High-dimensional-stability composite floor and making process thereof

A dimensionally stable, composite floor technology, used in building construction, synthetic resin layered products, paper/cardboard layered products, etc. Good physical and mechanical properties, good dimensional stability and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

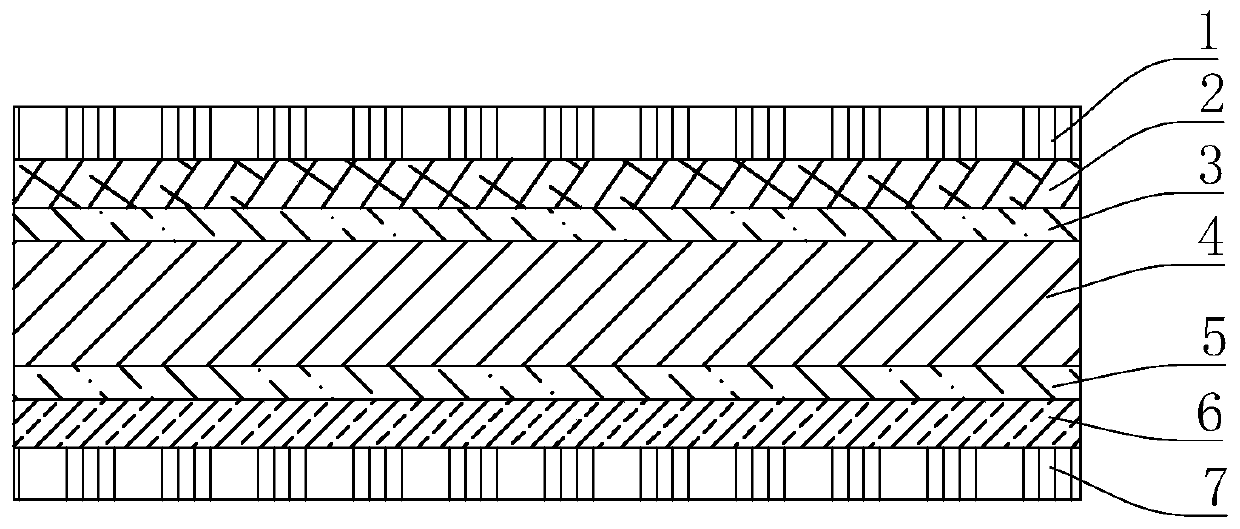

[0041] A high dimensional stability laminate flooring, referred to figure 1 , which includes a wear-resistant surface layer 1, a finish layer 2, a first glass fiber impregnated paper layer 3, a substrate layer 4, a second glass fiber impregnated paper layer 5, a balance layer 6 and a wear-resistant bottom layer 7 arranged in sequence. Among them, the wear-resistant surface layer 1 and the wear-resistant bottom layer 7 are all melamine wear-resistant paper layers; the finish layer 2 is a melamine pattern paper layer; the substrate layer 4 is an SPC substrate, and the surface of the SPC substrate layer is sanded Processing; the balance layer 6 is a balance paper layer. In addition, in the present embodiment, the first glass fiber impregnated paper layer 3 and the second glass fiber impregnated paper layer 5 are all selected with a grammage of 135g / m 2 Fiberglass impregnated paper impregnated with melamine glue.

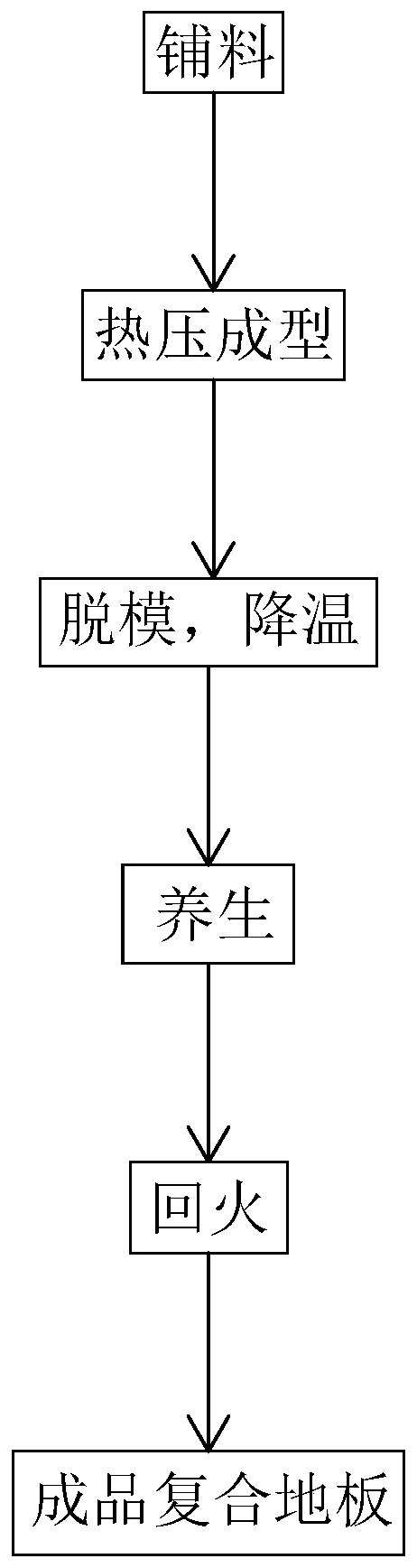

[0042] refer to figure 2 , its manufacturing process includes ...

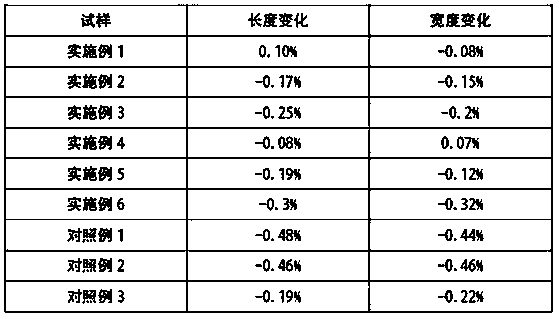

Embodiment 2

[0045] A composite floor with high dimensional stability, based on Example 1, the difference between this example and Example 1 is that the gram weights of the first glass fiber impregnated paper layer 3 and the second glass fiber impregnated paper layer 5 are average 80g / m 2 .

[0046] Example: 3:

[0047] A composite floor with high dimensional stability, based on Example 1, the difference between this example and Example 1 is that the gram weights of the first glass fiber impregnated paper layer 3 and the second glass fiber impregnated paper layer 5 are average 20g / m 2 .

Embodiment 4

[0049] A composite floor with high dimensional stability, based on Example 1, the difference between this example and Example 1 is that the gram weights of the first glass fiber impregnated paper layer 3 and the second glass fiber impregnated paper layer 5 are average 60g / m 2 , and the balance layer 6 is a base paper layer of melamine pattern paper.

[0050] Its manufacturing process is as follows:

[0051]Wear-resistant bottom layer 7, balance layer 6, second glass fiber impregnated paper layer 5, substrate layer 4, first glass fiber impregnated paper layer 3, facing layer 2 and wear-resistant surface layer in sequence from bottom to top 1 Mold laid on lamination equipment. Hot pressing is carried out at 140°C and 10MPa, and the hot pressing time is controlled at 50 minutes, so that the composite floor is shaped; after natural cooling, the composite floor is demoulded; after the composite floor is completely cooled and kept healthy for 24 hours, it is placed at 75°C. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com