Full-automatic vacuum molding control system and method

A technology of vacuum injection molding and control system, which is applied in the field of automatic vacuum injection molding control system and method, and can solve problems such as difficult product quality assurance, low production efficiency, and adjustment of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

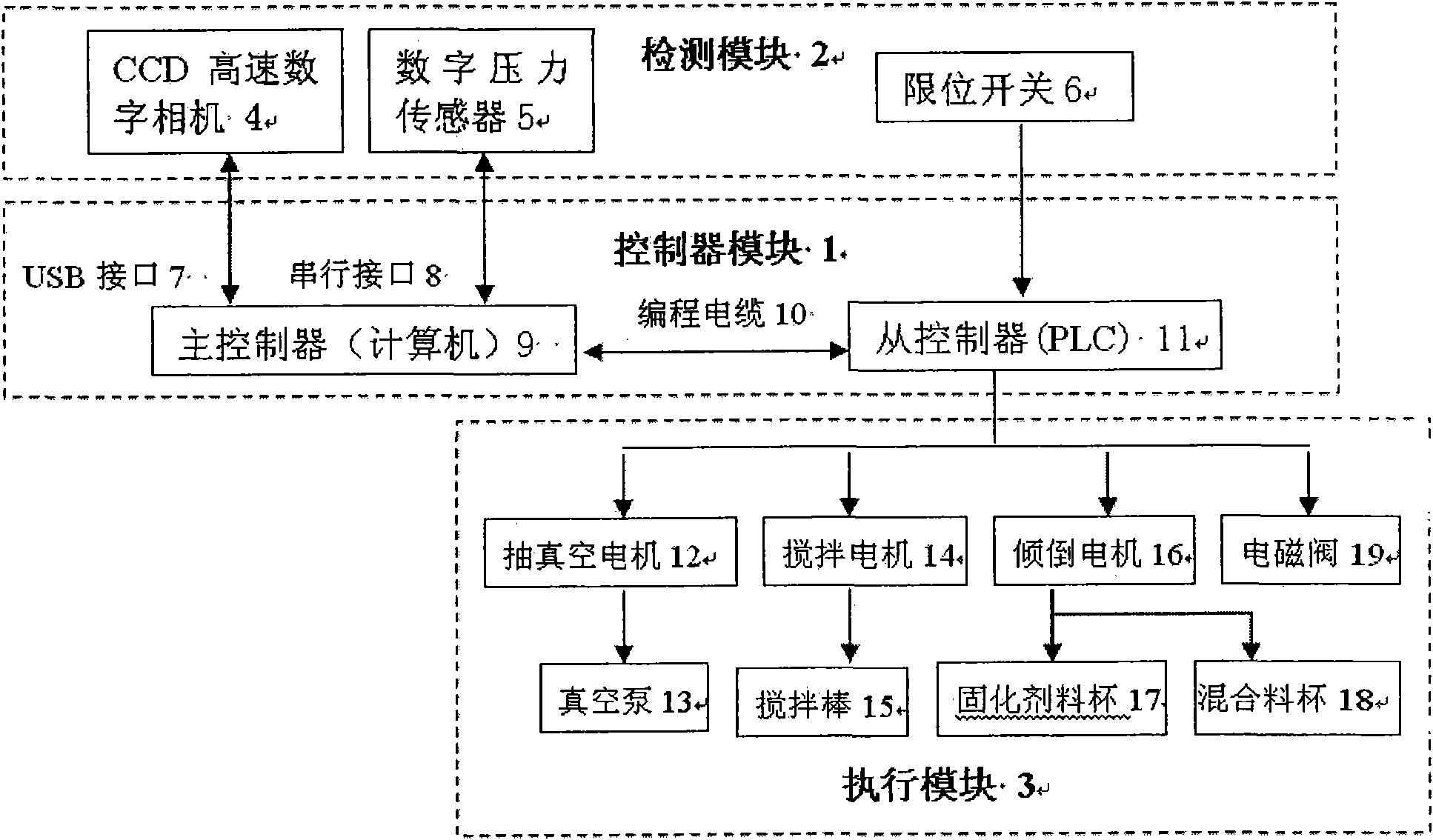

[0094] join figure 1 , the automatic vacuum injection control system is composed of a controller module, a detection module and an execution module, the controller module is connected to the detection module and the execution module, and it is characterized in that: the controller module consists of a The main controller is connected with a slave controller; the detection module is composed of a CCD high-speed digital camera, a digital pressure sensor and four limit switches; the execution module is composed of a vacuum motor connected with a vacuum pump, a stirring motor connected A stirring rod, two pouring motors are respectively connected with a curing agent cup and a mixing cup, and an electromagnetic valve; in the controller module, the main controller is a computer, and the slave controller is a programmable logic controller, which can The programming logic controller is connected to the computer through the SC-09 programming cable; the limit switch in the detection mod...

Embodiment 2

[0096] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0097] This embodiment takes the preparation of a thin-walled transparent plastic part (20g) with a complex cavity as an example, and introduces the specific implementation process of the automatic vacuum injection molding control system in detail with reference to the accompanying drawings.

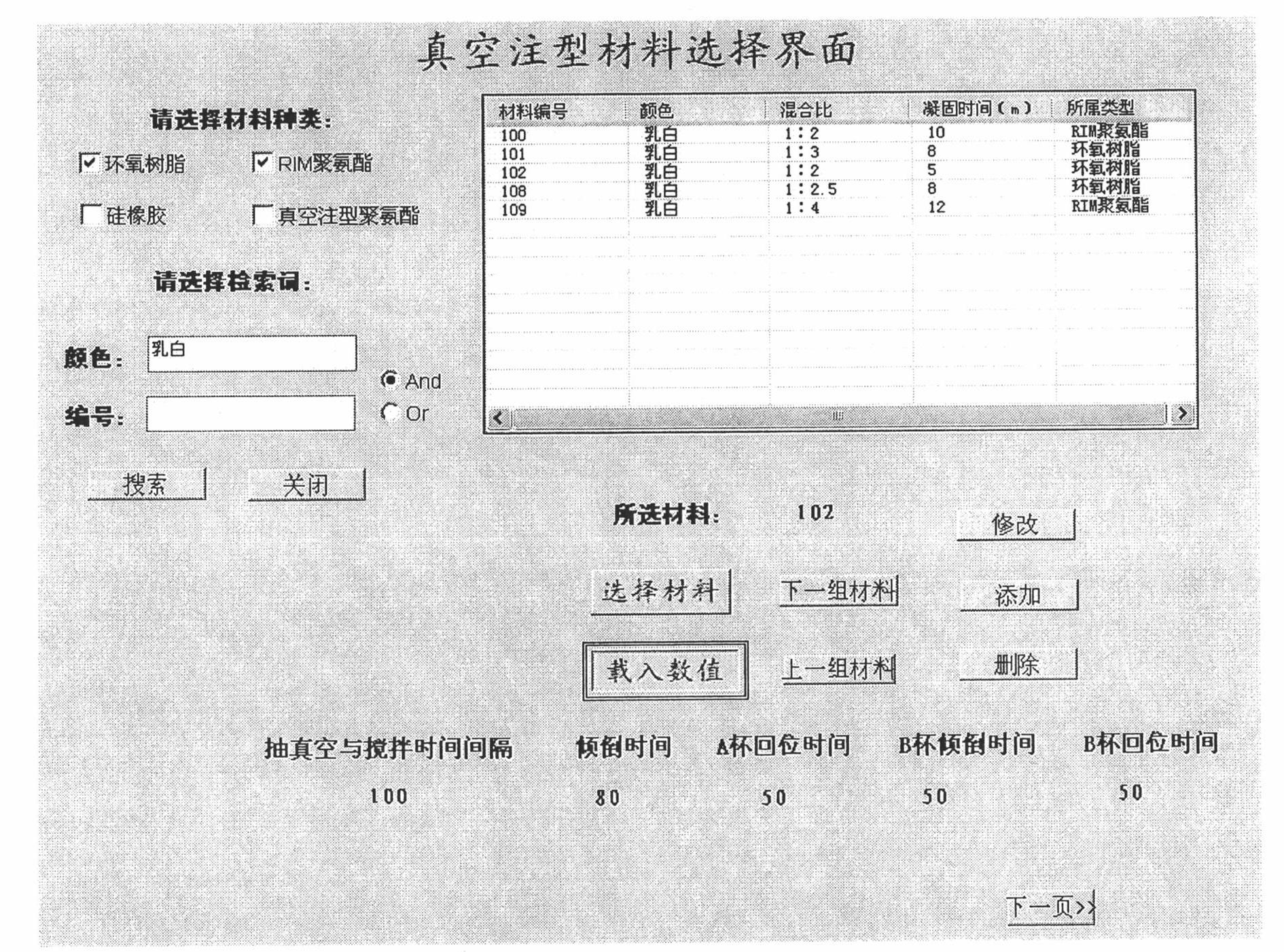

[0098] 1. Connect the camera to the computer via a USB data cable, and turn on the dedicated light source controller. Adjust the shooting angle of the camera so that the liquid level of the mixing cup is fully displayed in the monitoring window, and adjust the focal length of the lens according to the height of the liquid level of the mixing cup to make the image of the liquid surface clearest. Considering that the liquid surface is in motion, the maximum linear velocity is 0.18m / s. Set the maximum exposure time of the camera to 0.0001s. Due to the dark light in the vacuum chamber, t...

Embodiment 3

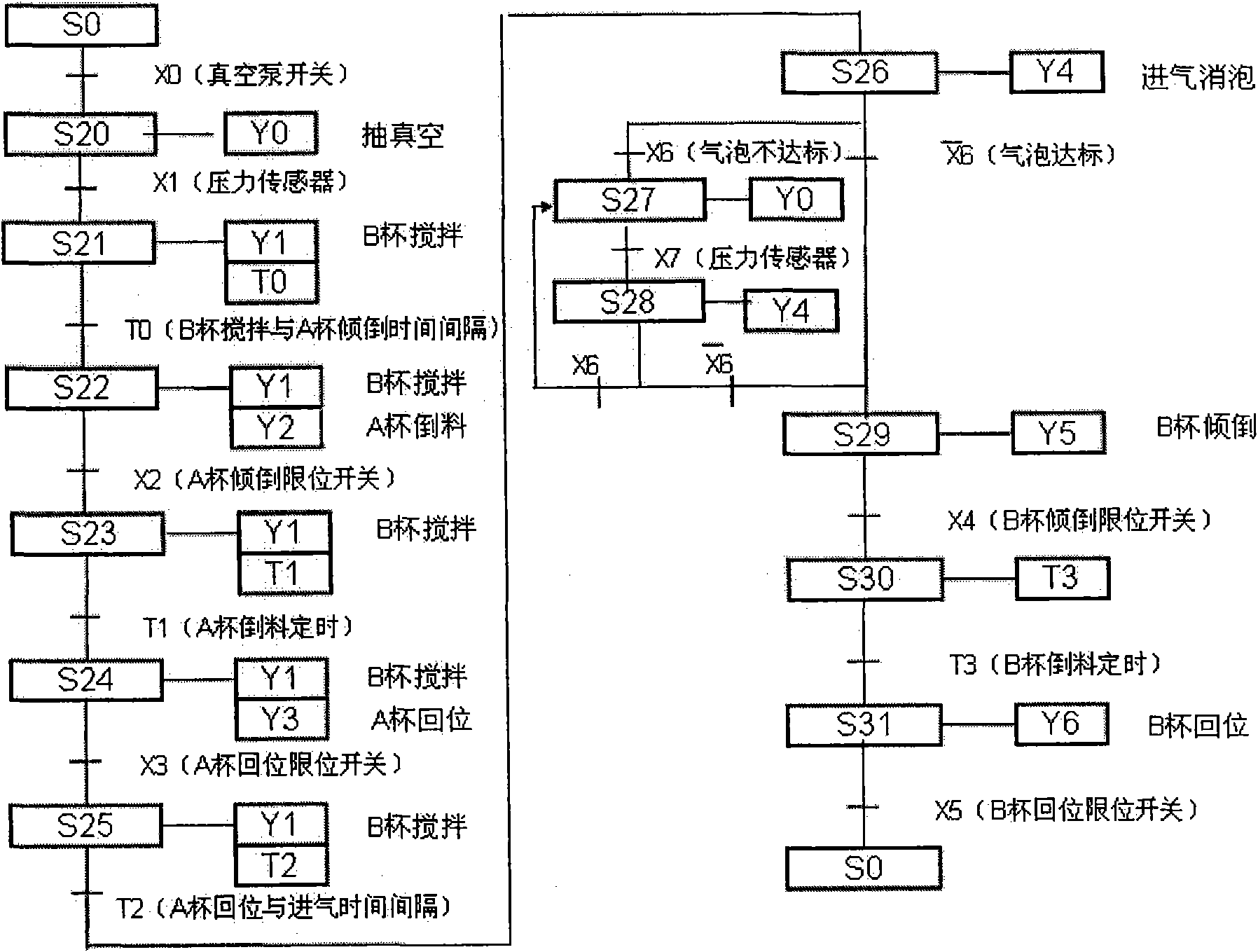

[0112] In this fully automatic vacuum injection molding control method, the control system described in Embodiment 1 is used for vacuum injection molding, and the specific control steps are as follows:

[0113] (1) When the vacuum pump switch X0 is pressed, the vacuum motor (Y0) is started to drive the vacuum pump to start pumping;

[0114] (2) The digital pressure sensor detects the pressure of the vacuum chamber in real time and transmits it to the pressure variable in the configuration through the serial port communication. When the pressure value reaches the set value, the vacuum stop condition associated with the pressure variable is satisfied (that is, X1 is closed). Start the stirring motor (Y1) at the right time to drive the stirring rod to mix and stir the materials in the mixing cup (B cup), and at the same time, the time interval timer (T0) for stirring and pouring the curing agent starts timing;

[0115] (3) When the time interval between stirring and curing agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com