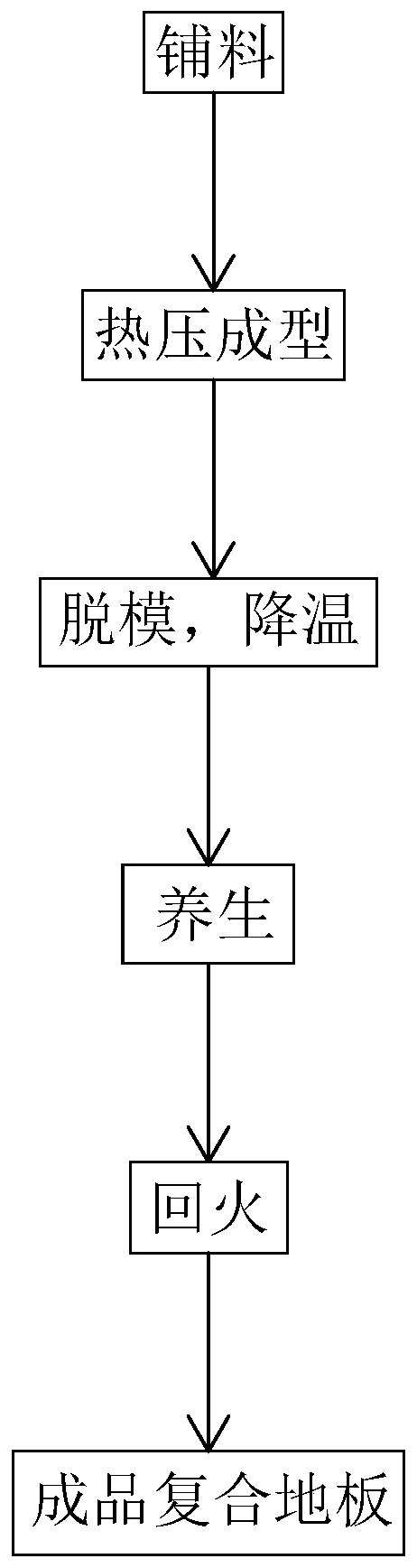

High-dimensional-stability composite floor and making process thereof

PendingCN110409748AGood dimensional stabilityGood chemical resistanceSynthetic resin layered productsLaminationFiberGlass fiber

The invention discloses a high-dimensional-stability composite floor. The high-dimensional-stability composite floor comprises a wear-resisting surface layer, a facing layer, a first glass fiber impregnation paper layer, a base material layer, a second glass fiber impregnation paper layer, a balance layer and a wear-resisting bottom layer which are arranged in sequence. The glass fiber impregnation paper layers are arranged on the front face and the back face of the base material layer, the composite floor size dimensional stability is improved, and particularly, under the humid environment, the dimensional stability is improved. In addition, the invention correspondingly discloses a making process of the composite floor. The process comprises the steps of spreading, hot pressing, demolding and tempering. The making process is simple in step, and the made composite floor has the advantage of keeping the high dimensional stability under the humid environment.

Owner:JIANGSU LANGYUE NEW MATERIALS TECH CO LTD

Nylon composite material and preparation method thereof

The invention discloses nylon composite material and a preparation method thereof. The material is composed of nylon 66 slices, thermotropic liquid crystalline polymer, needle-like mineral fiber, coupling agent and antioxidant. The weight ratio of the nylon 66 slices, the thermotropic liquid crystalline polymer, the needle-like mineral fiber, the coupling agent and the antioxidant is 60-70: 10-15: 20-30: 4.5: 0.5. The preparation method comprises the following steps: the nylon 66 slices, the thermotropic liquid crystalline polymer, the needle-like mineral fiber, the coupling agent and the antioxidant with weight ratio of 60-70: 10-15: 20-30: 4.5: 0.5 are mixed evenly under the agitating condition, and then extruded, drawn and granulated at 280 DEG C or 295 DEG C, and molded by injection into the sample to obtain the nylon system composite material. The nylon system of the invention can attain the remarkable enhancement effect under the circumstance of a little thermotropic liquid crystalline, and can have the effects on lightening the warping of the product, reducing the roughness of the product surface and reducing the cost.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

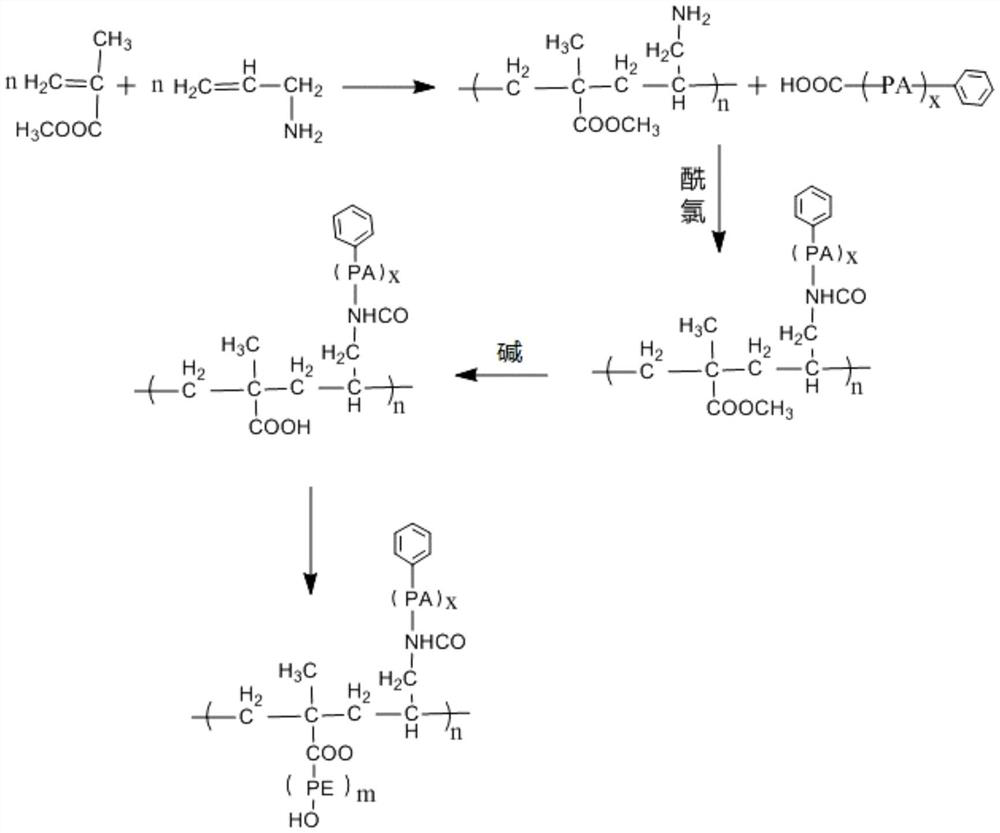

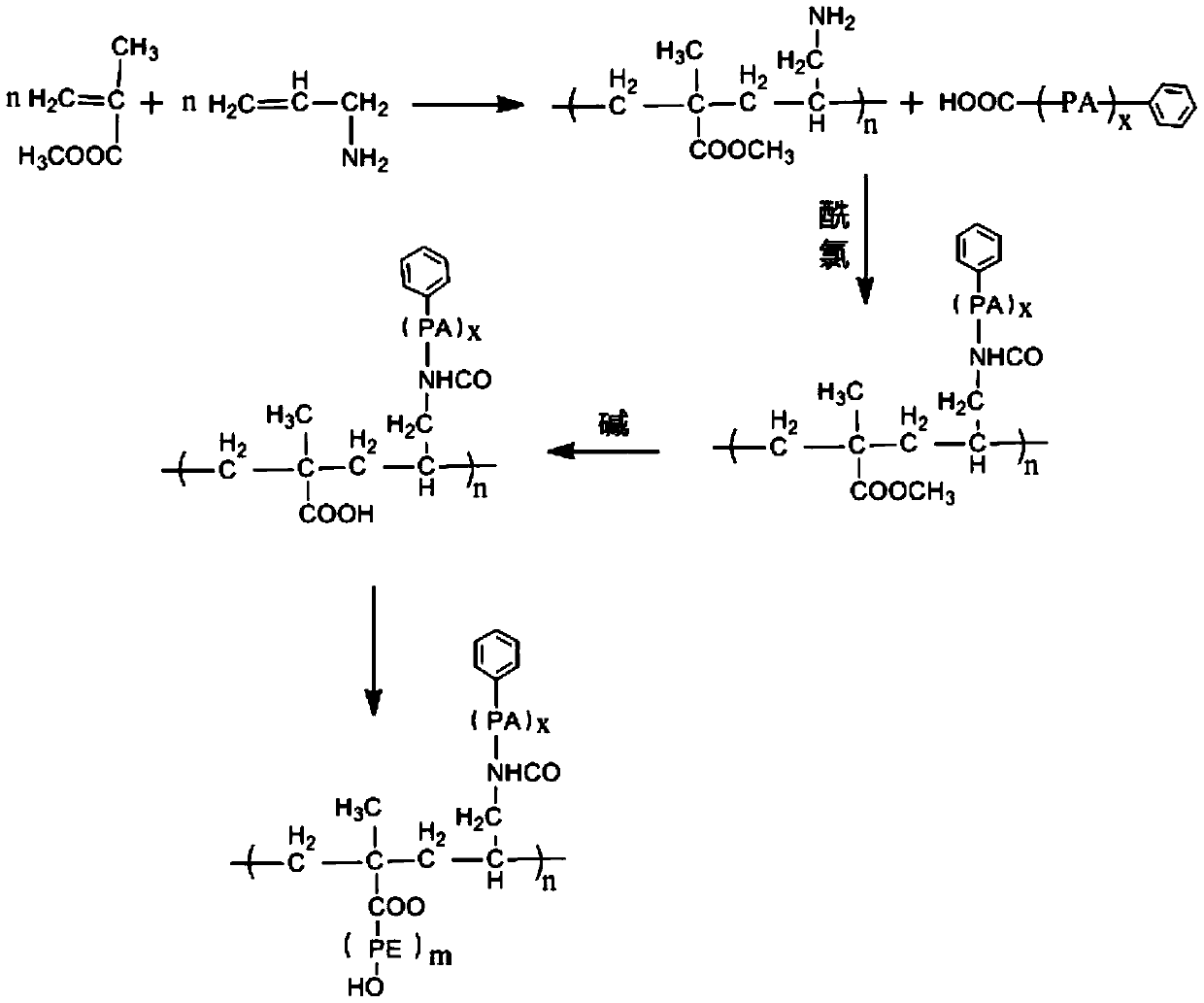

A new type of nylon material, its preparation method and its application in 3D printing

ActiveCN111454458BSolve the crystallization problemSolve the warping problemAdditive manufacturing apparatusPolymer dissolutionPolymer science

The invention provides a novel nylon material, a preparation method and its application in 3D printing. The preparation method of the nylon material comprises: 1) making acrylate monomers and functionalized olefin monomers under oxygen-free conditions Polymerization to prepare polymer a; 2) react the polyamide hard segment with the amine group or carboxyl group in polymer a to prepare polymer b; 3) dissolve polymer b, add alkali catalyst to hydrolyze its ester group generating carboxyl groups to prepare polymer c; 4) adding an esterification catalyst to react the carboxyl groups generated by the hydrolysis of polymer c with the hydroxyl groups in the soft segment of polyether polyol to prepare the nylon material. The nylon molecule prepared by the method of the present invention has a polyacrylate segment as the main chain, and a polyamide hard segment and a polyether polyol soft segment as side chains, which can solve the problem that nylon materials are easy to warp during 3D printing.

Owner:WANHUA CHEM GRP CO LTD +1

Metal product punching equipment

PendingCN109365626AAchieve fixationSolve the problem of poor punching qualityMetal-working feeding devicesPositioning devicesPunchingCoupling

The invention discloses metal product punching equipment. The metal product punching equipment comprises a top plate, a punching mechanism, stand columns and a base, the four corners of the lower partof the top plate are provided with the stand columns, the four stand columns are installed on the base, and the middle position above the top plate is provided with the punching mechanism; the punching mechanism comprises a mounting base, a machining box, a hydraulic machine, an air cylinder A and a punching head, wherein a workbench is installed right below the punching head, and a Y-axis transmission mechanism is installed at the middle position inside the workbench; and the Y-axis transmission mechanism comprises a Y-axis motor, a Y-axis screw rod, the Y-axis motor is installed at the leftend inside the workbench, and an output shaft of the Y-axis motor is rotationally connected with the Y-axis screw rod through a coupler. According to the metal product punching equipment, the punching mechanism is arranged, so that the problems that in the prior art, the positioning is not accurate, and the two sides of an aluminum alloy tube are prone to warping during punching are solved.

Owner:FOSHAN UNIVERSITY

A protective treatment process for cutting and rolling of protective film

ActiveCN110919765BWill not deformEasy to useMetal working apparatusStructural engineeringKnife blades

The invention discloses a protection treatment process for protective film cutting and rolling, and specifically relates to the technical field of protective film cutting and rolling, which includes the following processing steps: Step 1, firstly collect the waste materials produced by the protective film processing, clean them up and arrange them for standby; step 2. Before cutting the processed and rolled protective film, determine the position of the cutting knife, and then wrap the protective film waste sorted in step 1 outside the protective film to be cut, and correspond to the position of the lower knife ;Step 3: After the lower knife position of the protective film is wrapped and thickened by the waste protective film, the roll cutting machine is turned on, and a circular blade is used on the roll cutting machine to carry out the roll cutting work. Thick protective film waste, after the waste is removed, the protective film wrapped by the waste is intact. The invention adopts the process of wrapping the protective film with the protective film waste and then cutting it into rolls. The protective film can be cut into rolls directly by using a round knife. It is simple and easy to operate during use, and the cut rolls of the protective film do not warp.

Owner:昆山云松电子材料有限公司

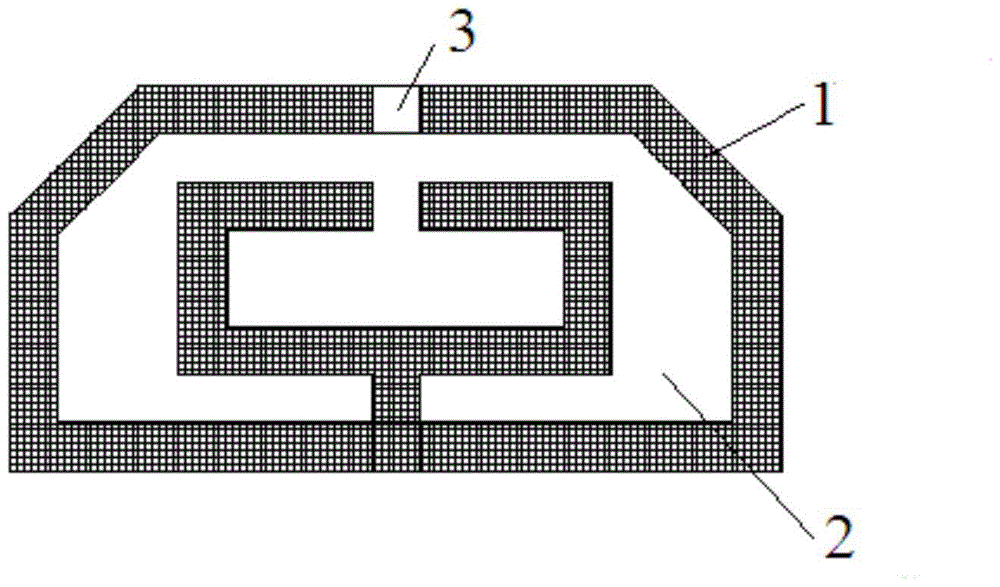

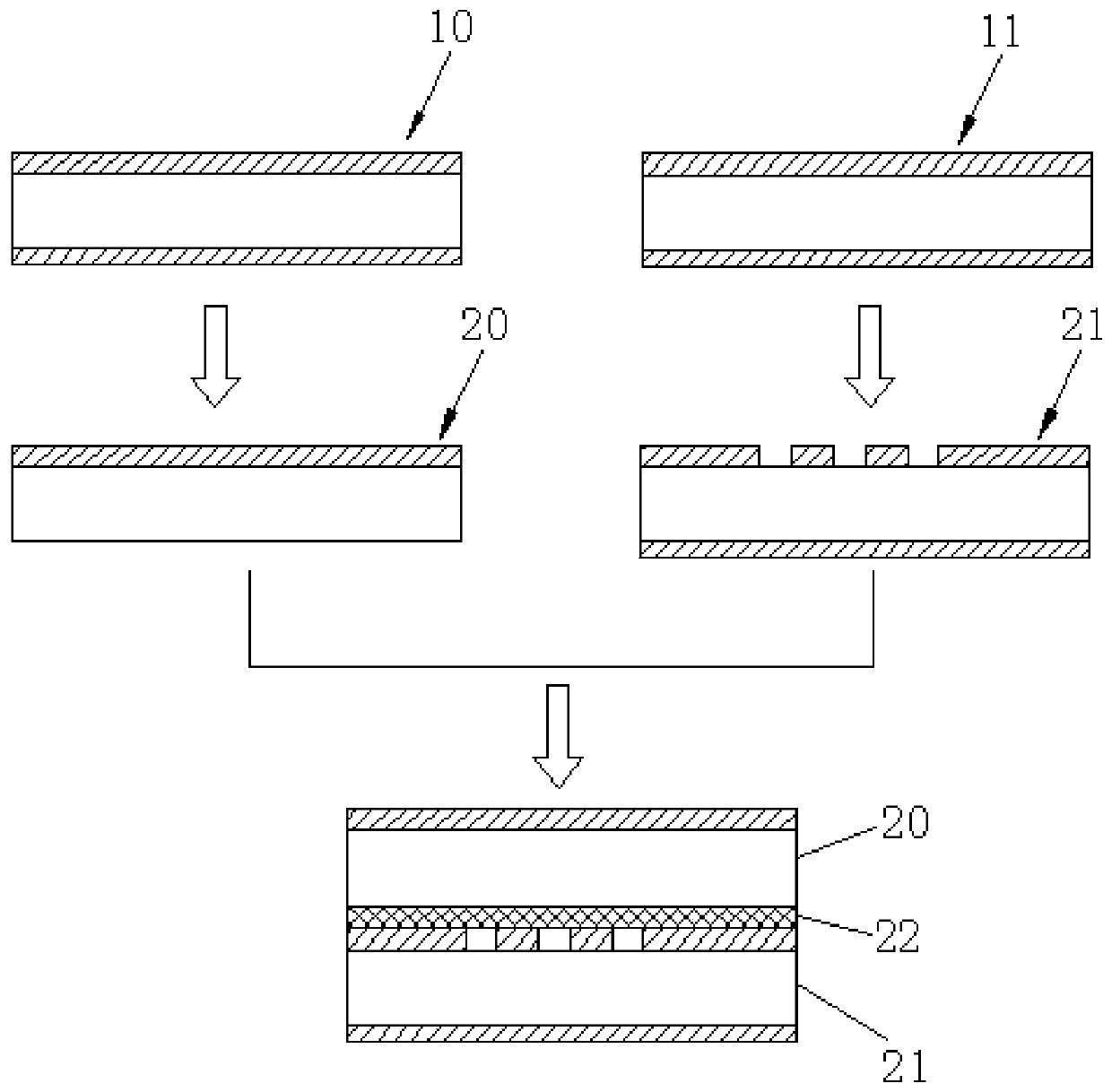

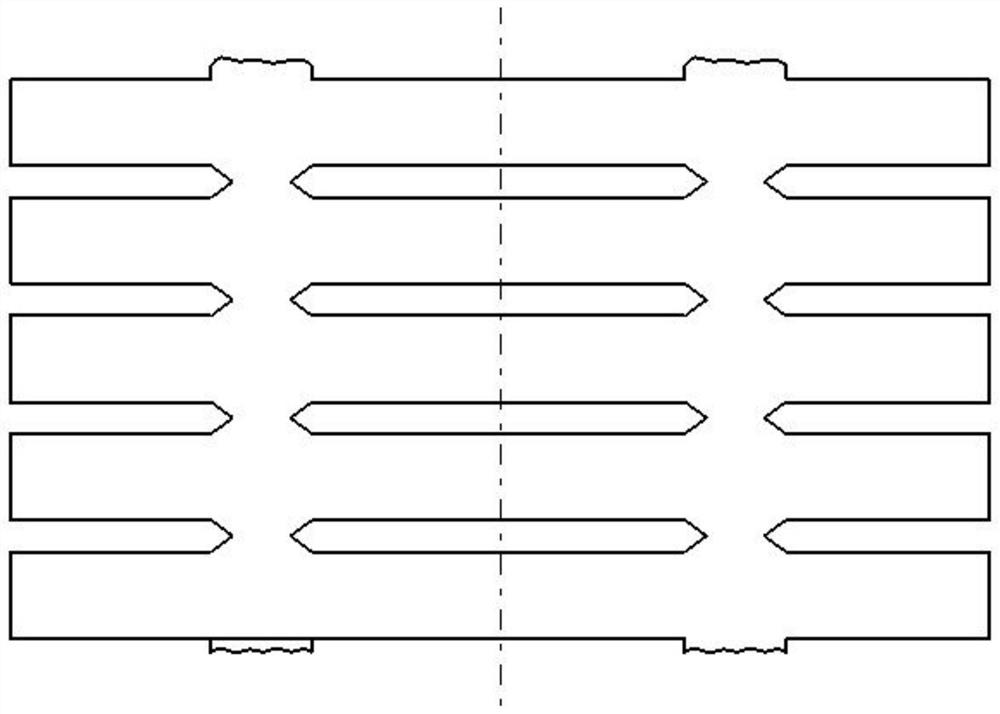

MEMS package carrier plate stack-up structure and manufacturing method thereof

ActiveCN111328217ASolve the warping problemGuaranteed qualityConductive material chemical/electrolytical removalMultilayer circuit manufactureManufacturing engineeringElectrical and Electronics engineering

The invention discloses an MEMS package carrier plate stack-up structure and a manufacturing method thereof. The manufacturing method comprises the following steps: preparing a copper-clad substrate Aand a copper-clad substrate B; processing the copper-clad substrate A to obtain a single-sided copper-clad substrate; processing the copper-clad substrate B to obtain a double-sided copper-clad substrate II with a single-sided circuit; and sequentially stacking, aligning and laminating the single-sided copper-clad substrate, a PP sheet and the double-sided copper-clad substrate II to form an MEMSpackaging substrate stack-up structure with a pseudo four-layer plate structure. The manufacturing method of the MEMS package carrier plate stack-up structure is relatively simple and easy to operate, the warping problem is well solved, the quality of a circuit board product is ensured, and the production cost is reduced.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

Conductive paste for solar cell and preparation method thereof

ActiveCN101820002BImprove photoelectric conversion efficiencyMeet the requirementsFinal product manufacturePhotovoltaic energy generationConductive pasteHigh volume manufacturing

Owner:BYD CO LTD

Novel nylon material and preparation method thereof, and application of novel nylon material in 3D printing

ActiveCN111454458AImprove rigidityShorten the lengthAdditive manufacturing apparatusPolymer dissolutionPolymer science

The invention provides a novel nylon material and a preparation method thereof, and application of the novel nylon material in 3D printing. The preparation method of the nylon material comprises the following steps: 1) polymerizing an olefine acid ester monomer and a functionalized olefin monomer under an anaerobic condition to prepare a polymer a; 2) reacting a polyamide hard segment with amino or carboxyl groups in the polymer a to prepare a polymer b; 3) dissolving the polymer b, and adding a base catalyst to hydrolyze an ester group of the polymer b so as to generate carboxyl groups, thereby preparing a polymer c; and 4) adding an esterification catalyst to enable carboxyl groups generated by hydrolysis of the polymer c to react with hydroxyl groups in a polyether polyol soft segment,thereby obtaining the nylon material. According to a nylon molecule prepared by the method disclosed by the invention, a polyolefine acid ester chain segment is used as a main chain, and the polyamidehard segment and the polyether polyol soft segment are used as side chains, so the problem that a product is easy to warp when a nylon material is used for 3D printing can be solved.

Owner:WANHUA CHEM GRP CO LTD +1

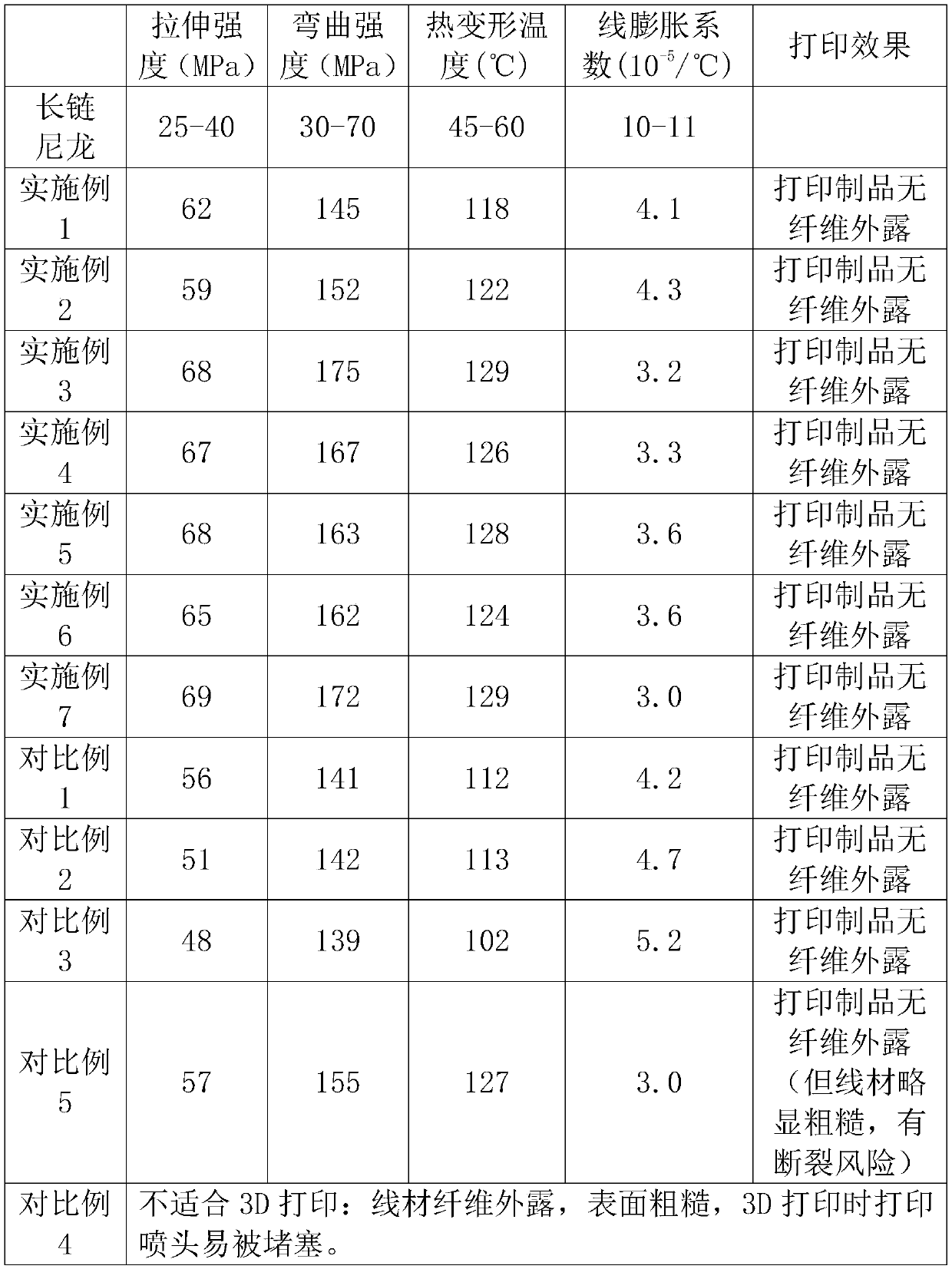

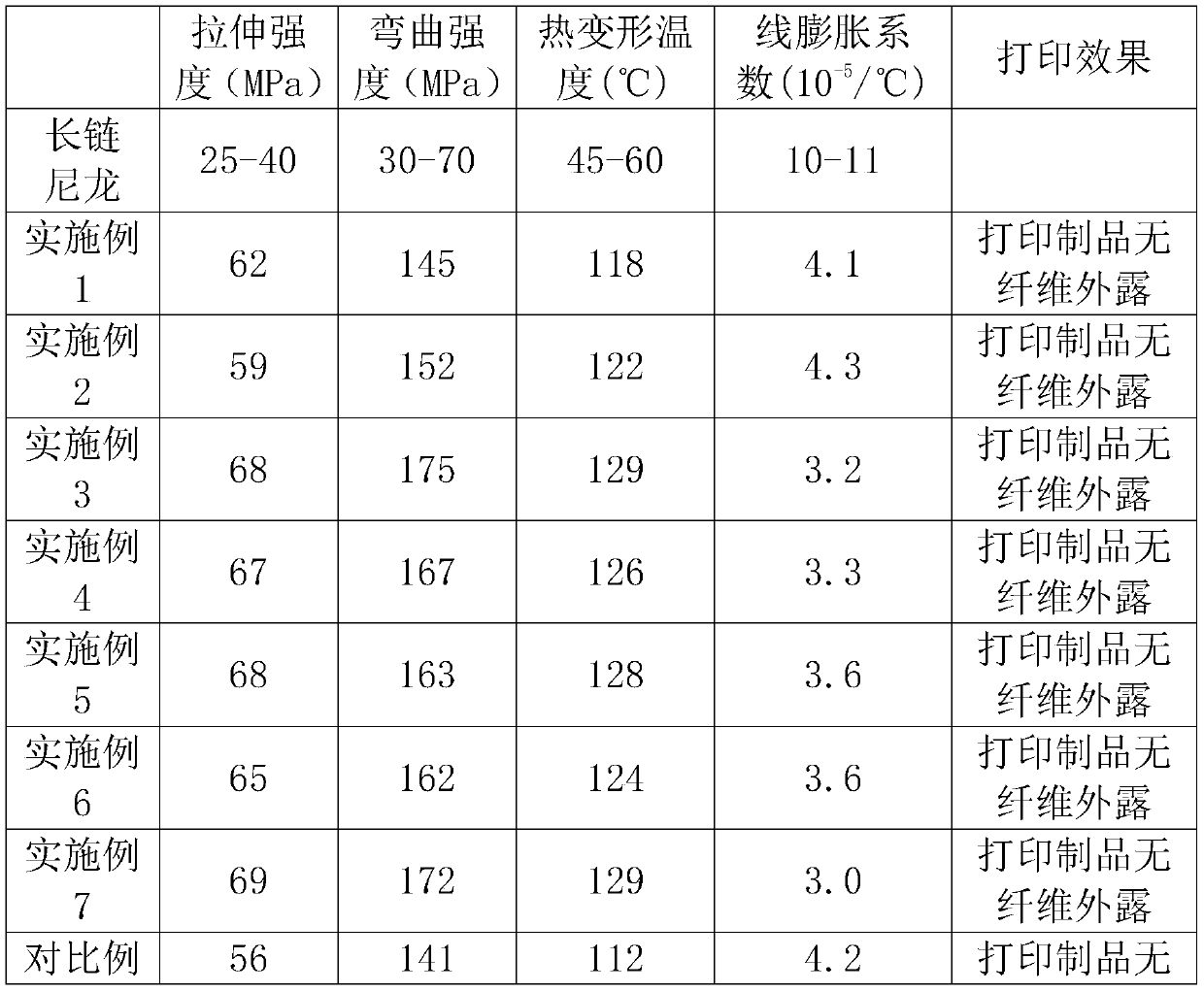

A preparation method of long-chain nylon composite material for 3D printing

ActiveCN108047708BHigh tensile strengthImprove bending strengthAdditive manufacturing apparatusFiberPolymer science

The invention relates to a preparing method of a long-chain nylon compound material for 3D printing. The preparing method comprises the following steps of preparing, by weight, 100 parts of long-chainnylon, 5-10 parts of kevlar chopped fiber, 5-15 parts of wollastonite, 0.1-0.3 part of coupler, 3-8 parts of flexibilizer, 0.5-1 part of hyperbranched resin and 0.2-1 part of antioxygen; spraying a coupling agent solution while stirring wollastonite, and conducting drying and cooling; uniformly mixing coupling-agent-modified wollastonite, the long-chain nylon, the kevlar chopped fiber, the flexibilizer, hyperbranched resin and antioxygen; adding a premixed raw material into a double-screw extruder for extrusion pelleting to obtain modified particles; adding the dried modified particles into asingle screw extruder to extrude out a plastic melt, and conducting hot water and cold water treatment to obtain wires. The preparing method is suitable for large-batch production, the prepared printing product has no obvious exposed fiber, the stretching strength, the bending strength and the thermal deformation temperature are high, and the size is stable.

Owner:诺思贝瑞新材料科技(苏州)有限公司

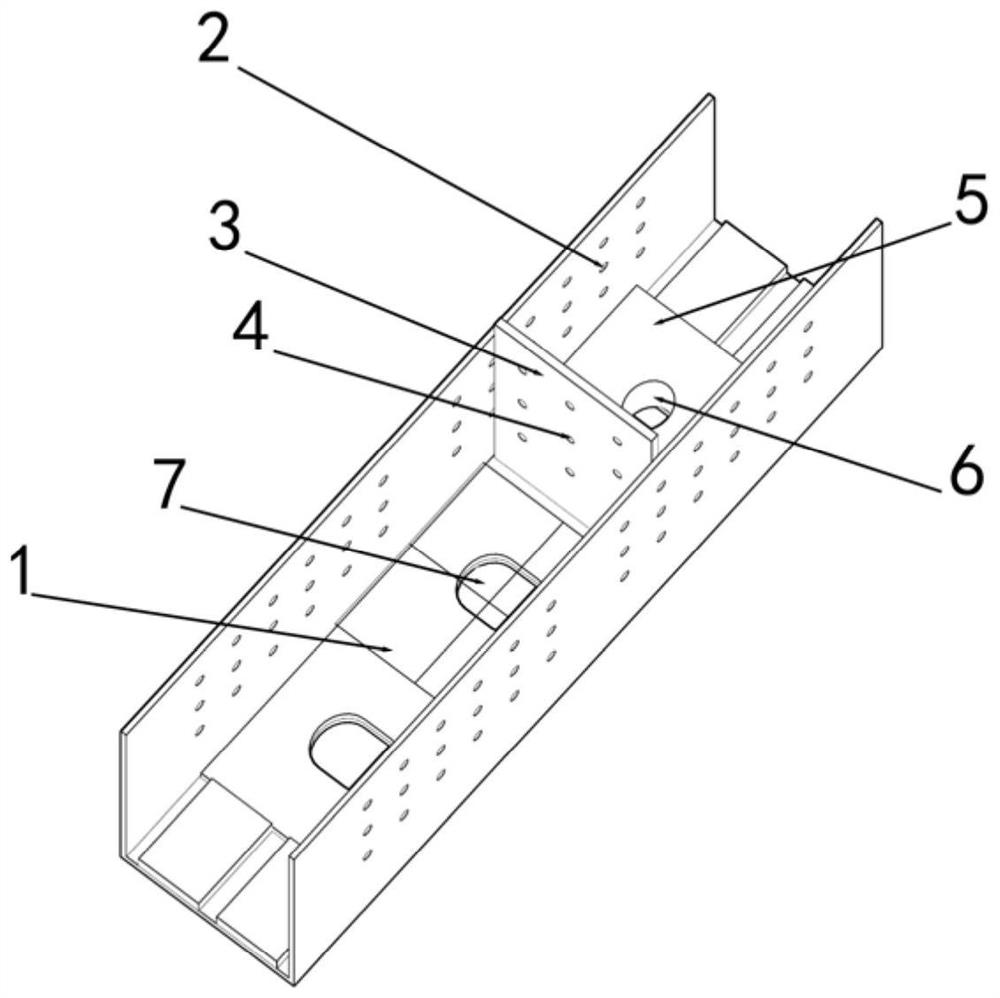

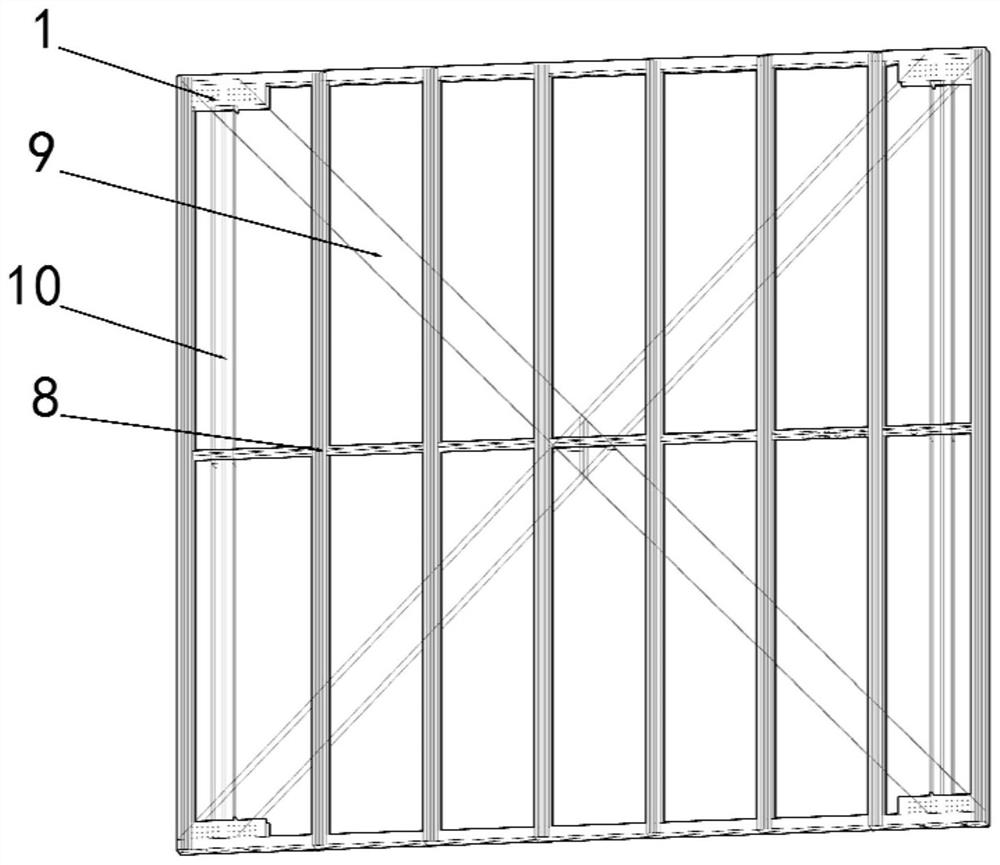

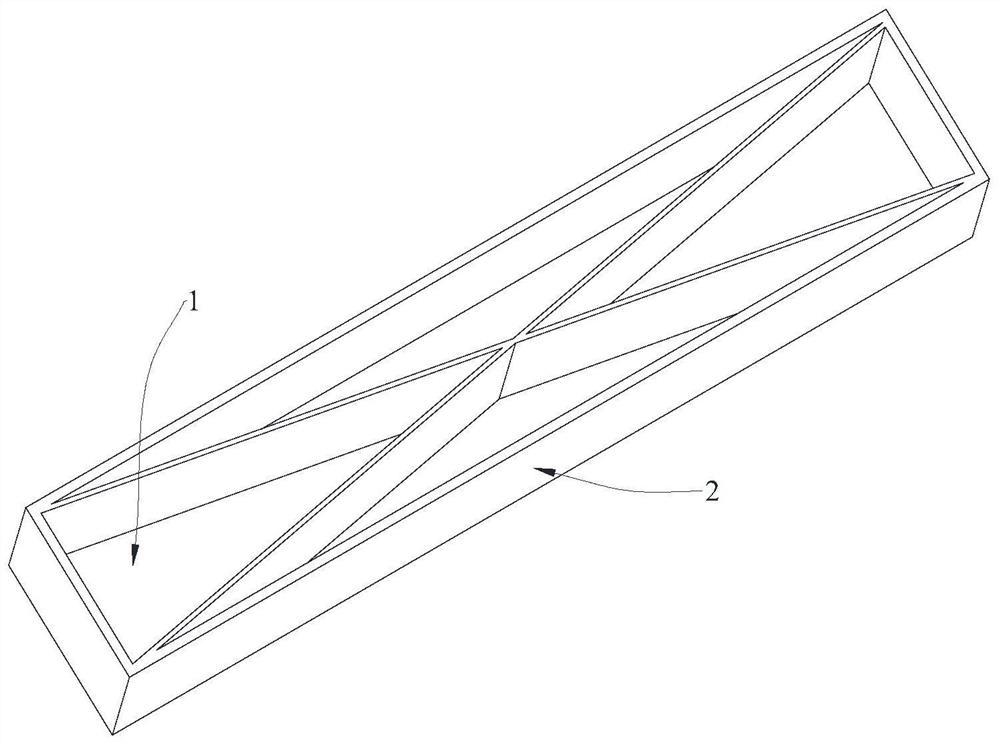

Connecting piece and reinforced light steel keel wall integrated with prestressed flat steel strip

The invention relates to the technical field of building partition walls, in particular to a connecting piece and a reinforced light steel keel wall integrated with prestressed flat steel strips. The U-shaped mounting frame comprises a belly part and two wing parts, the belly part is connected with a main body structure of the light steel keel wall, and mounting holes are formed in the wing parts. A reinforced light steel keel wall integrated with prestressed flat steel strips comprises a light steel keel wall body. The four connecting pieces are fixed to the inner sides of the four corners of the light steel keel wall correspondingly. The two groups of flat steel belts are respectively fixed on the two wall surfaces, each group of flat steel belts comprises two flat steel belts which are arranged in a crossed manner, and the two ends of each flat steel belt are respectively fixed on the two connecting pieces which are distributed diagonally. When the flat steel strip is installed, the flat steel strip is prevented from being connected with a frame through a hole and a bolt, the waterproof performance of the end is enhanced, the problems of rusting, corrosion and the like caused by leakage of a light steel keel wall are solved, and the service life of the light steel keel wall is prolonged.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

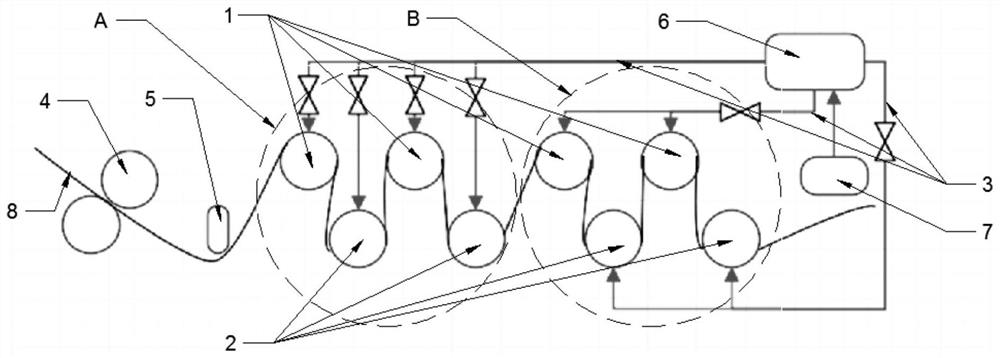

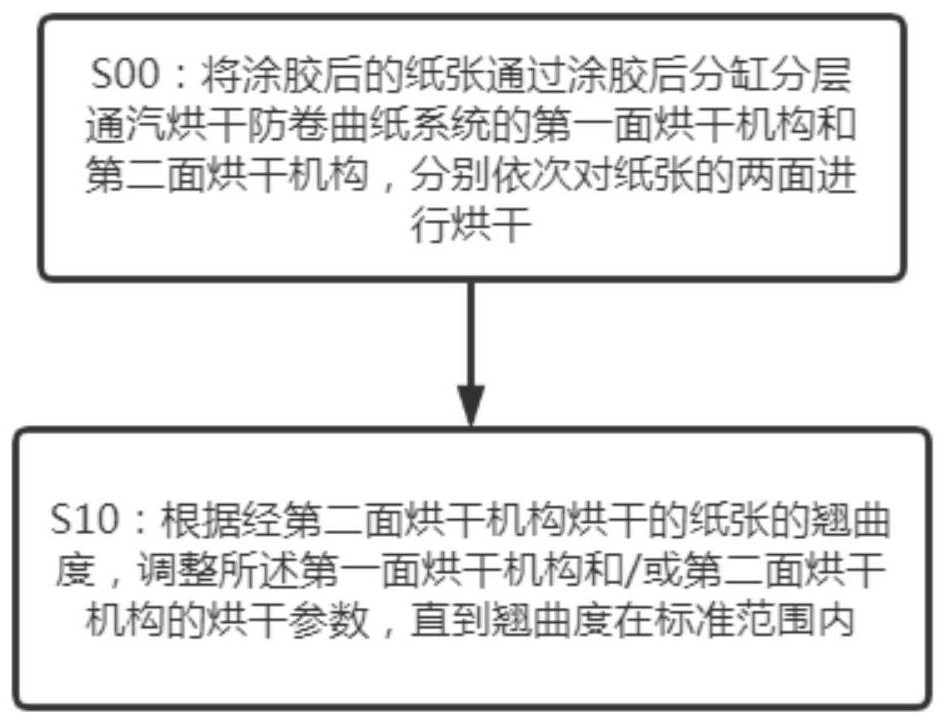

System and method for drying anti-curl paper through steam introduction in different cylinders and layers after gluing

ActiveCN113668289ASolve the warping problemSolve wrinklePhysical paper treatmentPapermakingProcess engineering

The invention relates to a system and a method for drying anti-curl paper through steam introduction in different cylinders and layers after gluing, and belongs to the field of papermaking. The system comprises: a drying mechanism, and the drying mechanism comprises a first surface drying mechanism and a second surface drying mechanism; and the first surface drying mechanism and the second surface drying mechanism are respectively arranged on the first surface side and the second surface side of the paper from the surface gluing machine for drying. The method comprises the following steps: enabling glued paper to pass through the first surface drying mechanism and the second surface drying mechanism of the system for drying anti-curl paper through steam introduction in different cylinders and layers after gluing, and respectively and sequentially drying two surfaces of the paper; and according to the warping degree of the paper dried by the second surface drying mechanism, adjusting the drying parameters of the first surface drying mechanism and / or the second surface drying mechanism until the warping degree is within the standard range. The system and the method can solve the problem that the water absorption added value deviation of the front and back surfaces of the paper is too large in the drying process after papermaking gluing, so that the finished paper is curled, and use is affected.

Owner:LEE & MAN PAPER MFG

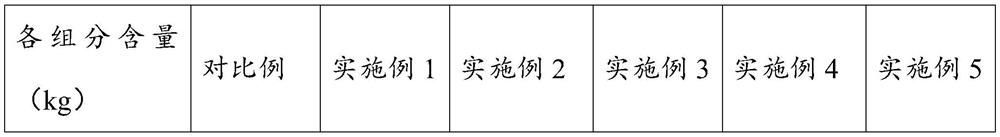

Filling modified PP material and preparation method thereof

The invention discloses a filling modified PP material which comprises the following components in parts by weight: 30-70 parts of PP resin, 10-20 parts of talcum powder, 40-50 parts of composite glass fibers and 0.1-1 part of a processing aid. The invention also discloses a preparation method of the filling modified PP material. Compared with the prior art, PP is filled with the modified composite glass fibers, the modified composite glass fibers can improve the distribution uniformity of the glass fibers in PP resin and eliminate the orientation of the fibers in the resin, uniform dispersion of the base material and the glass fibers is finally achieved, the shrinkage rate of a workpiece is reduced, and meanwhile the problem of warping of the workpiece is solved.

Owner:珠海格力新材料有限公司 +1

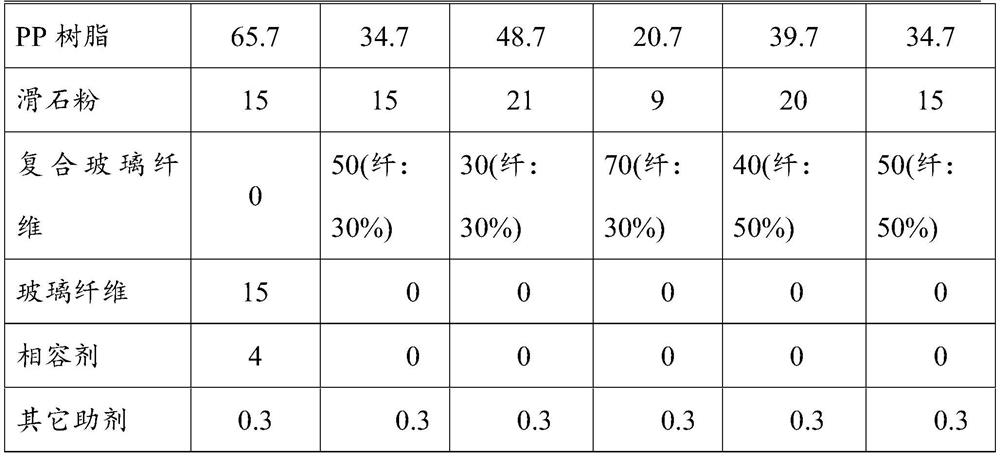

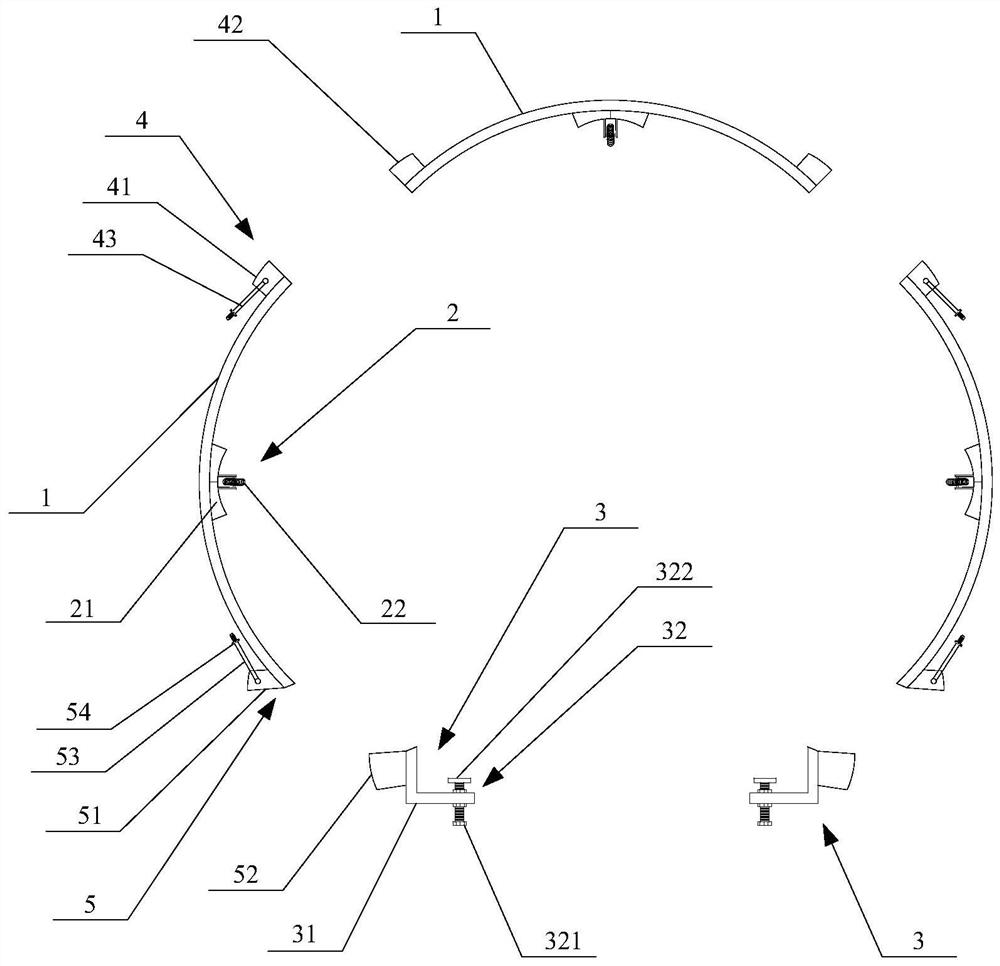

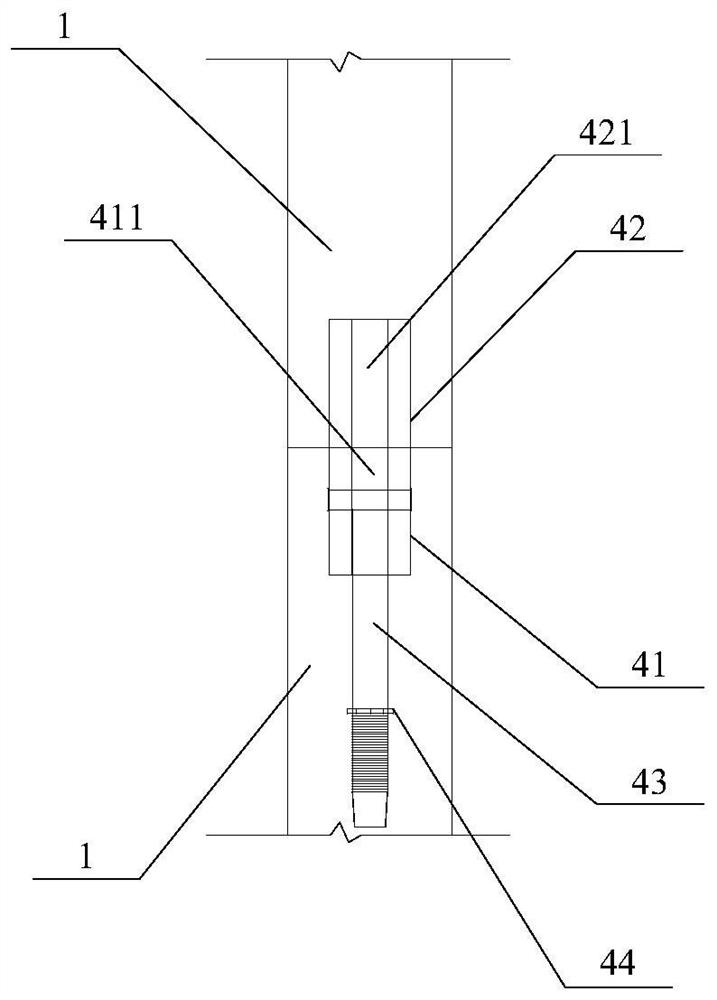

Anti-tilting device and pipe jacking system

ActiveCN113175561AAvoid liftingGuaranteed to move normallyPipe laying and repairStructural engineeringMechanical engineering

The invention provides an anti-tilting device and a pipe jacking system. The device comprises at least two arc-shaped bodies, at least two resistance reduction mechanisms and two fastening mechanisms, the arc-shaped bodies are sequentially and detachably connected to form an annular structure with an opening, and the annular structure is arranged at the joint of two adjacent cylindrical bodies in a sleeving mode. The bottoms of the two cylindrical bodies are movably arranged on a guide rail; and the resistance reduction mechanisms are arranged on the inner sides of the arc-shaped bodies in a one-to-one correspondence mode and make contact with the cylindrical bodies so that resistance can be reduced when the two cylindrical bodies move. The two fastening mechanisms are detachably connected with the two arc-shaped bodies arranged at the opening of the annular structure in a one-to-one correspondence mode, and the two fastening mechanisms jointly act to enable the annular structure and the guide rail to be fastened so as to limit the two cylindrical bodies from tilting. According to the anti-tilting device and the pipe jacking system, the annular structure is arranged at the joint of the two adjacent cylindrical bodies in a sleeving mode, the annular structure and the guide rail at the bottoms of the cylindrical bodies are fastened through the combined action of the two fastening mechanisms, and therefore the two cylindrical bodies are continuously limited, and the two cylindrical bodies are prevented from tilting.

Owner:CHINA FIRST METALLURGICAL GROUP

A long-chain nylon composite material for 3D printing

ActiveCN108164997BHigh tensile strengthImprove bending strengthAdditive manufacturing apparatusFiberHeat deflection temperature

The invention relates to a long-chain nylon composite material for 3D printing. The long-chain nylon composite material for 3D printing comprises, by weight, 100 parts of long-chain nylon, 5-10 partsof kevlar short-cut fibers, 5-15 parts of wollastonite, 0.1-0.3 part of a coupling agent, 3-8 parts of a toughening agent, 0.5-1 part of hyperbranched resin and 0.2-1 part of an antioxidant. Wires andprinted products have no obvious fiber exposure, and the printed products also have the advantages of high tensile strength, high bending strength, high thermal deformation temperature and stable sizes.

Owner:诺思贝瑞新材料科技(苏州)有限公司

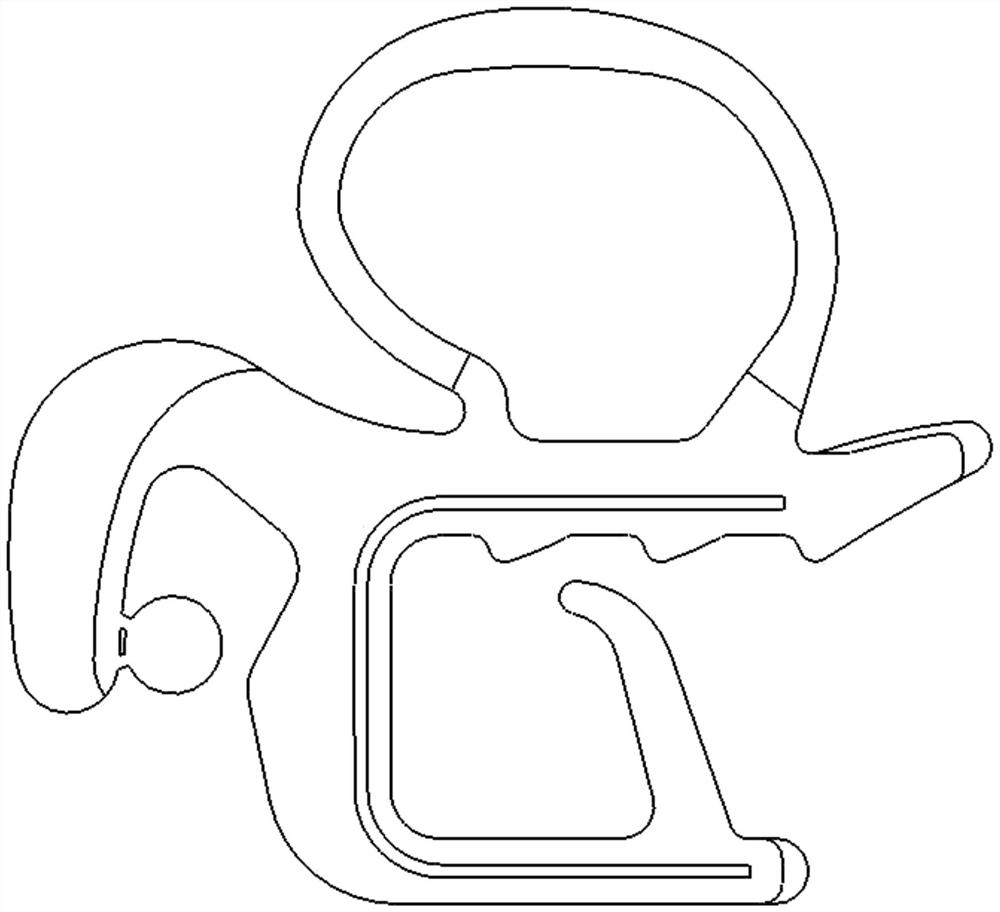

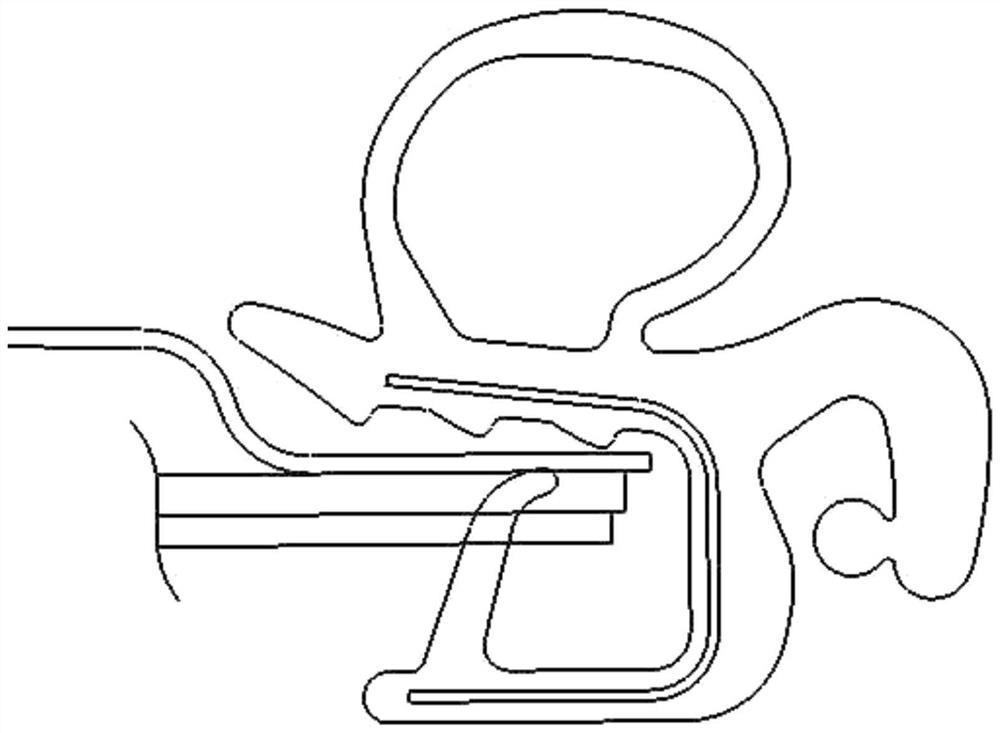

Automobile door opening sealing strip and installation method thereof

PendingCN111775675AReduce rigidityTendency to reduce splayEngine sealsVehicle sealing arrangementsEngineeringStructural engineering

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com