Method for producing asymmetrically laminated printed circuit board

A printed circuit board, asymmetric technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of different layer thicknesses or copper foil thicknesses on both sides, product quality problems, and increased scrap volume. Leveling steps, the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

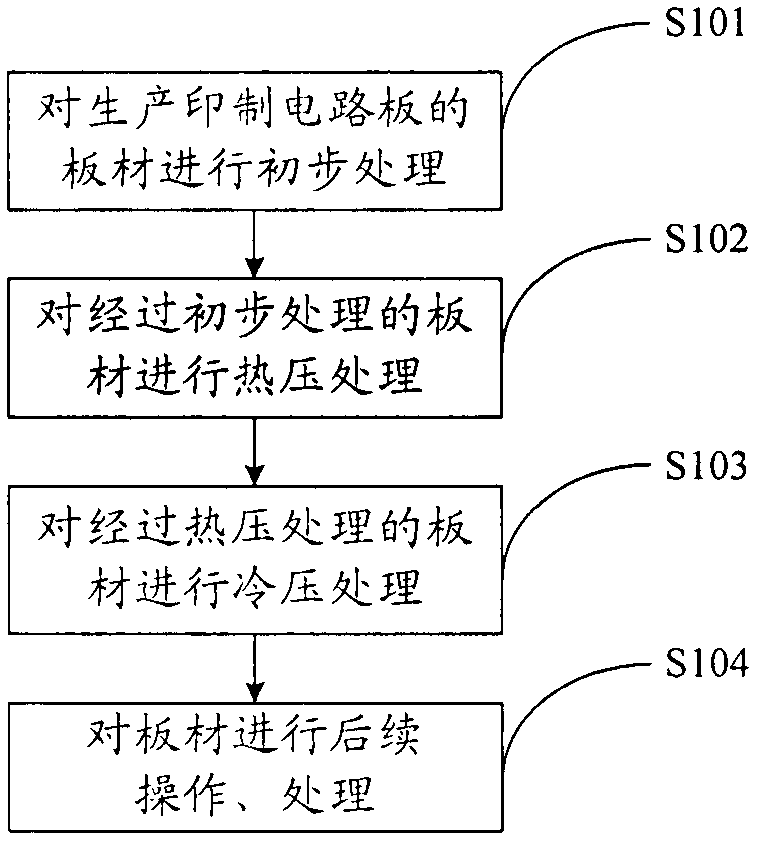

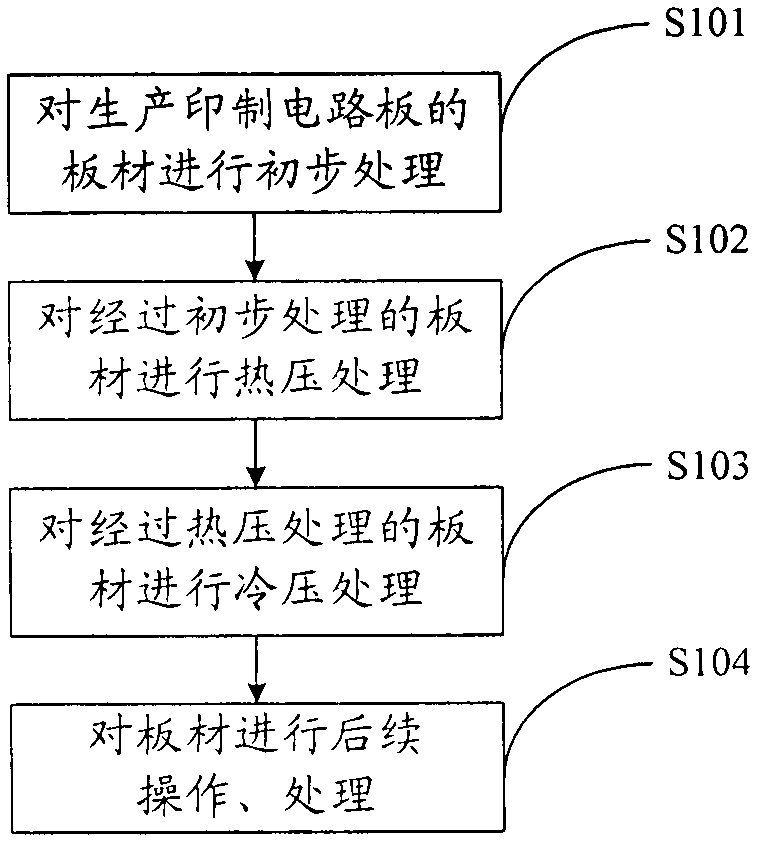

[0013] figure 1 The implementation flow of the method for producing an asymmetrical laminated printed circuit board provided by the embodiment of the present invention is shown.

[0014] The method includes the following steps:

[0015] In step S101, preliminary processing is performed on the plate for producing printed circuit boards;

[0016] In step S102, hot pressing is performed on the preliminarily treated plate;

[0017] In step S103, cold press treatment is performed on the plate that has undergone hot press treatment;

[0018] In step S104, subsequent operations and processing are performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com