MEMS package carrier plate stack-up structure and manufacturing method thereof

A technology for encapsulating carrier boards and manufacturing methods, which is applied in chemical/electrolytic methods to remove conductive materials, multilayer circuit manufacturing, and printed circuit manufacturing. There are many technical difficulties and other problems to achieve the effect of reducing product scrap rate, facilitating mass production, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

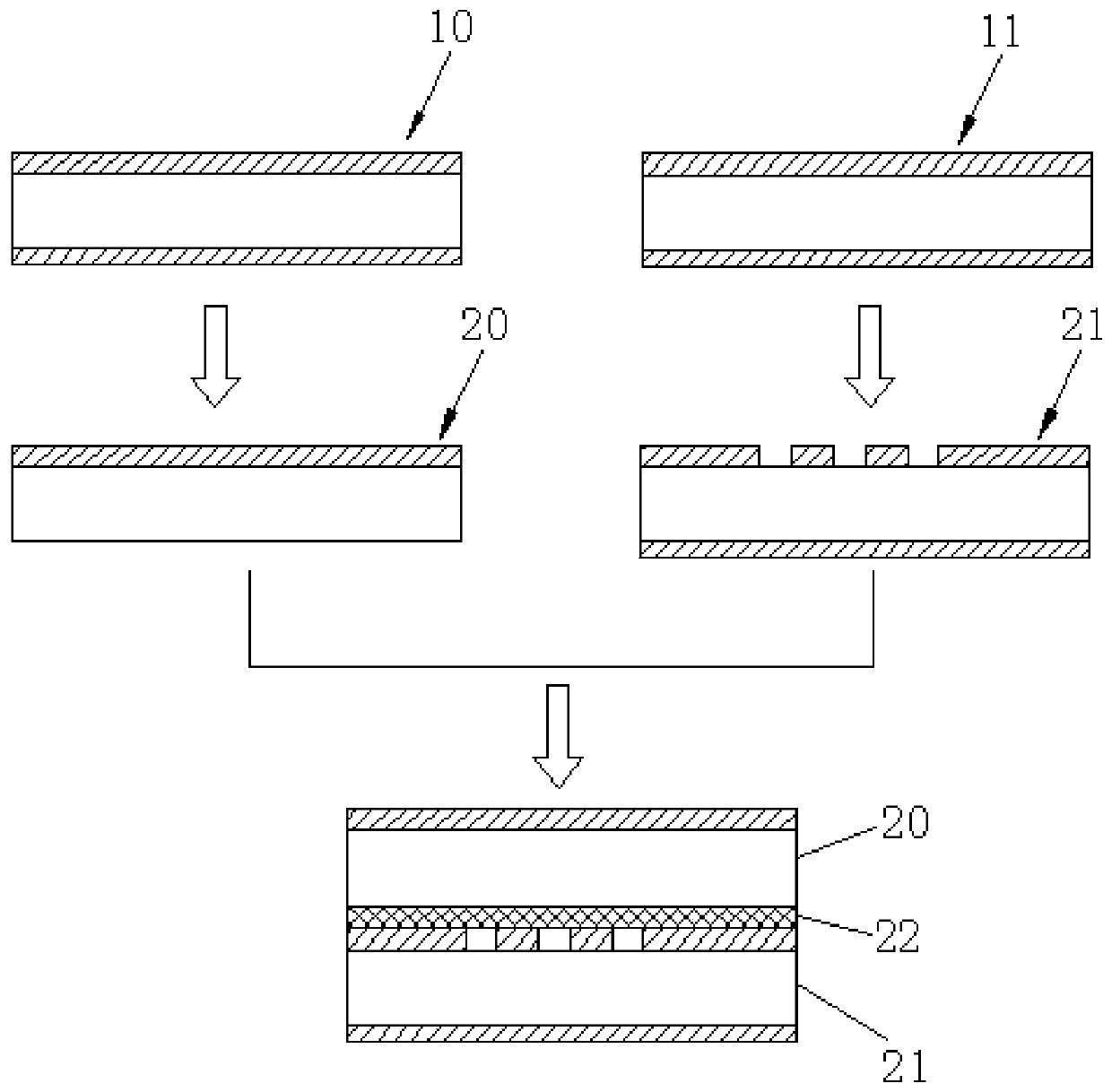

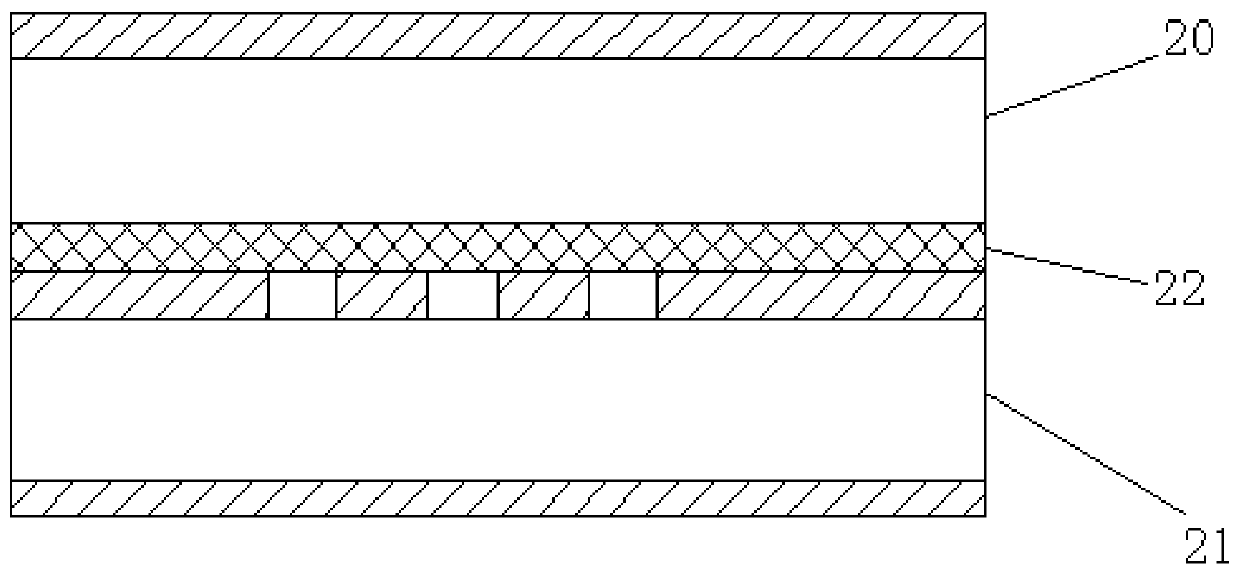

[0031] Please refer to the attached figure 1 And attached figure 2 As shown in FIG. 2 , they are the fabrication flow chart of the stacked structure of the MEMS package substrate and the schematic diagram of the enlarged structure, respectively, according to the present invention.

[0032] The invention provides a method for manufacturing a MEMS packaging carrier stack structure, comprising the following steps:

[0033] Step 1), prepare two double-sided copper-clad substrates I, and define them as copper-clad substrate A10 and copper-clad substrate B11 respectively;

[0034] Step 2), processing the copper-clad substrate A10 to obtain a single-sided copper-clad substrate 20, and the specific processing method is: 2a), performing surface treatment on the copper-clad substrate A10, that is, the copper-clad substrate A Oxidation and dirt removal on the surface of the two-layer copper foil to enhance the adhesion between the dry film and the copper foil; 2b), laminating a layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com