Viscidity-reducing adhesive tape for lamination edge seal of solar double-glass photovoltaic module and preparation method of viscidity-reducing adhesive tape

A dual-glass photovoltaic and module layer technology, applied in adhesives, pressure-sensitive films/sheets, film/sheet-like adhesives, etc., can solve the problems of poor initial adhesive tape, high production cost pressure, easy to warp, etc. Achieve the effect of reducing production cost, improving production efficiency and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

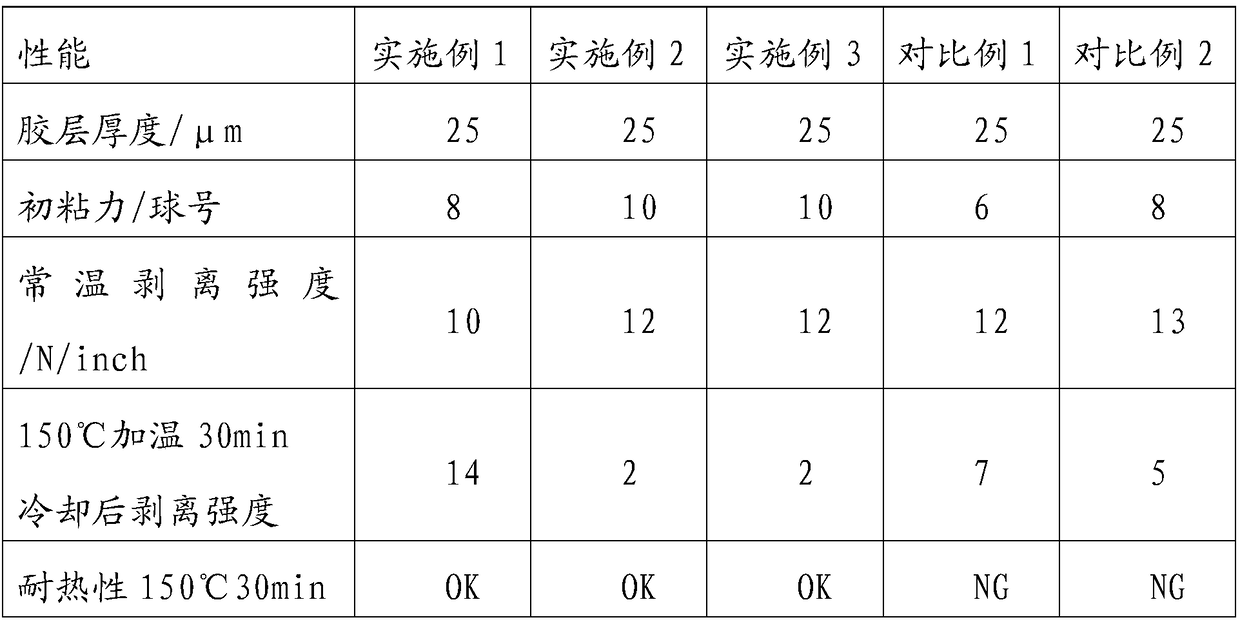

Examples

Embodiment 1

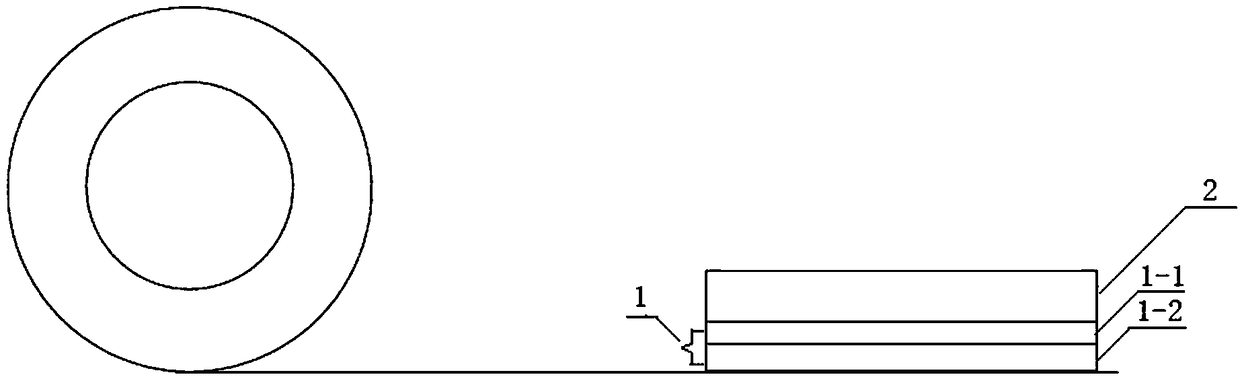

[0027] A solar double-glass photovoltaic module lamination edge-sealing adhesive tape, comprising a flexible substrate layer and an acrylate pressure-sensitive adhesive layer rolled inside the flexible substrate layer;

[0028] Wherein, the flexible substrate layer is a composite film of polyester film and polyolefin film, the thickness of the polyester film is 12 μm, and the thickness of the polyolefin film is 38 μm;

[0029] The thickness of the acrylate pressure-sensitive adhesive layer is 25 μm, including 100 parts of CF-62E, 1 part of common cross-linking agent TDI-TMP and 3 parts of high-temperature deblocking cross-linking agent S-610.

[0030] The preparation method of the above-mentioned solar double-glass photovoltaic module lamination edge-sealing adhesive tape, the steps are as follows:

[0031] (1) The polyester film surface of the flexible substrate layer is subjected to corona treatment, and the corona value of the surface of the polyester layer after treatment ...

Embodiment 2

[0036] A solar double-glass photovoltaic module lamination edge-sealing adhesive tape, comprising a flexible substrate layer and an acrylate pressure-sensitive adhesive layer rolled inside the flexible substrate layer;

[0037] Wherein, the flexible substrate layer is a composite film of polyester film and polyolefin film, the thickness of the polyester film is 25 μm, and the thickness of the polyolefin film is 25 μm;

[0038] The thickness of the acrylate pressure-sensitive adhesive layer is 25 μm, including 100 parts of Y-1150W, 1 part of common cross-linking agent TDI-TMP and 3 parts of high-temperature deblocking cross-linking agent S-610.

[0039] The preparation method of the above-mentioned solar double-glass photovoltaic module lamination edge-sealing adhesive tape, the steps are as follows:

[0040] (1) The polyester film surface of the flexible substrate layer is subjected to corona treatment, and the corona value of the surface of the polyester layer after treatment...

Embodiment 3

[0045] A solar double-glass photovoltaic module lamination edge-sealing adhesive tape, comprising a flexible substrate layer and an acrylate pressure-sensitive adhesive layer rolled inside the flexible substrate layer;

[0046] Wherein, the flexible substrate layer is a composite film of polyester film and polyolefin film, the thickness of the polyester film is 12 μm, and the thickness of the polyolefin film is 38 μm;

[0047] The thickness of the acrylate pressure-sensitive adhesive layer is 25 μm, including 100 parts of Y-1150W, 3 parts of high-temperature deblocking crosslinking agent S-610 and 1 part of high-temperature deblocking crosslinking agent UN-7038.

[0048] The preparation method of the above-mentioned solar double-glass photovoltaic module lamination edge-sealing adhesive tape, the steps are as follows:

[0049] (1) The polyester film surface of the flexible substrate layer is subjected to corona treatment, and the corona value of the surface of the polyester la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com