Spraying-facilitating mineral enhanced PA66 material and preparation method thereof

A PA66, mineral technology, applied in the field of PA66 materials, can solve the problems of improving product scrap rate, high scrap rate, complicated output, etc., to reduce production scrap rate, improve surface adhesion, and improve productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

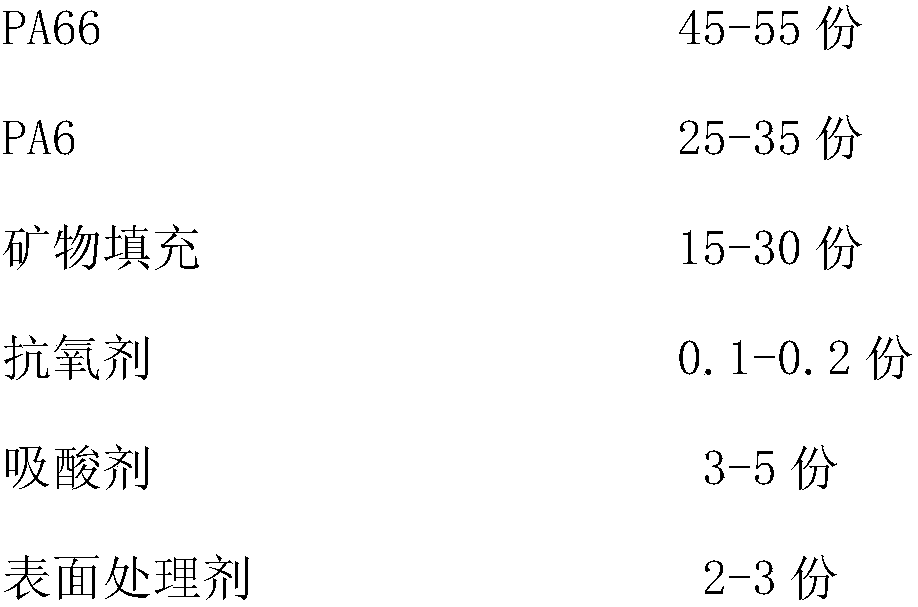

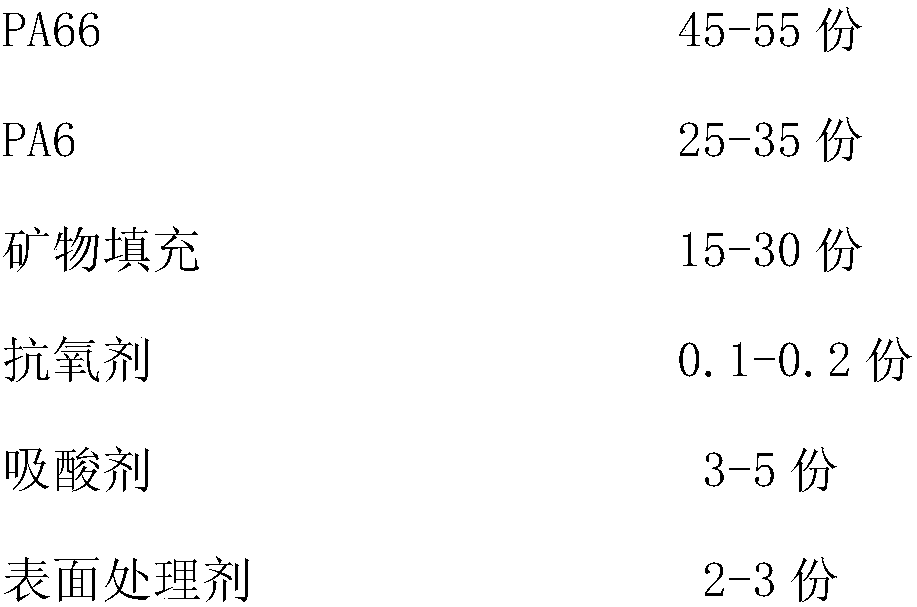

Method used

Image

Examples

Embodiment 1

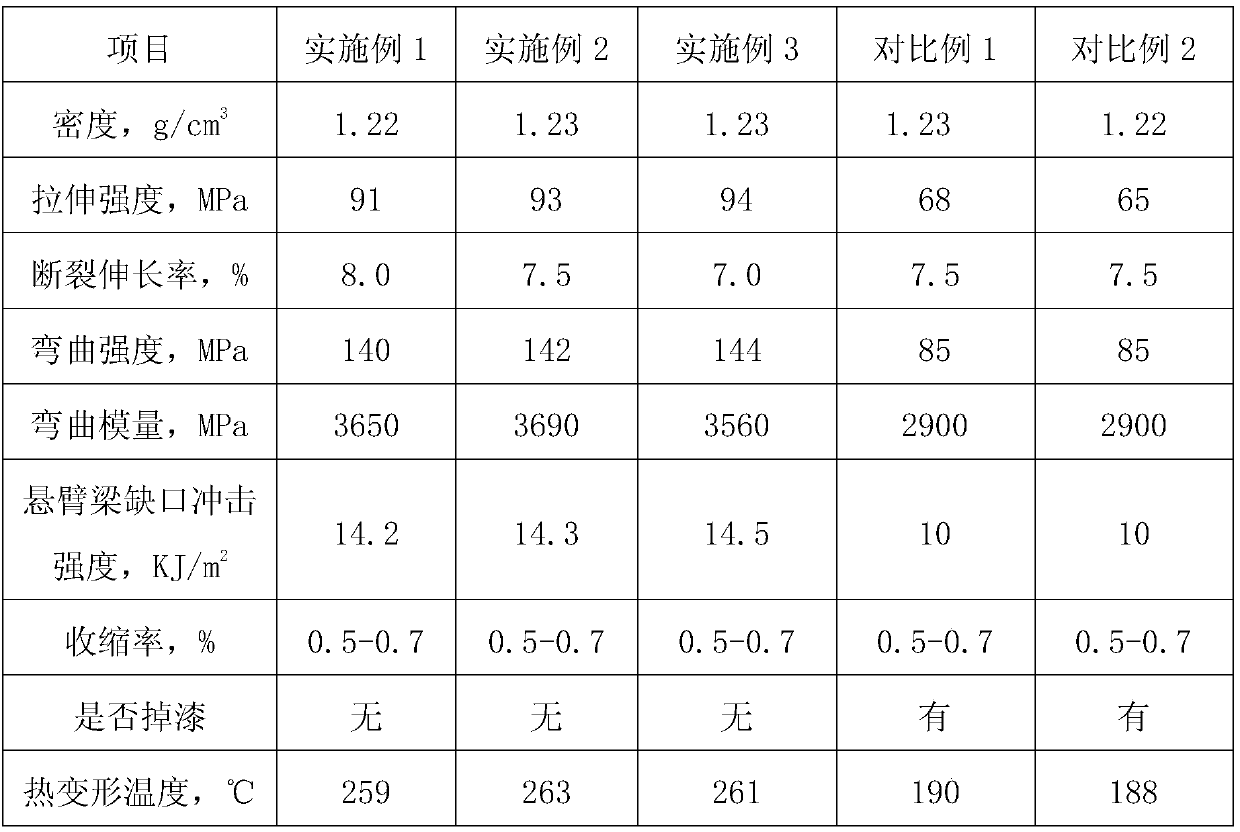

[0022] Get PA66 slices (6010A, Yuyao Guanghui Nylon Technology Co., Ltd.) 55KG, PA6 slices (YH800, Shanghai Xiwei New Material Co., Ltd.) Bao) 60g, acid absorbing agent (magnesium oxide) 3KG, surface treatment agent (PVA1788, Zhengzhou Yuteng Chemical Products Co., Ltd.) 2KG, add in the high-speed mixer and stir to disperse evenly, discharge, add it in the twin-screw extruder Melt blending, extruding, granulating, and drying to obtain flame-retardant pellets. The samples were injected by an injection molding machine, and the mechanical properties were tested. After washing with water, the surface adhesion effect was tested. The results are shown in Table 1.

Embodiment 2

[0024] Get PA66 slices (6010A, Yuyao Guanghui Nylon Technology Co., Ltd.) 50KG, PA6 slices (YH800, Shanghai Xiwei New Material Co., Ltd.) Bao) 60g, acid absorbing agent (magnesium oxide) 2KG, surface treatment agent (PVA1788, Zhengzhou Yuteng Chemical Products Co., Ltd.) 3KG, add in the high-speed mixer and stir to disperse evenly, discharge, add it in the twin-screw extruder Melt blending, extruding, granulating, and drying to obtain flame-retardant pellets. The samples were injected by an injection molding machine, and the mechanical properties were tested. After washing with water, the surface adhesion effect was tested. The results are shown in Table 1.

Embodiment 3

[0026] Get PA66 slices (6010A, Yuyao Guanghui Nylon Technology Co., Ltd.) 50KG, PA6 slices (YH800, Shanghai Xiwei New Material Co., Ltd.) Bao) 60g, acid absorbing agent (magnesium oxide) 3KG, surface treatment agent (PVA1788, Zhengzhou Yuteng Chemical Products Co., Ltd.) 2KG, add in the high-speed mixer and stir to disperse evenly, discharge, add it in the twin-screw extruder Melt blending, extruding, granulating, and drying to obtain flame-retardant pellets. The samples were injected by an injection molding machine, and the mechanical properties were tested. After washing with water, the surface adhesion effect was tested. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com