Nylon composite material and preparation method thereof

A nylon composite material, nylon technology, applied in the field of nylon composite materials, can solve the problems of unsolvable compatibility problems, composite material performance decline, processing machine wear, etc., to improve melt flow rate, improve processing performance, reduce effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

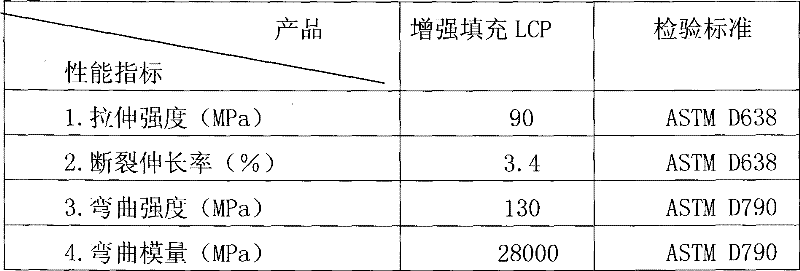

[0028] In parts by weight, weigh 60 parts of nylon 66 slices (engineering plastic grade nylon 66 slices produced by China Shenma Group Co., Ltd.), 10 parts of Vectra A-type thermotropic liquid crystal polymers (produced by Goodfellow Company in the United States), 25 parts of needle-shaped Wollastonite (produced by Nanfang Wollastonite Industrial Company, Xinyu City, Jiangxi), 4.5 parts of maleic anhydride and styrene copolymer type coupling agent (produced by Shanghai Shibida Company), 0.5 part of Lunchemao-R hindered phenol antioxidant (produced by Great Lakes Corporation of the United States); under stirring conditions, mix the above components evenly, then extrude, draw, and granulate the resulting mixture in an extruder at 290 ° C, and make samples by injection molding, and perform performance test. The mechanical properties of the sample were tested according to the following standards. The results are shown in Table 1. It can be seen from the table that compared with pu...

Embodiment 2

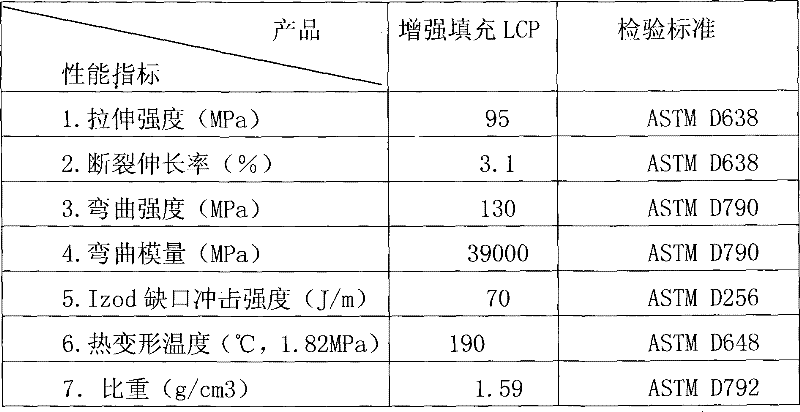

[0033] In parts by weight, weigh 70 parts of nylon 66 slices (engineering plastic grade nylon 66 slices produced by China Shenma Group Co., Ltd.), 10 parts of Zenite type thermotropic liquid crystal polymers (produced by U.S. Dupont Company), 15 parts of acicular silicon Limestone (produced by Nanfang Wollastonite Industrial Company, Xinyu City, Jiangxi Province), 4.5 parts of maleic anhydride and styrene copolymer type coupling agent (produced by Shanghai Shibida Company), 0.5 part of Lunchemao-R hindered phenol antioxidant ( Produced by Great Lakes Corporation of the United States); under stirring conditions, the above components are mixed uniformly, and then the resulting mixture is extruded, drawn, and pelletized in an extruder at 285 ° C, and injected into samples for performance testing . The mechanical properties of the sample were tested according to the following standards, and the results are shown in Table 2: As can be seen from the table, compared with pure nylon 6...

Embodiment 3

[0037]In parts by weight, weigh 60 parts of nylon 66 slices (engineering plastic grade nylon 66 slices produced by China Shenma Group Co., Ltd.), 10 parts of Vectra A-type thermotropic liquid crystal polymers (produced by Goodfellow Company in the United States), 25 parts of needle-shaped Wollastonite (produced by Southern Wollastonite Industrial Company, Xinyu City, Jiangxi Province), 4.5 parts of EPON coupling agent (produced by Aldrich Company of the United States), 0.5 part of Lunchemao-R type hindered phenol antioxidant (produced by Great Lakes Company of the United States); under stirring conditions The above components were mixed uniformly, and then the resulting mixture was extruded, drawn, pelletized in an extruder at 290°C, and injected into samples for performance testing. The mechanical properties of the sample were tested according to the following standards, and the results are shown in Table 3: As can be seen from the table, compared with pure nylon 66, the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com