Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Reduce product scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

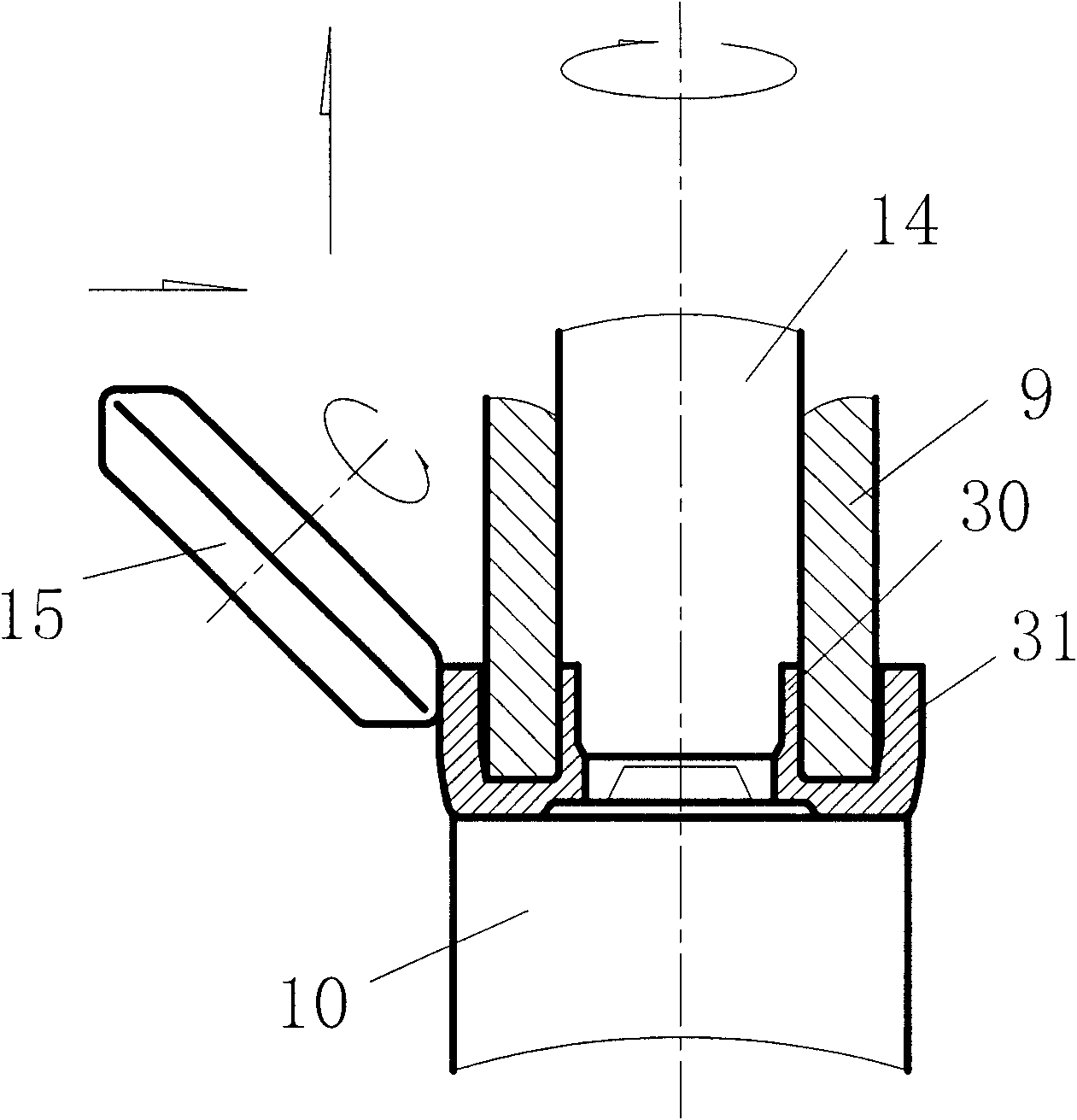

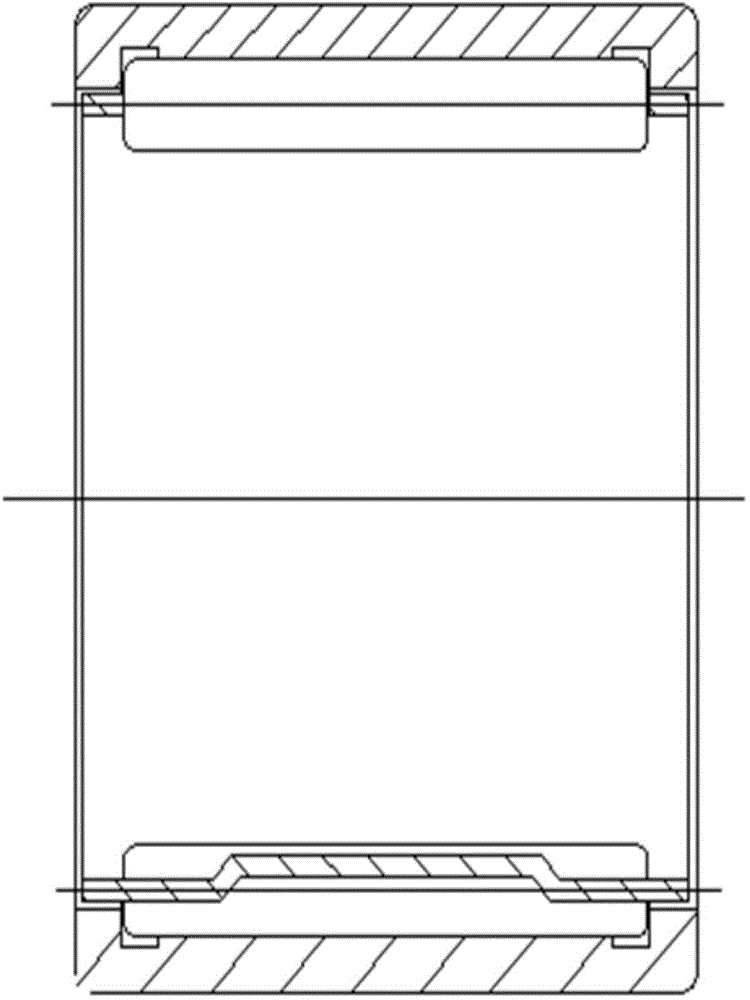

Cylinder type lithium ion battery cell and making method thereof

InactiveCN101640284AReduce leak rateReduce product scrap rateFinal product manufactureSecondary cellsWork in processLithium-ion battery

The invention discloses a cylinder type lithium ion battery cell and making method thereof; wherein the making method of the cylinder type lithium ion battery cell includes the following steps: (1) making an aluminium lug and a nickel lug; (2) making a positive plate and a negative plate by respectively welding the aluminium lug and the nickel lug with a positive substrate and a negative substratefirmly; (3) obtaining an aluminium plastic composite membrane with dual circular arc structure by adopting a mould with circular structure to punch the aluminium plastic composite membrane; (4) winding the positive plate, the negative plate and a diaphragm in to a winding core; (5) placing the winding core into the aluminium plastic membrane for sealing the two end faces, so as to obtain sealed semi-finished product cell; (6) baking the semi-finished product cell and then injecting electrolyte containing Li<+>, and carrying out precharge after the semi-finished product cell is laid for a period of time; (7) vacuumizing and sealing the side of the cell after precharge, and then cutting excessive aluminium plastic composite membrane, so as to the obtain finished product cell.

Owner:珠海汉格能源科技有限公司

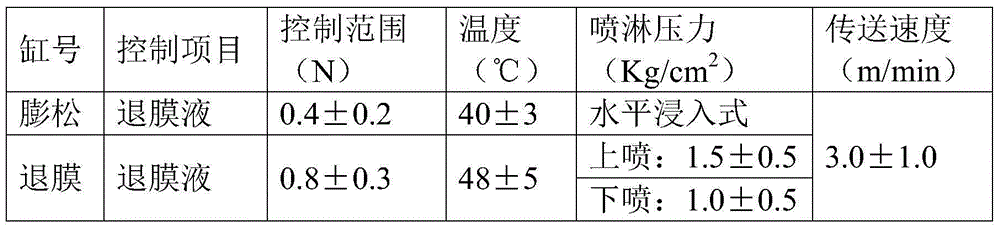

Process for protecting goldfinger and bonding pad in rigid-flex printed circuit board

InactiveCN105246263AReduce production scrap rateImprove qualityConductive pattern reinforcementNon-metallic protective coating applicationSurface finishingPrinted circuit board

The invention discloses a process for protecting a goldfinger and a bonding pad in a rigid-flex printed circuit board. The process comprises the following steps of S1, respectively carrying out board cutting; S2, carrying out a front procedure; S3, coating the surface of a flexible board with a cover film and carrying out first rapid lamination; S4, coating the goldfinger and the bonding pad of the flexible board with a high-temperature resistant adhesive tape, and carrying out second rapid lamination; S5, carrying out brownification on a copper surface of the flexible board, carrying out lamination on the flexible board, a prepreg and a rigid board, and milling an appearance; S6, removing the high-temperature resistant adhesive tape, and carrying out nickel and gold deposition treatment on a goldfinger region and a bonding pad region which are exposed; and S7, carrying out a post procedure. By coating the high-temperature resistant adhesive tape, the problem that glue residue is remained on the prepreg on the goldfinger region and the bonding region, or the goldfinger and the bonding pad are polluted by other impurities during the lamination process and are difficult to clean is solved, normal surface treatment can be carried out on the goldfinger and the bonding pad after the high-temperature resistant adhesive tape is removed, no glue residue is remained, the production rejection rate is reduced, the product quality is improved, and the production cost is saved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

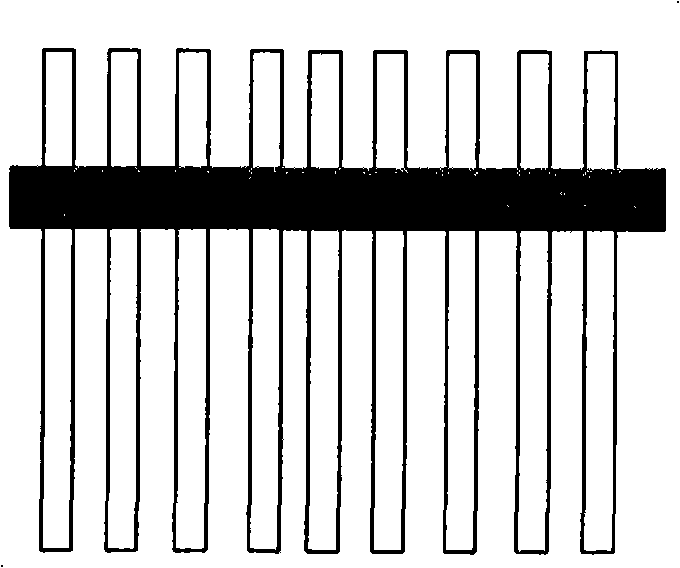

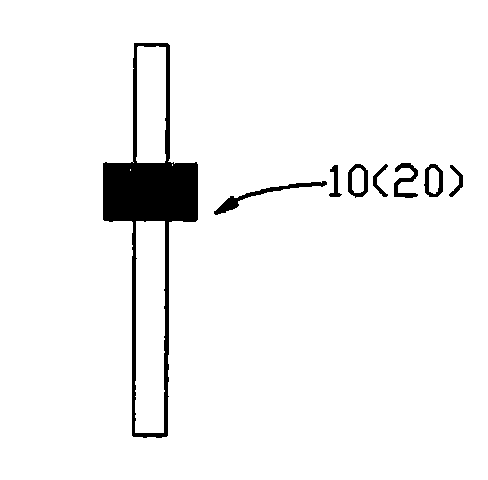

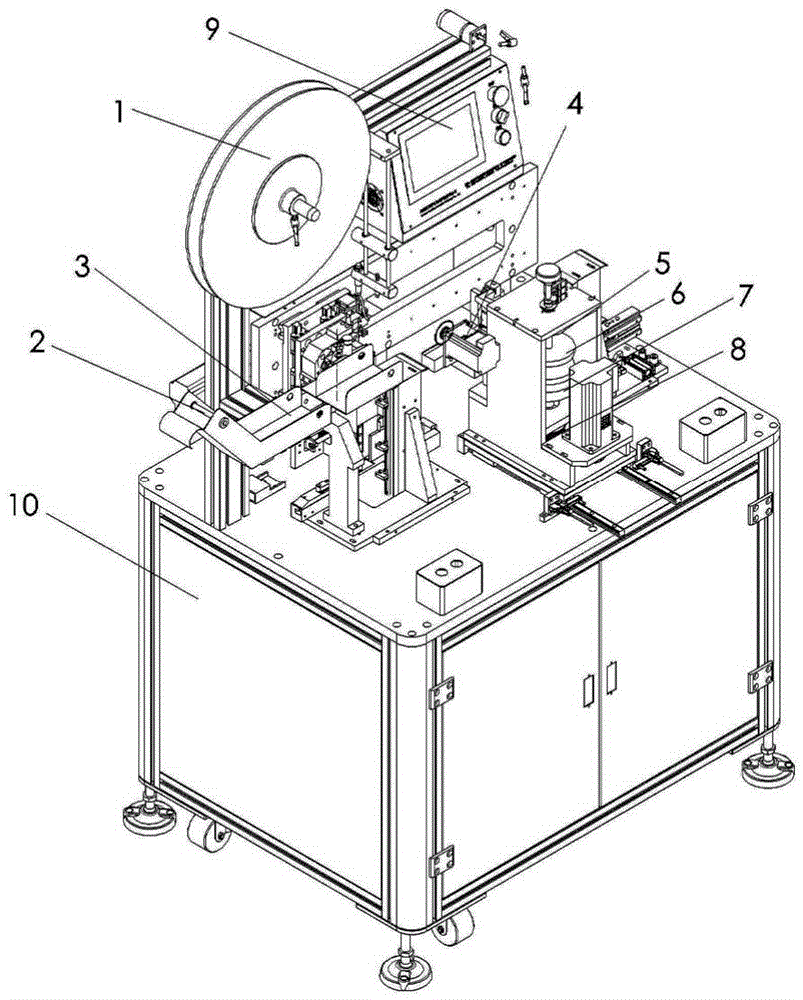

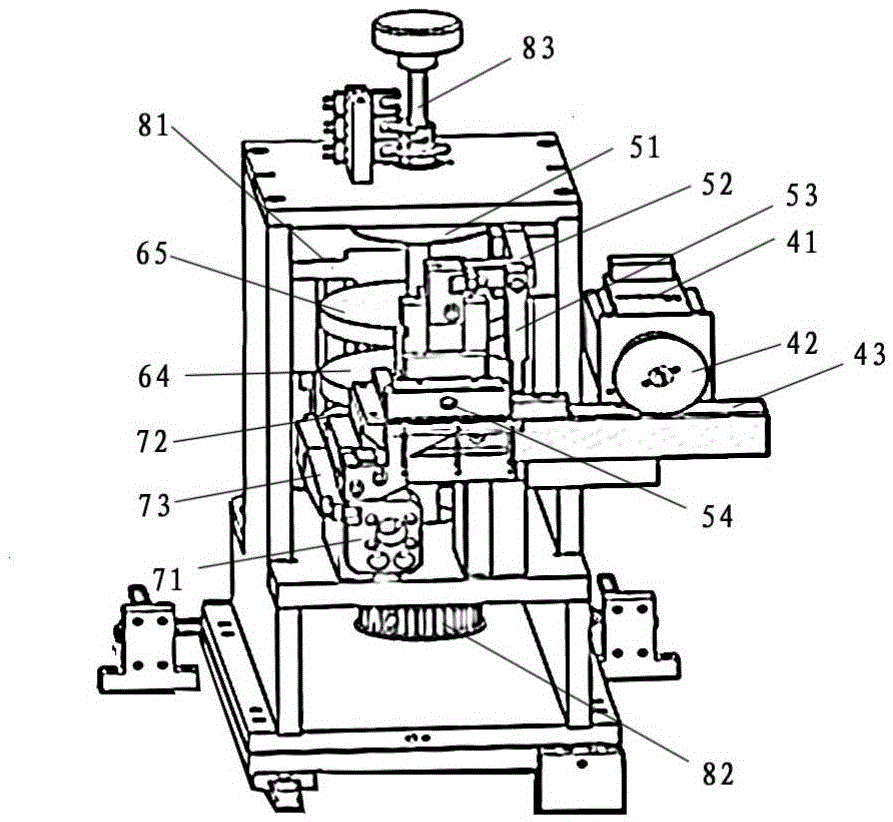

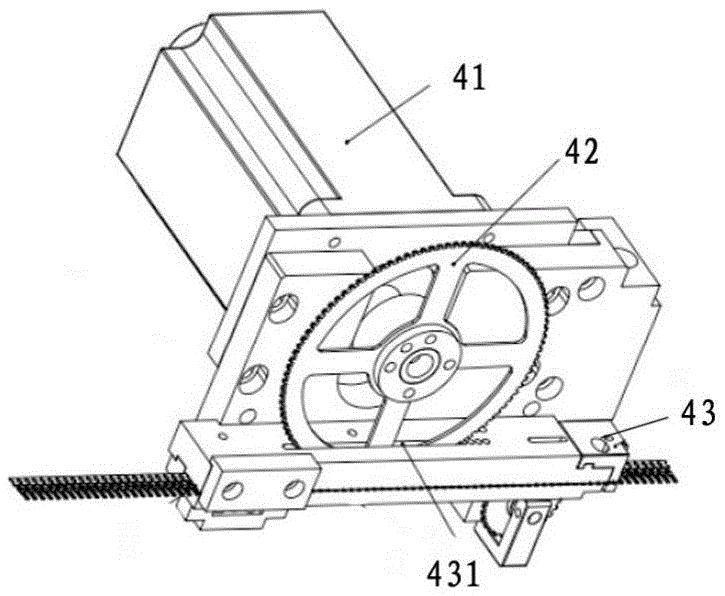

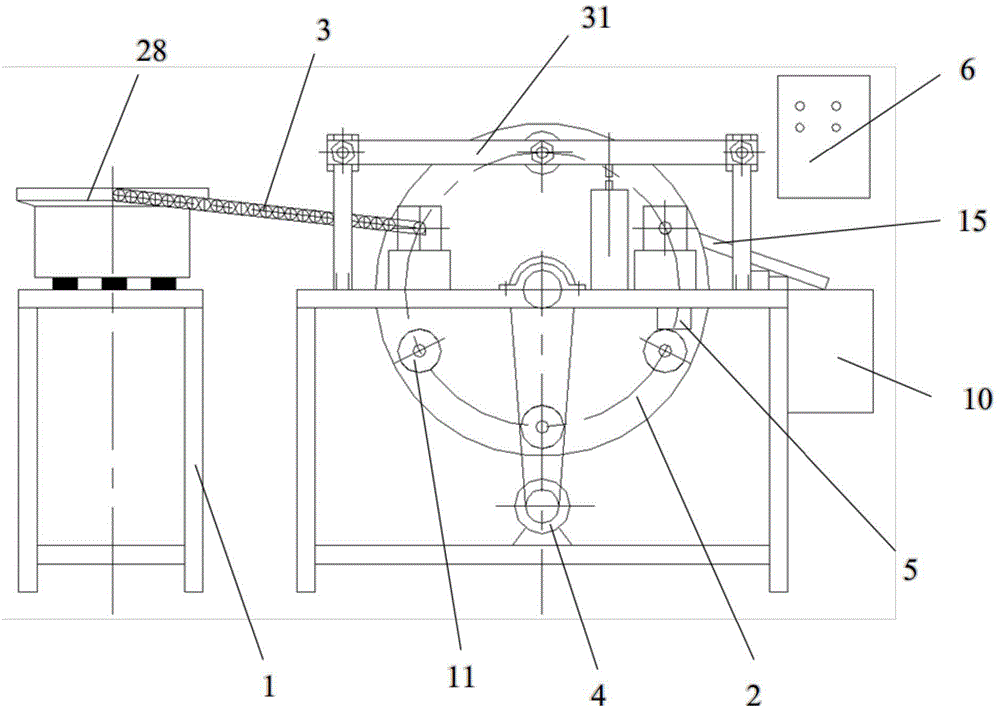

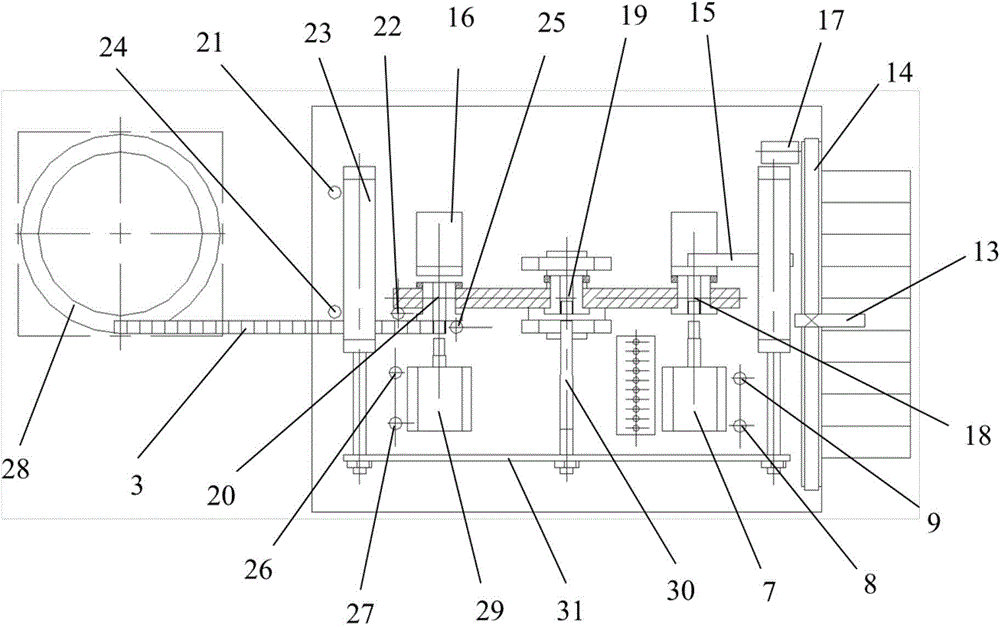

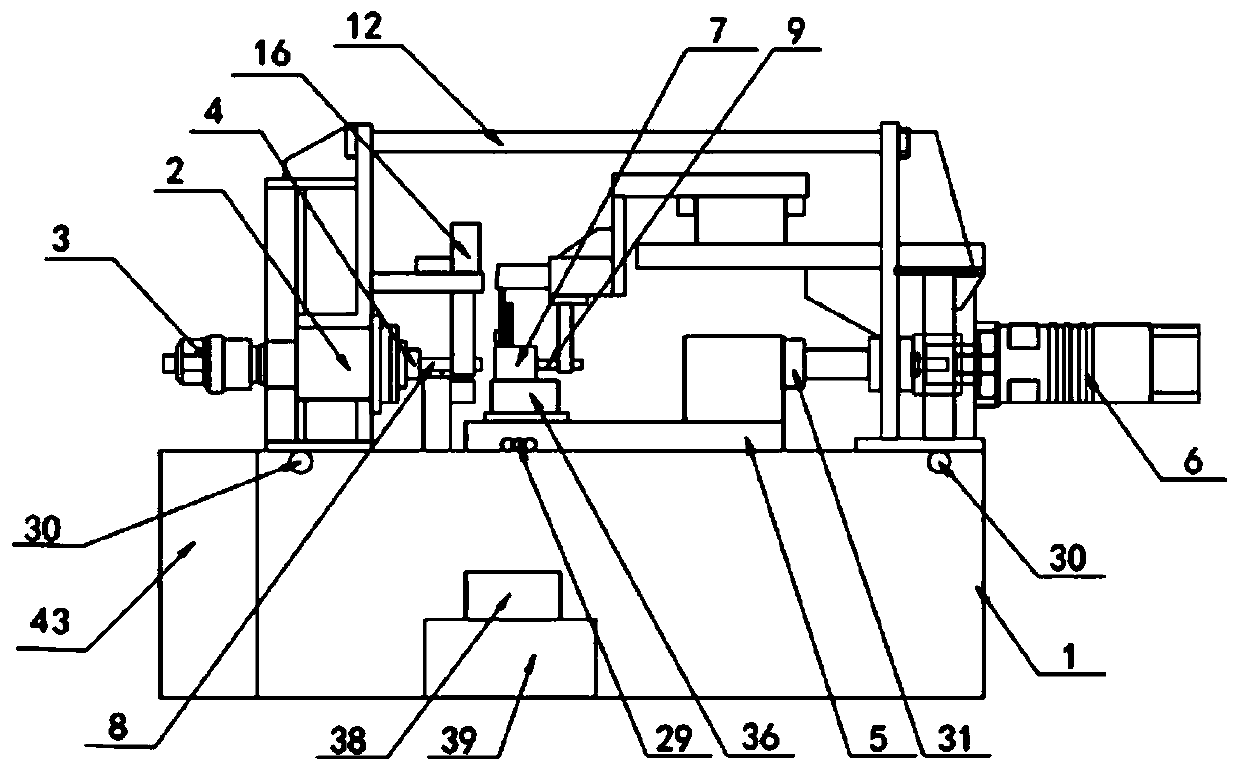

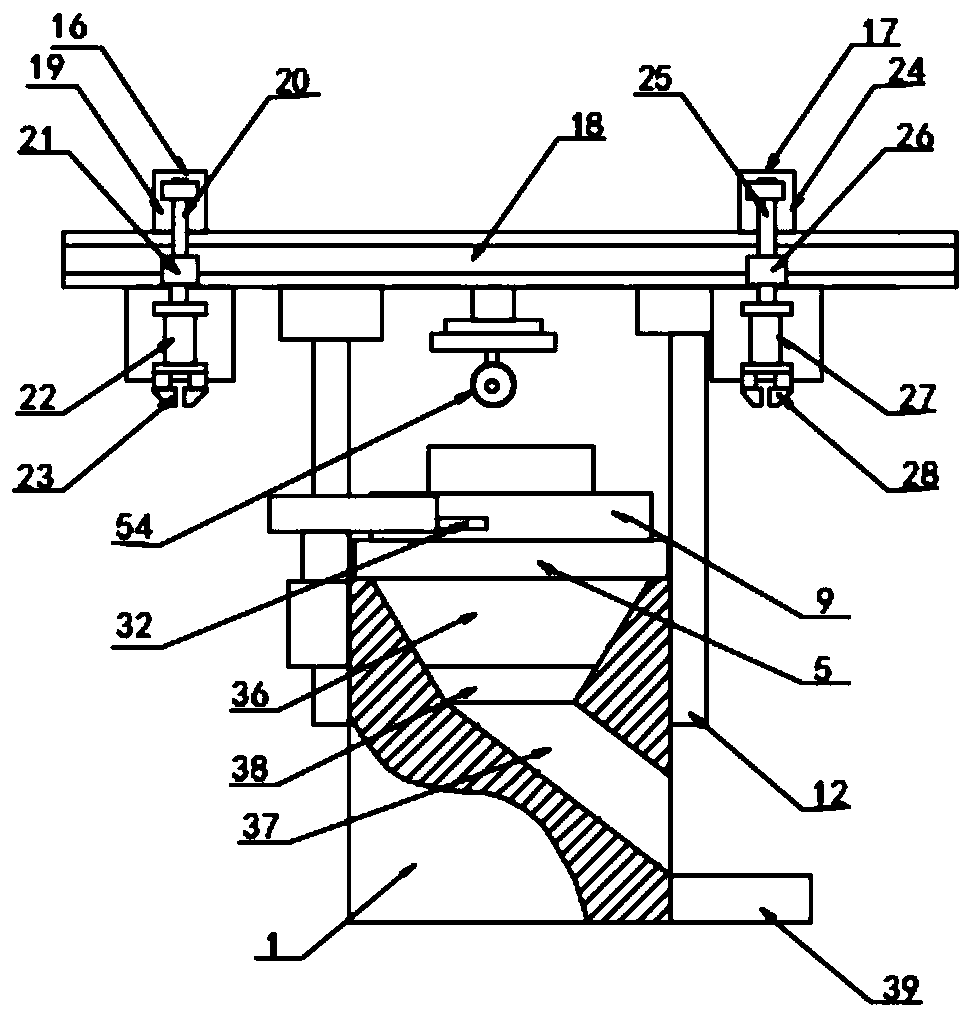

FPC cam pin inserting machine

InactiveCN105633765AImprove yield rateIncrease capacityContact member assembly/disassemblyDrive shaftEngineering

The invention relates to the field of product pin assembly for the electronic connector industry, in particular to an FPC cam pin inserting machine. The FPC cam pin inserting machine comprises a rack, a discharge plate, a feed roller, a transport track, a feeding mechanism, a pin pressing mechanism, a pin inserting mechanism, a cutting and bending mechanism, a transmission device and a control assembly, wherein the discharge plate is arranged at one side of the rack and is used for placing a to-be-inserted part of an FPC; the feed roller is arranged below the discharge plate; the transport track is arranged on the rack and is connected with the discharge plate; the feeding mechanism is arranged at one side of the transport track; the pin pressing mechanism is arranged at one side of the feeding mechanism for pressing and fixing the to-be-inserted part of the FPC; the pin inserting mechanism is arranged below the pin pressing mechanism and can take out the pin and insert the pin into the to-be-inserted part of the FPC; the control assembly controls various mechanisms to act; the transmission device comprises a drive servo motor, a cam transmission synchronizing wheel and a transmission shaft; the drive servo motor is connected with the cam transmission synchronizing wheel; the cam transmission synchronizing wheel is fixedly connected to the bottom end of the transmission shaft; the pin pressing mechanism, the pin inserting mechanism, the cutting and bending mechanism are sequentially fixed on the transmission shaft from top to bottom; and the control assembly is connected with the discharge plate, the transmission device and the feeding mechanism respectively.

Owner:DONGGUAN LITY CHUANGXI AUTOMATION TECH CO LTD

Processing technology of spinning belt pulley with inner and outer lug bosses

The invention relates to a processing technology of a spinning belt pulley with inner and outer lug bosses, which belongs to the field of manufacturing belt pulleys. The processing technology comprises the following steps of: stamping and performing a blank, reprocessing the performed blank and spinning the reprocessed and performed blank, wherein the reprocessing step of the performed blank comprises the following steps of: cold extruding a formed blank A into a performed blank B with a predetermined size; and rolling and forming the performed blank B by a spinning mode to form the performed blank C with inner and outer lug bosses. Compared with the traditional processing technology, the processing technology of the spinning belt pulley with the inner and outer lug bosses has wide source of raw materials, low cost, high production efficiency and low rejection rate, the spinning mode is used for replacing a stamping mode to produce the blank with the inner and outer lug bosses, products are not easy to deform, the dimensions of the product can achieve higher required precision, and an adopted spinning machine has small erosion, low power consumption and convenient maintenance.

Owner:广东港润机电科技有限公司 +1

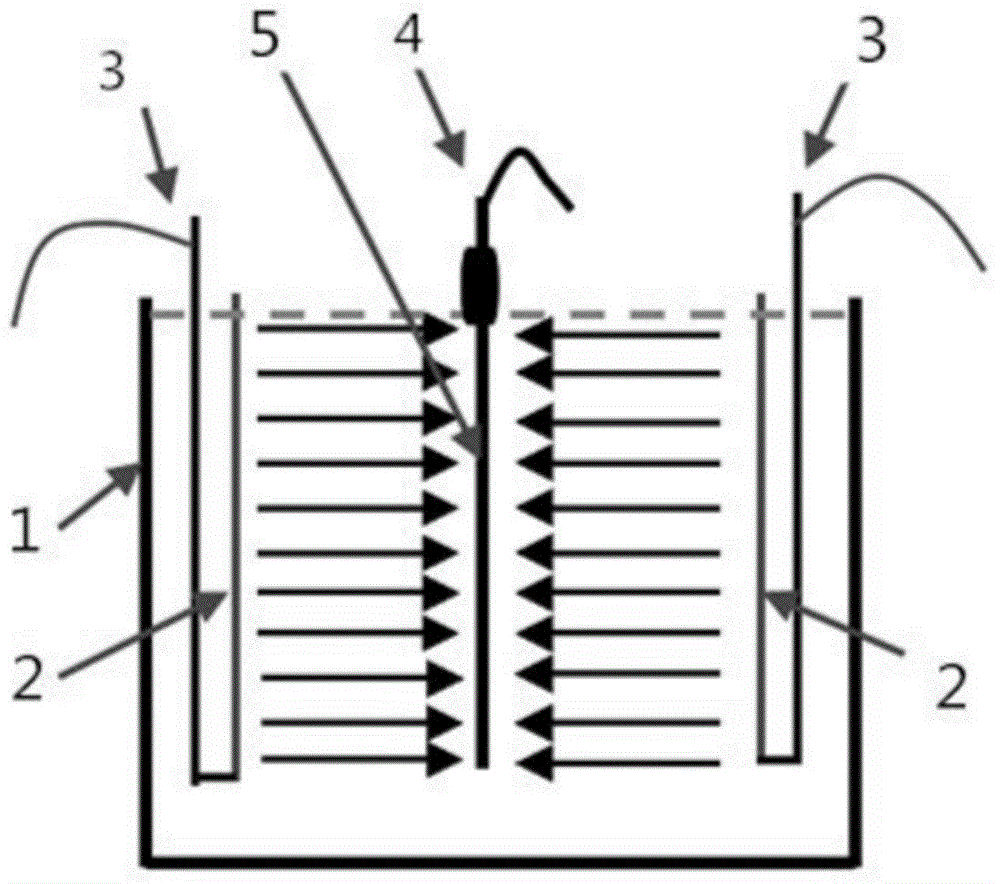

Method for improving electroplating layer uniformity of PCB (printed circuit board) vertical electroplating line

InactiveCN104878424AEliminate vertical length differencesUniform current distributionElectrodesEtchingEngineering

The invention belongs to the field of circuit board processing, and relates to a method for improving the electroplating uniformity of a PCB (printed circuit board). By adopting the method disclosed by the invention, an anode is converted into an up-and-down sliding mode from a position fixing mode so as to ensure that the vertical length difference between a cathode and the anode can be eliminated, and uniform current distribution in an electroplating process can be ensured; a conventional wire connection mode of the anode can be changed so as to ensure that the electrical potential size difference of the current distribution of the anode can be changed and can be complementary with the electrical potential size difference of the current distribution of the cathode; the uniformity of an electroplating copper layer can be improved, and the copper consumption per unit area can be reduced; in a copper electroplating process, integral resistance in an electroplating cylinder is relatively balanced, so that power lines distributed in the electroplating cylinder are uniform, and thus the electrical potential size difference of upper and lower current distribution in the electroplating cylinder can be effectively eliminated; and by adopting the electroplating copper layer with good uniformity, difficulties of circuit etching can be reduced, the purposes of reducing the production scrap rate and improving the quality of the PCB can be achieved, and great market economic values and application prospects can be achieved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

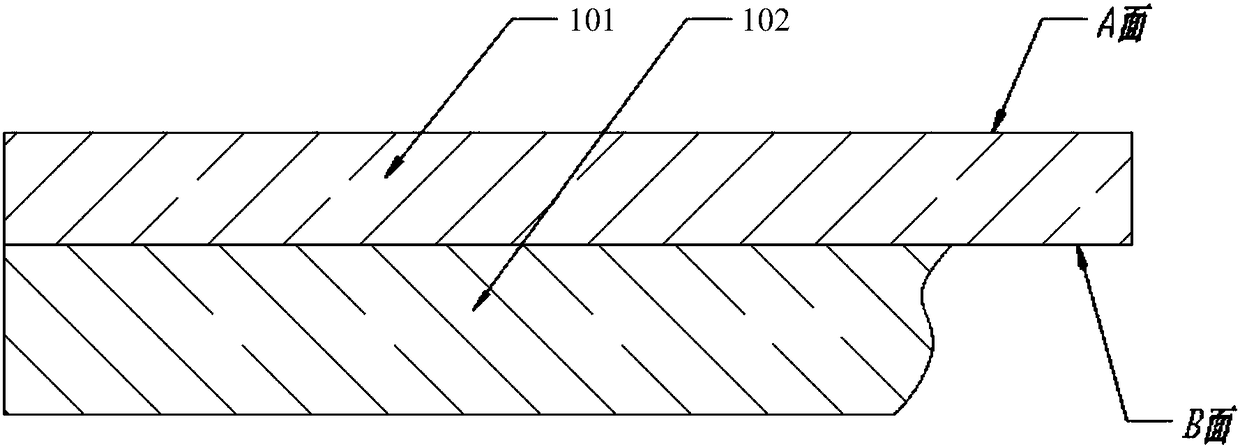

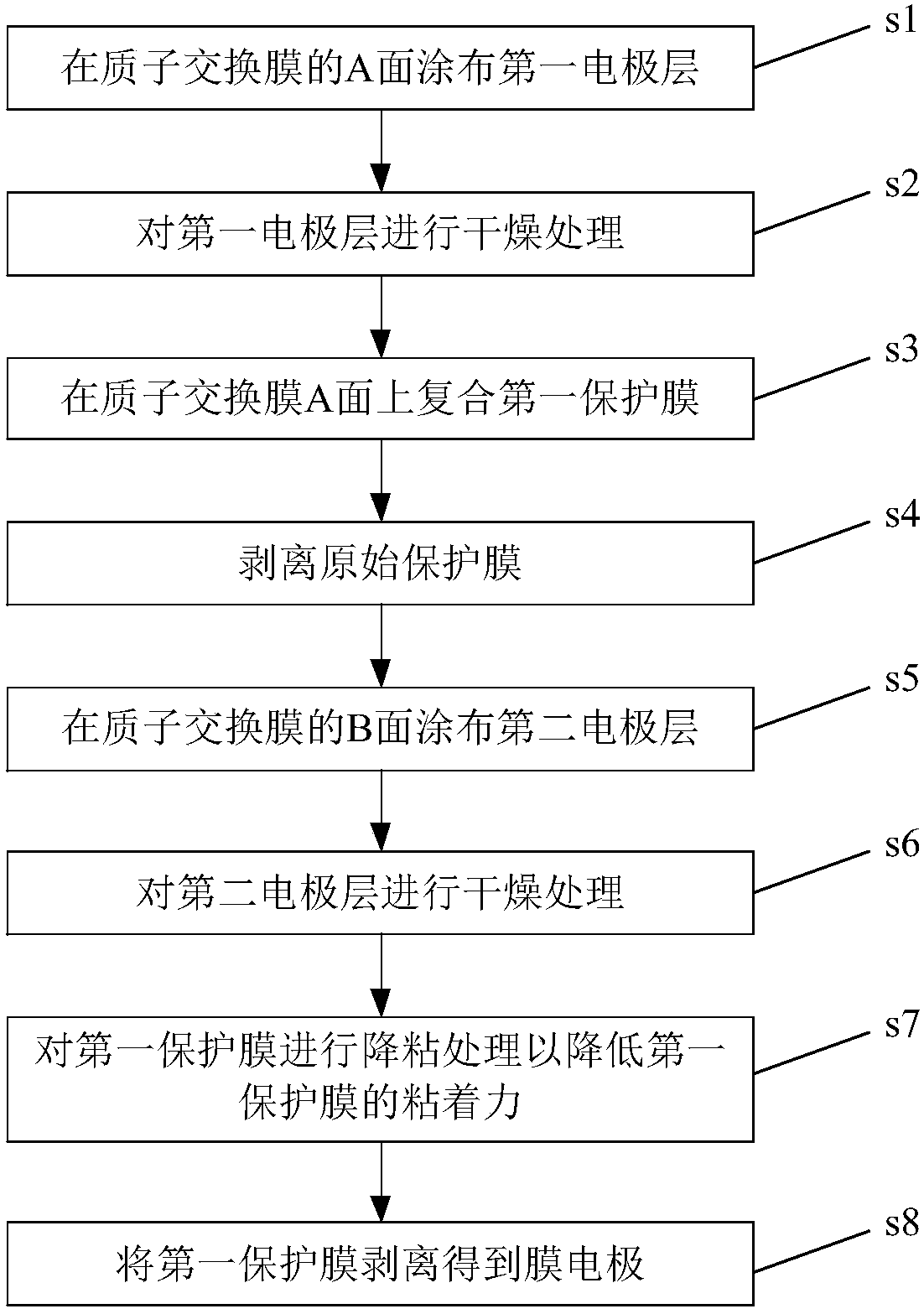

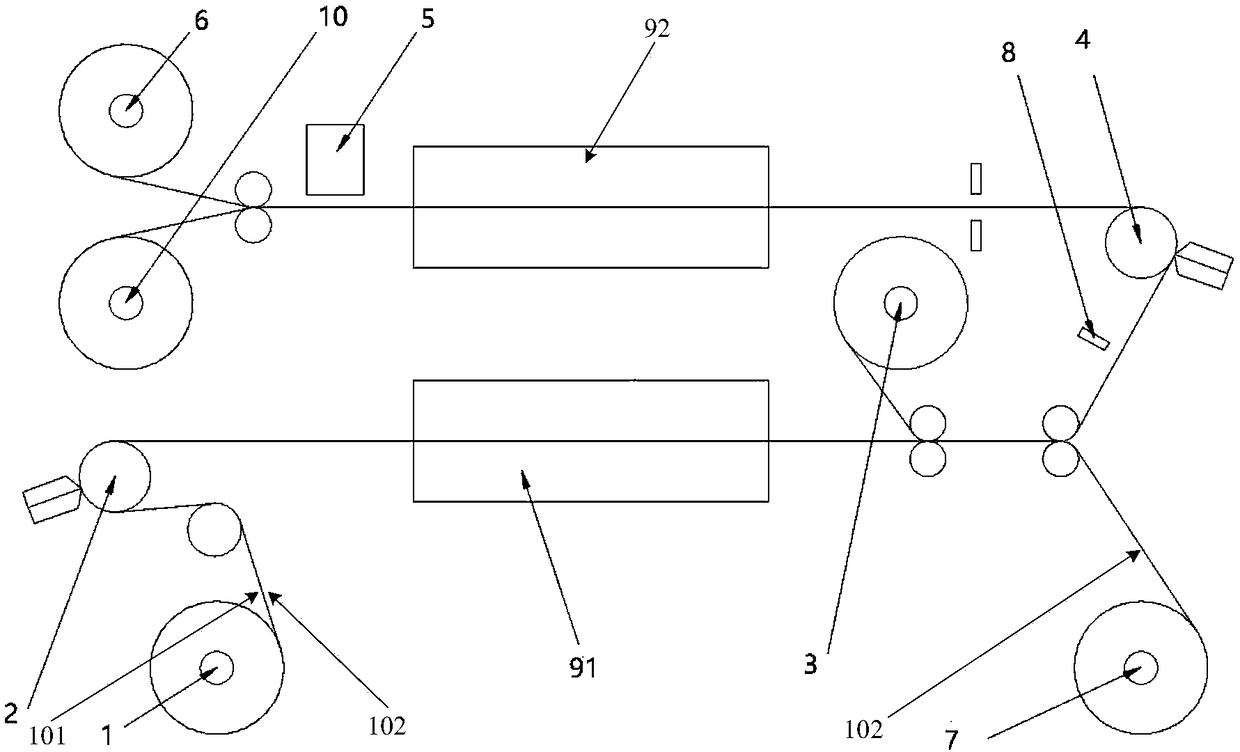

Method and device for manufacturing fuel cell membrane electrode

PendingCN108448139AIncrease productivityReduce production scrap rateCell electrodesFinal product manufactureScrapChemistry

The invention belongs to the technical field of fuel cells, and discloses a method for manufacturing a fuel cell membrane electrode. The method comprises the following steps: coating the A side of a proton exchange membrane with a first electrode layer, compounding A side of a proton exchange membrane with a first protection membrane, coating the B side of the proton exchange membrane with a second electrode layer, performing viscosity reduction treatment on the first protection membrane, and stripping the first protection membrane to obtain the membrane electrode, wherein the first electrodelayer applied to the A side is protected with the first protection membrane to avoid damages of coating of the second electrode layer to the first electrode layer, the size of the first electrode layer is detected during the coating of the second electrode layer, and the second electrode layer is applied according to the size of the first electrode layer to make the first electrode layer and the second electrode layer aligned in size in order to reduce the production scrap rate. The invention also discloses a manufacturing device. T whole process is completed by using the automatic device without using transferring printing, so the production efficiency is improved.

Owner:SHENZHEN SHINING AUTOMATION CO LTD

Self-repairing aluminum oxide-based ceramic composite material and preparation thereof

The invention relates to a self-healing alumina-based ceramic composite material and a preparation method thereof. The material is characterized in that the compositions thereof comprise 5-20 percent of carborundum or titanium carbide, 1.0-2.0 percent of zirconia, 1.0-2.0 percent of magnesia, 2.0-5.0 percent of aluminum powder, 0.5-3 percent of methylcellulose and rest of powdered alumina by weight percent; the self-healing treatment conditions of the crackles are heat insulation for 1-3h at 800-1200 DEG C. The self-healing alumina-based ceramic composite material of the invention can effectively overcome the inherent brittleness of the ceramic material; the addition of silicon carbide whiskers not only plays the role of strengthening the ceramic material, but more importantly, the silicon carbide fills the crackles through a series of reactions in the self-healing process of the ceramic crackles. The self-healing alumina-based ceramic composite material has the advantages of improving the quality of ceramic products, reducing the reject rate of the products and playing a significant role in reducing cost and enhancing the efficiency for the enterprise.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

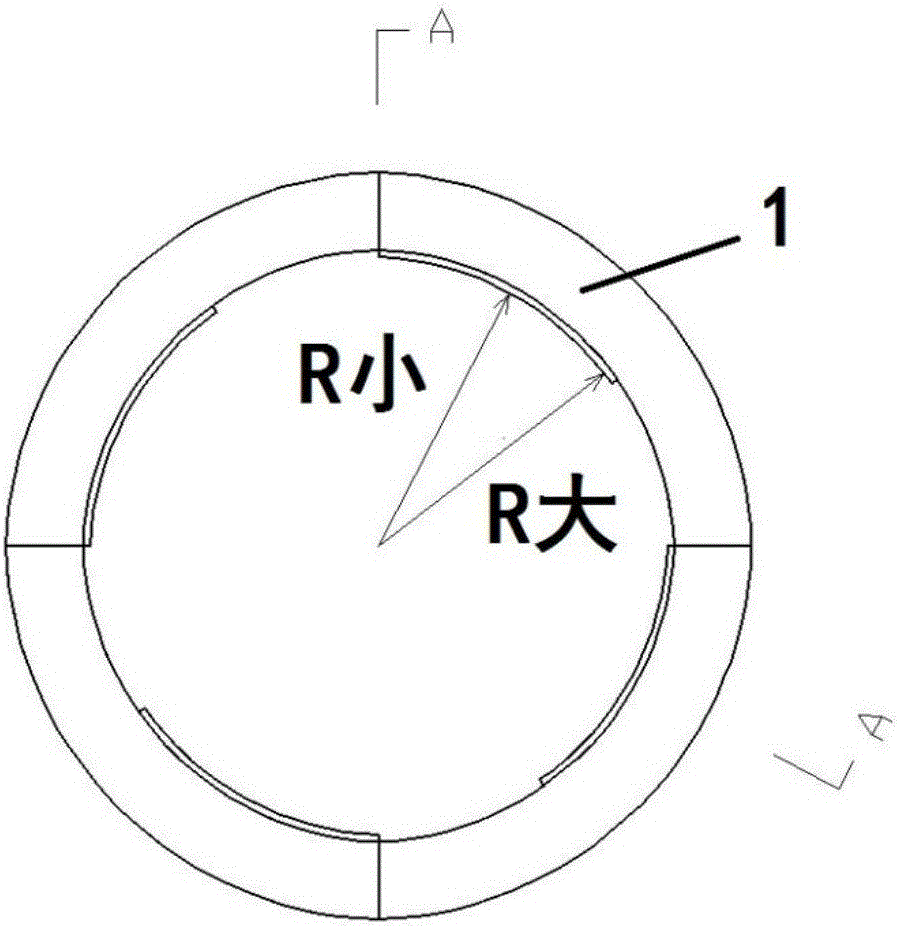

Female die for stamping of automobile parts and machining method thereof

InactiveCN103521621AAccurate dimensional accuracyReduce product scrap rateShaping toolsEngineeringDimensional precision

The invention discloses a female die for stamping of automobile parts. The female die comprises a female die body. The female die body comprises a female die first part, a female die second part and a female die third part, wherein the female die first part, the female die second part and the female die third part are coaxially arranged in sequence from left to right. The outer diameter of the female die first part is larger than that of the female die second part, and the outer diameter of the female die second part is larger than that of the female die third part. A first middle hole is formed in the center of the female die first part, and the depth of the first middle hole is larger than the axial thickness of the female die first part. A second middle hole which is coaxial with the first middle hole and communicated with the first middle hole is formed in the center of the female die third part, and the diameter of the first middle hole is larger that that of the second middle hole. The female die has high dimensional precision, and can be used repeatedly and guarantee manufacturing precision and assembly precision of the automobile parts which are manufactured through the female die. The invention further discloses a machining method of the female die. By means of the machining method, the dimensional precision of the female die in a stamping die is high, the female die can be qualified at a time through the production process, and the product rejection rate is low.

Owner:昆山精创模具有限公司

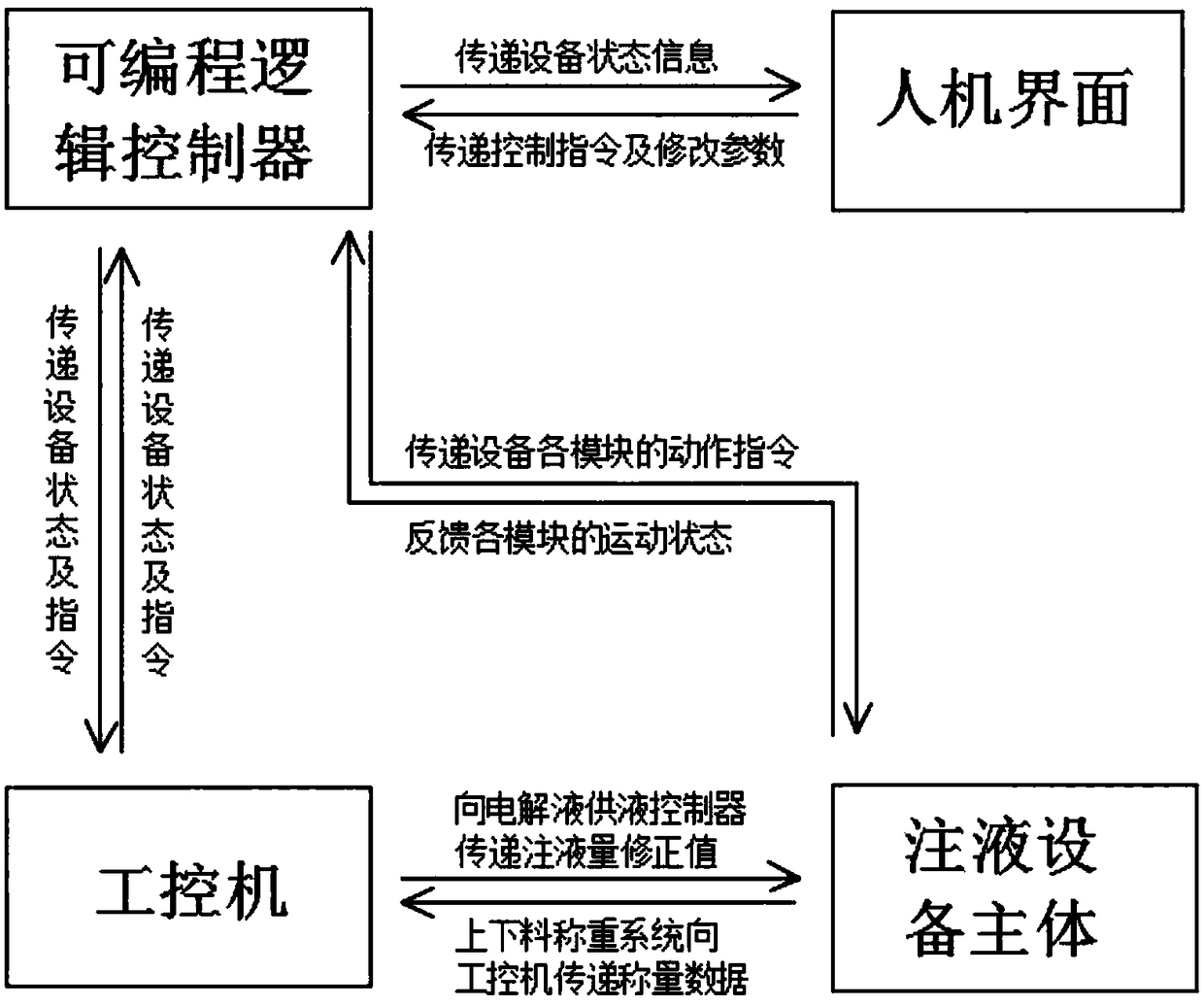

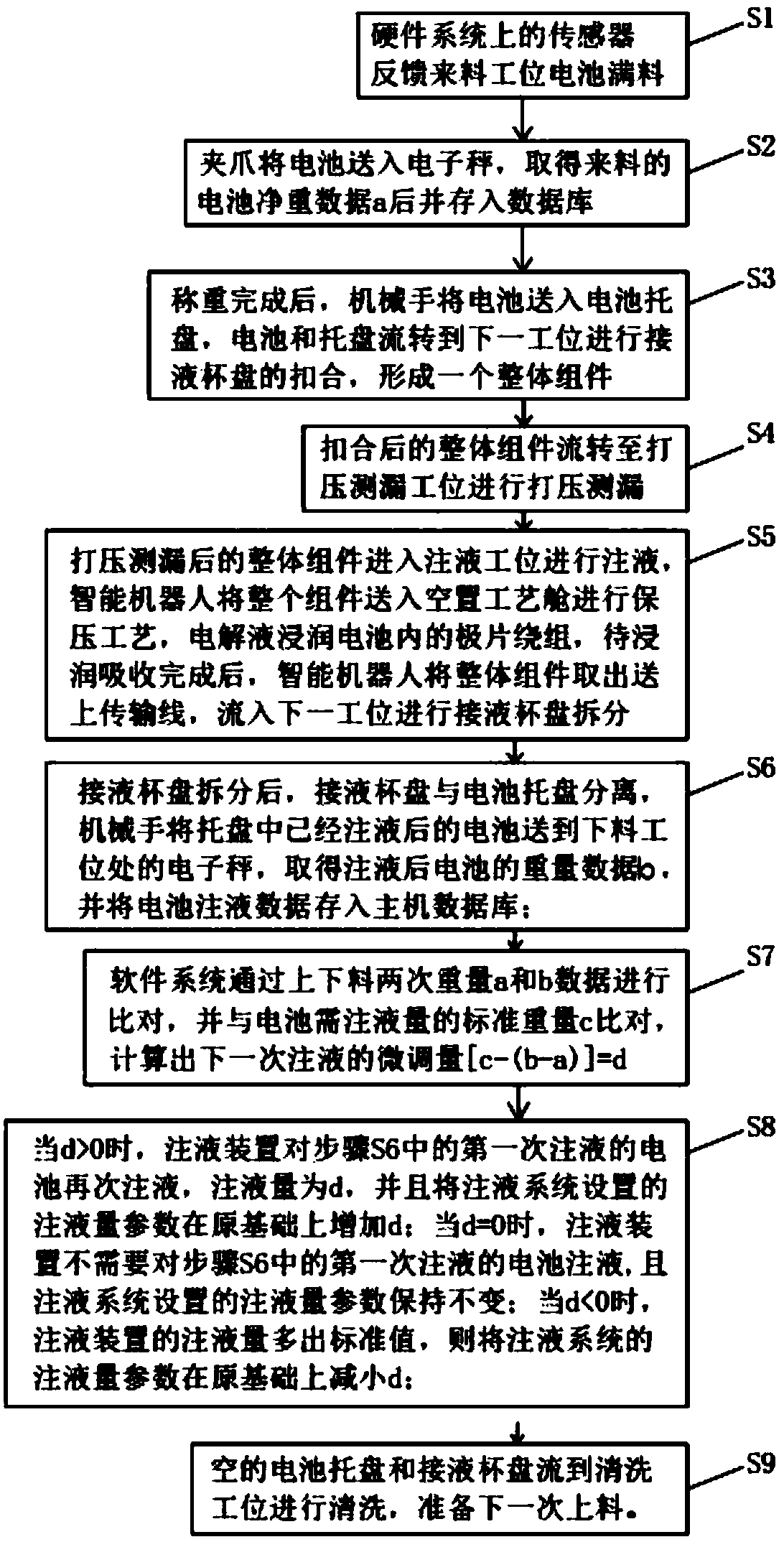

Liquid injection implementing method of full-automatic lithium battery liquid injection machine

ActiveCN108321350APrecision injectionRehydration is convenientFinal product manufactureCell component detailsSoftware systemControl system

The invention discloses a liquid injection implementing method of a full-automatic lithium battery liquid injection machine. The method comprises a software system and a hardware system. By mutual cooperation of the software system and the hardware system, liquid is accurately injected into a lithium battery. The full-automatic lithium battery liquid injection machine organically combines the functions by using the software system and the hardware system to form a complete and interoperable intelligent system. The system not only has the functions, but also has functions of automatic analysis,automatic fine adjustment of a liquid injection amount and the like, and can automatically count liquid injection amount data, automatically compare the liquid injection amount data with a standard liquid injection amount and automatically calculate a liquid injection fine adjustment amount, so that the next liquid injection is more precise, and a real intelligent closed-loop control system is formed.

Owner:深圳市东汇精密机电有限公司

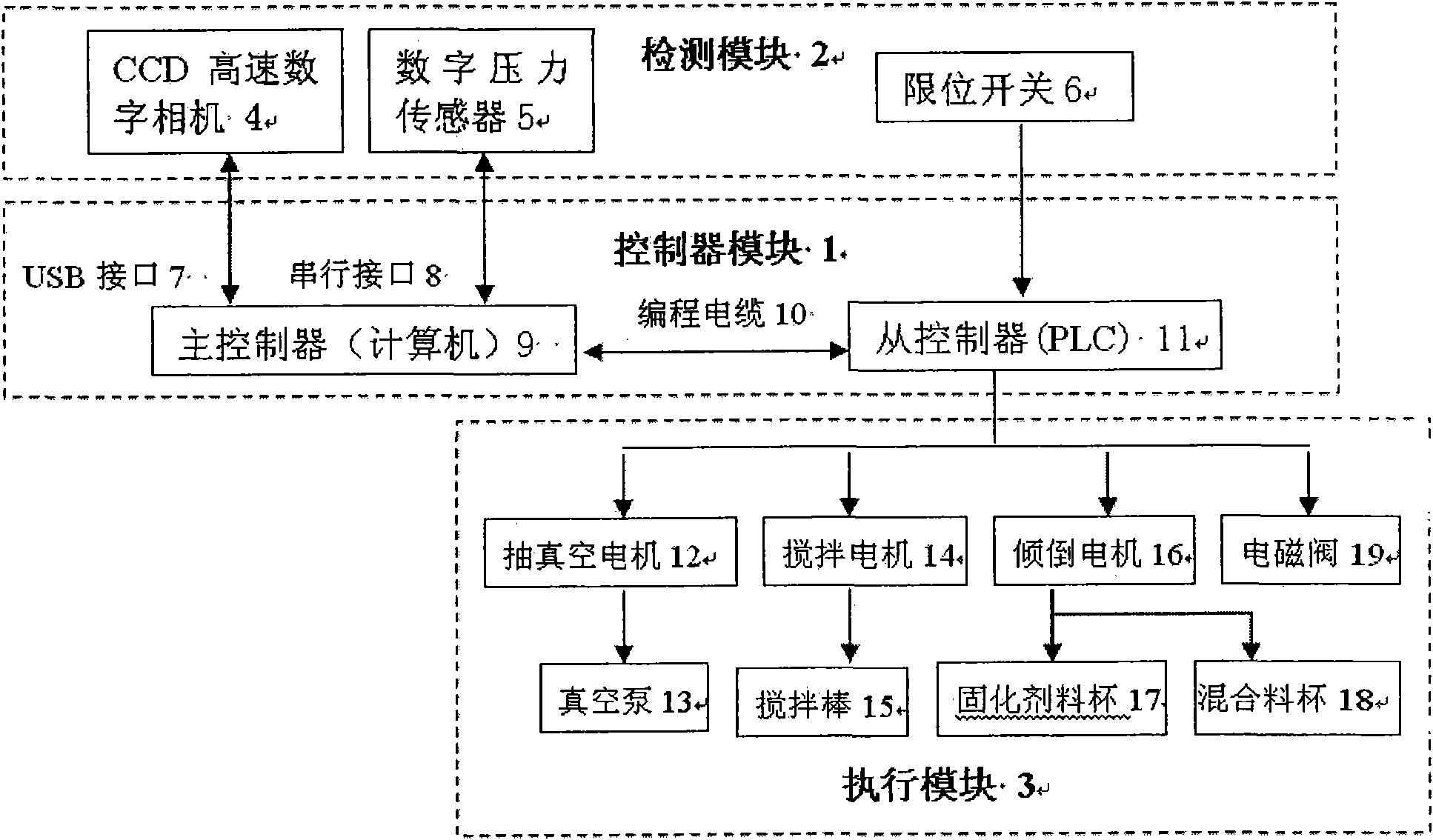

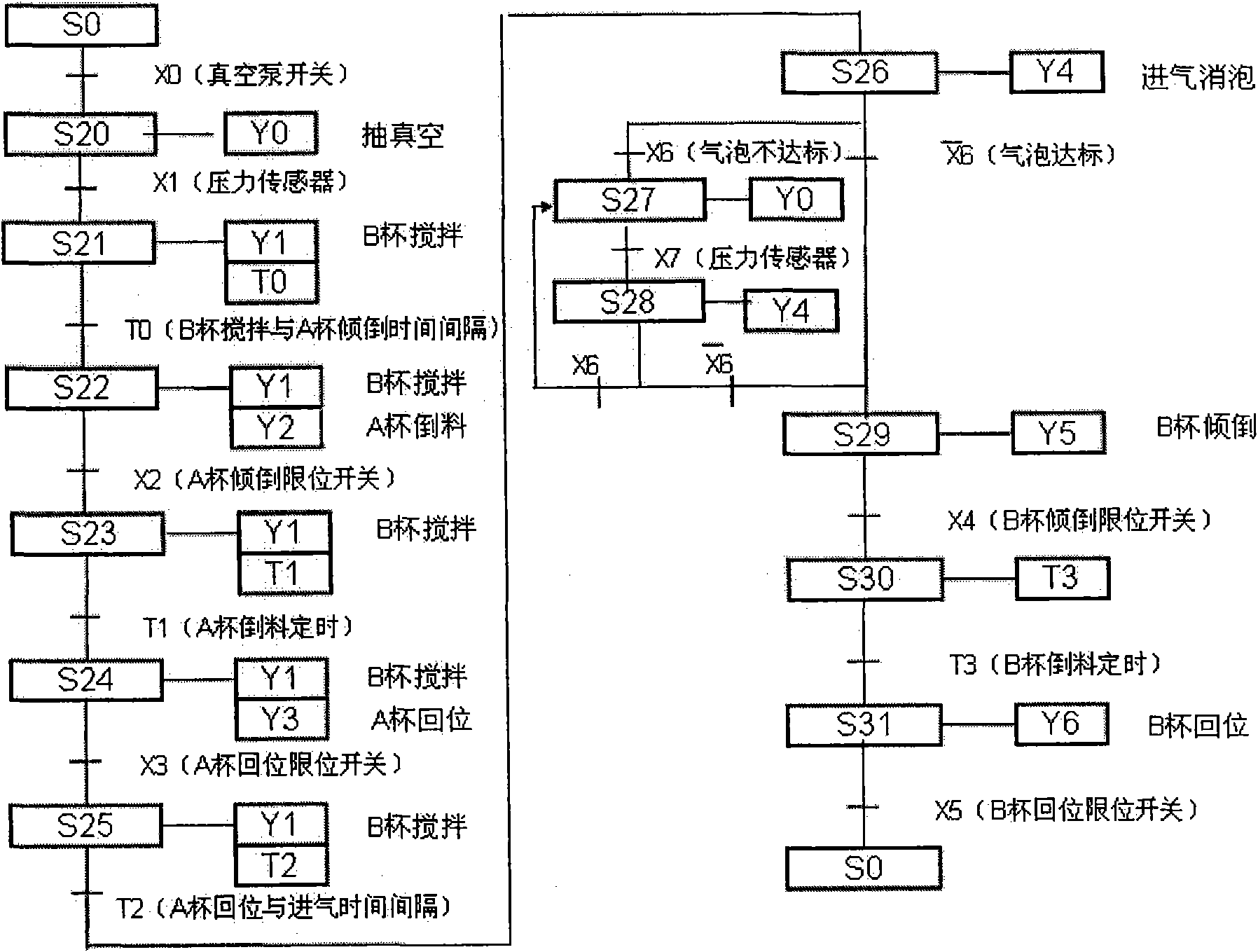

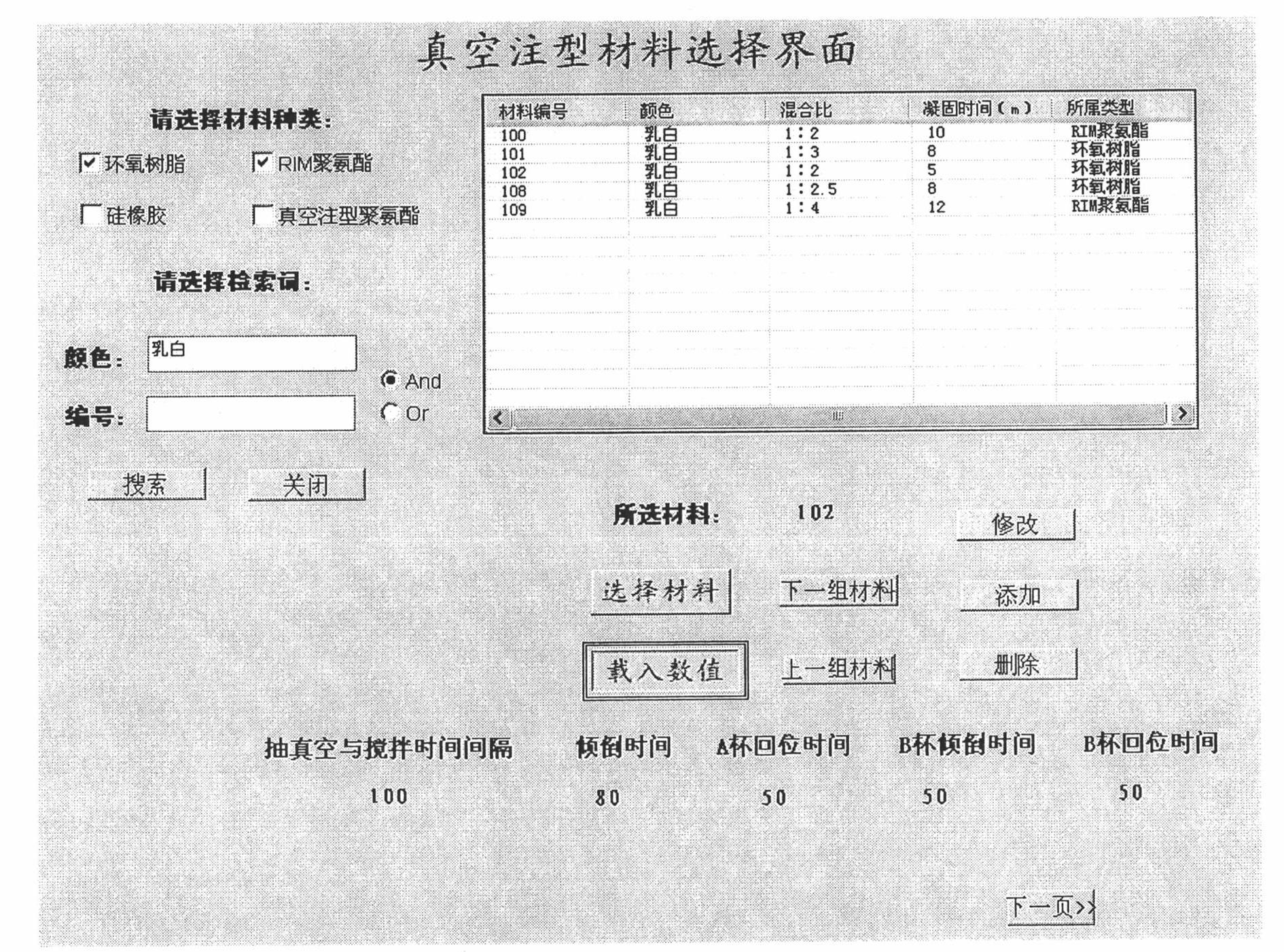

Full-automatic vacuum molding control system and method

The invention relates to a full-automatic vacuum molding control system and a method. The system comprises a detection module, a control module and an execution module, wherein the control module comprises a computer as a main controller and a programmable logic controller as a secondary controller, the detection module comprises a CCD (Charge-Coupled Device) high-speed digital camera, a digital pressure sensor and a limit switch, the execution module comprises a vacuum pump connected with a vacuumizing motor, a stirring rod connected with a stirring motor, and a firming agent material cup and a mixed material cup connected with a tilted motor as well as an electromagnetic valve for air intake. The control method realizes visual, automatic and intelligent control of the vacuum molding process. The invention can greatly save the labor resource cost and improve the molding working efficiency and the product quality.

Owner:SHANGHAI UNIV

Etching method for external layer of thick copper plate

ActiveCN105208781AGood uniformity of outer layer etchingImprove etching effectConductive material chemical/electrolytical removalEtchingCopper

The invention relates to an etching method for an external layer of a thick copper plate, and belongs to the technical field of PCB production. Twice etching is used, the up / down orientation of the thick copper plate is changed in the twice etching, each of the two surfaces of the thick copper plate is orientated downwards once and sprayed by an etching solution upwardly, technical parameters including the speed that the thick copper plate passes an etching cylinder, the spraying pressure of the etching solution and the concentration of the etching solution are adjusted, and the adjusted technical parameters cooperate with the twice etching manners, so that the etching uniformity of the external layer of the thick copper plate is high, areas of dense circuits can be cleaned via etching, and areas including fewer circuits are prevented from excessive etching and too thin etching lines. According to the method of the invention, the etching effect for the external layer of the thick copper plate is good.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

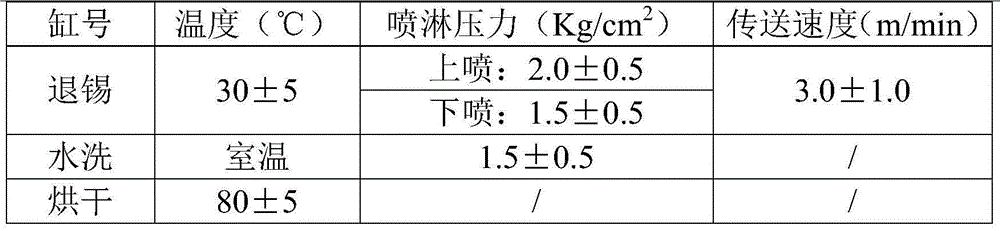

High performance crosslinked elastomeric insulation material

InactiveCN103396615AImprove flame retardant performanceExtended storage timePlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a high performance crosslinked elastomeric insulation material, which is composed of the following raw materials by weight part: 90-100 of chlorinated polyethylene CPE135B, 3-5 of a curing agent DCBP, 2-4 of triallyl isocyanurate, 8-15 of magnesium oxide, 100-110 of 1250-mesh talcum powder, 10-15 of precipitated white carbon black, 10-15 of kaolin, 2-3 of polypropylene adipate, 3-4 of bisphenol A phosphite, 1-2 of dibutyltin dilaurate, 1-2 of dibasic lead phosphite, 15-20 of chlorinated paraffin 52, 4-6 of ethylene bis stearamide, 2-4 of hydrated zinc borate, 8-10 of diethylene glycol dibenzoate, 50-55 of light calcium carbonate, 1-2 of an antiager AW, and 10-15 of an auxiliary filler. The insulation material produced in the invention has good oil resistance, high strength, strong tear resistance, good flame retardance, and superior overall performance.

Owner:安徽龙庵电缆集团有限公司

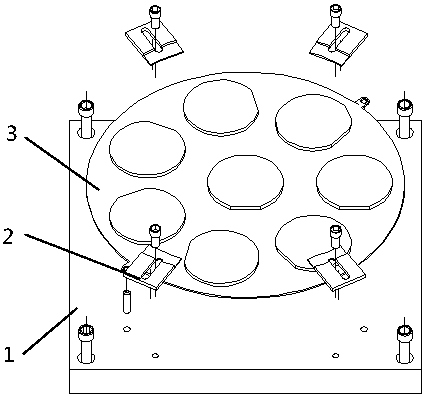

Automatic grouping system without inner ring needle bearing

ActiveCN104355069AHigh measurement accuracyImprove pass rateMechanical diameter measurementsJigging conveyorsNeedle roller bearingMechanical engineering

The invention discloses an automatic grouping system without an inner ring needle bearing. The automatic grouping system comprises a bracket, a turntable motor, a rotating material plate, a loading station, an inner diameter detecting station, a discharging station and a controller used for controlling the loading station, the inner diameter detecting station and the discharging station to work; a locking module located on the rotating material plate is driven to rotate to the loading station by the rotating material plate; a to-be-detected workpiece is pressed into the locking module by the loading station; the locking module is rotated to the inner diameter detecting station; the inner diameter detecting station is used for detecting the to-be-detected workpiece which is pressed into the locking module; the workpiece after being detected and the locking module are together rotated to the discharging station; the discharging station is used for grouping and discharging the workpiece after being detected. The automatic grouping system provided by the invention has the advantages that the measuring precision of products and the yield of the products are increased, the quality of the products is effectively ensured, and the cost is lowered.

Owner:SUZHOU XINHAO BEARING

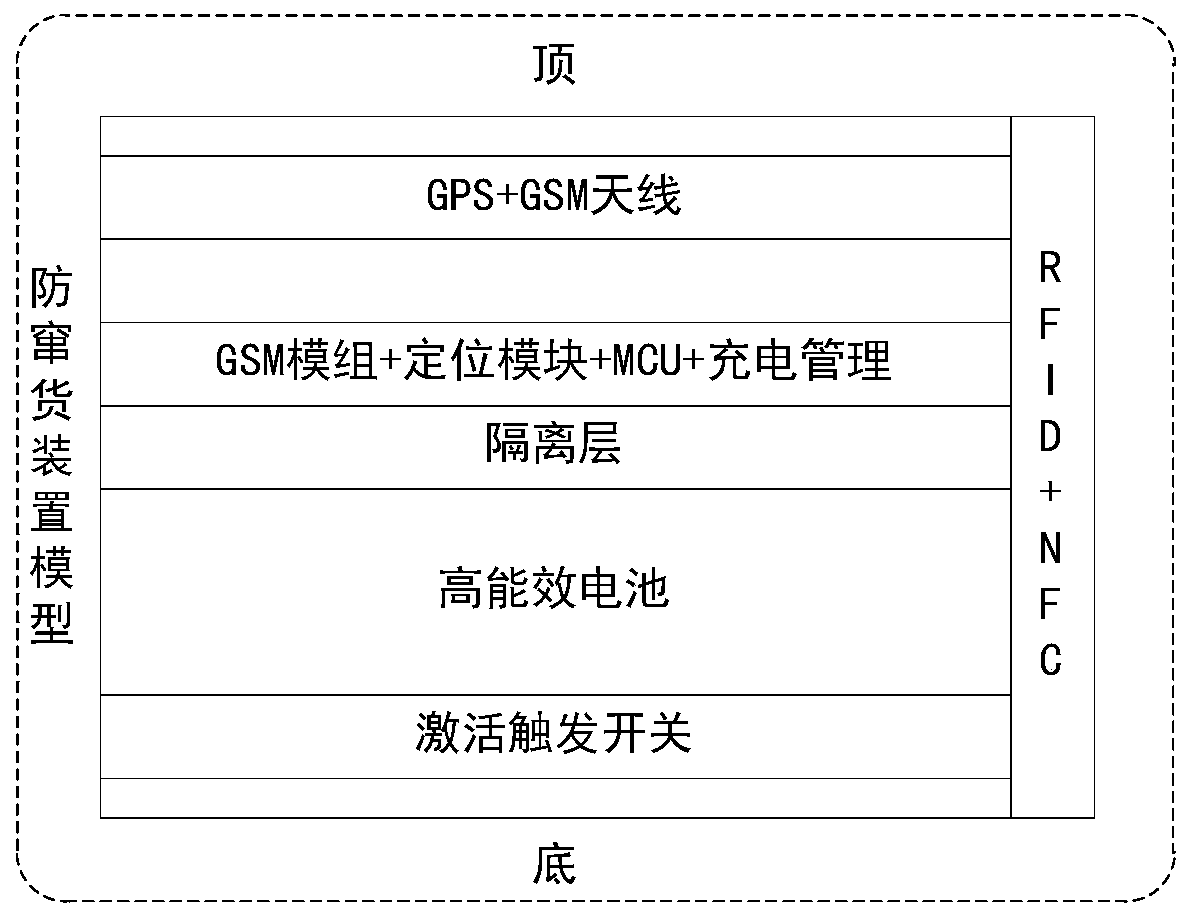

Traceability anti-channel conflict system and method based on Internet of Things and block chain

ActiveCN111127045AImprove transport efficiencyGuaranteed to be true and effectiveCo-operative working arrangementsCommerceThe InternetEmbedded system

The invention discloses a traceability anti-channel conflict system and method based on the Internet of Things and a block chain. The system comprises an SAAS service module, a block chain alliance chain platform and a traceability terminal device. The traceability terminal device is internally provided with a GPS antenna, a GSM antenna, a GSM module, a GPS positioning module, an MCU module, a charging management module, a battery module, an activation trigger switch, an RFID tag, an NFC tag and a two-dimensional code identification module. The GPS antenna and the GMS antenna are respectivelyconnected with the GSM module and the GPS positioning module; the MCU module is connected with the GSM module, the GPS positioning module, the charging management module, the activation trigger switch, the RFID tag, the NFC tag and the two-dimensional code identification module, and the charging management module is connected with the battery module. According to the invention, through the uniqueidentification of the traceability device for the product, one object and one code can be truly realized, one-to-one correspondence between physical world commodities and the system is realized, collection of track data of the commodities from delivery to use is realized, and channel conflict sales is prevented.

Owner:CHENGDU JIUZHOU ELECTRONIC INFORMATION SYSTEM CO LTD

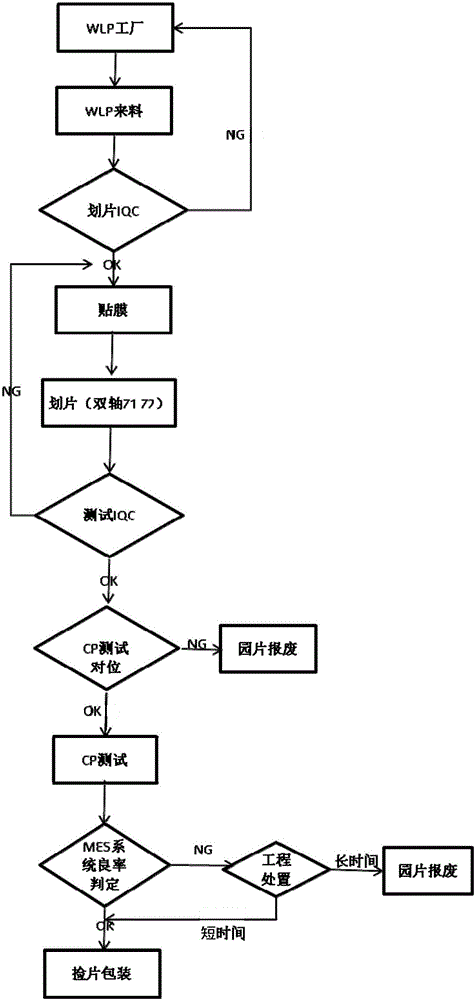

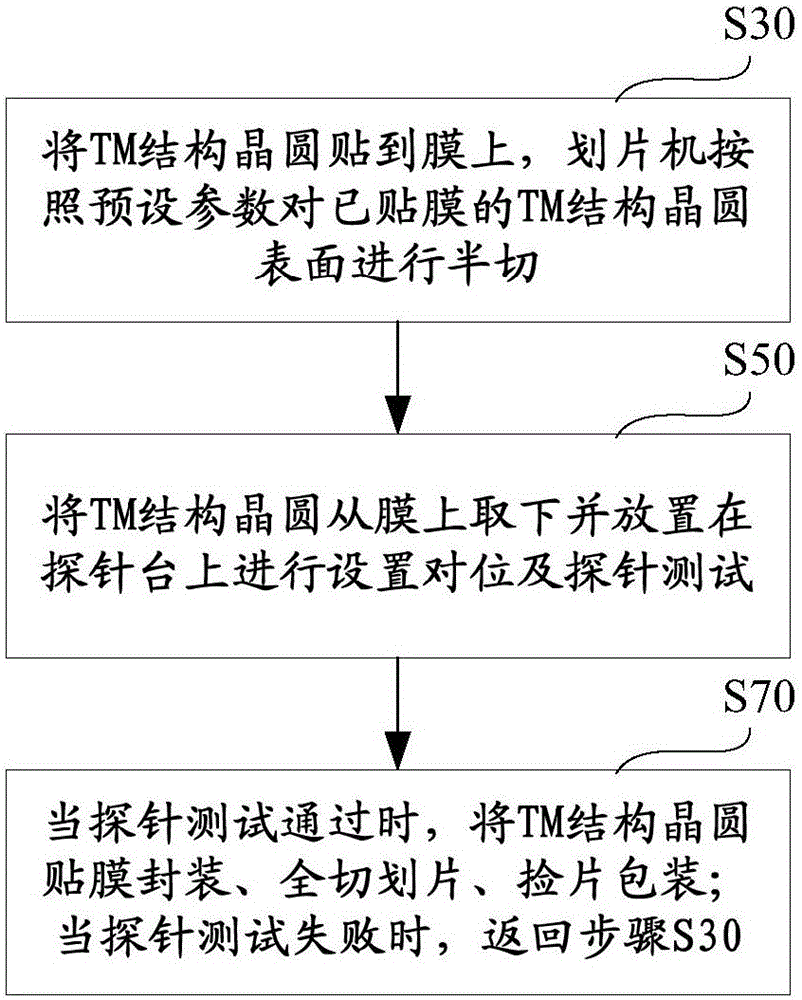

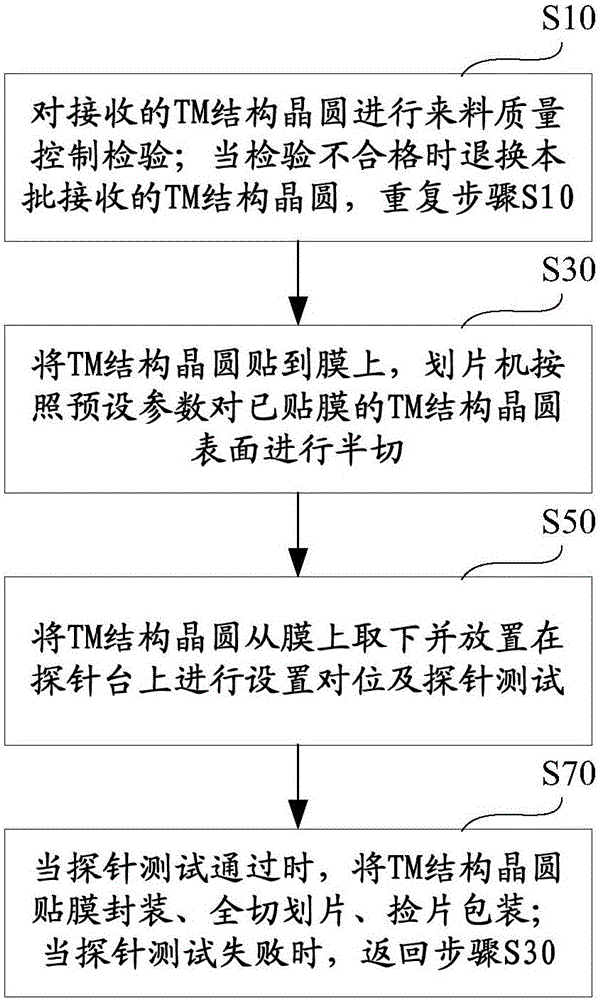

TM-structured wafer semi-cut test method

InactiveCN104966680AReduce product scrap rateAvoid needle misalignmentSemiconductor/solid-state device testing/measurementDislocationEngineering

The invention provides a TM-structured wafer semi-cut test method. The method comprises the following steps that (S30) a TM-structured wafer is attached to a film; a wafer scriber performs semi-cutting on the surface of the TM-structured wafer with the film attached; (S50) the TM-structured wafer is removed from the film and placed on a probe station for alignment and probe testing; (S70) film attaching, packaging, full-cut scribing and wafer-picking packaging are performed on the TM-structured wafer after the probe tests are passed; and the step S30 is referred to again when the probe tests fail. The risks that the whole wafer cannot be tested due to film attaching deviation can be prevented. The product disability rate can be thus lowered. Conditions of stitching deviation due to a dislocation between bonding pads caused by attaching film contraction and expansion can be prevented. The product yield rate is improved. The wafer picking difficulties during a wafer picking operation can be further prevented. The method provided in the invention has the advantages of simple operations and improved product qualified rate, etc.

Owner:NANTONG FUJITSU MICROELECTRONICS

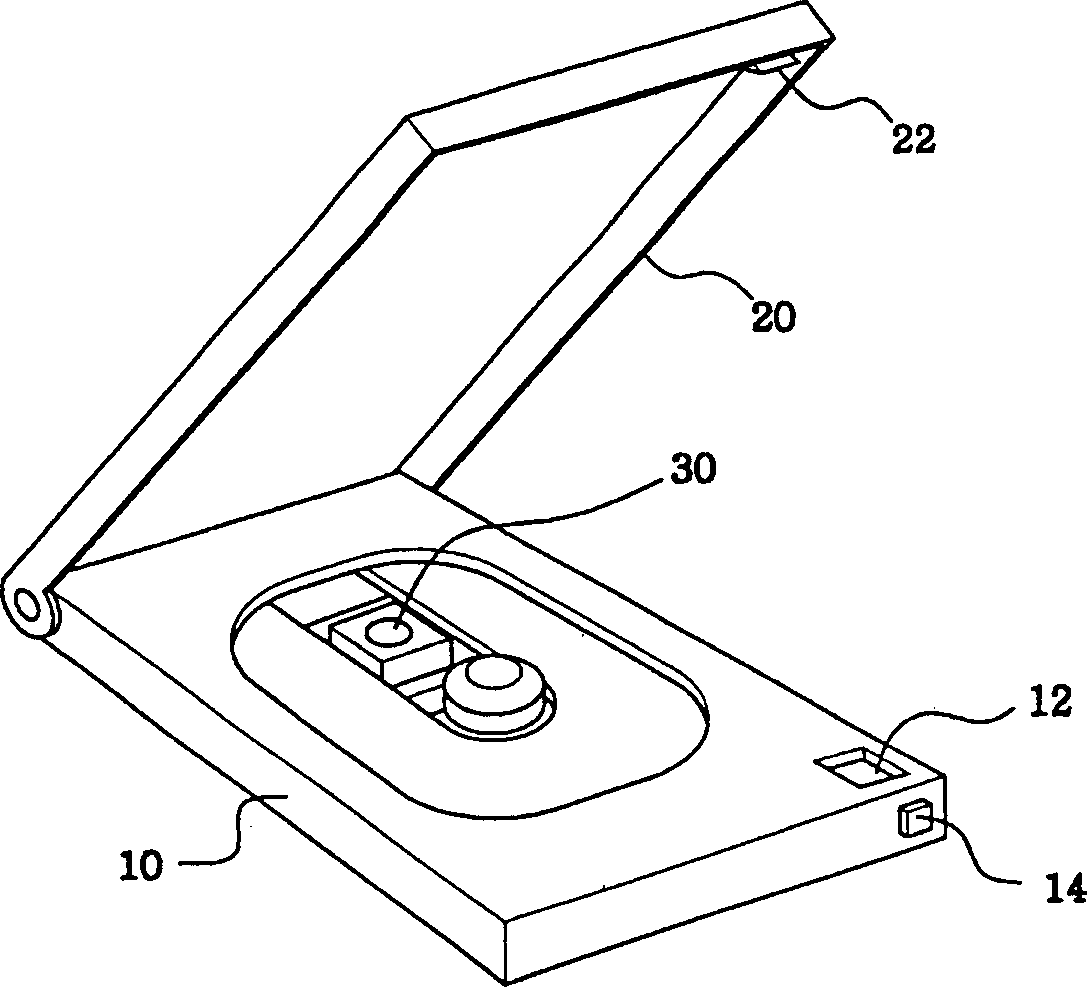

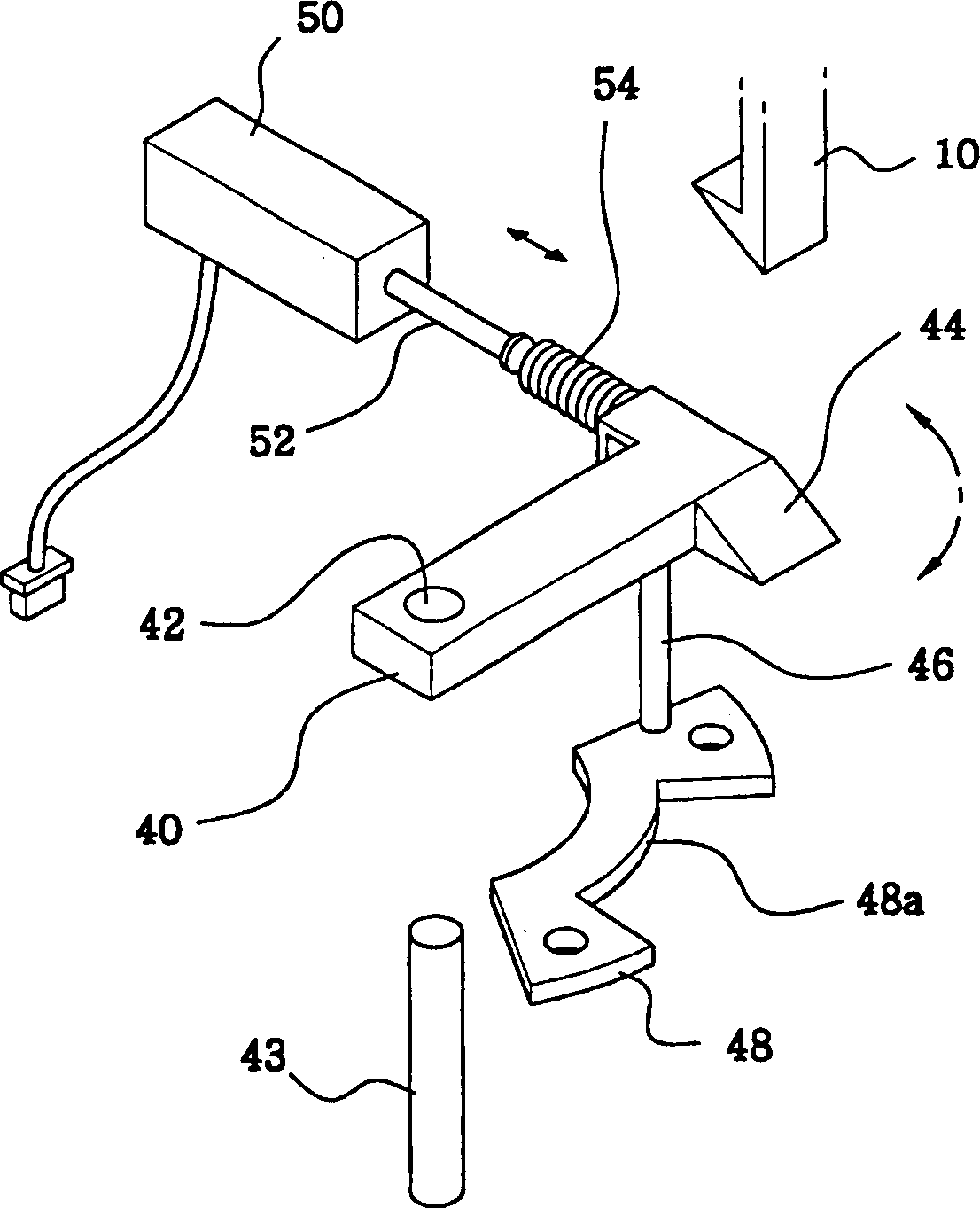

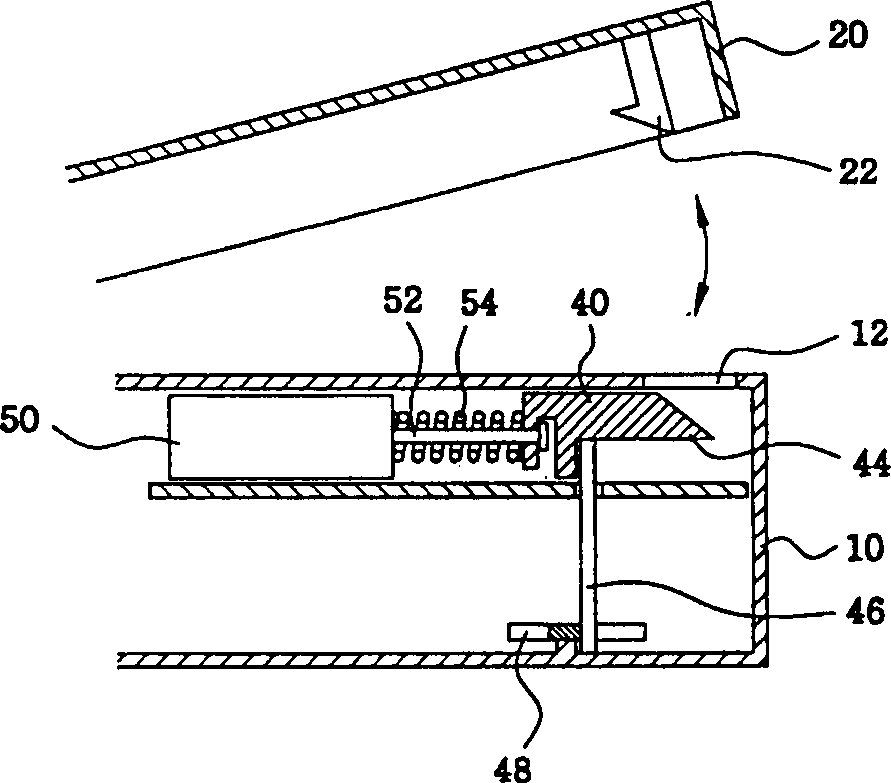

Device for opening and closing CD player cover

InactiveCN1444227AReduce in quantityReduce manufacturing costDriving/moving recording headsCarrier coversProduction rateManufacturing cost reduction

The present invention discloses a device for opening and closing the cover of an optical disc player. By reducing the number of parts, the device can reduce manufacturing cost, improve assembly efficiency and productivity, and can reduce product scrap rate to the minimum. The device comprises: a player main body, with a button and a locking hole; a cover, hinged with the rear end of the player main body to cover the player main body, and biased upward by a spring, the cover has a hook protruding downward; an optical head, set In the main body of the player, it can move back and forth, and a push rod is set for the optical head; the locking buckle, set in the main body of the player, can move back and forth, and has a locking protrusion engaged with the hook and a contact plate in contact with the push rod , and also has a connecting rod connected between the locking projection and the contact plate; and a spring, arranged in the main body of the player, for biasing the locking buckle forward.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

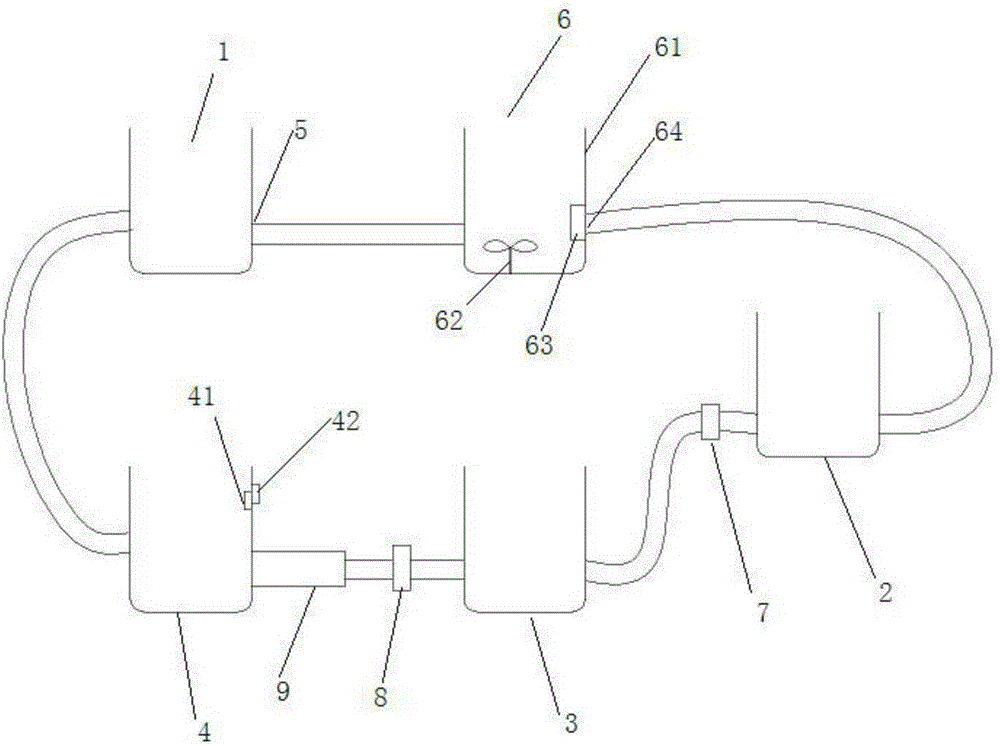

EPS plastic foam cooling water circulating system and method for cooling EPS plastic foam using same

The invention discloses an EPS plastic foam cooling water circulating system, which comprises a cooling device, a first settling pond, a second settling pond and a reservoir, wherein a water outlet is formed in the cooling device; the water outlet is connected with a cooling water receiving system through a pipeline; the cooling water receiving system, the first settling pond, the second settling pond and the reservoir are sequentially connected with one another through a pipeline; a filter net or a filter is arranged between the first settling pond and the second settling pond; water softening equipment is arranged between the second settling pond and the reservoir; air cooling equipment is arranged between the water softening equipment and the reservoir; and the reservoir is connected with the cooling device through the pipeline. The overall pipeline cycle control is achieved; losses and waste of cooling water in the circulating process are reduced; a manual operation is reduced; the cooled water is clarified; pipe blockage is avoided; water hardness is softened; workshop production equipment and an EPS plastic foam mold are protected; the service lifetime is prolonged; the maintenance cost is reduced; and the yield of EPS foam is improved.

Owner:贵州贵乌包装材料有限公司

Machining technology for reducing deformation of thin-wall parts

The invention discloses a machining technology for reducing deformation of thin-wall parts, and belongs to the field of part machining. The machining technology comprises the following steps of (1) carrying out rough machining of the parts, (2) carrying out tempering and stress relief, (3) carrying out finish machining of the parts, and (4) carrying out inspection, wherein in the step (3), plate pressing and the glue method are combined and are improved, so that the flatness and the parallelism of the parts after finish machining are guaranteed.

Owner:靖江佳仁半导体科技有限公司

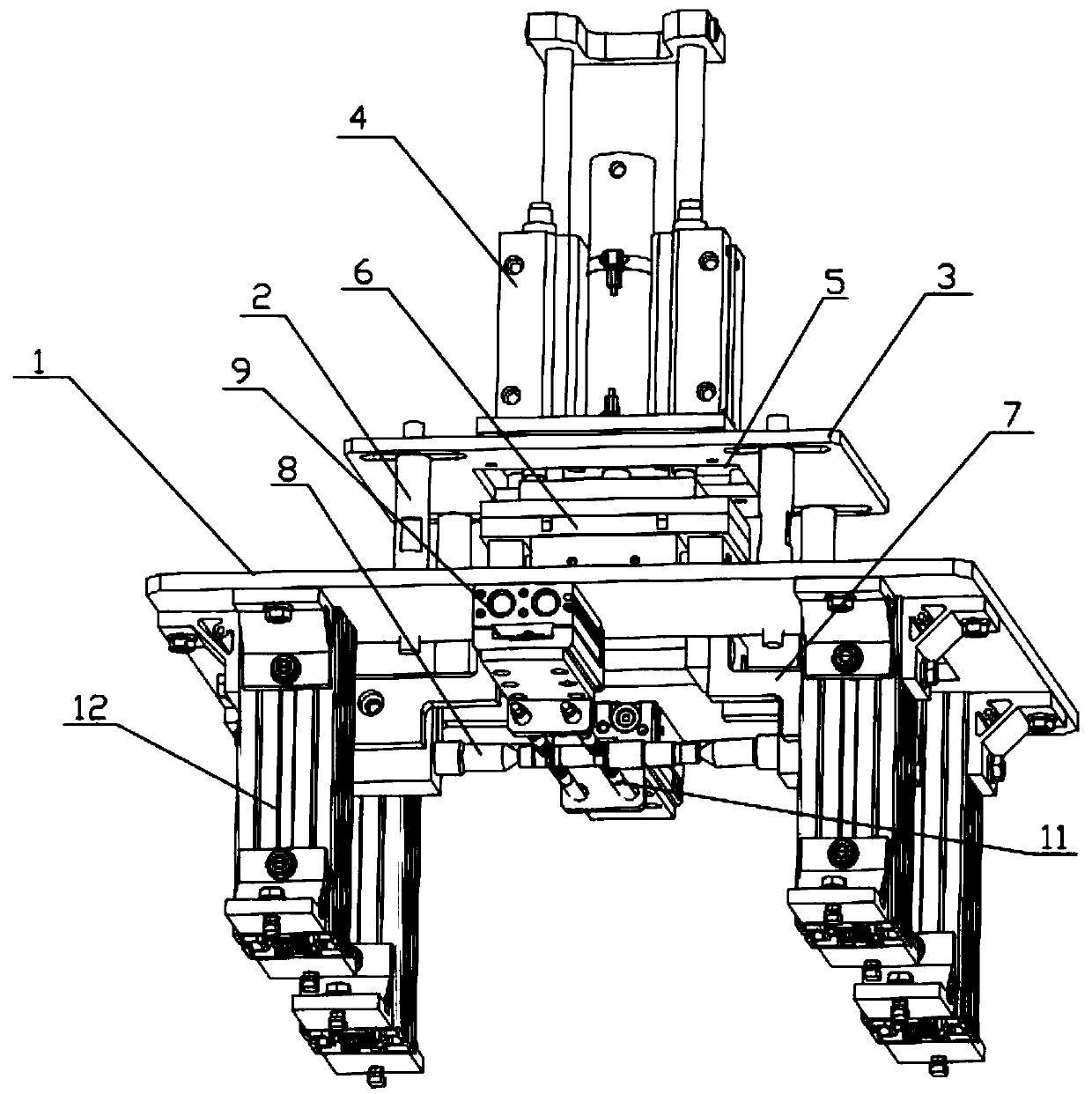

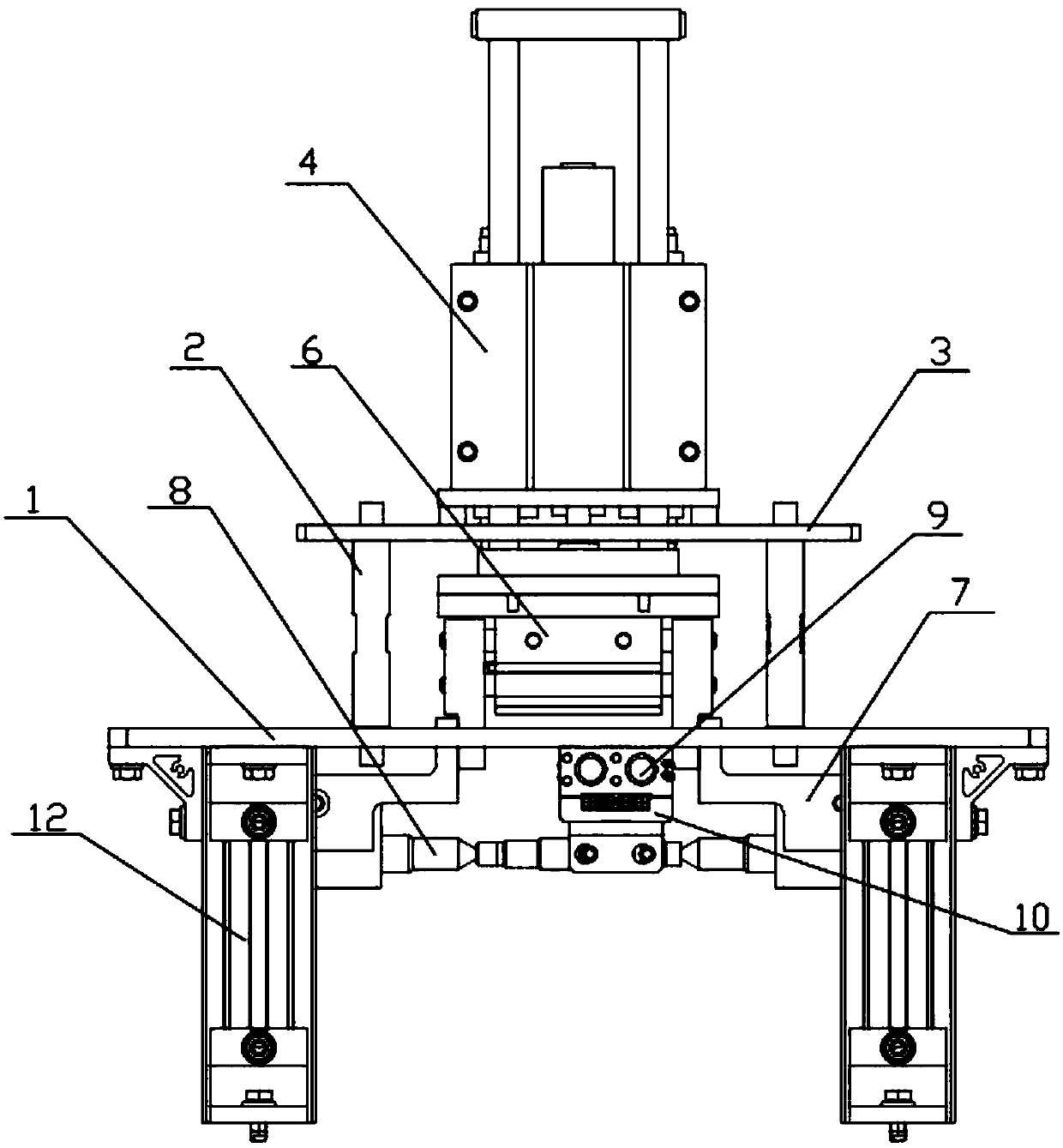

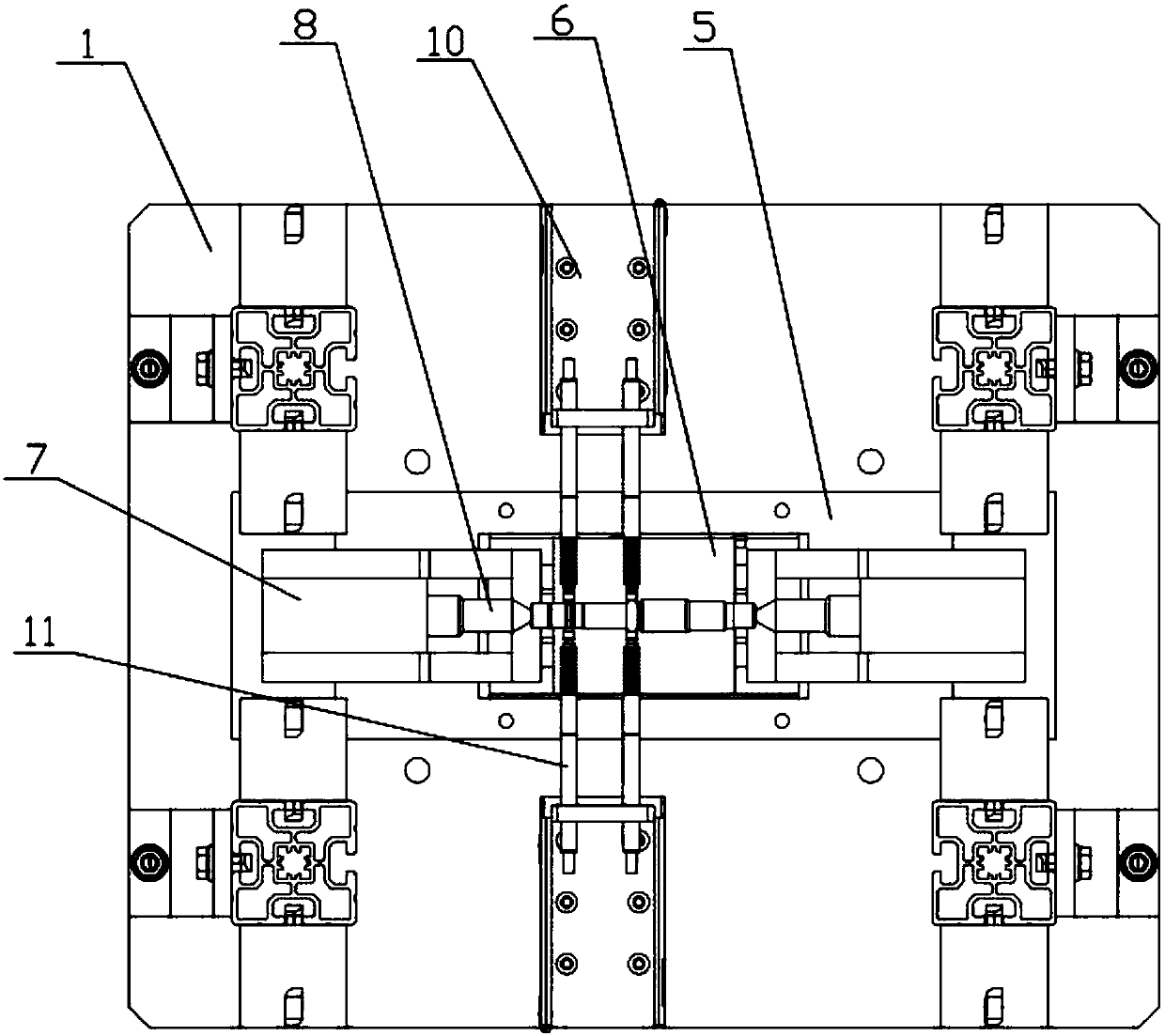

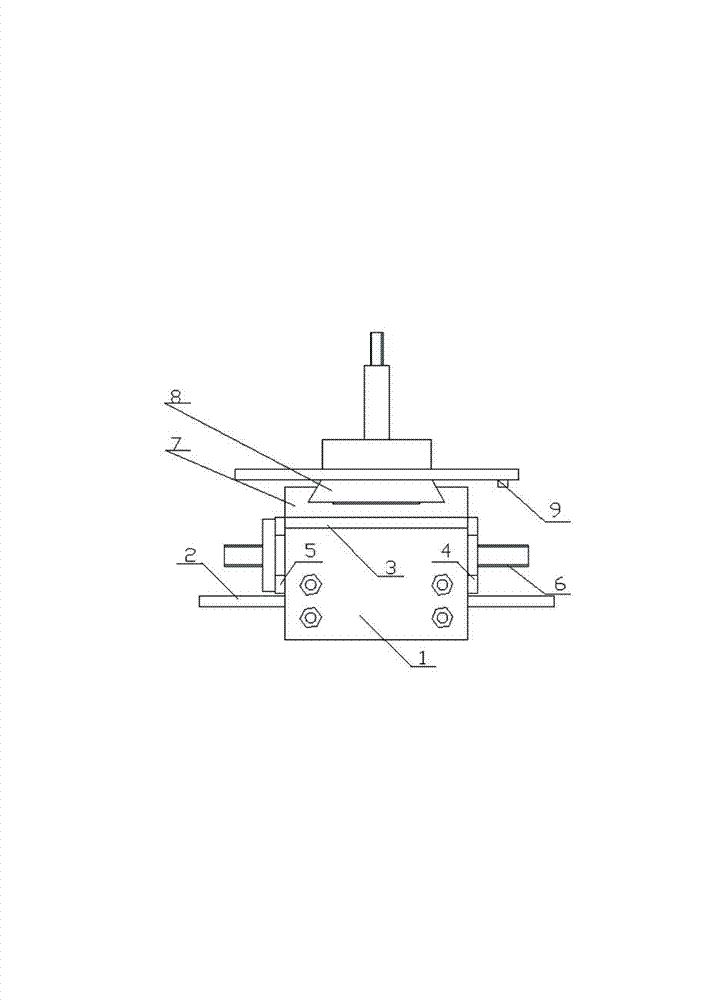

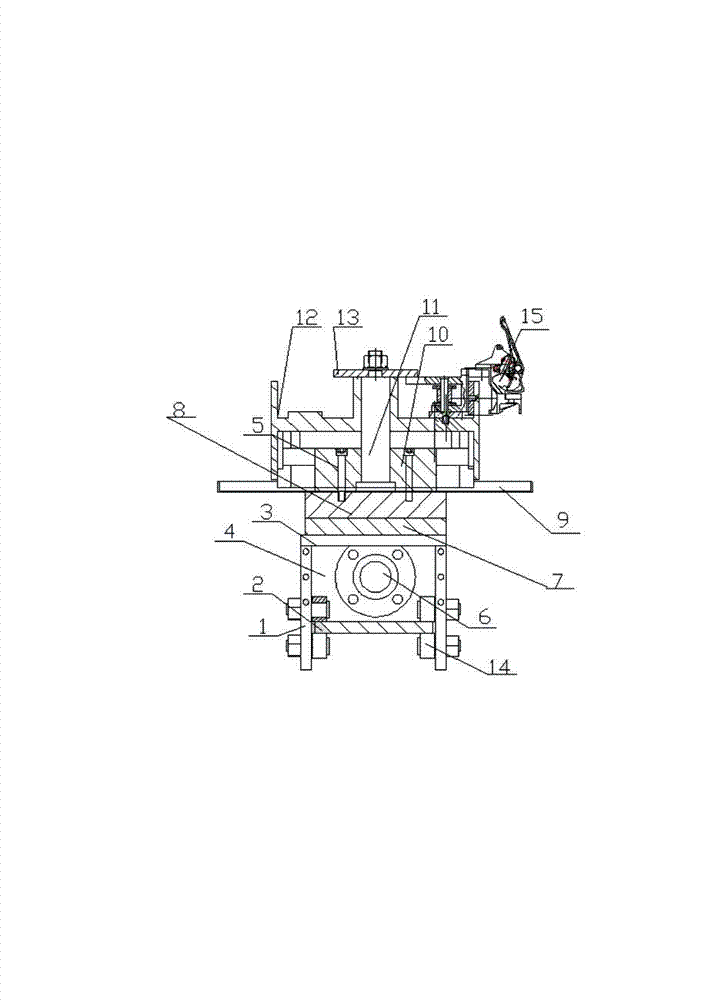

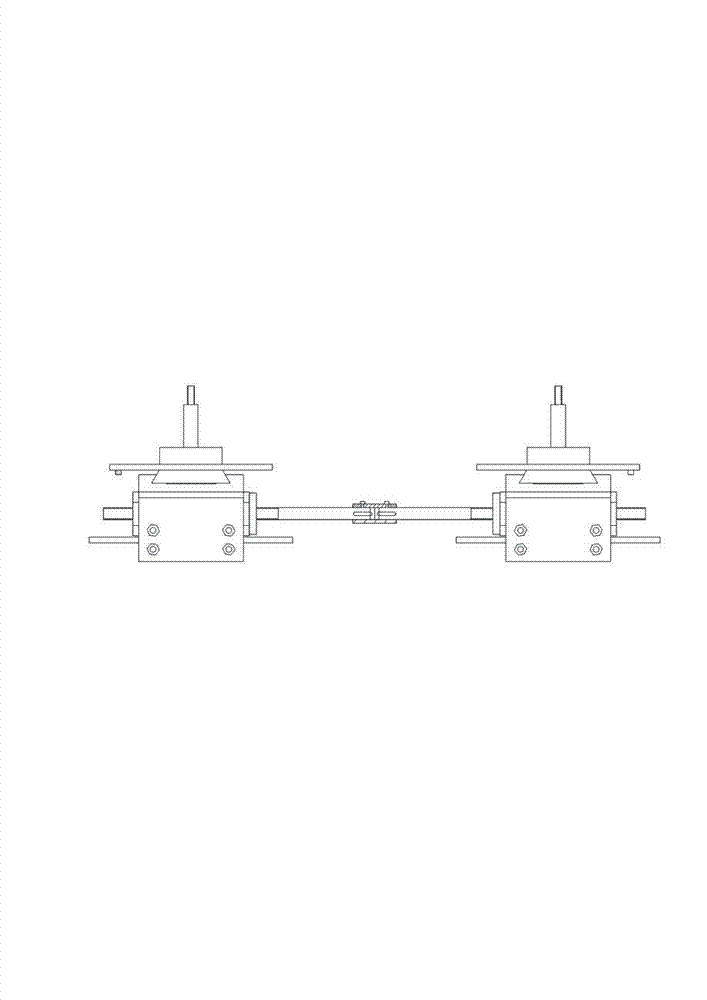

Full automatic tooling clamp for semi-crankshaft finish machining

ActiveCN104772637ARealize fully automatic unmanned processingRealize automatic shutdownMeasurement/indication equipmentsPositioning apparatusManipulatorCrankshaft

The invention discloses a full automatic tooling clamp for semi-crankshaft finish machining. The tooling clamp is characterized by comprising a base, two side plates, a cover plate, two locating blocks, a floating pressing mechanism, a locating pin and a radial pressing mechanism, wherein the bottom parts of the two side plates are fixedly welded on the base, the cover plate is fixedly connected with the top parts of the two side plates through screws, and an n shape is formed by the two side blocks and the cover plate; the top of the cover plate is transversely and fixedly provided with the two locking blocks, the top surfaces of the two locking blocks are located in a same horizontal plane, a locating pin mounting hole and a crankshaft journal mounting hole which vertically penetrate through the cover plate are formed between the two locating blocks of the cover plate and the locating pin is arranged in the locating pin mounting hole; the cover plate is longitudinally provided with the radial pressing mechanism, and the floating pressing mechanism is arranged above the locating block. The full automatic unmanned processing can be realized; furthermore, each link can be detected, including the feeding and discharging in-place detection of a manipulator, work-piece clamping and loosening detection, work-piece clamping in-place request processing or discharging detection and the like.

Owner:JINAN FIRST MACHINE TOOL GROUP

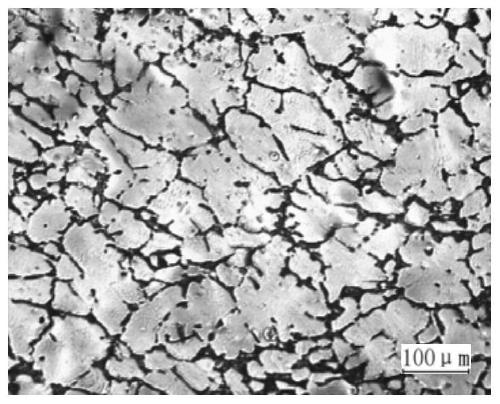

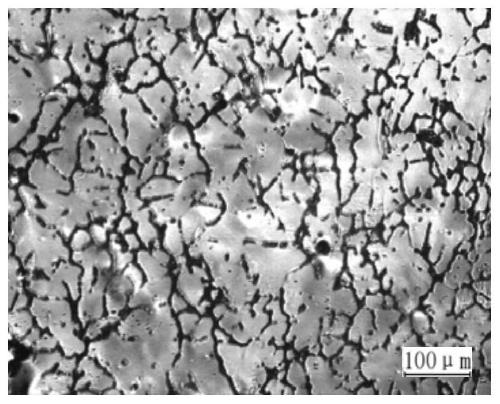

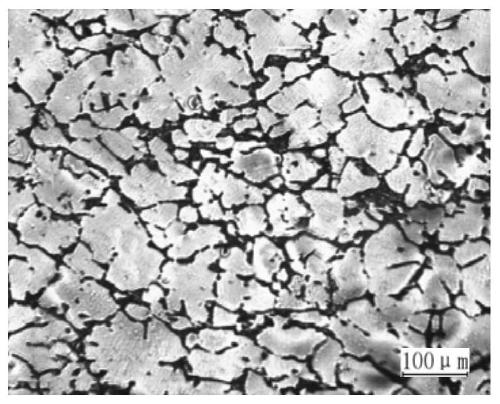

3003 aluminum alloy plate and pretreatment process thereof

The invention provides a pretreatment process of a 3003 aluminum alloy plate. The process comprises the following steps of primary refining, primary deterioration and thermal treatment. According to the technical scheme, Al5TiB and Ce are combined for deterioration of molten aluminum, the impurity removal rate is improved by 31.8% compared with the scheme of only adopting Al5TiB, the crystal particle size of obtained aluminum alloy is reduced, and distribution is relatively uniform. Under the same thermal deformation condition, the cube texture strength in the 3003 aluminum alloy treated according to the technical scheme is maximum, deep drawing deformation is facilitated, the product rejection rate caused by the earing rate is reduced, production cost is reduced, and enterprise benefitsare improved.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

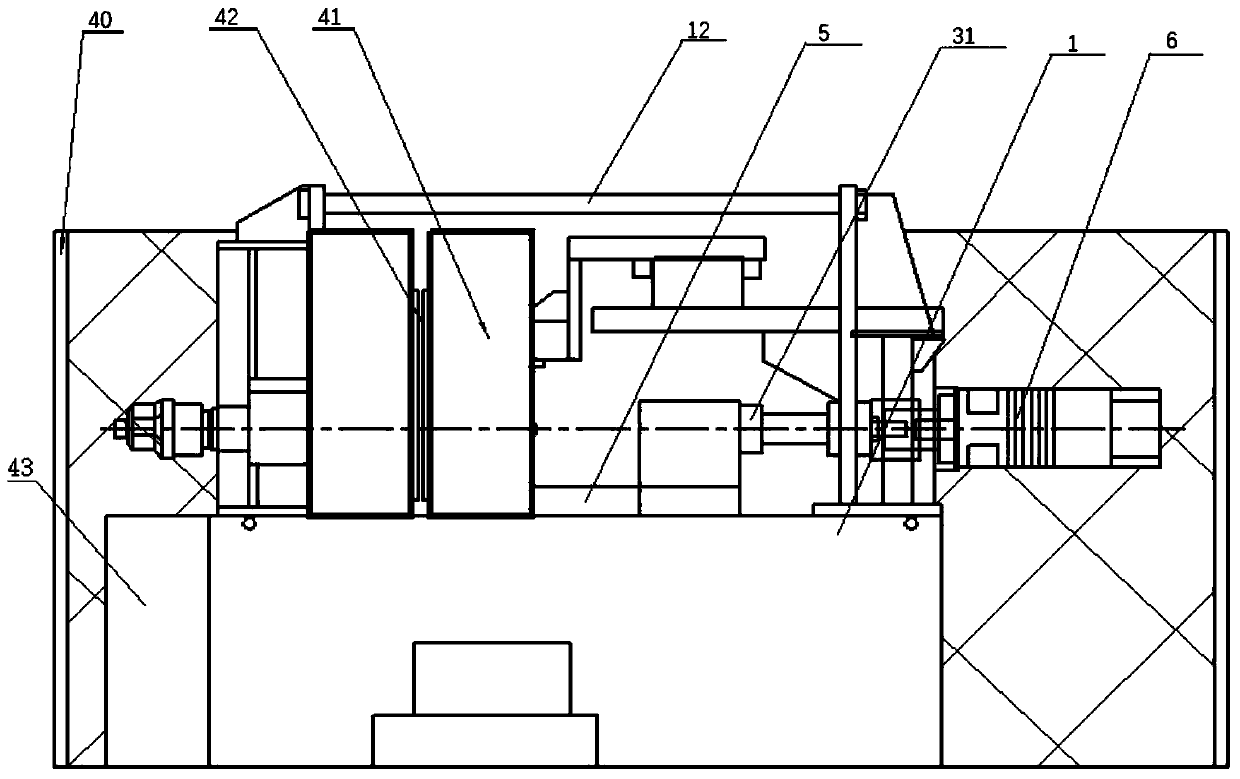

Novel friction welding equipment and production line

PendingCN111266871AImprove stabilityImprove firmnessWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingConvex structure

The invention discloses novel friction welding equipment and a production line. The novel friction welding equipment comprise a bench and a controller, wherein a rotation mechanism and a translation mechanism are arranged on the bench; the rotation mechanism comprises a main shaft connected to the bench, a first driving unit connected to the rear end of the main shaft, and a first clamp connectedto the front end of the main shaft; the first clamp is used for clamping a first workpiece; the translation mechanism comprises a mobile platform slidably connected to the bench, a second driving unitconnected to the rear end of the mobile platform, and a second clamp connected to the front end of the mobile platform; the second clamp is used for clamping a second workpiece; and the surface of aclamping position of the second clamp is provided with convex structures and so forth. Because the mechanical strength of the second workpiece is low, when the second workpiece is clamped by the second clamp, grooves matched with the convex structures are formed in the surface of the second workpiece. Therefore, the second workpiece is prevented from falling through the matching of the grooves andthe convex structures, and the clamping stability of the second workpiece is improved.

Owner:JILIN ZHONG YING HIGH TECH CO LTD

Diameter detection mechanism for shaft-class parts

InactiveCN107806849AReduce labor intensityReduce labor costsMeasurement devicesConveyor partsEngineeringContact type

The invention relates to a diameter detection mechanism for shaft-class parts. A substrate is provided with a plurality of vertical uprights of which the lower ends are connected with the substrate; the upper ends of the vertical uprights are provided with a horizontal supporting plate; the supporting plate is provided with vertical lifting air cylinders; the piston ends of the lifting air cylinders are connected with a horizontal clamping air cylinder; two piston ends of the clamping air cylinder are connected with pushing tip frames; each pushing tip frames are provided with a pushing tip; the lower end surface of the substrate is provided with two opposite detection air cylinders; the detection air cylinders are vertical to the pushing tips; the piston ends of the detection air cylinders face a position between the two pushing tips; the piston end of each detection air cylinder is connected with a sensor frame; each sensor frame is provided with a contact type sensor; and the lowerend surface of the substrate is provided with a plurality of supports adjacent to the edges of the substrate. Compared with the prior art, the diameter detection mechanism of the invention has the advantages of high detection precision, accurate data and the like.

Owner:DALIAN DEMAISHI PRECISION TECH CO LTD

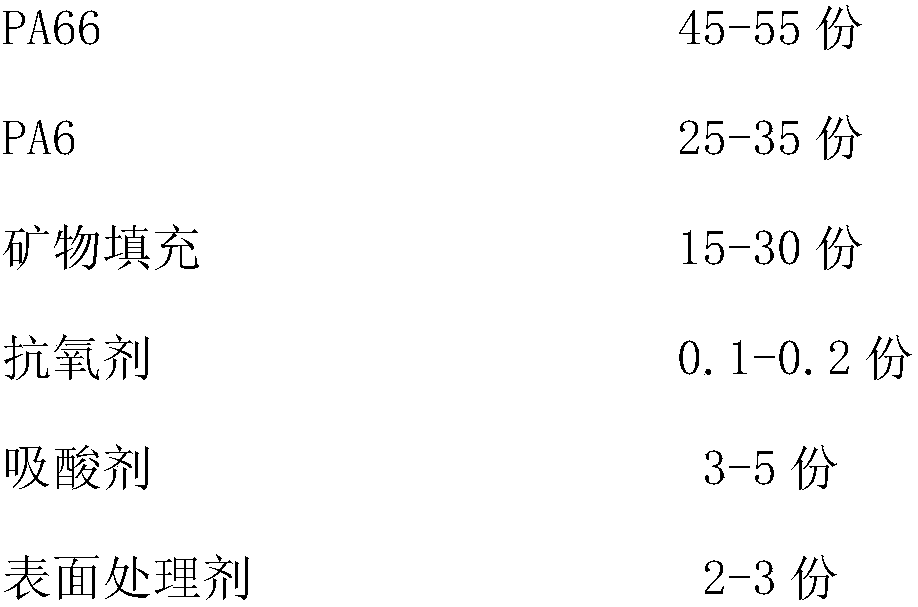

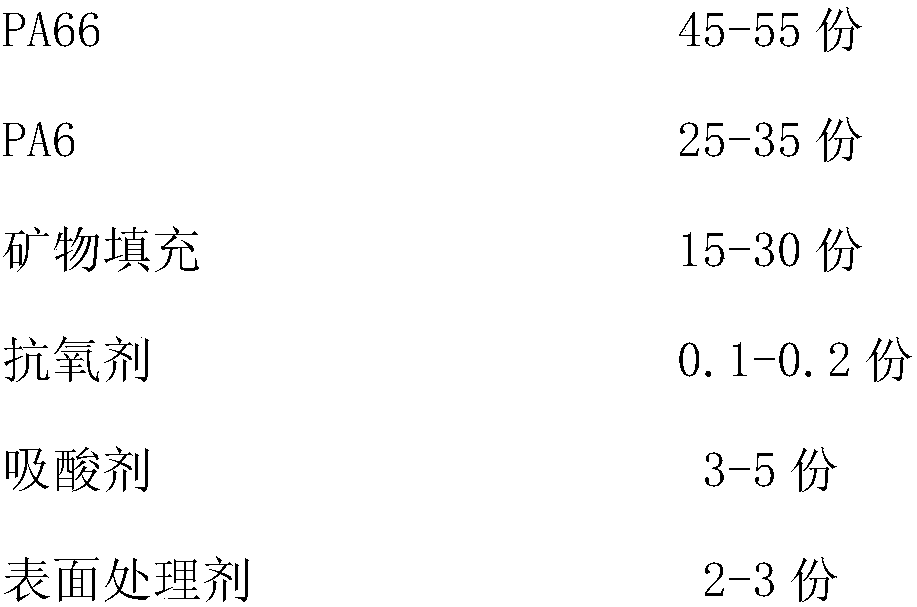

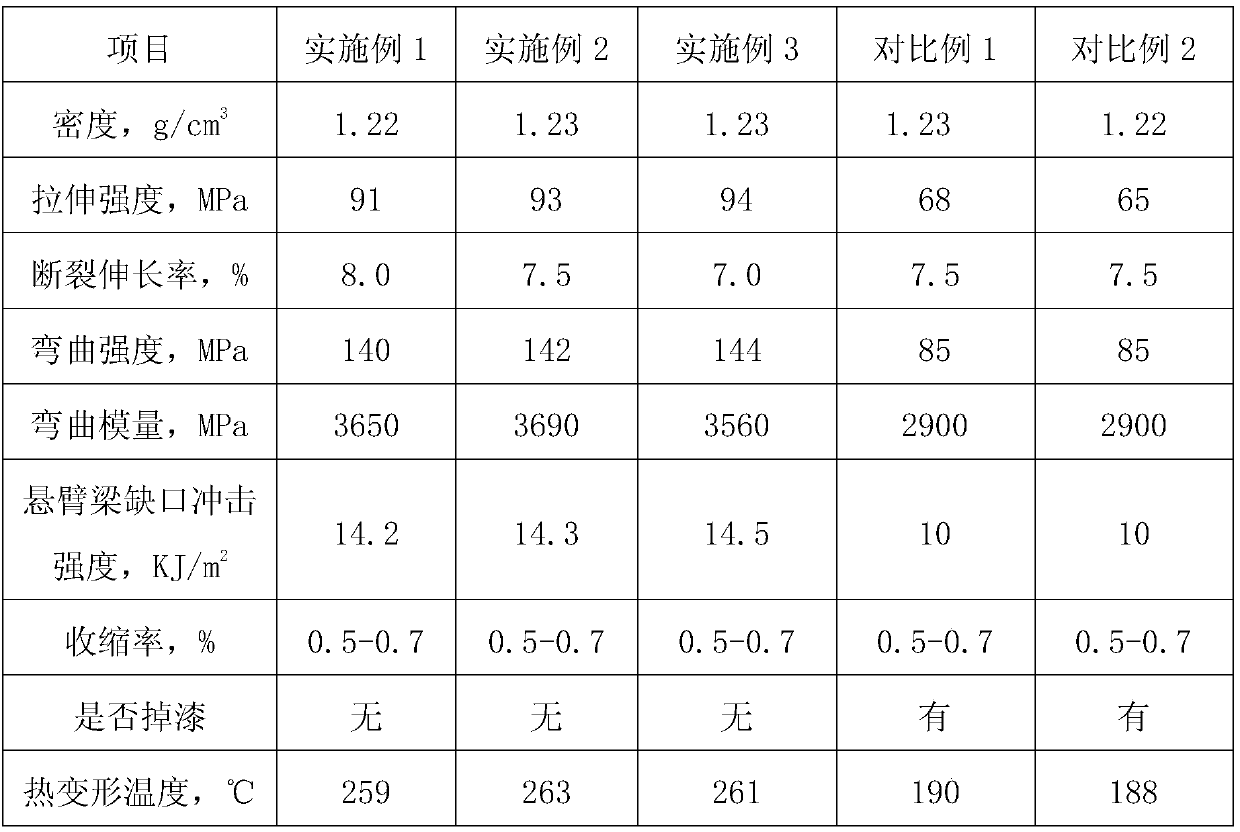

Spraying-facilitating mineral enhanced PA66 material and preparation method thereof

InactiveCN108034244AImprove mechanical propertiesGood dimensional stabilityProduction rateAntioxidant

The invention discloses a spraying-facilitating mineral enhanced PA66 material and a preparation method thereof. The spraying-facilitating mineral enhanced PA66 material is prepared from the followingraw material components: 45 to 55 parts of PA66, 25 to 35 parts of PA6, 15 to 30 parts of mineral fillings, 0.1 to 0.2 part of an antioxidant, 3 to 5 parts of an acid absorbent and 2 to 3 parts of asurfactant, wherein the mineral filling is talc grains of 2,500 meshes, and the part is mass part. According to the spraying-facilitating mineral enhanced PA66 material disclosed by the invention, through synergism and promotion of all the raw materials, on the basis that the mechanical property, the size stability and the temperature resistance of the material are all improved, the surface adhesion of a product is enhanced by adding the acid absorber and the surfactant, so that the product is only required to be washed with water, and burning and surface grinding are not required; the productis easy to spray; the productivity is improved, and the cost is reduced; moreover, the production rejection rate is also reduced.

Owner:NANJING HONGRUI PLASTIC PROD

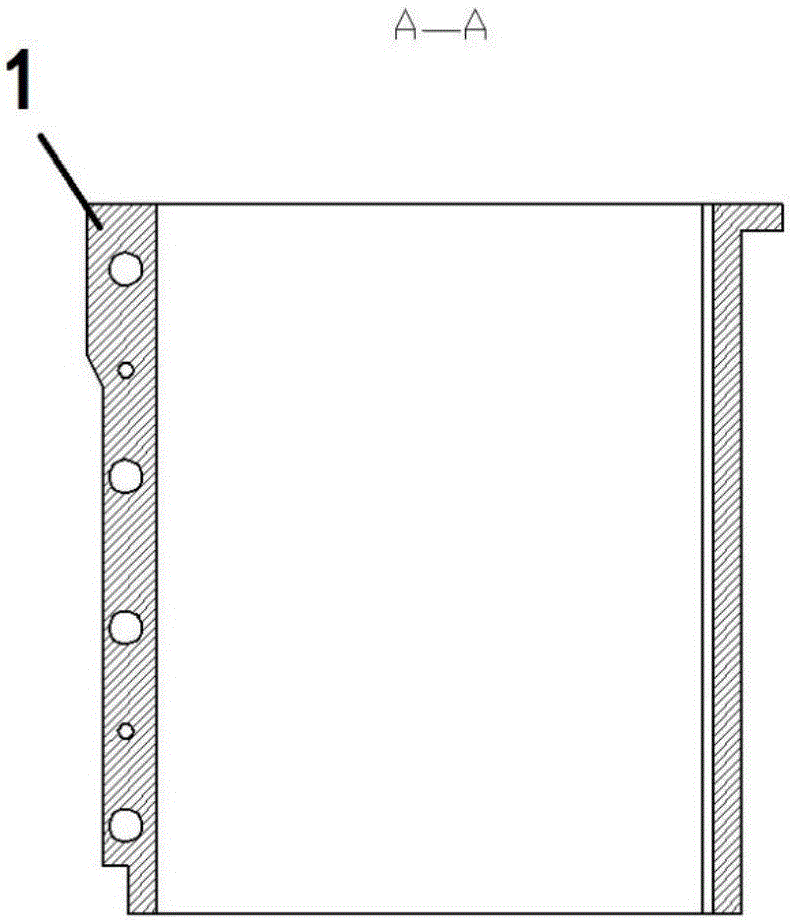

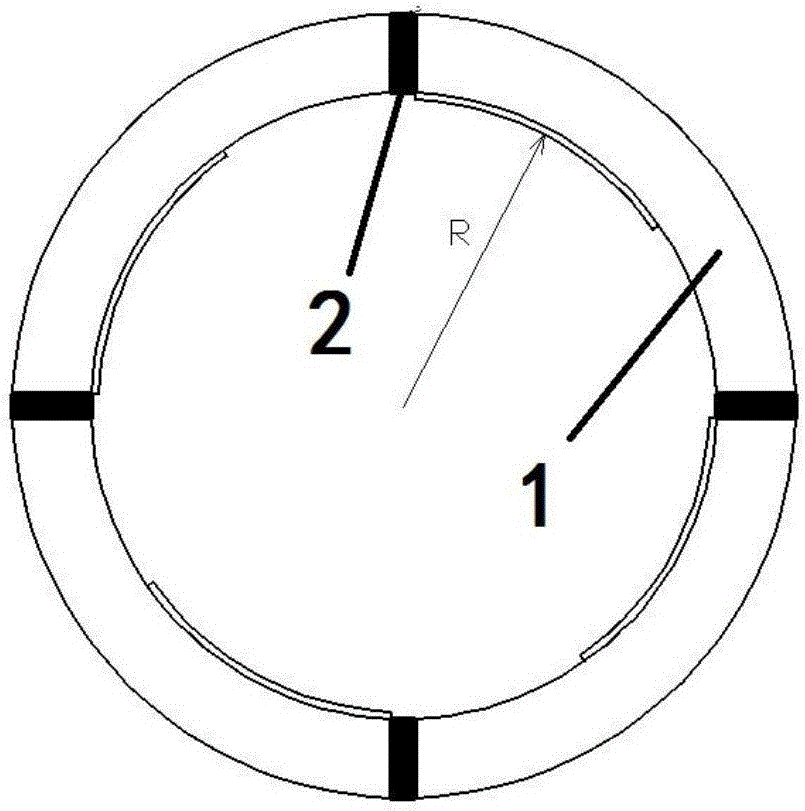

Processing method for four-piece unequal-diameter bearing body of large hydroelectric generating set

ActiveCN106312463AImprove machining accuracyImprove processing efficiencyRejection rateComputer science

The invention discloses a processing method for a four-piece unequal-diameter bearing body of a large hydroelectric generating set. The processing method comprises the following steps of: marking inspection, jointing surface processing, primary combination, rough turning, primary disassembly, car gasket assembly, secondary combination, secondary marking inspection, finish turning, detecting and secondary disassembly. In order to solve the technical limitation of four-piece unequal-diameter bearing body processing, a reasonable computing method is adopted, and a method of assembling a car gasket is adopted, so that the technical effects of simultaneously turning each piece of the four-piece bearing body are realized, processing workload and defective product risks are reduced, bearing body processing precision and efficiency are improved, and the processing method for the four-piece unequal-diameter bearing body of the large hydroelectric generating set is enriched. The processing method disclosed by the invention has the technical characteristics of being easy to popularize, high in processing precision, short in production period, relatively low in cost, low in rejection rate and remarkable in effect.

Owner:HARBIN ELECTRIC MASCH CO LTD

Preparation method of graphite crucible

The invention discloses a preparation method of a graphite crucible. The preparation method comprises the following steps: S1, raw material preparation: raw materials comprise graphite scraps, an Acheson furnace petroleum coke resistance material, an Acheson furnace petroleum coke thermal insulation material and medium-temperature coal pitch; s2, burdening: graphite is crushed and ground into graphite powder, then the graphite powder is mixed with the Acheson furnace petroleum coke resistance material, the Acheson furnace petroleum coke resistance material and the Acheson furnace petroleum coke heat preservation material according to the mass ratio of 3: 2: 5, the mixture is ground into mixed powder, the mixed powder is mixed with medium-temperature coal pitch, the mass percent of the mixed powder in the mixing process is 65%-85%, and the medium-temperature coal pitch is obtained; the mass percent of the medium-temperature coal pitch is 15%-35%; s3, mixing and kneading; s4, profiling is conducted; s5, roasting; and S6, processing. A hot-pressing cold-out one-time forming method is adopted, the obtained product is excellent in performance and shows good thermal shock resistance, ablation performance, leakage-proof performance and mechanical strength, and the preparation process has the advantages in the aspects of saving energy, protecting the environment, shortening the period and improving the aging efficiency.

Owner:吉林科工碳业有限公司

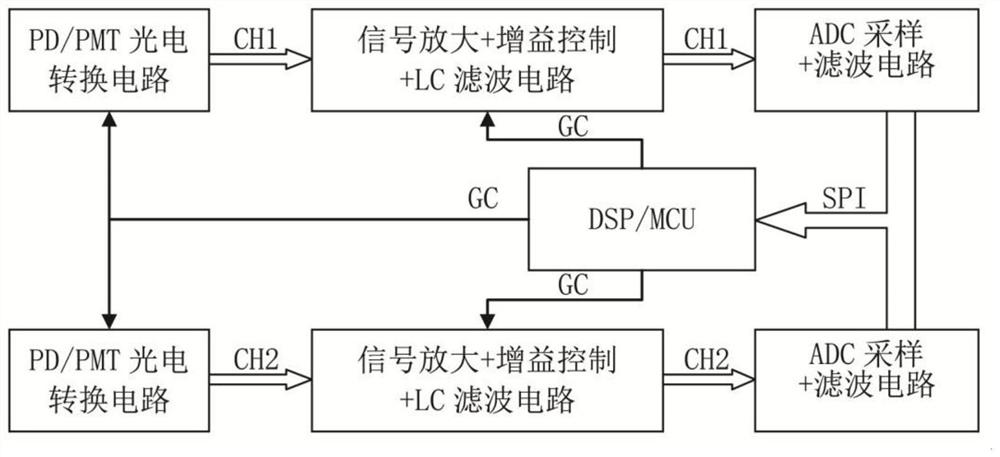

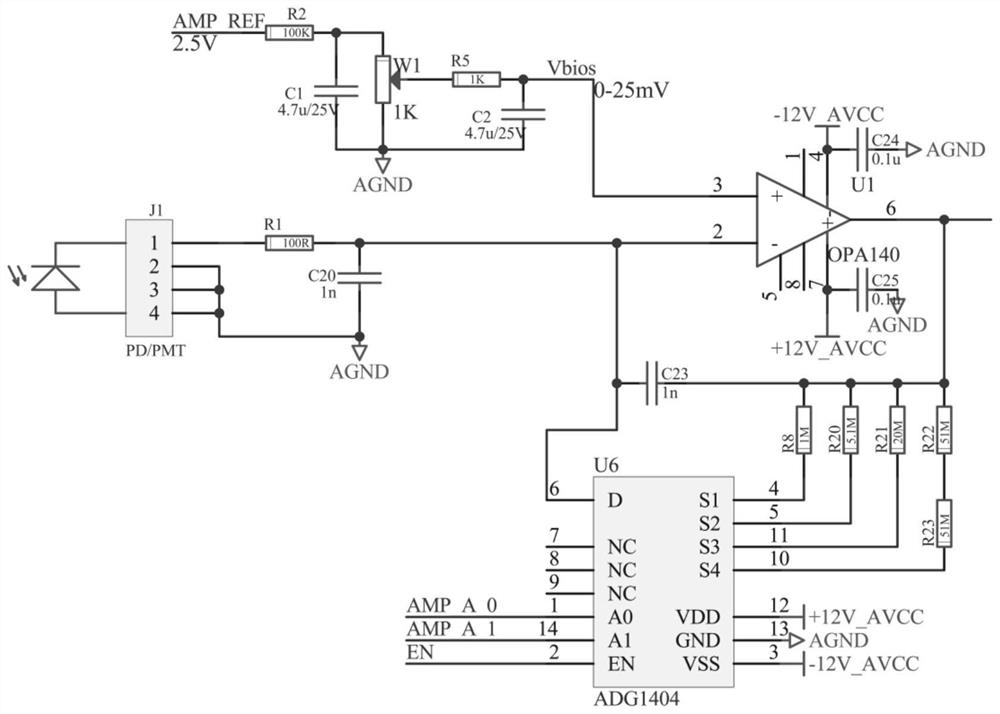

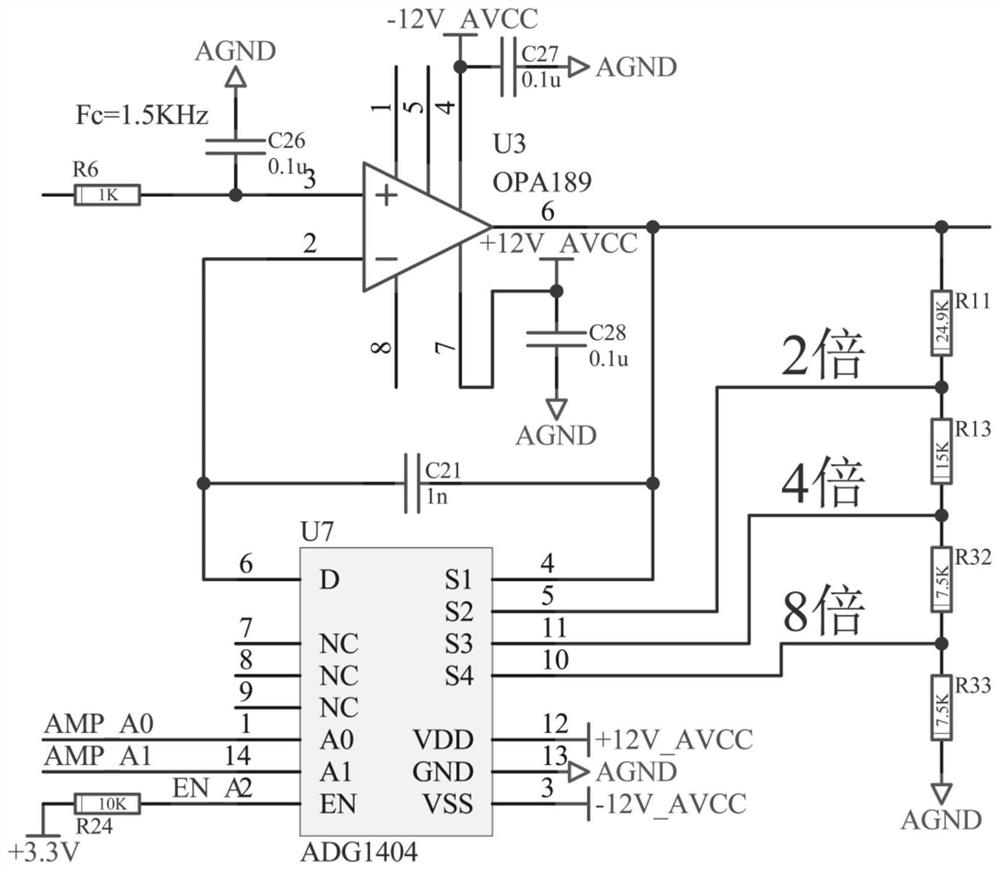

High-speed dual-channel synchronous optical signal sampling circuit

PendingCN113572473AZero driftSynchronous working frequencyAnalogue-digital convertersLow noiseDaisy chain

The invention discloses a high-speed dual-channel synchronous optical signal sampling circuit, which comprises a control unit, and is characterized in that the control unit comprises two groups of photoelectric conversion circuits, two groups of gain control amplification circuits and two groups of ADC sampling circuits. According to the invention, the latest 24-bit ADC sampling chip integrated with three filtering functions at present is adopted; the operational amplifier is high in broadband, ultralow in noise and zero in drift; the two ADC sampling chips use the same system clock and keep synchronous working frequency; the same REF reference voltage is used; the sampling circuit has a two-stage gain control function and a low-pass filtering function; a serial daisy chain mode of an ADC chip and a PIN port control mode are adopted, high-speed synchronous sampling and synchronous data output of two channels are achieved, instructions of a controller do not need to be received, and synchronous data are sent after automatic synchronous sampling.

Owner:上海天美科学仪器有限公司

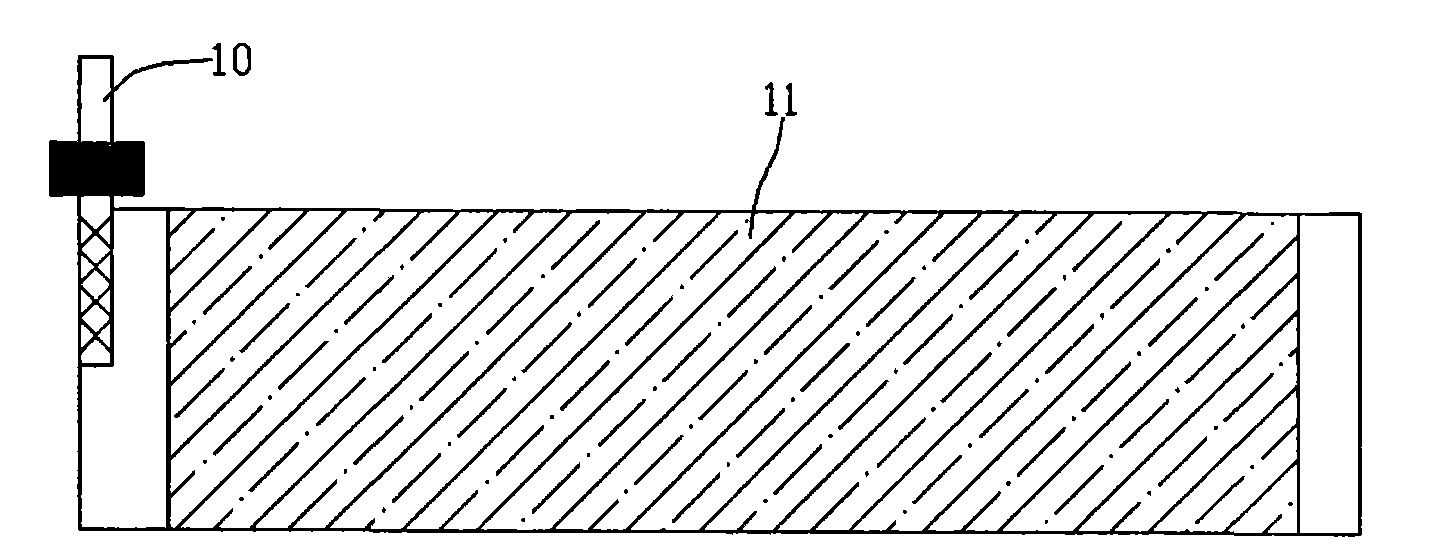

Ultrasonic cleaning line for axial diode

PendingCN108246715AAvoid damageImprove efficiencyCleaning using liquidsMegasonic cleaningSlide plate

The invention discloses an ultrasonic cleaning line for an axial diode. The ultrasonic cleaning line comprises a cleaning groove, a slide plate and an ultrasonic generator, wherein the slide plate isprovided with a through hole used for placing the diode, the slide rail arranged in the length direction of the cleaning groove is arranged in the cleaning groove, and the slide plate slides along theslide rail; and the ultrasonic generator is fixedly arranged, and emits an ultrasonic wave towards the bottom plate of the cleaning groove. The diode is placed on the slide plate, and the slide plateis enabled to move along the cleaning groove; equipment is capable of continuously carrying out cleaning working, high in cleaning speed, good in cleaning effect, small in damage to devices, low in product rejection rate, and capable of increasing the benefits of a production enterprise and improving the market competitiveness.

Owner:GUANGAN JIALE ELECTRONICS SCI & TECH

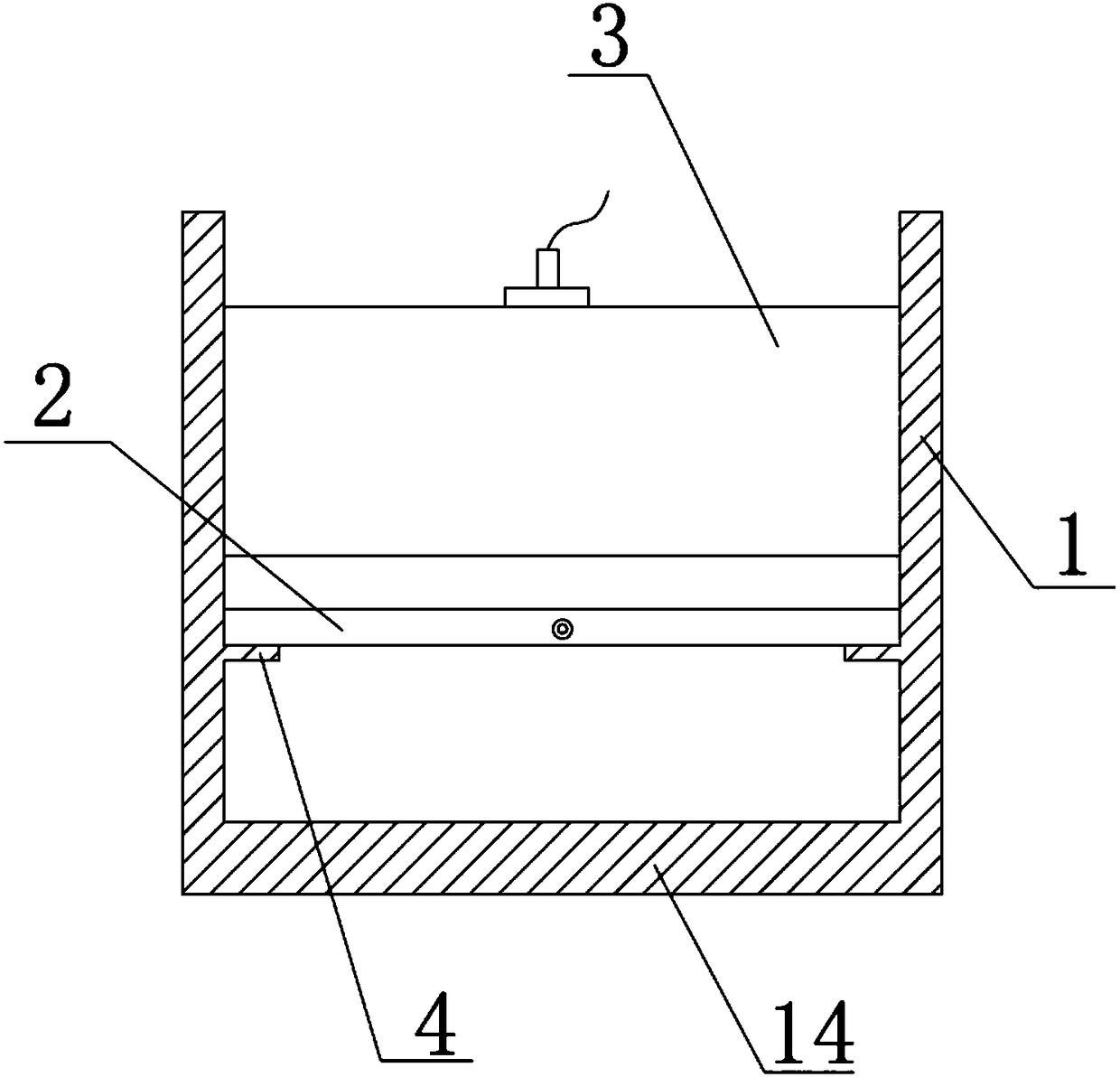

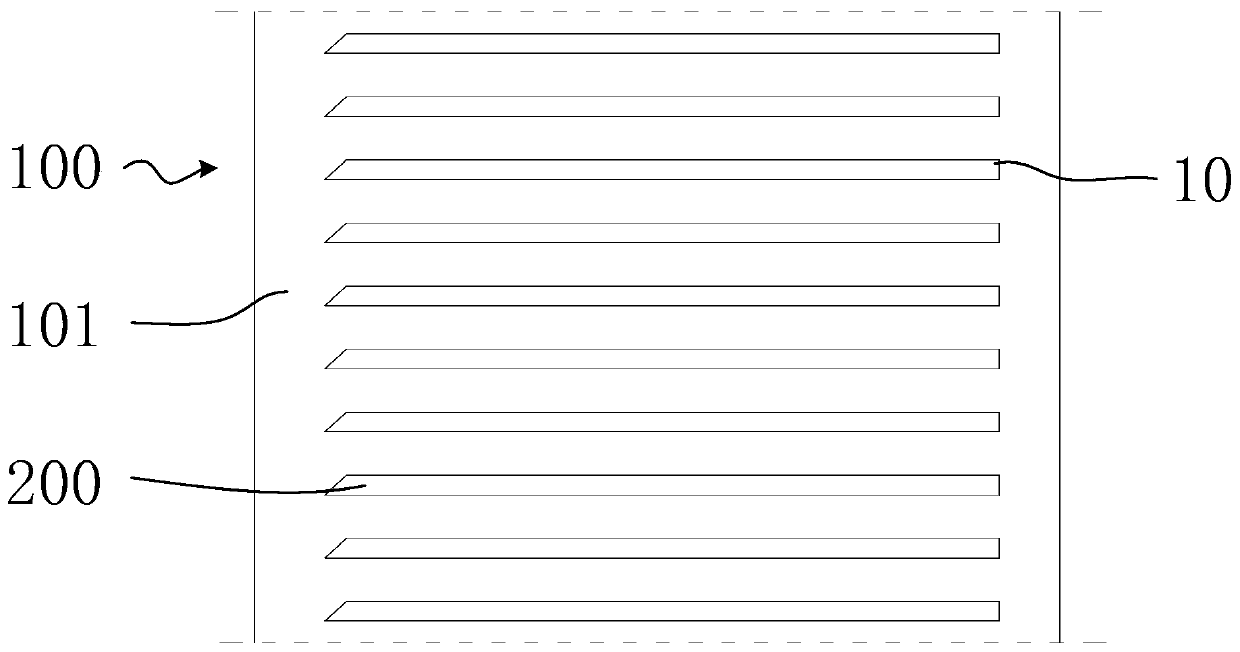

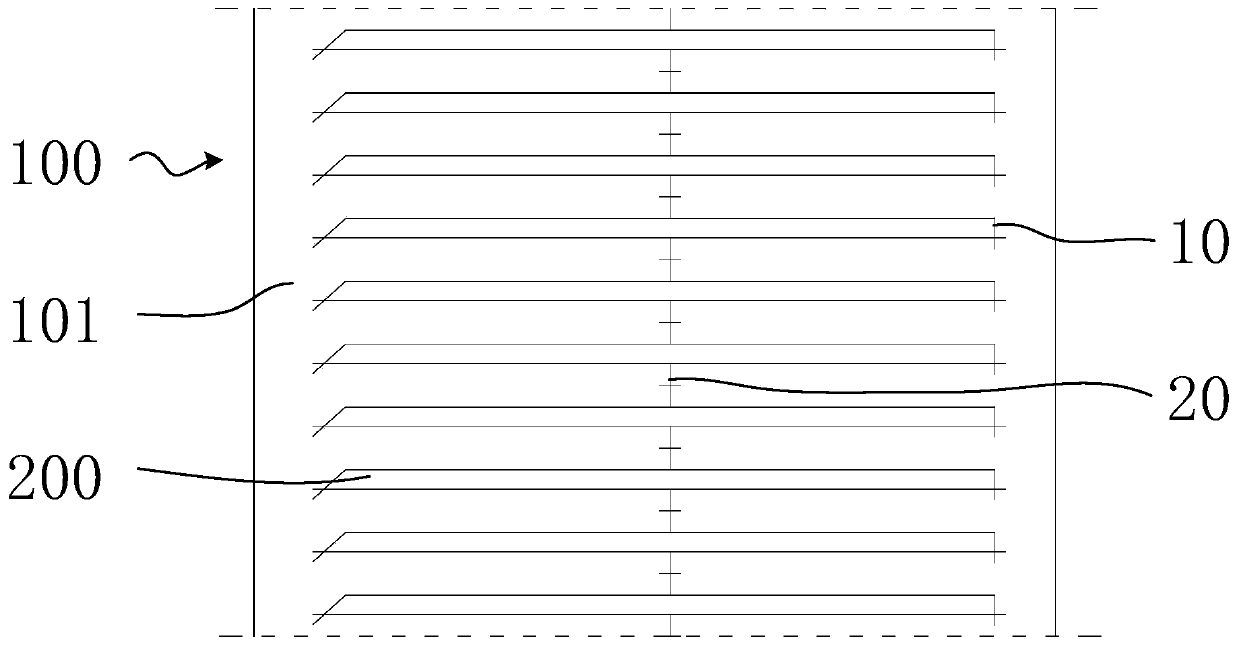

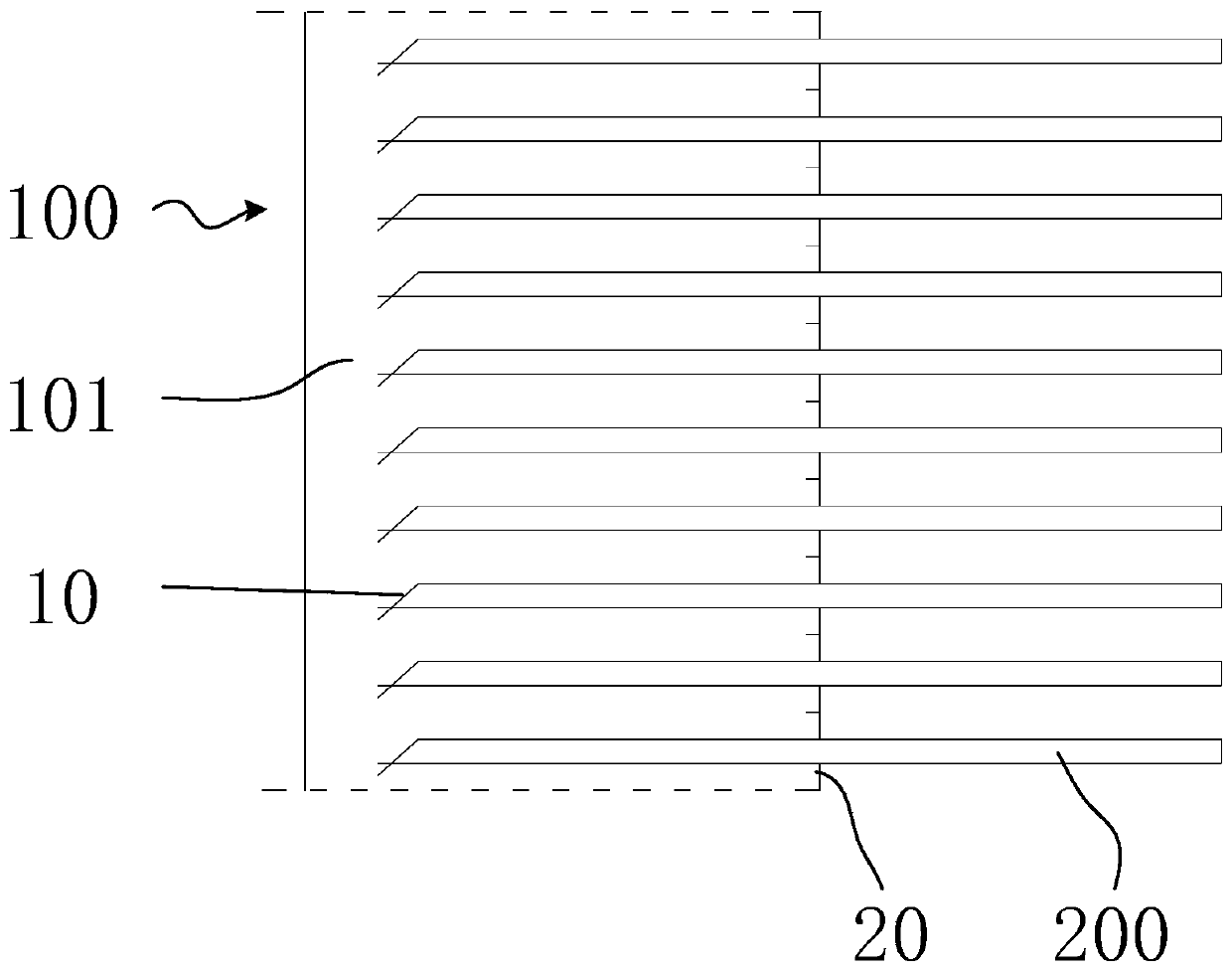

Sliding base specially used for BOPET (biaxially-oriented polyethylene terephthalate) sheet

ActiveCN102765191ADynamic sliding is stable and reliableReduce product scrap rateFlat articlesFailure ratePolyethylene terephthalate glycol

The invention discloses a sliding base specially used for a BOPET (biaxially-oriented polyethylene terephthalate) sheet, which comprises a left side plate, a right side plate, a guiding plate, an upper fixing plate, a front fixing plate, a rear fixing plate, a adjusting screw rods, a lower sliding rail, an upper sliding rail, an oil receiving disc, a positioning disc and a clamp guiding rail. The left side plate and the right side plate are respectively provided with a rolling shaft; the guiding plate is arranged in the middle of the rolling shafts; the upper fixing plate, the front fixing plate and the rear fixing plate are used for fixing the left side plate and the right side plate; the adjusting screw rods are arranged in the centers of both the front fixing plate and the rear fixing plate; the lower sliding rail is arranged on the upper fixing plate; the upper sliding rail is arranged on the lower sliding rail; the oil receiving disc is arranged on the upper sliding rail; the positioning disc is fixed on the oil receiving disc; the positioning shaft is fixed on the positioning disc; and the clamp guiding rail is fixed on the positioning shaft and the positioning disc through a pressing disc. The overall longitudinal and latitudinal adjustment of the clamp guiding rail can be realized, and the latitudinal centering bidirectional adjustment can be realized. Because of the longitudinal and latitudinal precision guiding, the guiding rail can slide dynamically, stably and reliably. In addition, due to the arrangement of the oil receiving disc, the lubricating oil can be recycled. The sliding base has the characteristics of convenience of adjustment, simple structure and low failure rate and is easy to operate.

Owner:青岛欣煜升新材料有限公司

Die-cutting cutting die and die-cutting method

PendingCN110202643AImprove waste rateReduce product scrap rateMetal working apparatusScrapDischarge rate

The invention discloses a die-cutting cutting die and die-cutting method. The die-cutting cutting die comprises a product cutter and a waste discharge cutter, wherein the product cutter is used for forming product cutter lines on a material belt, so that sheet products are molded through a material belt material cut off by the multiple intersected product cutter lines in an enclosing way; and thewaste discharge cutter is used for forming waste discharge cutter lines on the material belt, and two ends of any one waste discharge cutter line are connected with adjacent product cutter lines for enclosing two sheet products, so that after the whole material belt is die-cut, the material belt is at least divided into two disconnected parts except for the parts of the sheet products. According to the die-cutting cutting die and the die-cutting method provided by the invention, after the whole material belt is die-cut, only product wastes on one side of the material belt need to be discharged, and then product wastes on the other side are discharged, so that sheet products without wastes can be obtained. The waste discharge rate is improved, and the product rejection rate is reduced.

Owner:SUZHOU JINHE NEW MATERIAL

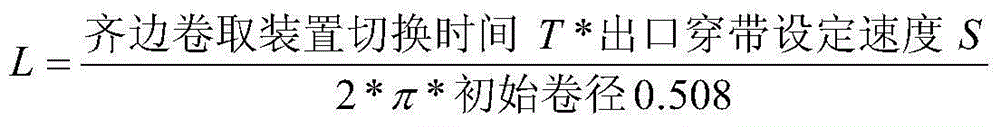

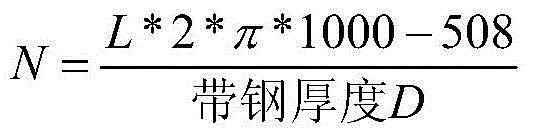

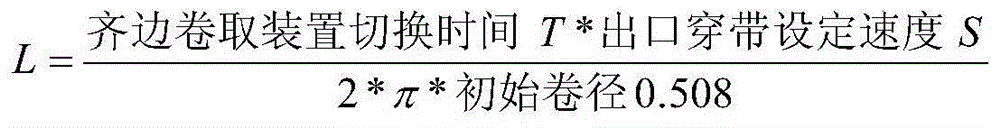

Method for inhibiting continuous hot-dip galvanizing and aluminizing unit coiling overflow edge

The invention relates to an inhibition method for continuous hot-dip galvanizing and aluminizing unit coiling overflow edge. The inhibition method for the continuous hot-dip galvanizing and aluminizing unit coiling overflow edge is aimed to solve the problem that an existing hot-dip galvanizing and aluminizing unit has serious product defects in a coiling overflow situation. The inhibition method for the continuous hot-dip galvanizing and aluminizing unit coiling overflow edge includes that firstly, an outlet section controller reads the switch time of a trimming coiling device from an alignment mode to an automatic mode, a set threading speed at the outlet section and strip steel thickness and calculates the running length of the strip steel during a non-control state period and the winded circle number of the strip steel on the coiling machine under the non-control state; secondly, the outlet section controller reads the roller diameter of a NO.9 tension roller, the sampling value of a coder, a gear ratio and a system sampling time, calculates the accumulated running distance of the head of the strip steel at the outlet section in the threading process and sets conditions for controlling actions of a trimming coiling device detection unit; finally, when the ratio of the tension detection value to the set value is higher than a preset ratio, the trimming coiling device is controlled to switch to the automatic mode. The inhibition method for the continuous hot-dip galvanizing and aluminizing unit coiling overflow edge is suitable for industrial automatic control.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com