Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce production scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

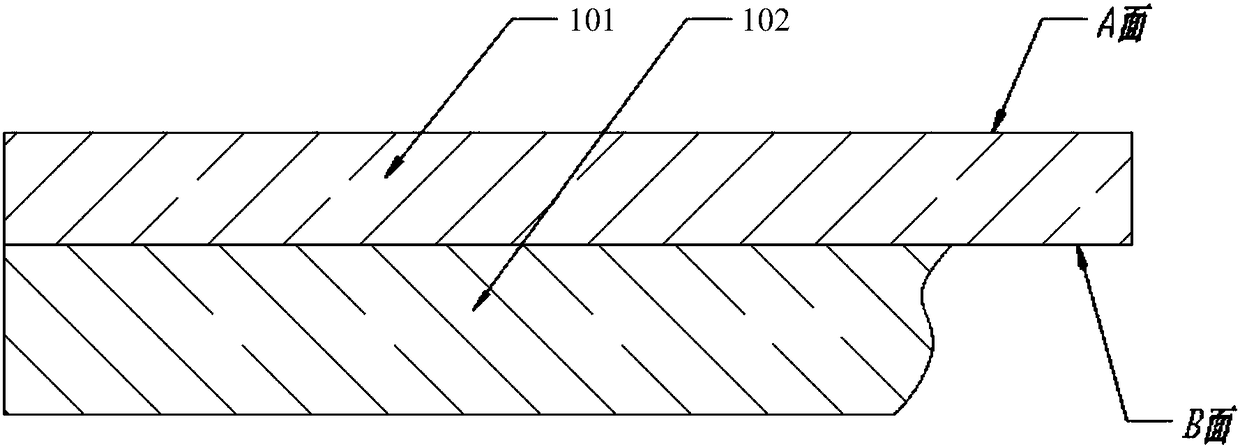

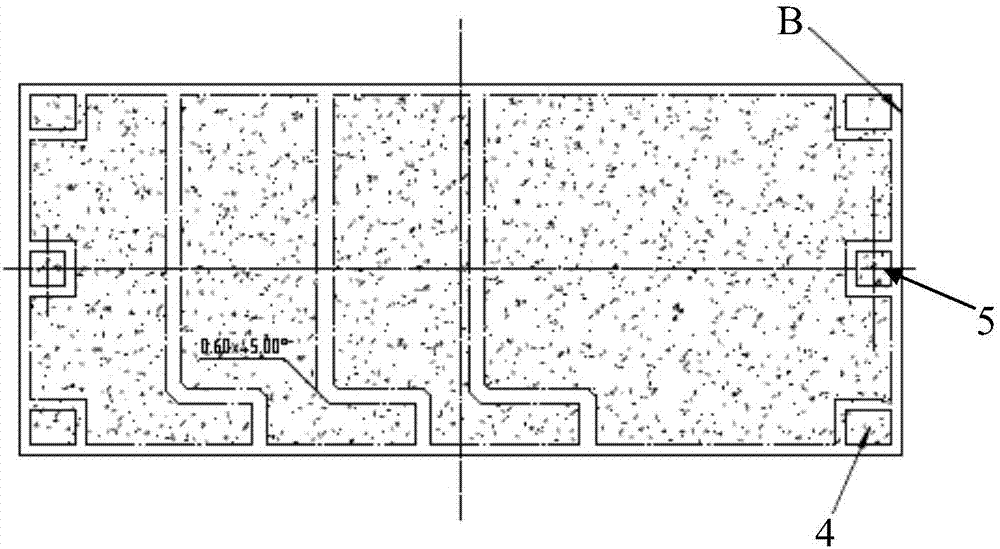

Process for protecting goldfinger and bonding pad in rigid-flex printed circuit board

InactiveCN105246263AReduce production scrap rateImprove qualityConductive pattern reinforcementNon-metallic protective coating applicationSurface finishingPrinted circuit board

The invention discloses a process for protecting a goldfinger and a bonding pad in a rigid-flex printed circuit board. The process comprises the following steps of S1, respectively carrying out board cutting; S2, carrying out a front procedure; S3, coating the surface of a flexible board with a cover film and carrying out first rapid lamination; S4, coating the goldfinger and the bonding pad of the flexible board with a high-temperature resistant adhesive tape, and carrying out second rapid lamination; S5, carrying out brownification on a copper surface of the flexible board, carrying out lamination on the flexible board, a prepreg and a rigid board, and milling an appearance; S6, removing the high-temperature resistant adhesive tape, and carrying out nickel and gold deposition treatment on a goldfinger region and a bonding pad region which are exposed; and S7, carrying out a post procedure. By coating the high-temperature resistant adhesive tape, the problem that glue residue is remained on the prepreg on the goldfinger region and the bonding region, or the goldfinger and the bonding pad are polluted by other impurities during the lamination process and are difficult to clean is solved, normal surface treatment can be carried out on the goldfinger and the bonding pad after the high-temperature resistant adhesive tape is removed, no glue residue is remained, the production rejection rate is reduced, the product quality is improved, and the production cost is saved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

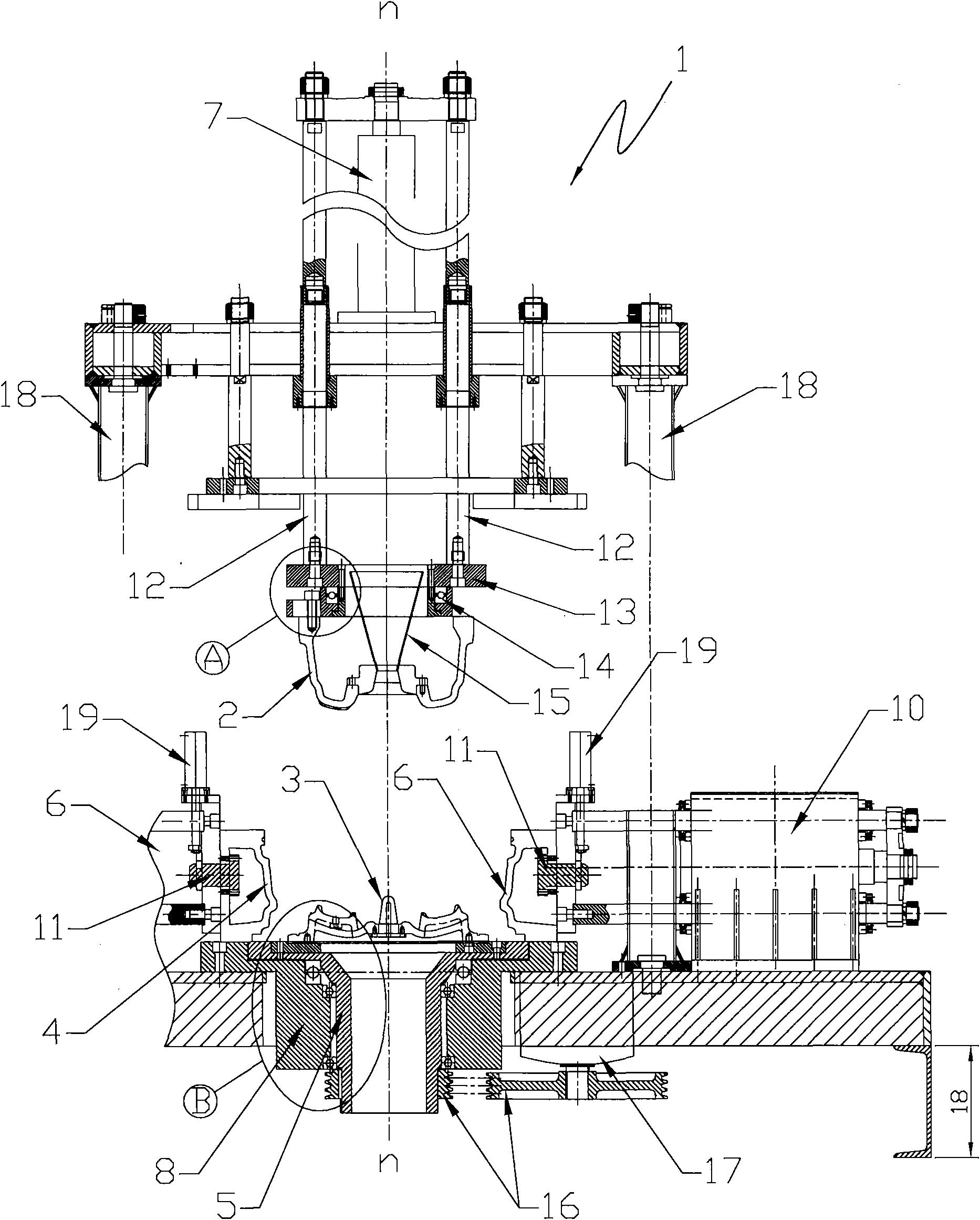

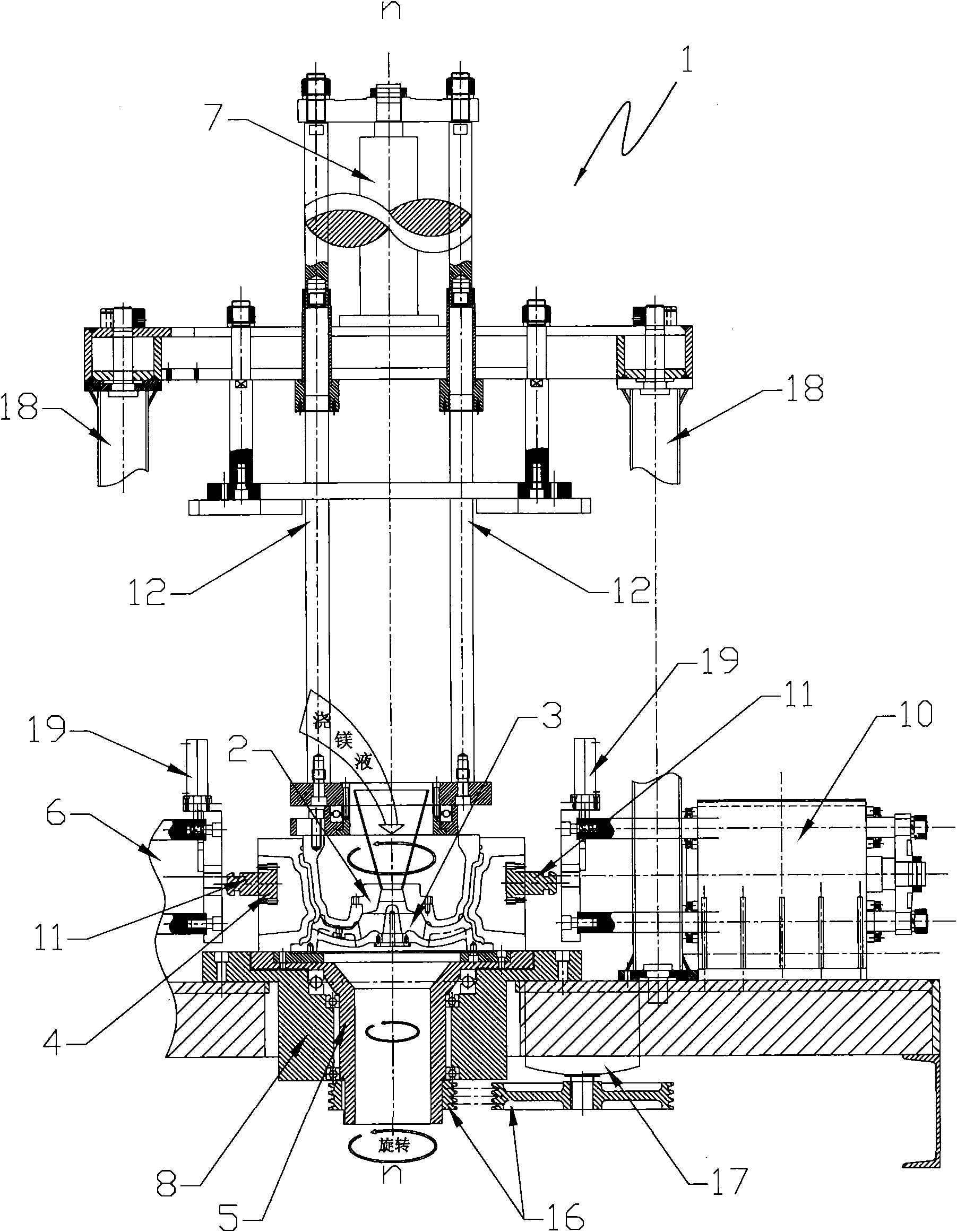

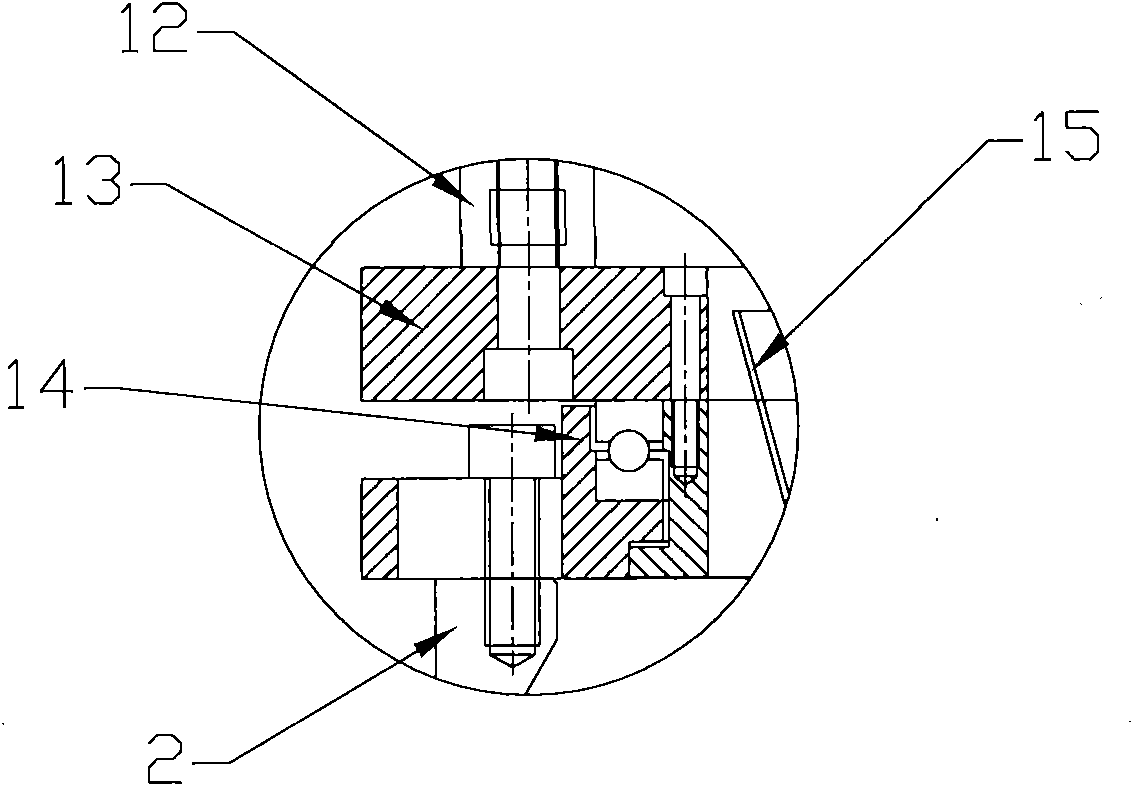

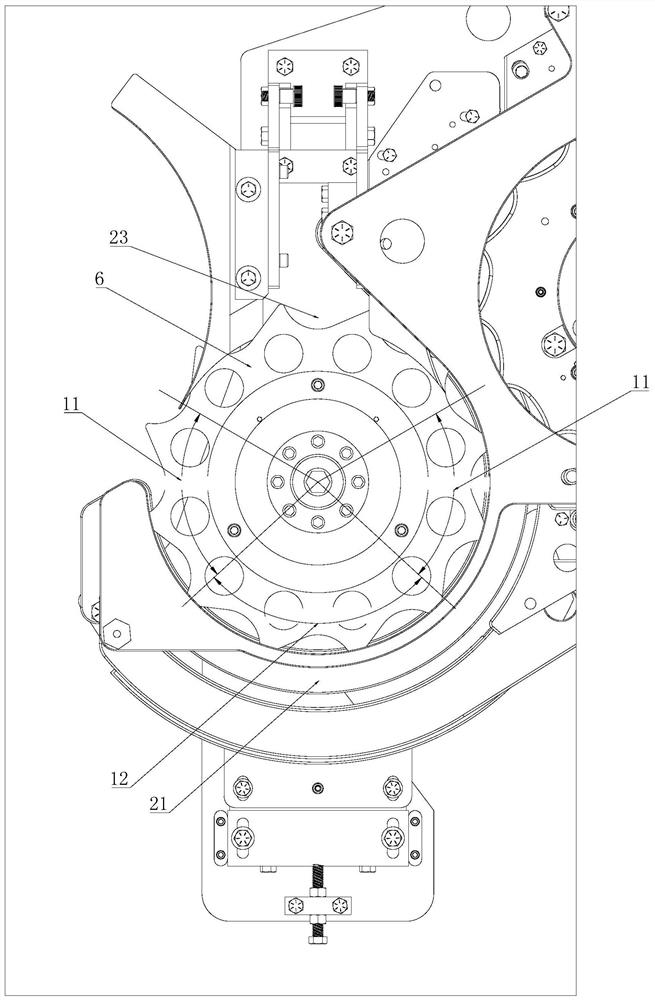

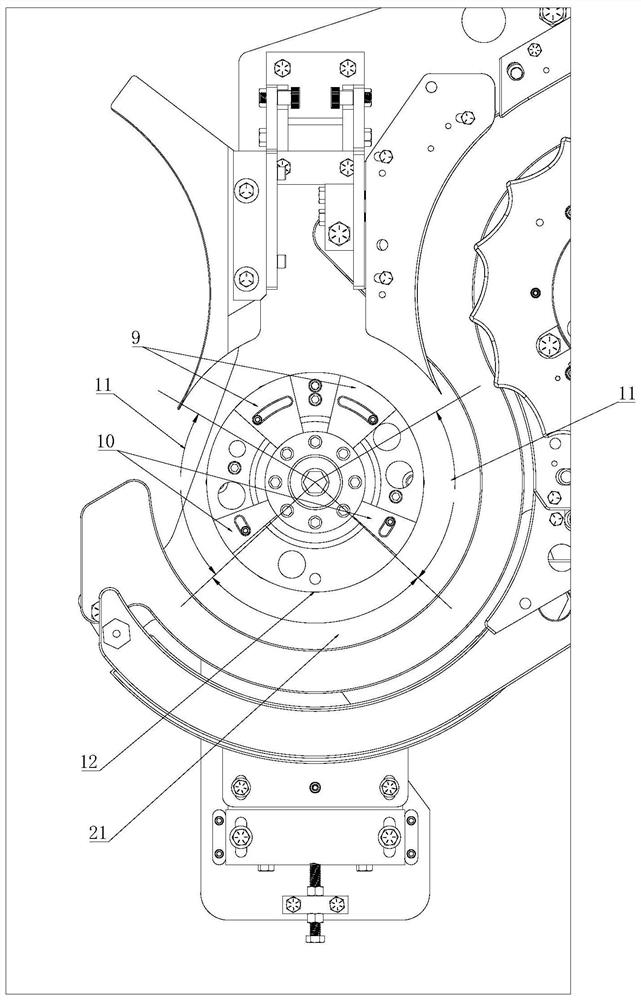

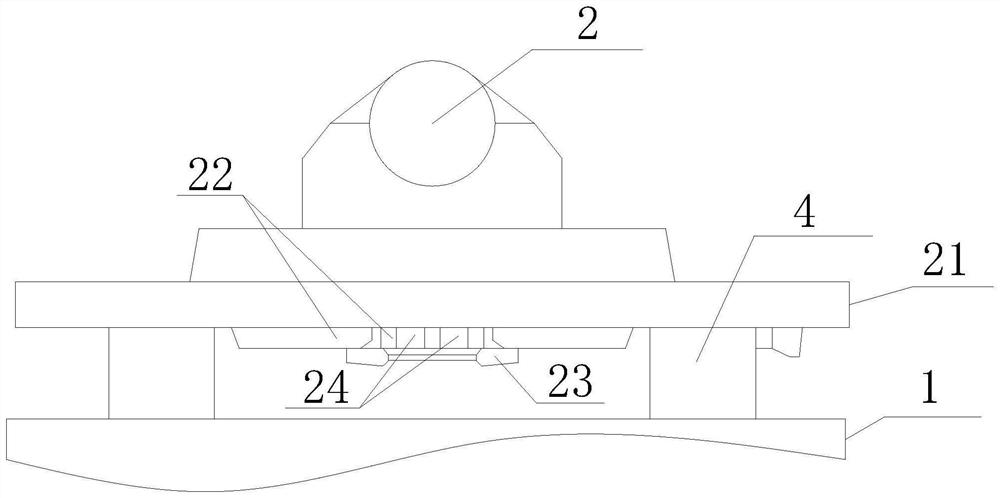

Centrifugal casting method and device of magnesium alloy hub

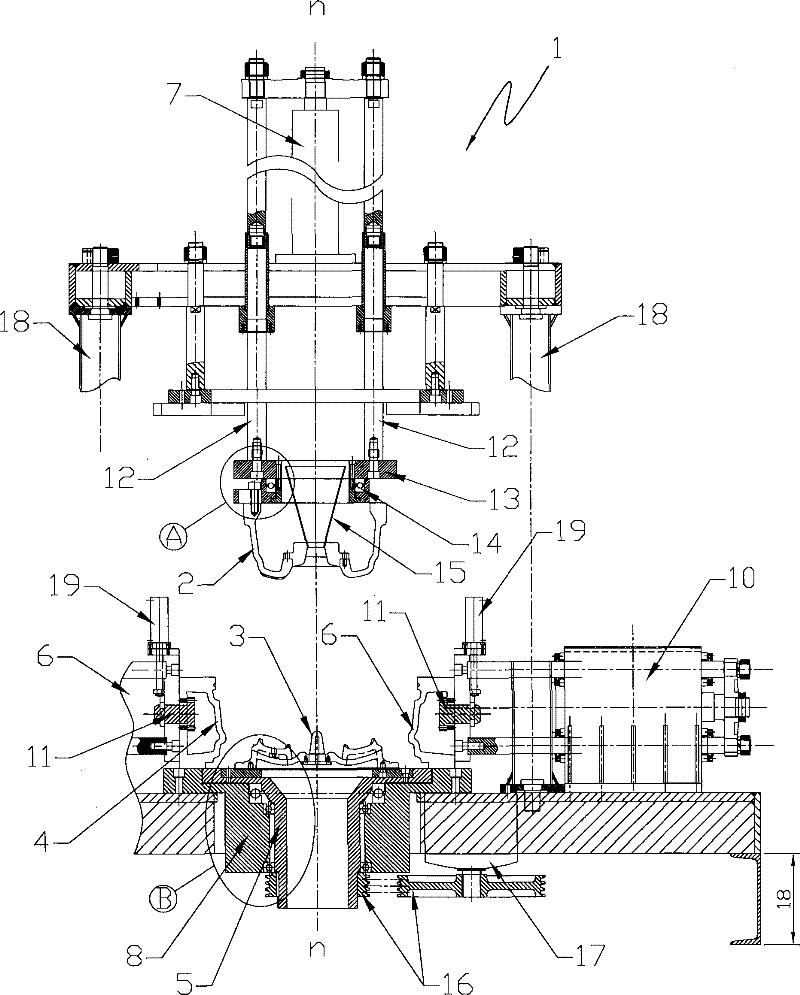

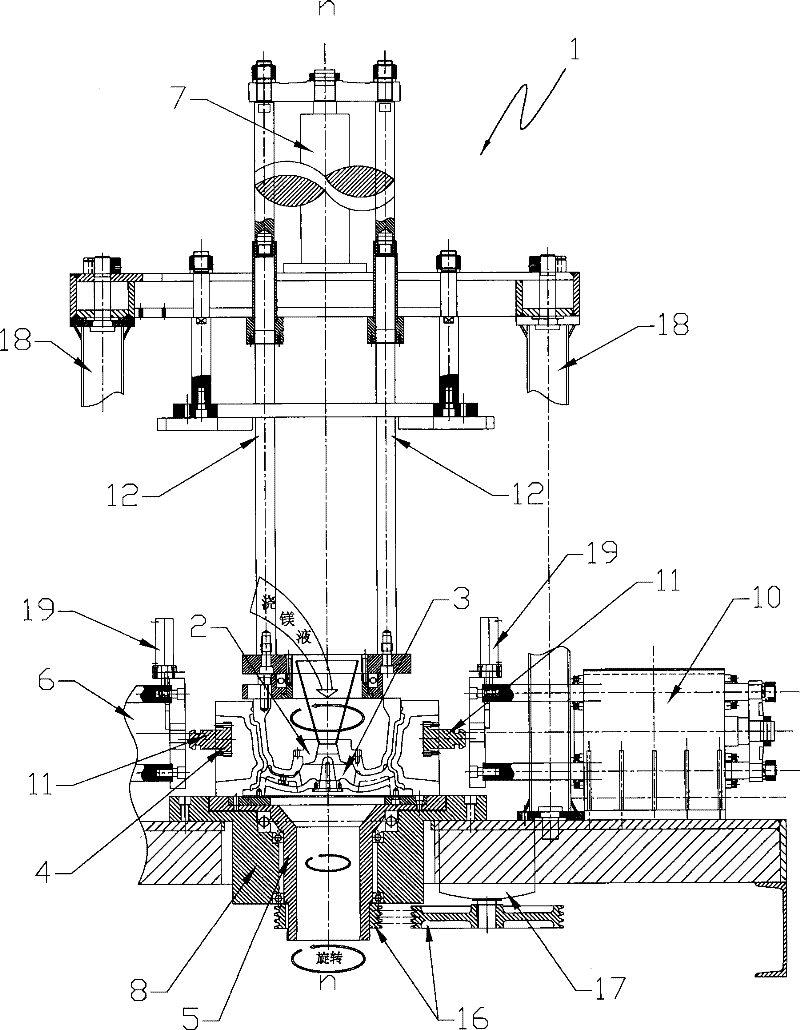

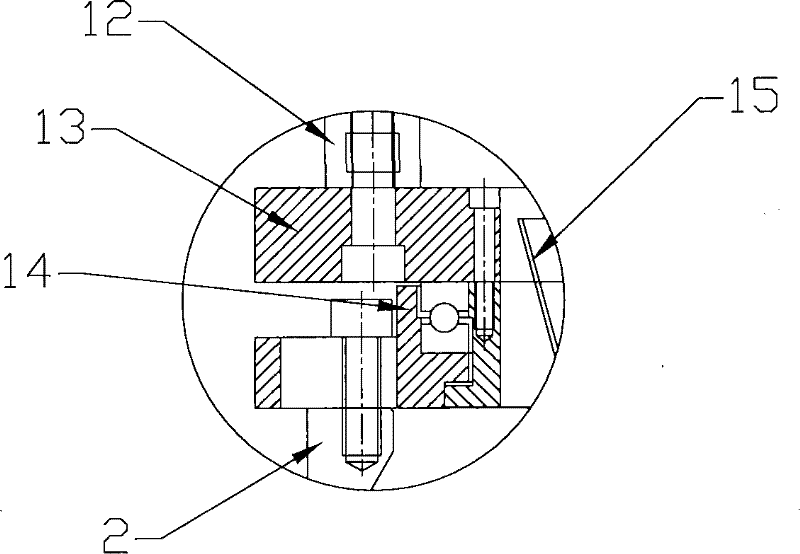

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die and a lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

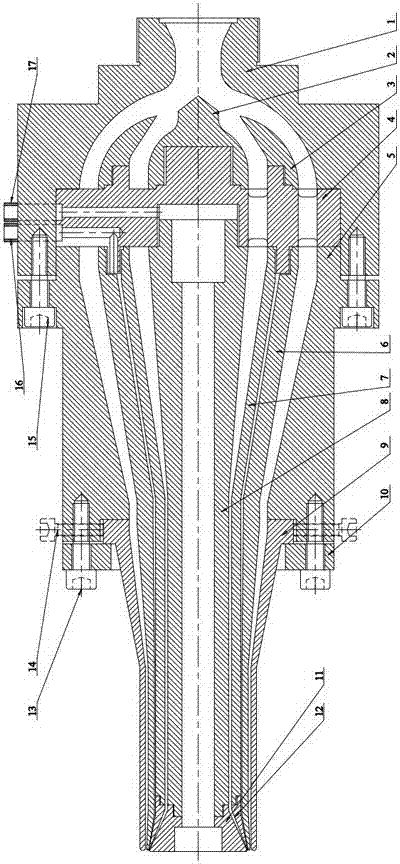

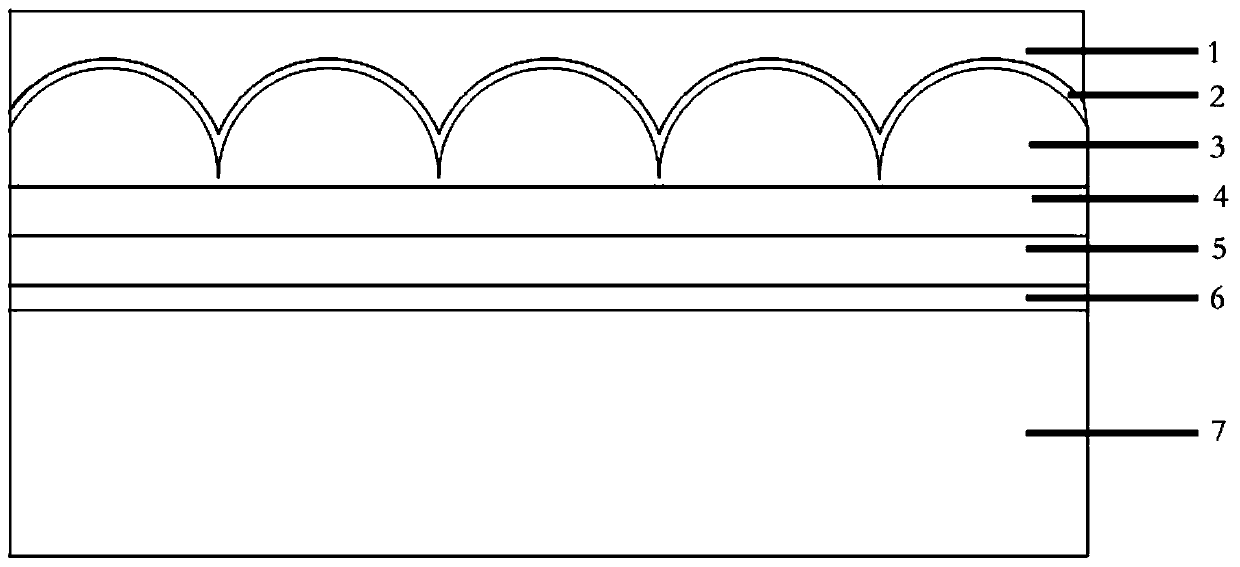

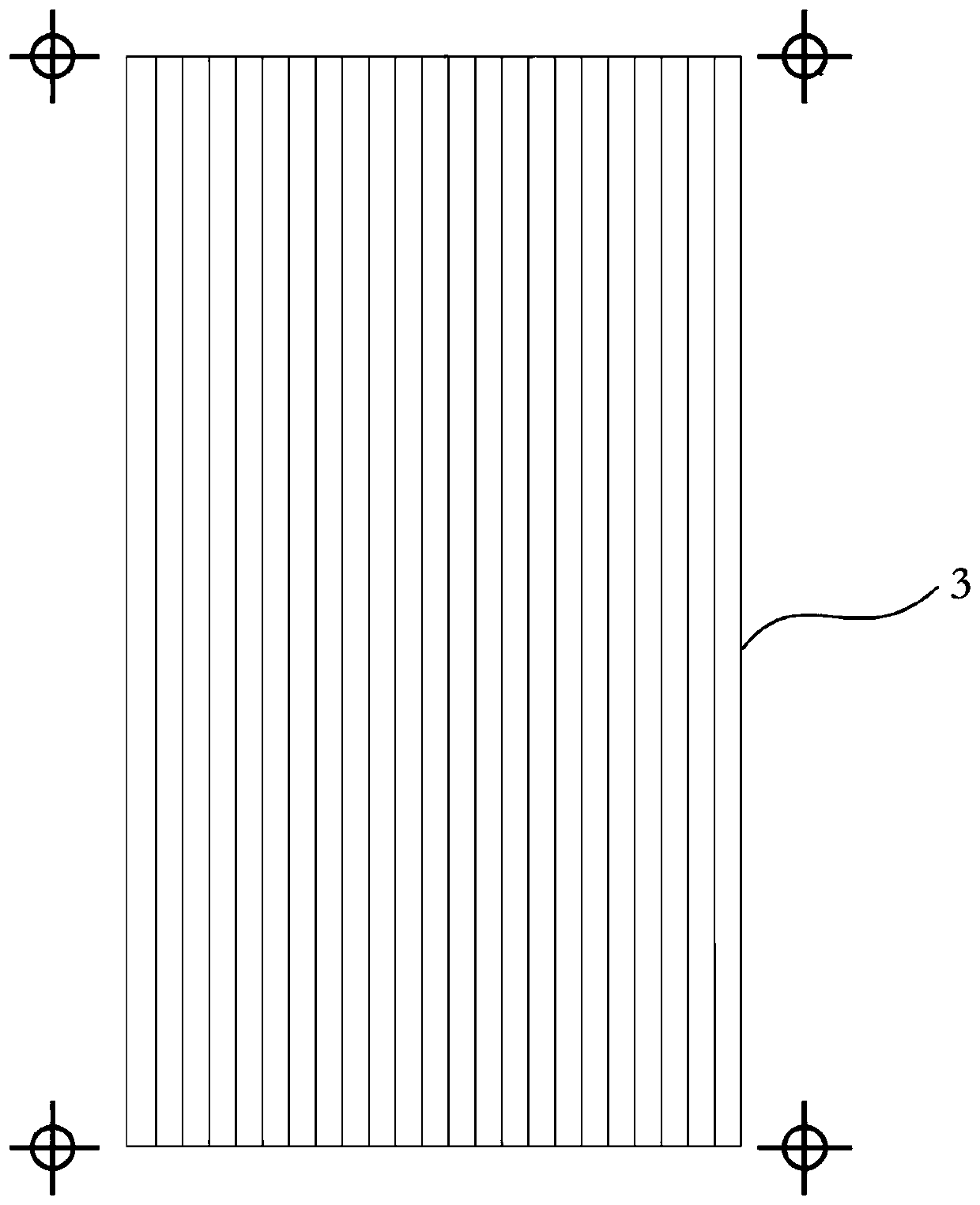

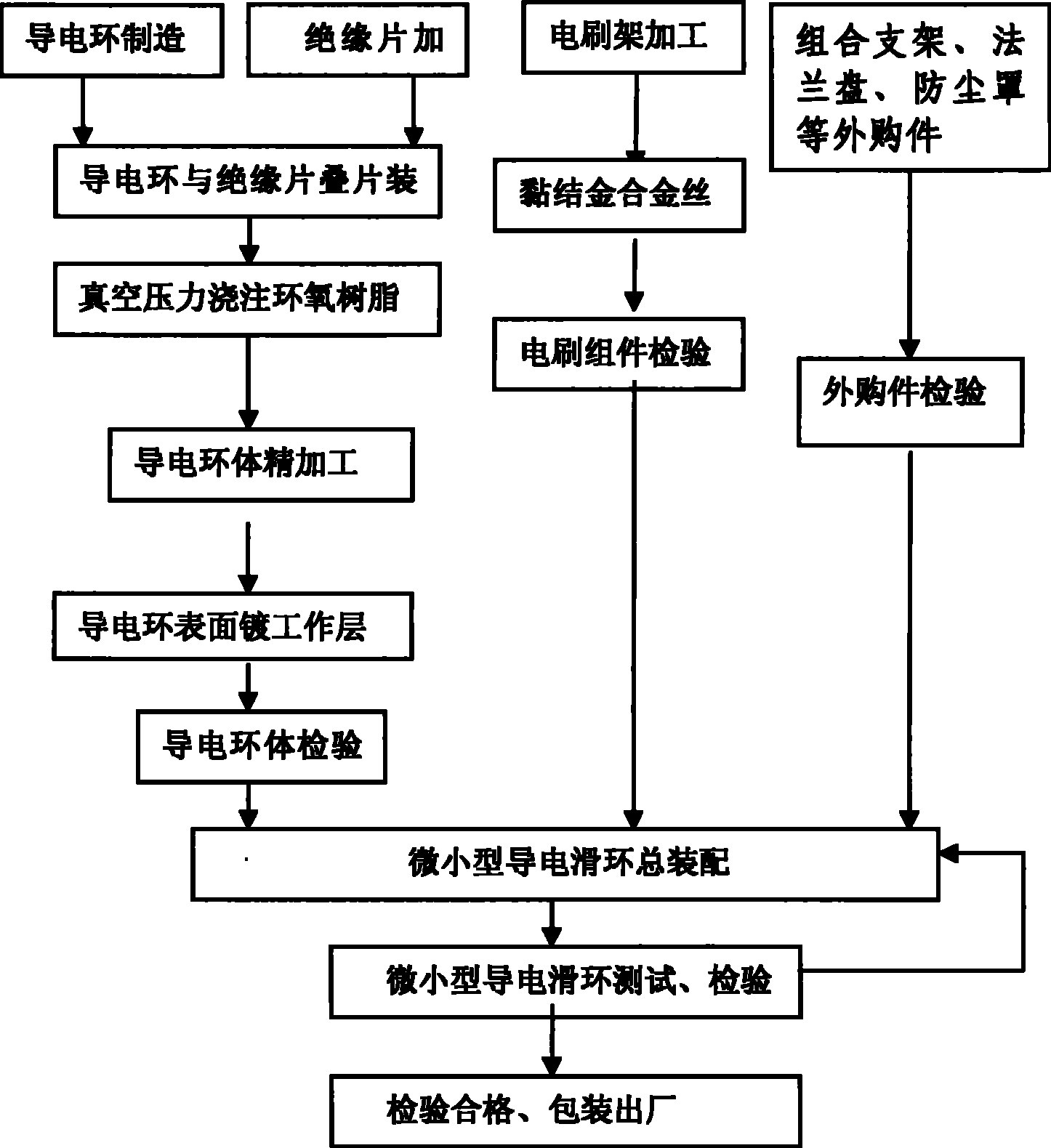

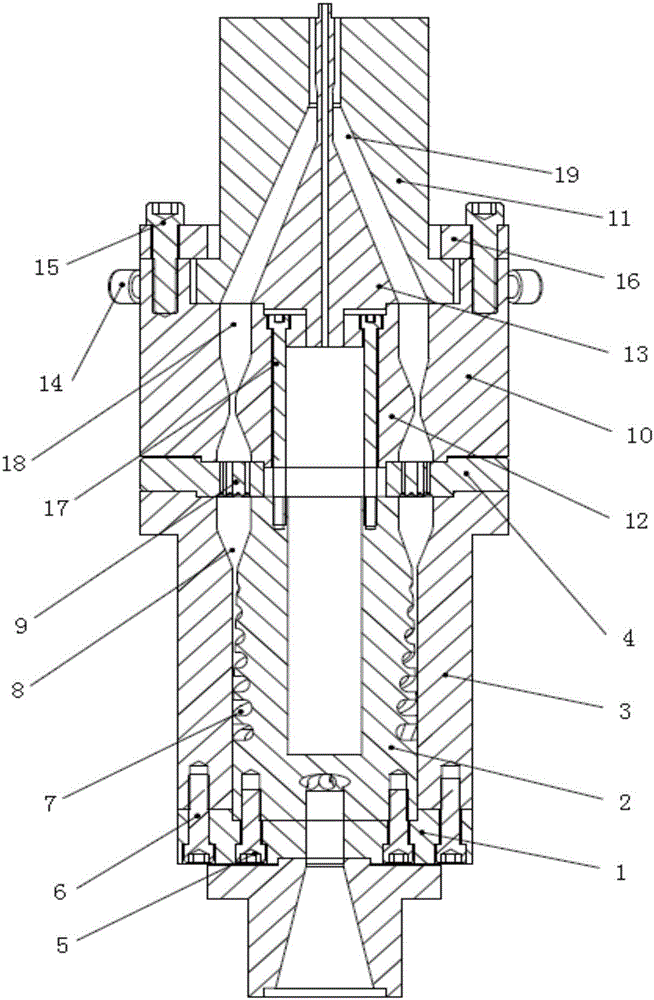

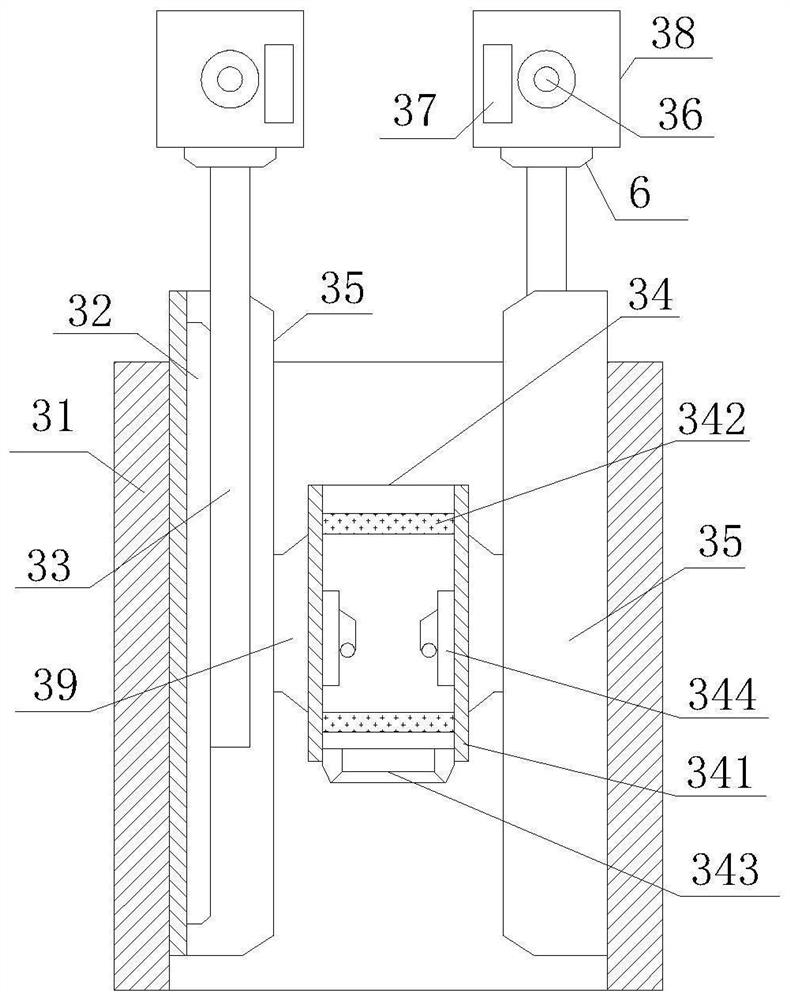

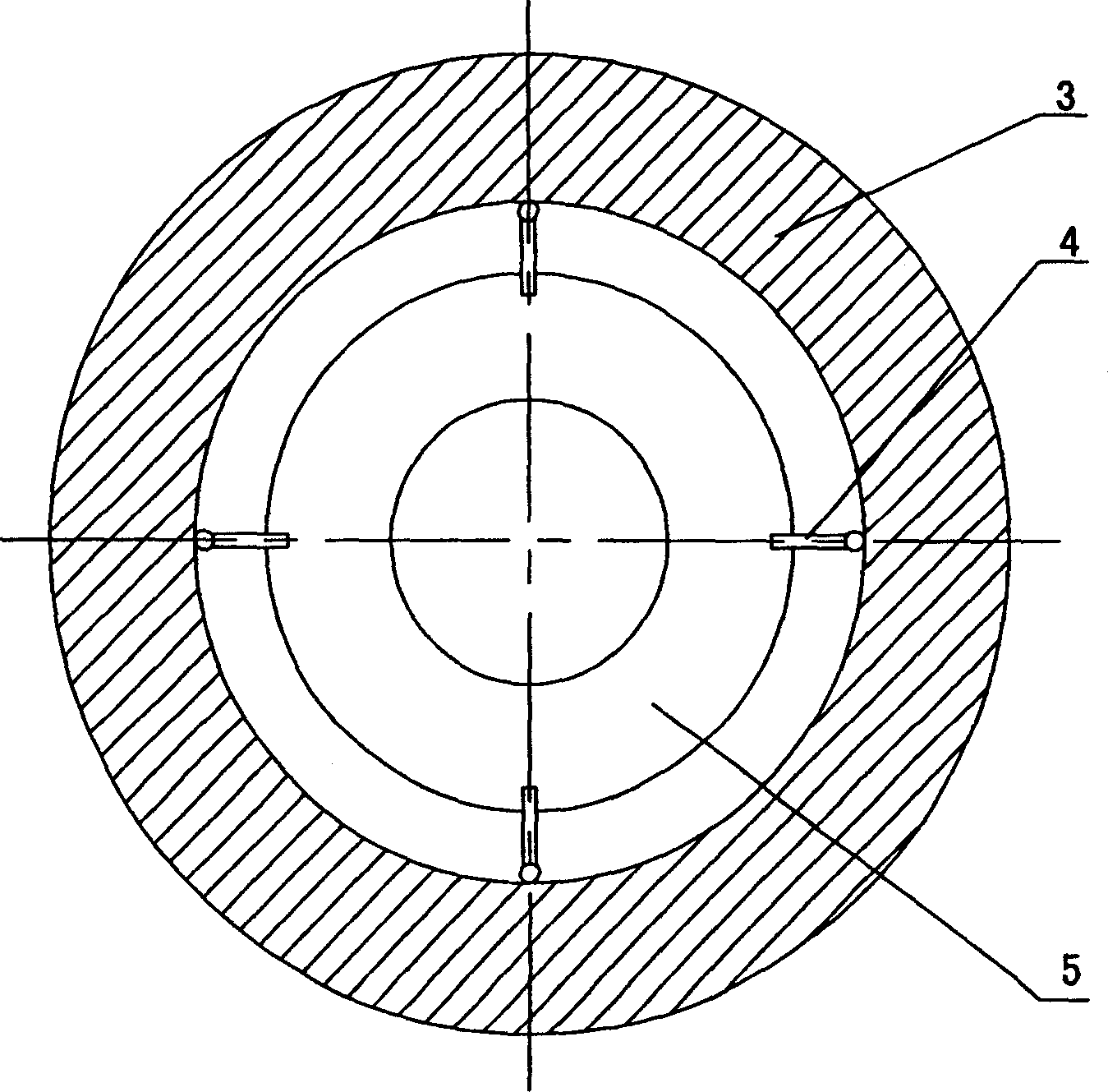

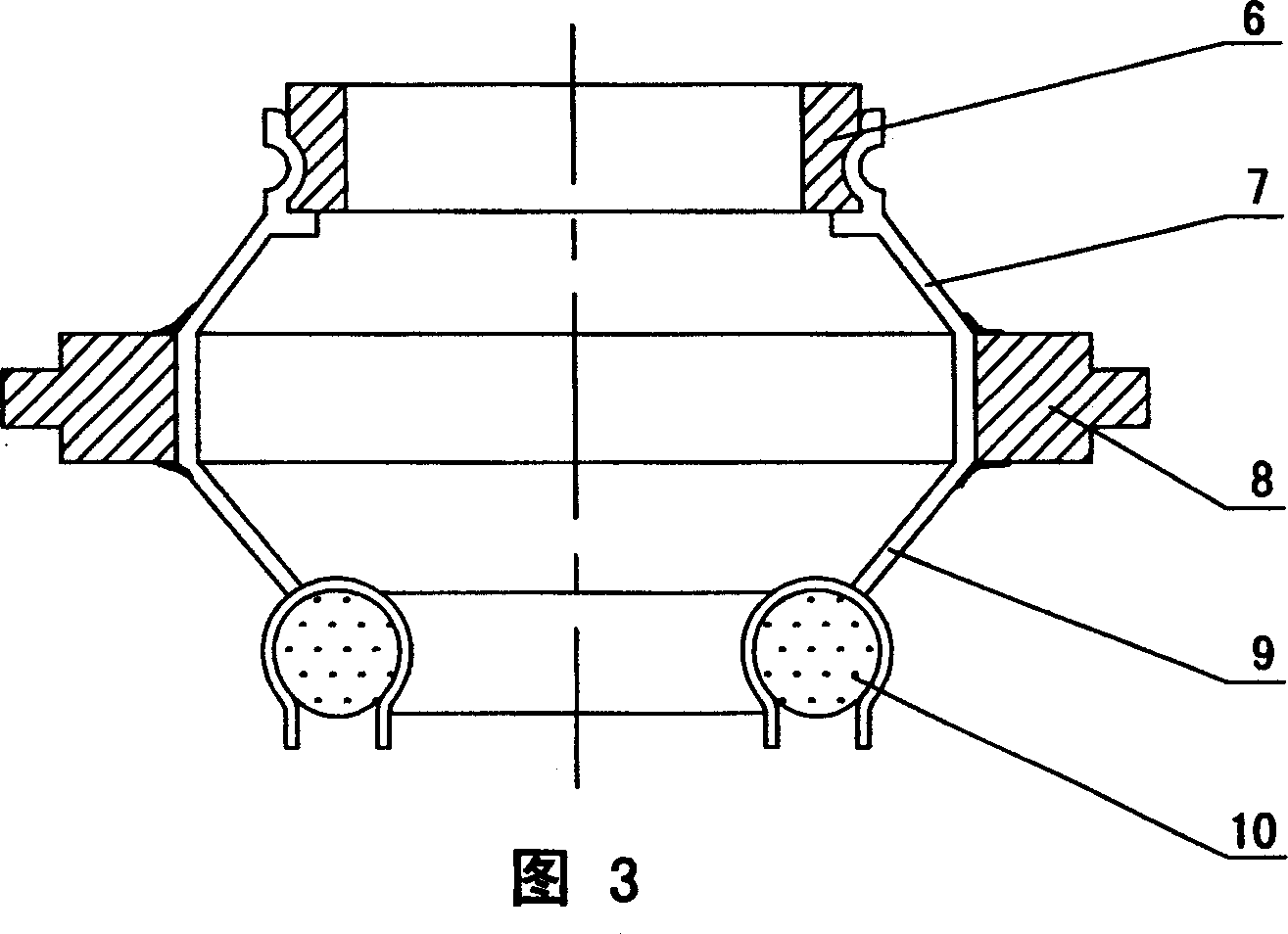

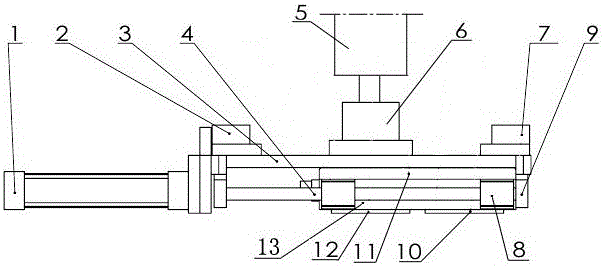

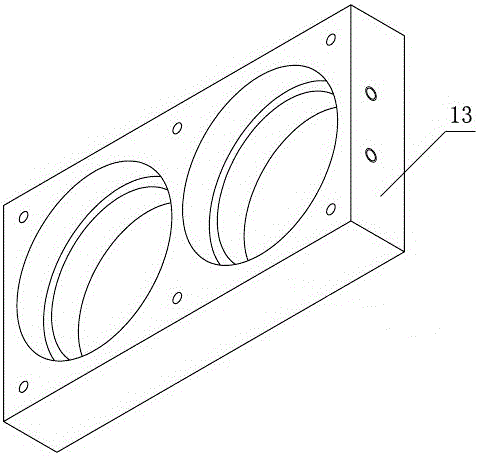

Lamination-vacuum pressure pouring process of micro conductive retractor collar

InactiveCN101340047AWon't fall offFirmly connectedRotary current collectorSlip-rings manufactureElectricityEpoxy

The invention discloses a lamination-vacuum pressure pouring technology of a microminiature conducting slip ring, which comprises the processing technology of a conducting ring, the processing technology of a brush holder and the general assembly technology of the microminiature conducting slip ring; after the conducting ring body and the brush component are inspected, the bought-in component inspection is carried out on the bought-in components such as a combination support, a flange, a dust shield, and the like; and then the conducting ring body, the brush holder component and the bought-in components are assembled into the microminiature conducting slip ring, and then tested and inspected; and after passing the inspections, the conducting ring body, the brush holder component and the bought-in components are packed and delivered. The lamination-vacuum pressure pouring technology of the microminiature conducting slip ring is characterized in that: after the conducting ring is manufactured and an insulating strip is processed, the conducting ring and the insulating strip are firstly laminated for assembly, epoxy resin is poured at the vacuum pressure, and then fine machining is performed on the conducting ring body. The lamination-vacuum pressure pouring technology of the microminiature conducting slip ring has the advantages that the two conducting rings are both mutually insulated and reliably connected, and rubber layers thereof can not fall off, the environmental suitability and operational reliability of the products are improved, the rate of defective products is low, and the performance of the product can correspond to that of the similar products abroad.

Owner:JIUJIANG JINGDA MEASUREMENT TECH

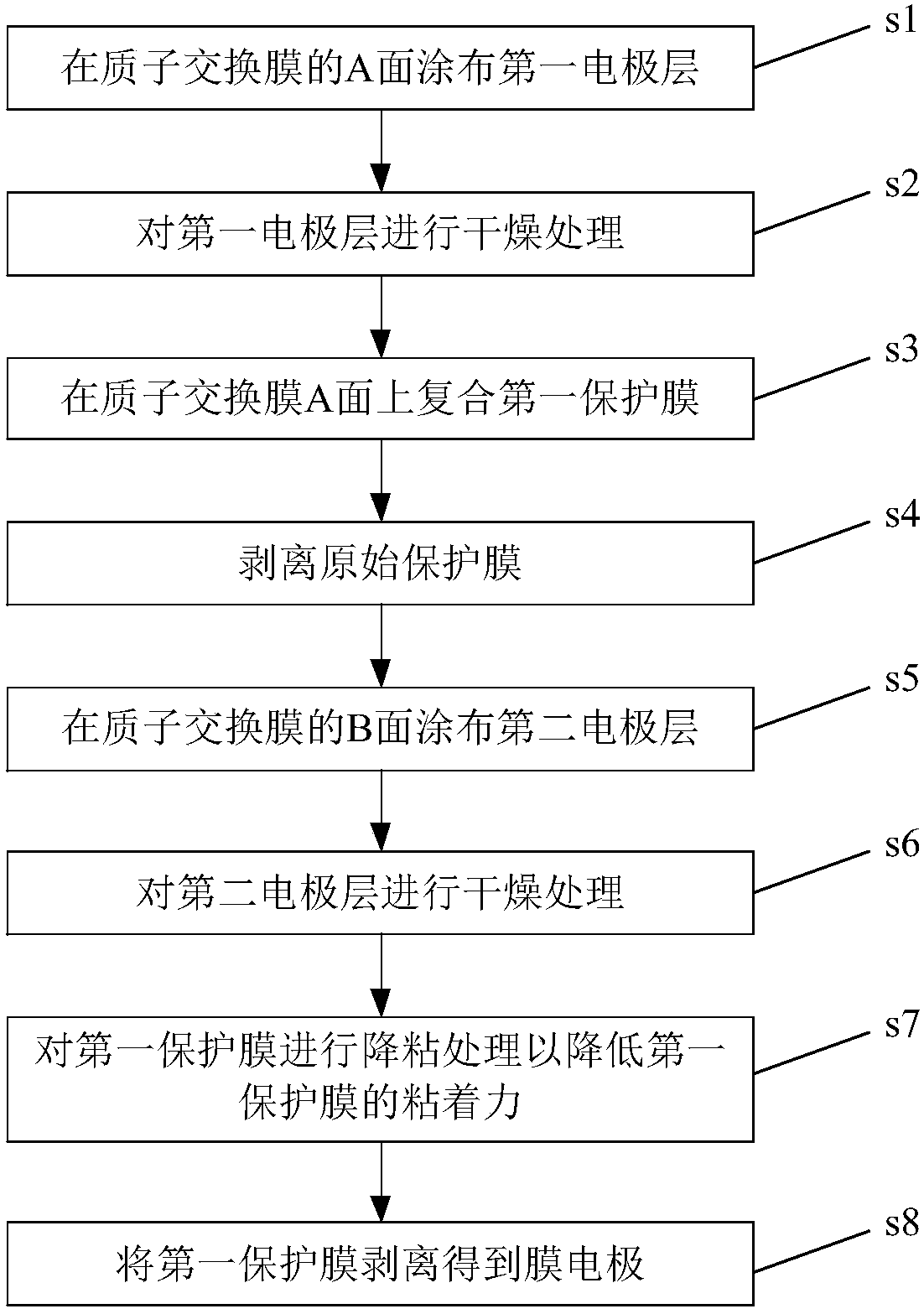

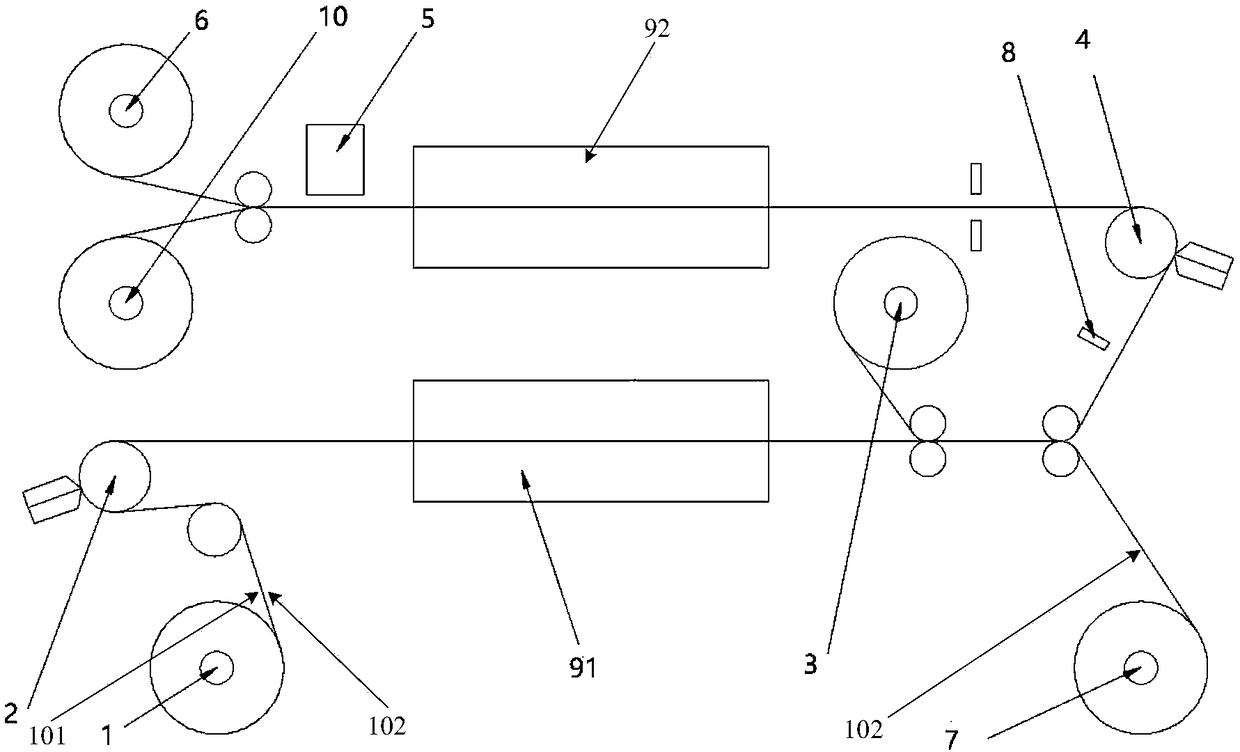

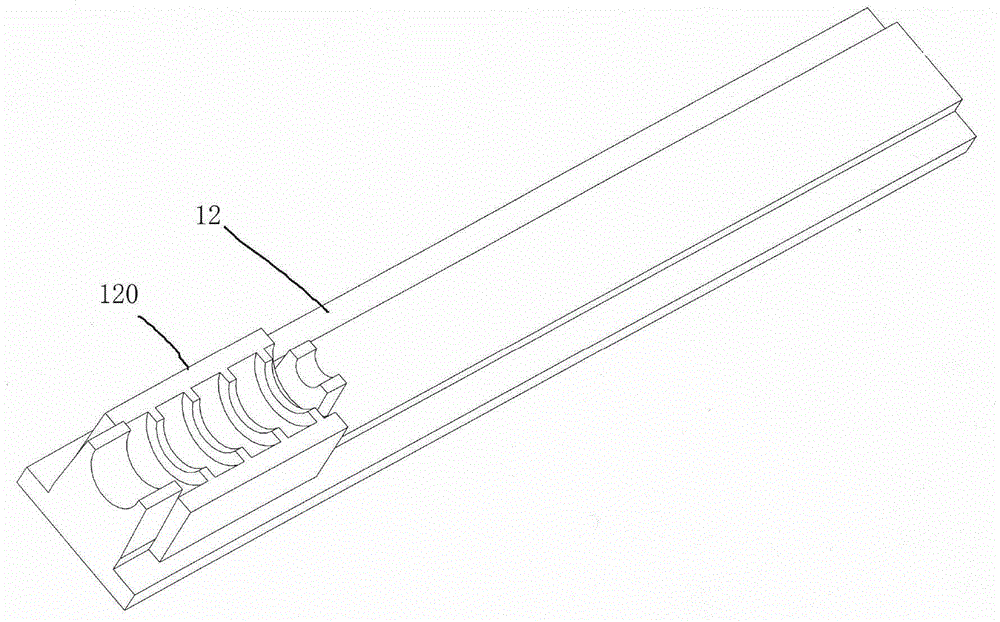

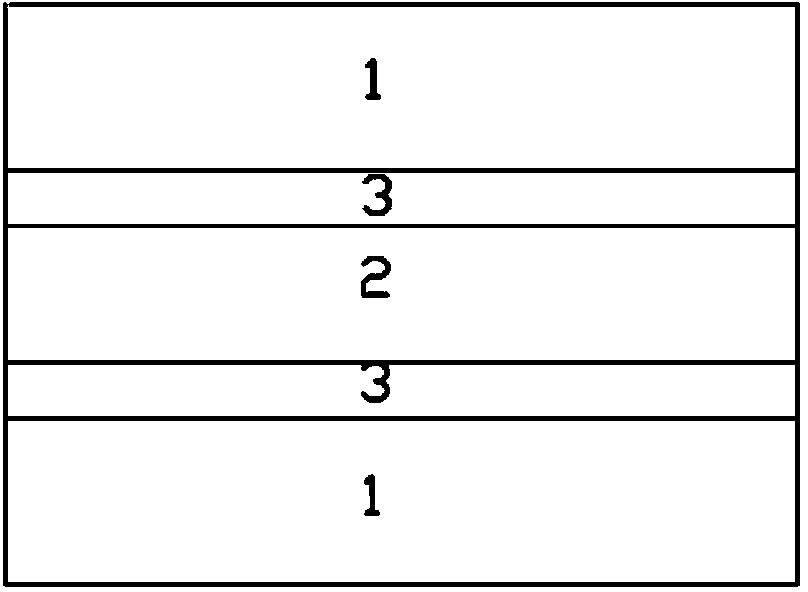

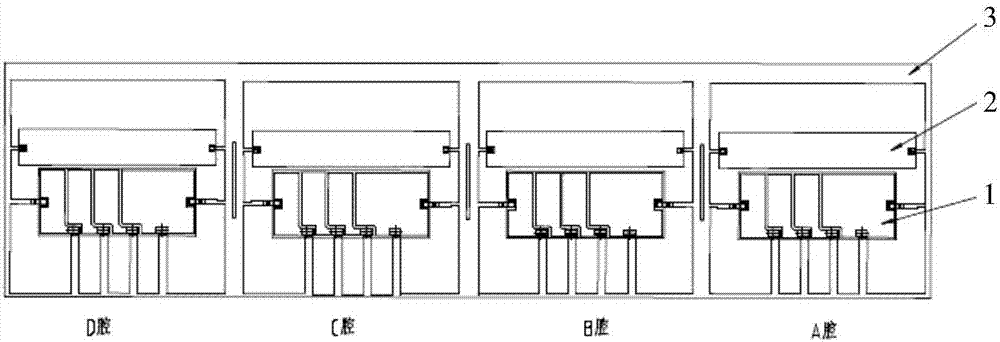

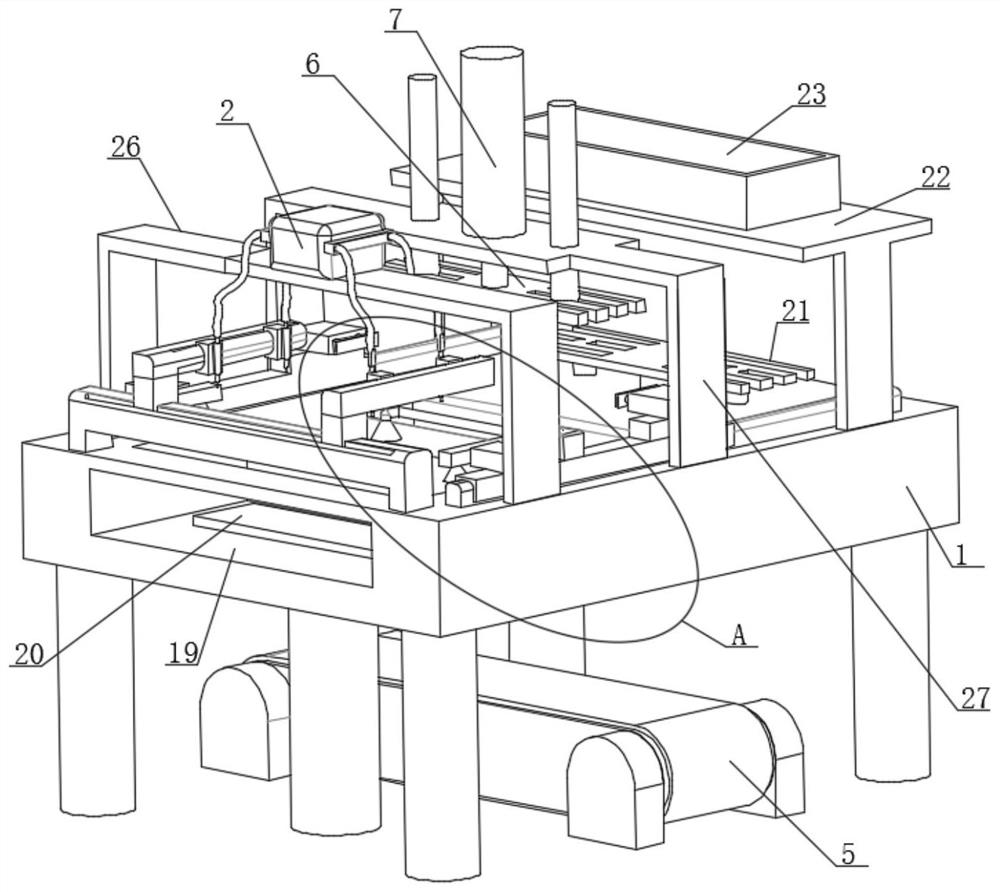

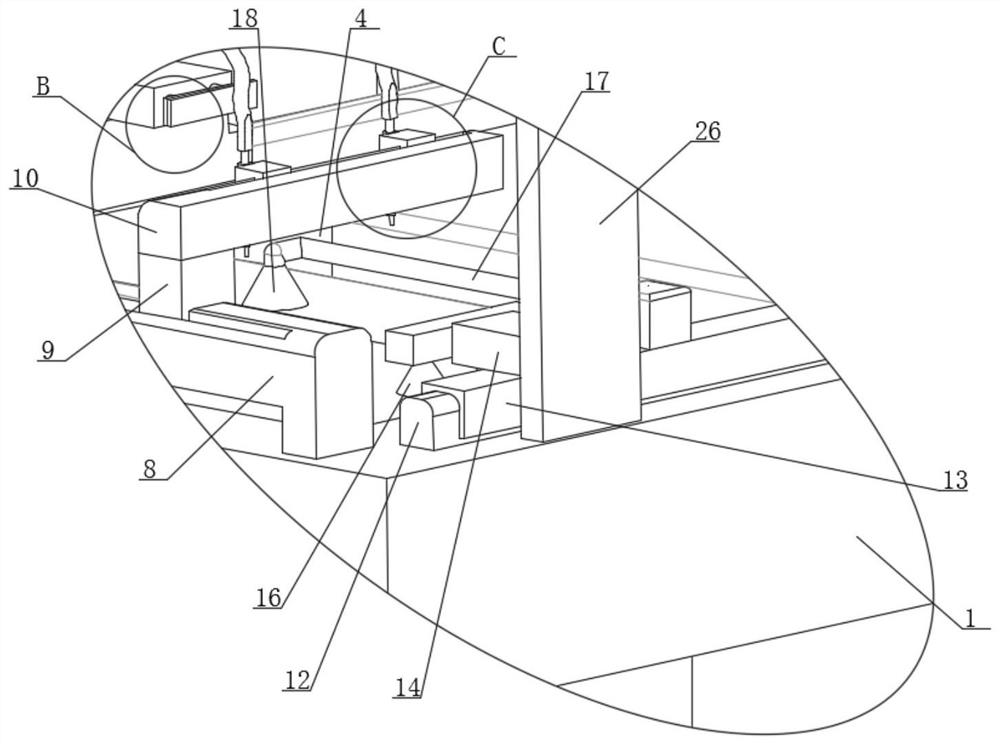

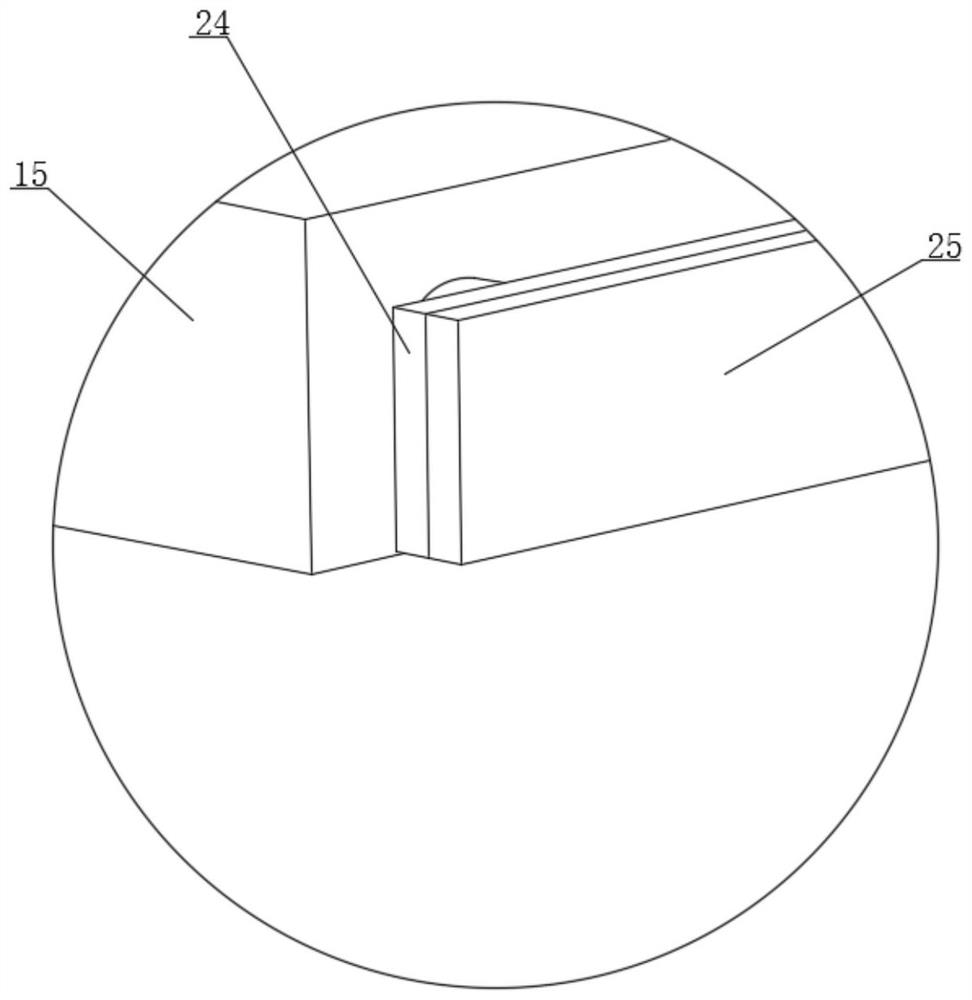

Method and device for manufacturing fuel cell membrane electrode

PendingCN108448139AIncrease productivityReduce production scrap rateCell electrodesFinal product manufactureScrapChemistry

The invention belongs to the technical field of fuel cells, and discloses a method for manufacturing a fuel cell membrane electrode. The method comprises the following steps: coating the A side of a proton exchange membrane with a first electrode layer, compounding A side of a proton exchange membrane with a first protection membrane, coating the B side of the proton exchange membrane with a second electrode layer, performing viscosity reduction treatment on the first protection membrane, and stripping the first protection membrane to obtain the membrane electrode, wherein the first electrodelayer applied to the A side is protected with the first protection membrane to avoid damages of coating of the second electrode layer to the first electrode layer, the size of the first electrode layer is detected during the coating of the second electrode layer, and the second electrode layer is applied according to the size of the first electrode layer to make the first electrode layer and the second electrode layer aligned in size in order to reduce the production scrap rate. The invention also discloses a manufacturing device. T whole process is completed by using the automatic device without using transferring printing, so the production efficiency is improved.

Owner:SHENZHEN SHINING AUTOMATION CO LTD

Cover plate type fiber bragg grating sensor and packaging method thereof

InactiveCN102980684AImprove firmnessHigh data acquisition accuracyThermometer detailsThermometers using physical/chemical changesFiberGrating

The invention discloses a cover plate type fiber bragg grating sensor and a packaging method thereof. The cover plate type fiber bragg grating sensor comprises a grating and a protection sleeve, wherein a wire jumper and tensile fibers are fixed in the protection sleeve. One end of the protection sleeve is fixedly connected with a flange interface, and the other end of the protection sleeve is fixedly connected with a temperature sensing box. The grating is packaged in the temperature sensing box, the wire jumper and the grating are connected with each other in the temperature sensing box. The packaging method of the cover plate type fiber bragg grating sensor includes preparing the sleeve, painting temperature-resistant AB glue, welding the wire jumper and the grating in fusion mode, leading the wire jumper to penetrate through the protection sleeve, fixing one end of the wire jumper not provided with the grating with the flange interface, arranging the grating at the central position of a sensing protection groove, and buckling a packaging cover plate on the sensing protection groove. Compared with the prior art, the cover plate type fiber bragg grating sensor is good in mechanical performance, sensor performance, insulation performance and firmness, and improves sensor firmness, data collection accuracy and data collection speed. The packaging method of the cover plate type fiber bragg grating sensor greatly improves production efficiency and production survival rate, simultaneously improves sensor firmness and enables the sensor not to split or fall easily.

Owner:YIBIN POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER +1

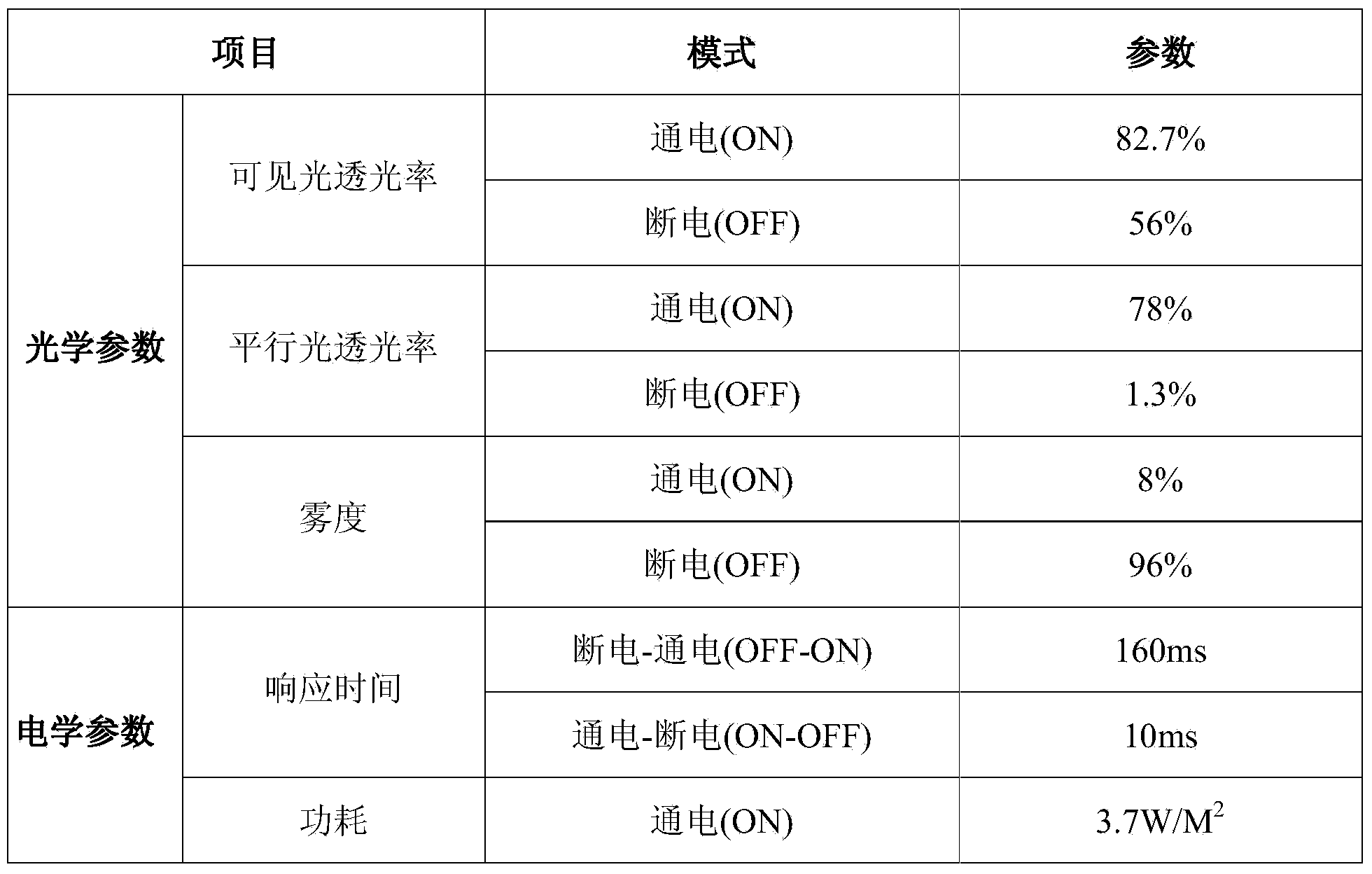

Smart glass using nano silver conducting layer and manufacturing method of smart glass

ActiveCN103760695AGood deformabilitySimple preparation processNon-linear opticsFilm-forming agentSlurry

The invention discloses smart glass using a nano silver conducting layer and a manufacturing method the smart glass. The smart glass comprises, by weight percentage, 0.1-15 of conductive filler, 0.05-8% of film forming agent, 0.01-6% of conductivity adjusting agent and the balance of solvent. The method includes: welling mixing the materials to prepare conductive slurry; evenly coating the conductive slurry on glass base material, heating at 50-180 DEG C to cure the conductive slurry so as to form an even conducting film layer and obtain the conductive glass; guiding out a wiring circuit from the edge on one side of each of two pieces of conductive glass, adhering the four lateral edges of the conductive glass, allowing the conducting film layers to face each other and a hollow layer to be formed between the two conducting film layers, filling liquid crystal in the hollow layer under a vacuum condition, and sealing the filling opening to obtain the smart glass using the nano silver conducting layer.

Owner:田耕

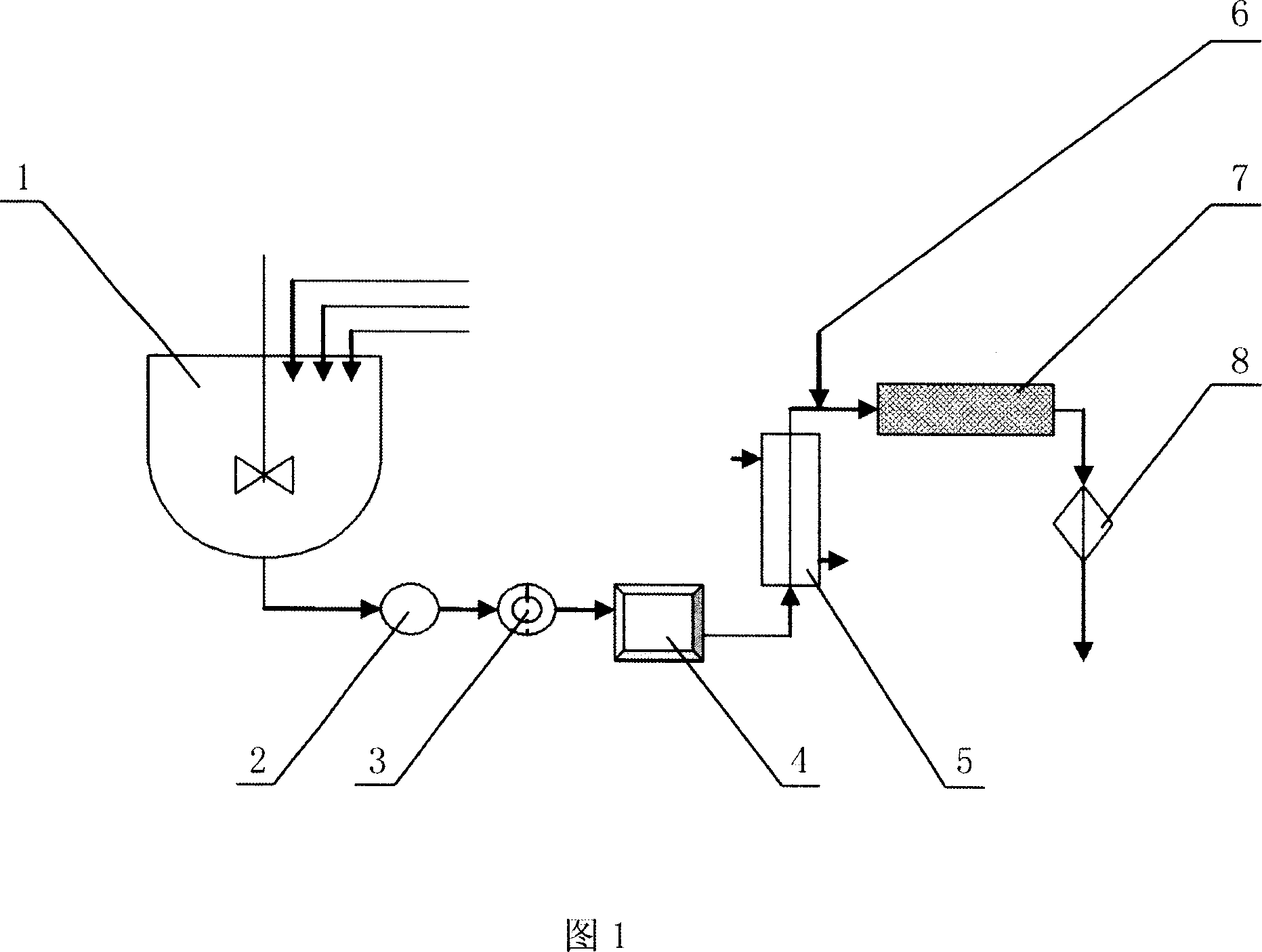

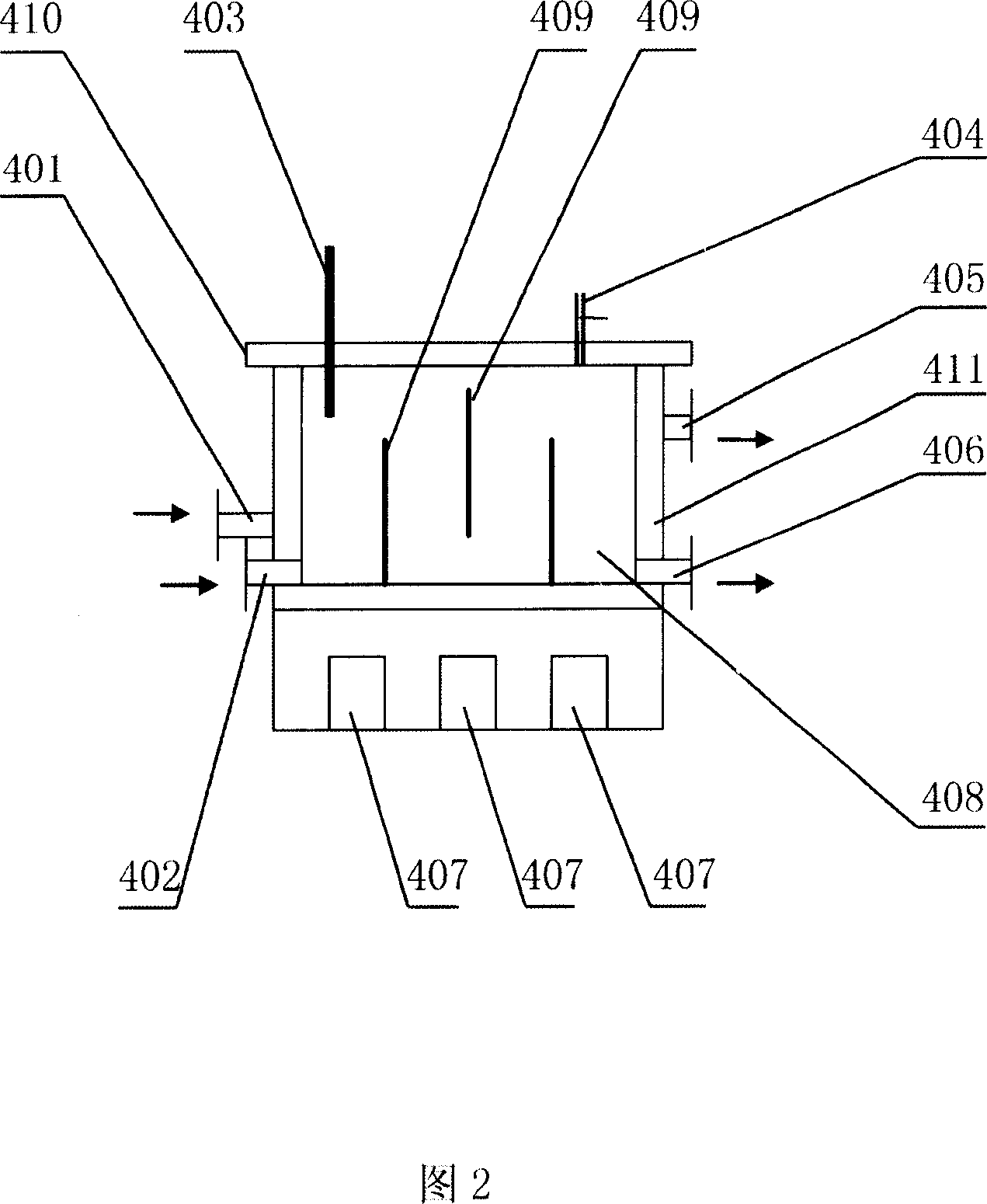

Method and device for applying liquid degasification

InactiveCN1919404ATo achieve the purpose of degassingReduce production scrap rateLiquid degasificationEngineeringLiquid surfaces

The invention discloses a degassing method of coating flow, which comprises the following steps: adopting ultrasonic wave with frequency at 25-39Hz as vibrating source, utilizing cavity action of ultrasonic wave shock to increase diameter of micro-bubble in the flow as well as lifting speed continuously until liquid surface, exhausting from vent, eliminating micro-bubble in the flow. The ultrasonic degassing device consists of flow degassing tank and at least one ultrasonic vibrator, wherein the degassing cavity is set in the flow degassing tank, the ultrasonic vibrator is set on the bottom of degassing tank, which lies under the degassing cavity.

Owner:汕头市华天富信材发展有限公司

Stable butt joint device for pipe fitting welding

InactiveCN114589451AAchieve peace of mindRest assured to achieveWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingButt joint

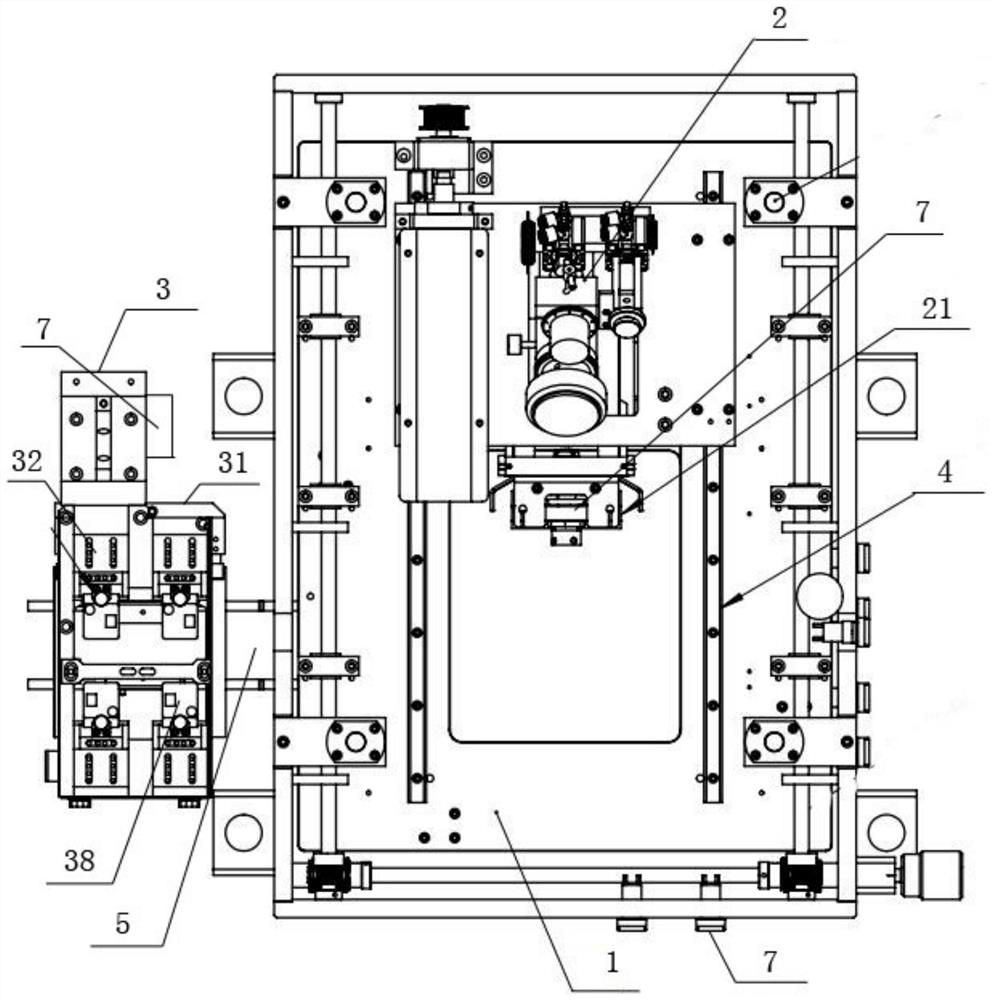

The invention is suitable for the technical field of pipe fitting welding, and provides a pipe fitting welding stable butt joint device which comprises a device base and further comprises a moving mechanism, the moving mechanism comprises a first moving assembly and a second moving assembly, the first moving assembly is connected with a clamping mechanism, and the second moving assembly is connected with a lifting rotating mechanism; the lifting and rotating mechanism is fixedly connected with the centering mechanism; and the centering mechanism comprises a centering seat, a power piece, a second transmission module, a first rotating piece, a driving seat, a first threaded shaft, a centering assembly, an abutting piece and a limiting seat. According to the stable butt joint device for pipe fitting welding, through the moving mechanism, the lifting rotating mechanism, the clamping mechanism and the centering mechanism, centering butt joint of two sets of pipe fittings can be achieved, the central axes of the two sets of pipe fittings coincide, the perpendicularity of the pipe fittings after welding is guaranteed, the welding quality and efficiency of the pipe fittings are improved, and the production rejection rate of the pipe fittings is reduced; and the production economic cost is saved.

Owner:XINGTAI POLYTECHNIC COLLEGE

Method for reducing overflow in injection molding of IPM (Intelligent Power Module) and DBC substrate

PendingCN107978530AReduce spillageUniform force balanceSemiconductor/solid-state device detailsSolid-state devicesDBcComputer module

The invention discloses a method for reducing overflow in injection molding of an IPM (Intelligent Power Module) and a DBC substrate. The method changes an island design on the DBC substrate and enables the DBC substrate to be balanced in stress in the injection molding process. In addition, a wedge-shaped table structure is designed on a DBC back copper layer at the back of the DBC substrate, a buffer table for the flow rate of an injection molding material at the back of the DBC substrate is formed, and the injection molding material overflowed towards the back of the DBC substrate is reduced under a condition that the DBC substrate is uneven. According to the invention, the method of reducing the overflow through changing the DBC design idea is adopted to replace a laser burr removing process, the production efficiency is improved, and the production cost and technological input are reduced.

Owner:XIAN YONGDIAN ELECTRIC

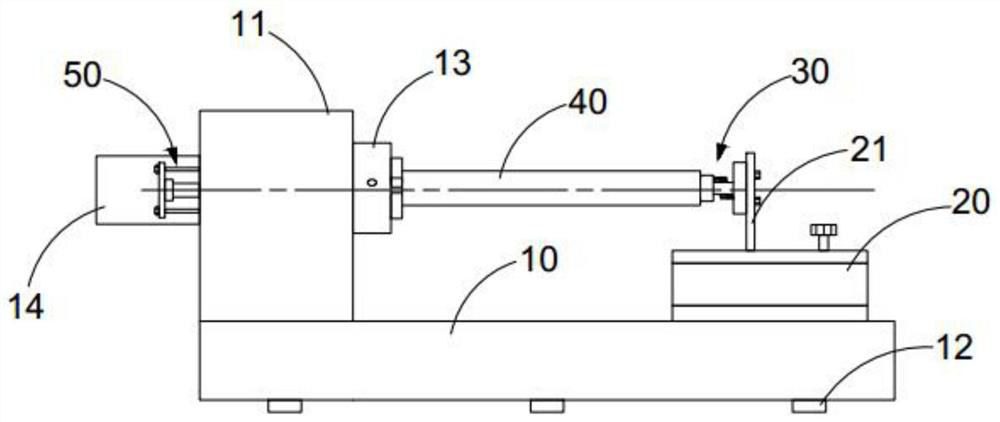

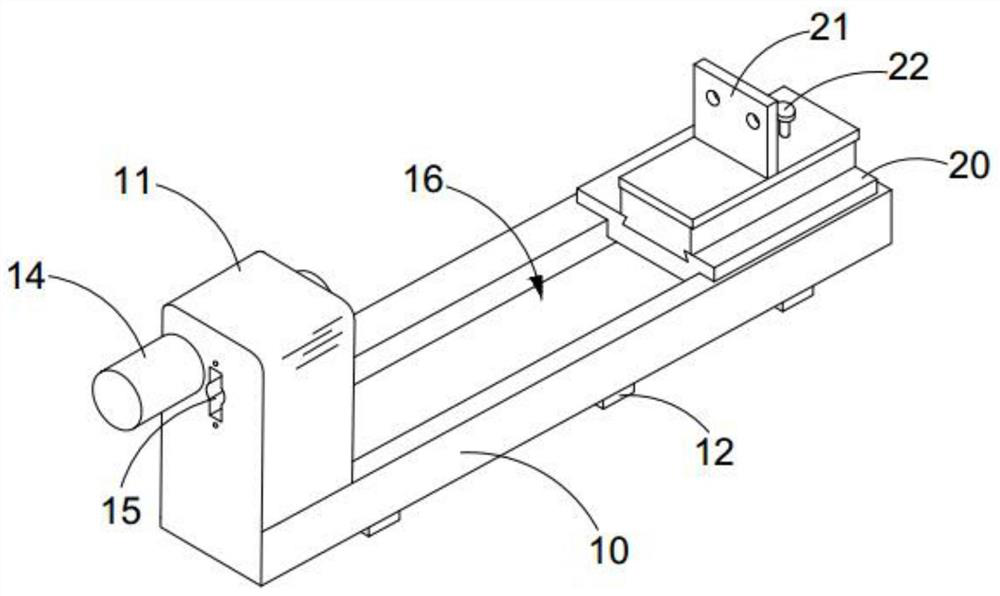

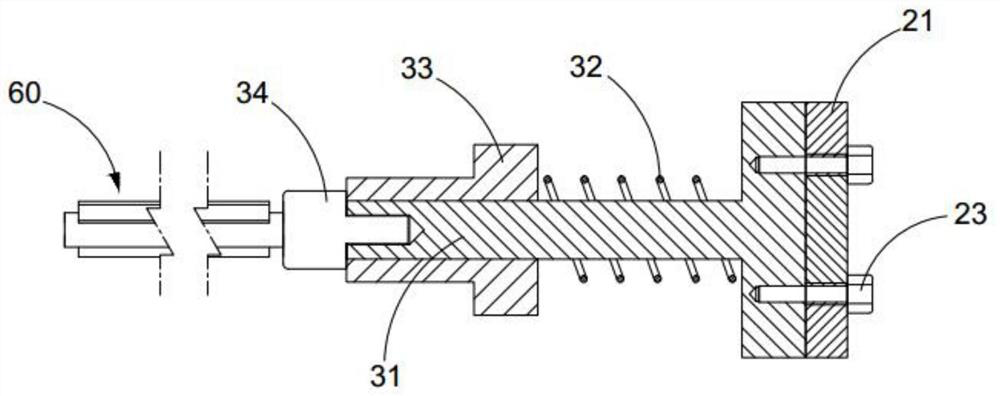

A rubber parts manufacturing automatic processing fixture

ActiveCN111390665BMeet manufacturing requirementsAvoid bending deformationEdge grinding machinesRevolution surface grinding machinesPipe fittingTailstock

The invention discloses a jig for automatic processing of rubber parts, which belongs to the technical field of jigs and jigs. The jig of the invention includes a bed. Frame, the first limit component, installed on the tailstock, the upper part of the tailstock is provided with a support connecting plate perpendicular to the horizontal plane, the support connecting plate is assembled with the first limit component on the opposite surface of the three-jaw chuck, the first limit component It includes the limit main part with a cylindrical structure, and the bottom of the cylindrical structure is provided with an assembly base plate that is connected with the support connecting plate; the limit component is sleeved with a limit accessory, and the limit accessory is a cylindrical sleeve structure. A limiting ring is arranged on the outer surface, a first spring is arranged between the limiting auxiliary part and the limiting main part, and the cylinder end of the limiting main part is connected with a grinding assembly through the connecting base. The fixture of the present invention is used to process the hole wall of the rubber part of the pipe fittings to obtain better surface roughness, the deformation rate of the rubber part during the processing is low, and the yield of the finished product is high.

Owner:HUANGSHAN SHANGYI RUBBER & PLASTIC PRODS

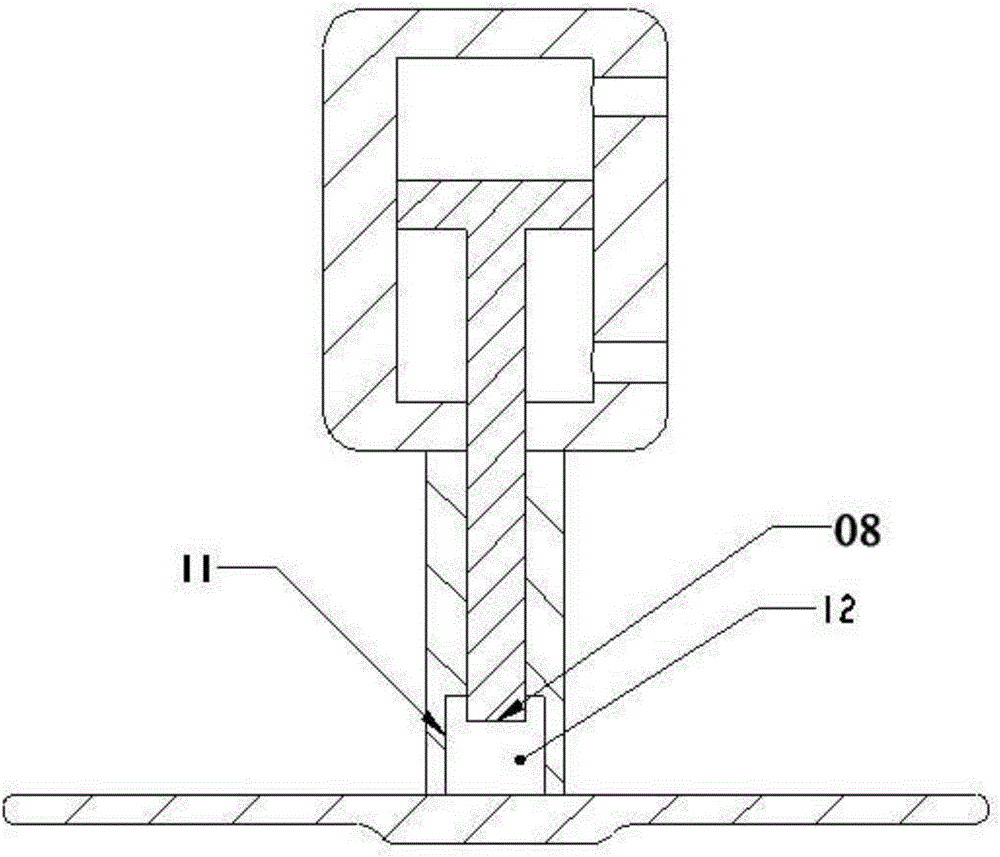

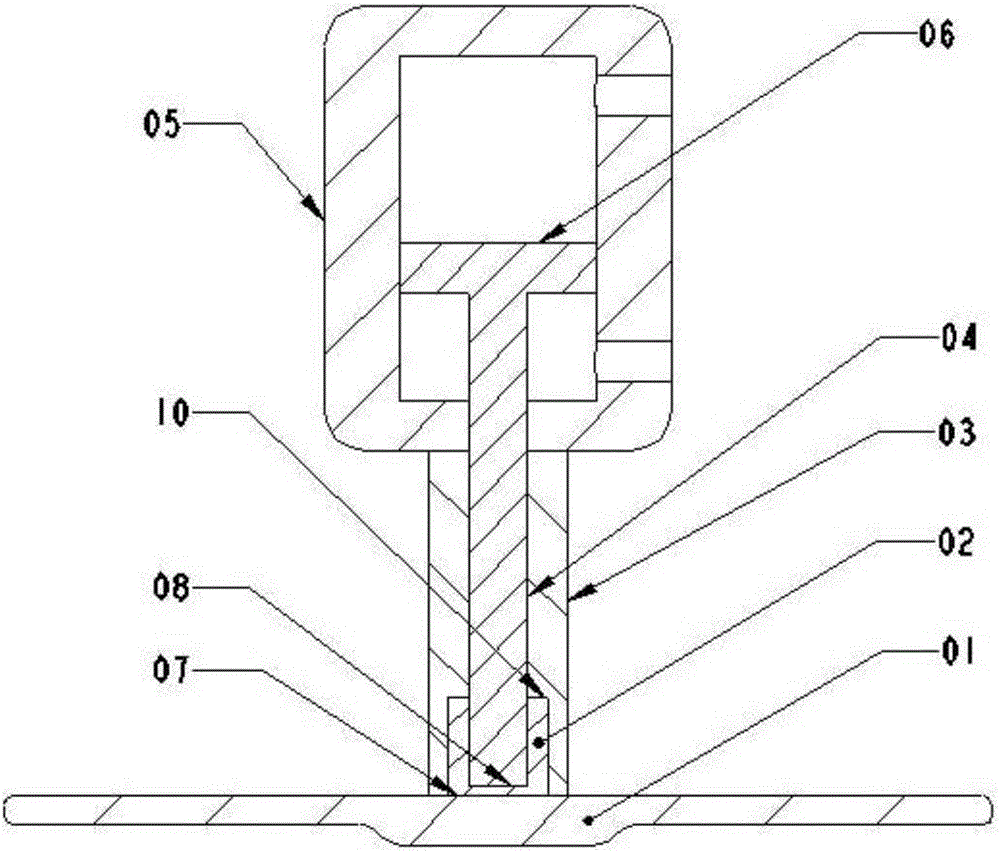

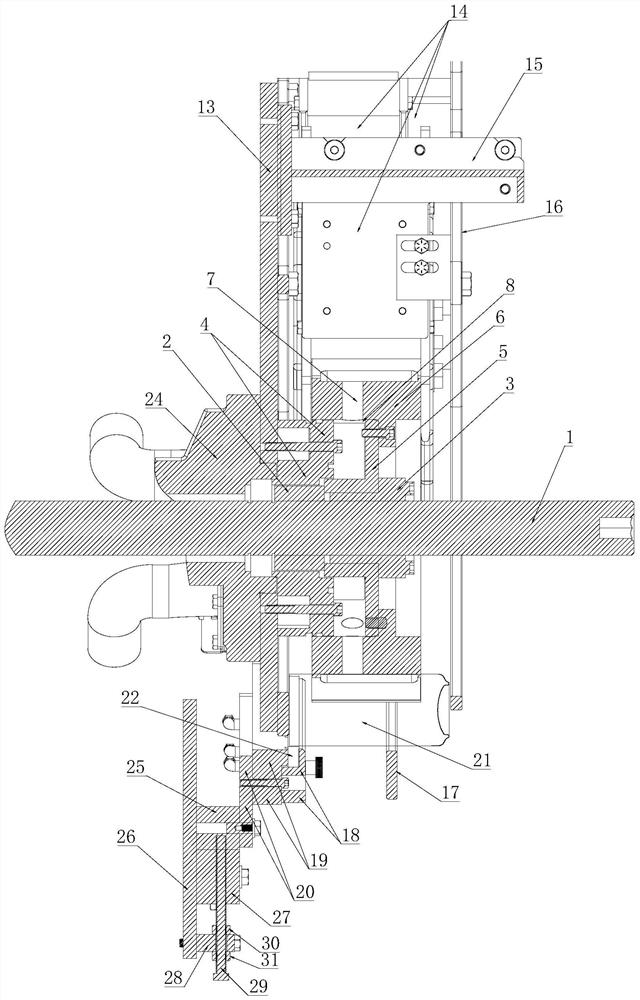

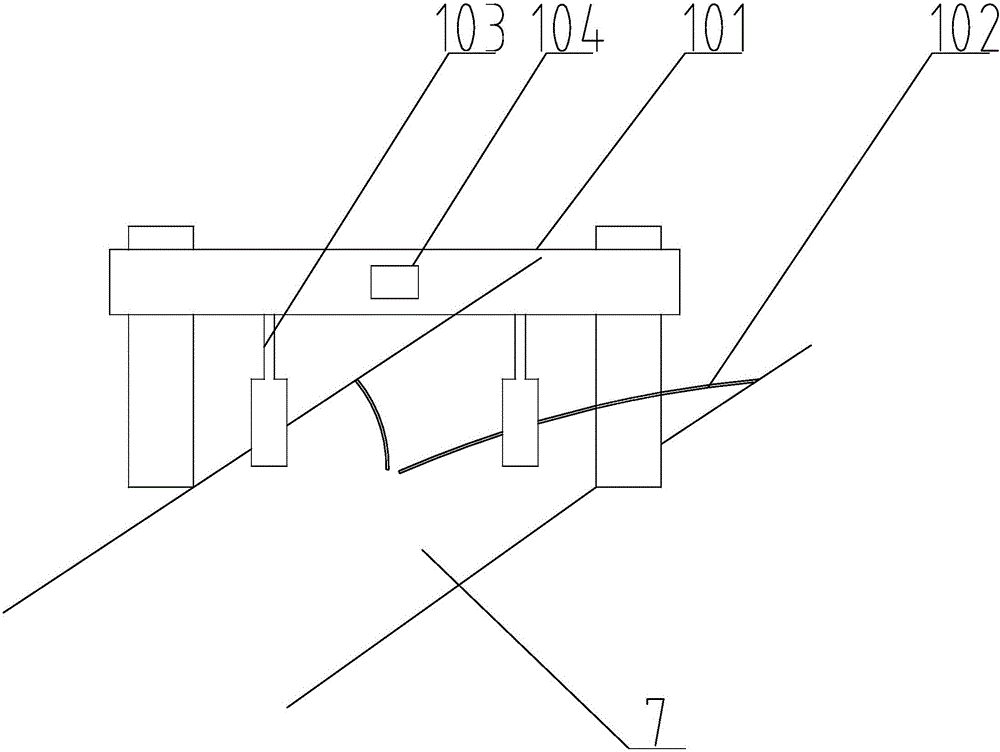

Local extrusion method used for high-pressure casting

InactiveCN106392033AGuaranteed Extrusion StrokeReduce shrinkage defectsEconomic benefitsHigh pressure

The invention provides a local extrusion method used for high-pressure casting. The method comprises the steps that a local extrusion device used for high-pressure casting is used for extruding the surface of a casting. The device is composed of an extrusion core sleeve (03), an extrusion rod (04), an extrusion oil cylinder (05) and an extrusion oil cylinder piston (06) and is characterized in that the extrusion oil cylinder (05) internally comprises the extrusion oil cylinder piston (06), the extrusion oil cylinder piston (06) is connected with the extrusion rod (04), the extrusion rod (04) is located in the extrusion core sleeve (03), and the extrusion core sleeve (03) and the extrusion oil cylinder (05) are fixed; the extrusion oil cylinder piston (06) is driven to drive the extrusion rod (04) to complete extrusion. The method has the beneficial effects that the extrusion stroke of the local extrusion process can be effectively ensured, meanwhile, the shrinkage defect of the large and thick portion of products is reduced, the production rejection rate is reduced, and the enterprise economic benefits are obviously improved.

Owner:CITIC DICASTAL

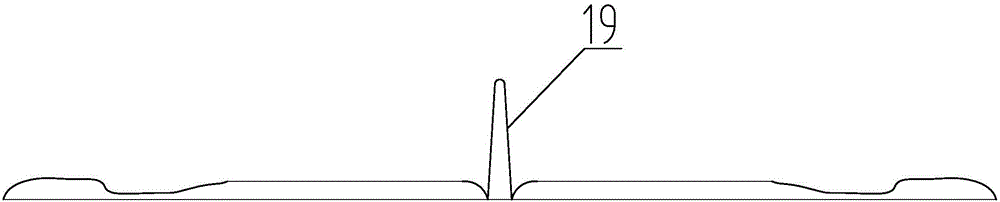

Finished-product rejection device of sanitary napkin with protective wing

The invention relates to a waste rejecting device for finished products sanitary towels with wings, and belongs to the technical field of sanitary towels. The waste rejecting device for the finished products sanitary towels with wings is characterized by comprising a cylinder, a sealing block and an adsorption plate, wherein the cylinder is connected with the sealing clock; the sealing block and the adsorption plated are assembled together oppositely; and one side of the ventilatory adsorption plate is provided with an air intake mechanism. The waste rejecting device has the advantages of simple structure, energy conservation, no pollution, low cost, safety and reliability, high production efficiency, easy combination with microelectronic and electrical technology to future form an automatic control system, and the like.

Owner:TIANJIN LITTLE NURSE IND & COMMERCE DEV

Mechanism for decreasing rejection rate of PVC double-wall corrugated pipe and method of mechanism

InactiveCN107471584ATightly boundCompact structureDomestic articlesTubular articlesDouble wallEngineering

The invention relates to the technical field of pipeline product production and application, in particular to a mechanism for decreasing the rejection rate of a PVC double-wall corrugated pipe and a method of the mechanism. According to the mechanism and the method, the structure is compact, and production operation is easier; gas-aided molding is conducted, and therefore an inner layer and an outer layer of a product can be combined more closely; innovative flow channel structure design is adopted, and the problems of production material burning, product yellowing and product cracking in use are solved; the mechanism and the method can be suitable for production of the same kind of PVC pipeline products, and the production rejection rate is decreased.

Owner:HESHAN LESSO IND DEV

Reflective grating gradient color explosion-proof membrane and preparation method thereof

InactiveCN111363489AConducive to industrial mass productionReduce production scrap rateFilm/foil adhesive primer layersDiffraction gratingsScreen printingGrating

The invention discloses a reflective grating gradient explosion-proof membrane and a preparation method thereof. The explosion-proof membrane comprises an ink layer, a reflecting layer, a UV structurelayer, a PET explosion-proof membrane layer and a multi-color printed layer, which are sequentially arranged from top to bottom, wherein the ink layer is formed by printing through screen printing equipment, the reflecting layer is formed by coating through a coating machine, the UV structure layer is formed by UV glue photo-curing, the UV structure layer is of a lenticular grating structure, andthe multi-color printed layer is formed by printing through a high-precision printing machine. According to the provided reflective grating gradient explosion-proof membrane, the patterns of the multi-color printed layer are subjected to a blending treatment by utilizing the lenticular grating structure of the UV structure layer, and natural gradient among multiple colors can be presented, so that the explosion-proof membrane with gradient colors is obtained. The preparation process of a traditional explosion-proof membrane is not changed, so that industrial mass production is facilitated, and the production rejection rate is reduced. On the other hand, due to the arrangement of the lenticular grating structure, the gradient colors have good consistency.

Owner:SUZHOU IMAGE LASER TECH

Lamination-vacuum pressure pouring process of micro conductive retractor collar

InactiveCN101340047BWon't fall offFirmly connectedRotary current collectorSlip-rings manufactureElectricityEpoxy

The invention discloses a lamination-vacuum pressure pouring technology of a microminiature conducting slip ring, which comprises the processing technology of a conducting ring, the processing technology of a brush holder and the general assembly technology of the microminiature conducting slip ring; after the conducting ring body and the brush component are inspected, the bought-in component inspection is carried out on the bought-in components such as a combination support, a flange, a dust shield, and the like; and then the conducting ring body, the brush holder component and the bought-incomponents are assembled into the microminiature conducting slip ring, and then tested and inspected; and after passing the inspections, the conducting ring body, the brush holder component and the bought-in components are packed and delivered. The lamination-vacuum pressure pouring technology of the microminiature conducting slip ring is characterized in that: after the conducting ring is manufactured and an insulating strip is processed, the conducting ring and the insulating strip are firstly laminated for assembly, epoxy resin is poured at the vacuum pressure, and then fine machining is performed on the conducting ring body. The lamination-vacuum pressure pouring technology of the microminiature conducting slip ring has the advantages that the two conducting rings are both mutually insulated and reliably connected, and rubber layers thereof can not fall off, the environmental suitability and operational reliability of the products are improved, the rate of defective products is low, and the performance of the product can correspond to that of the similar products abroad.

Owner:JIUJIANG JINGDA MEASUREMENT TECH

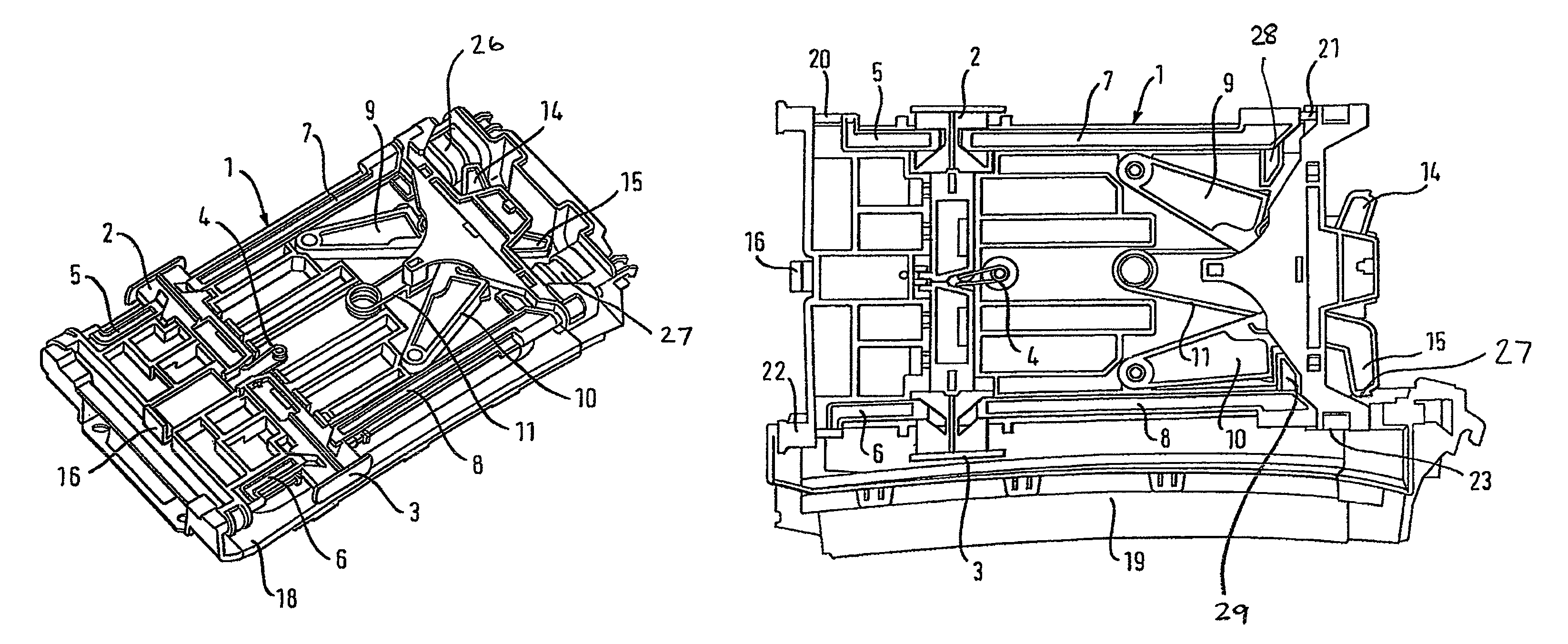

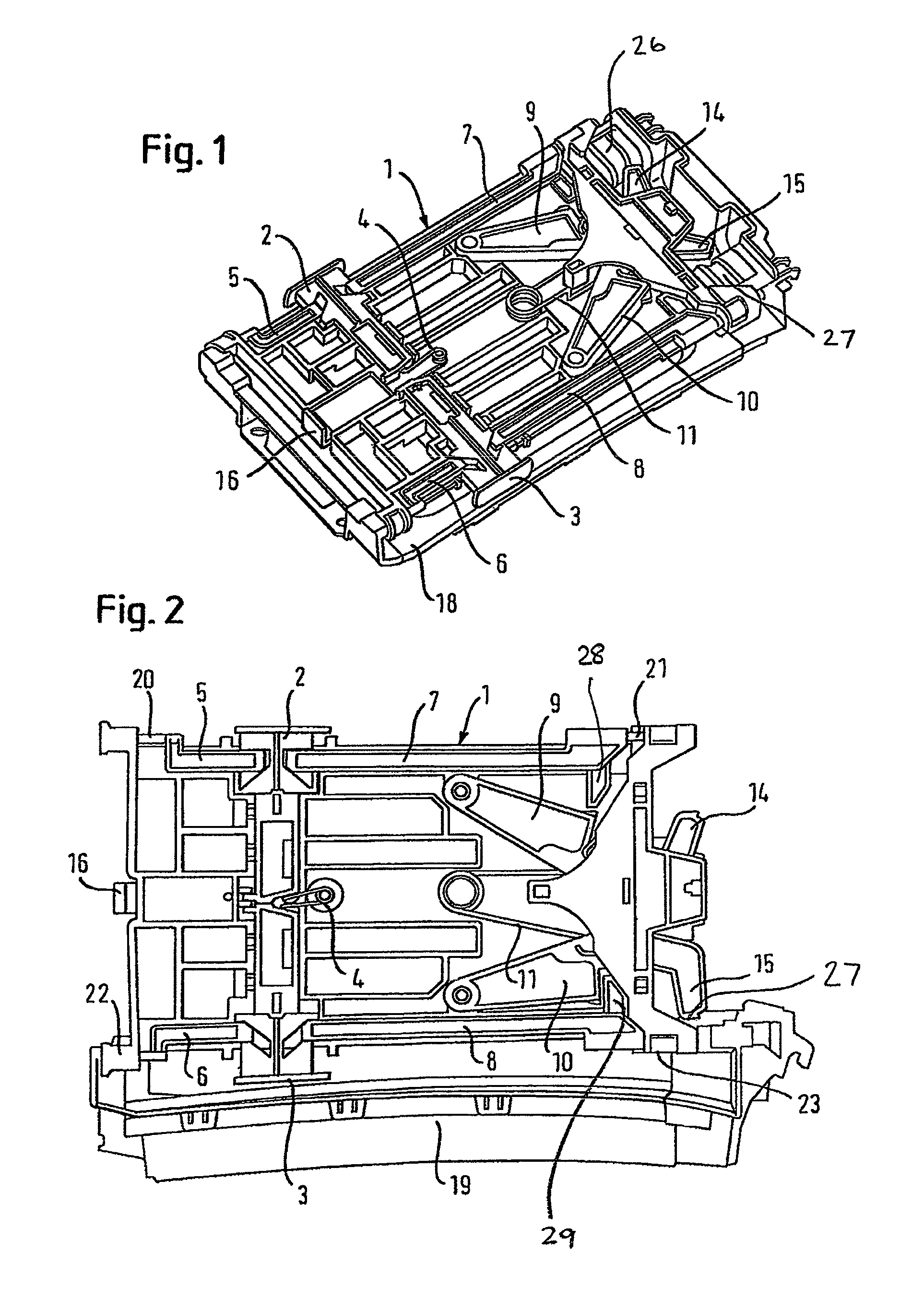

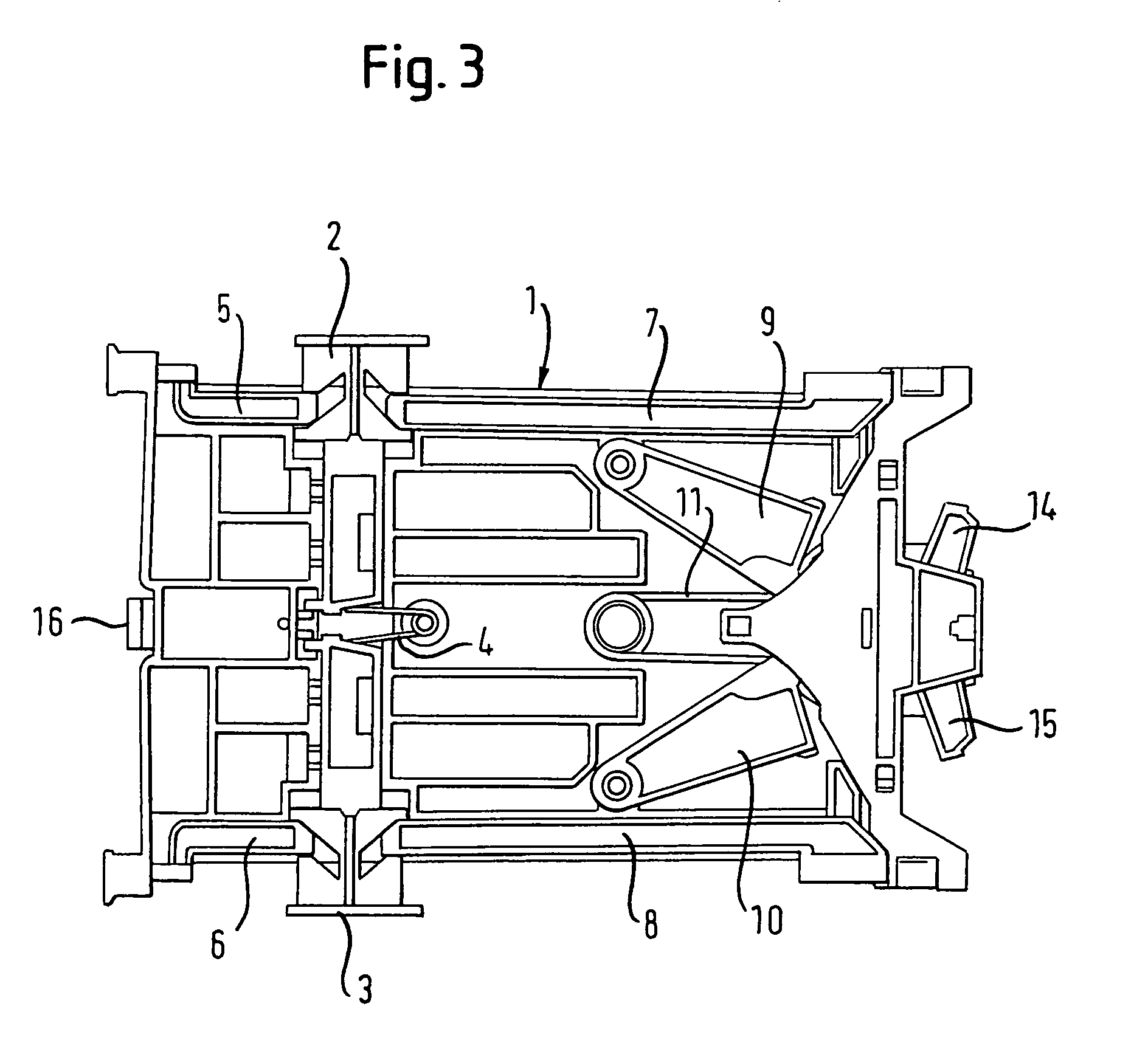

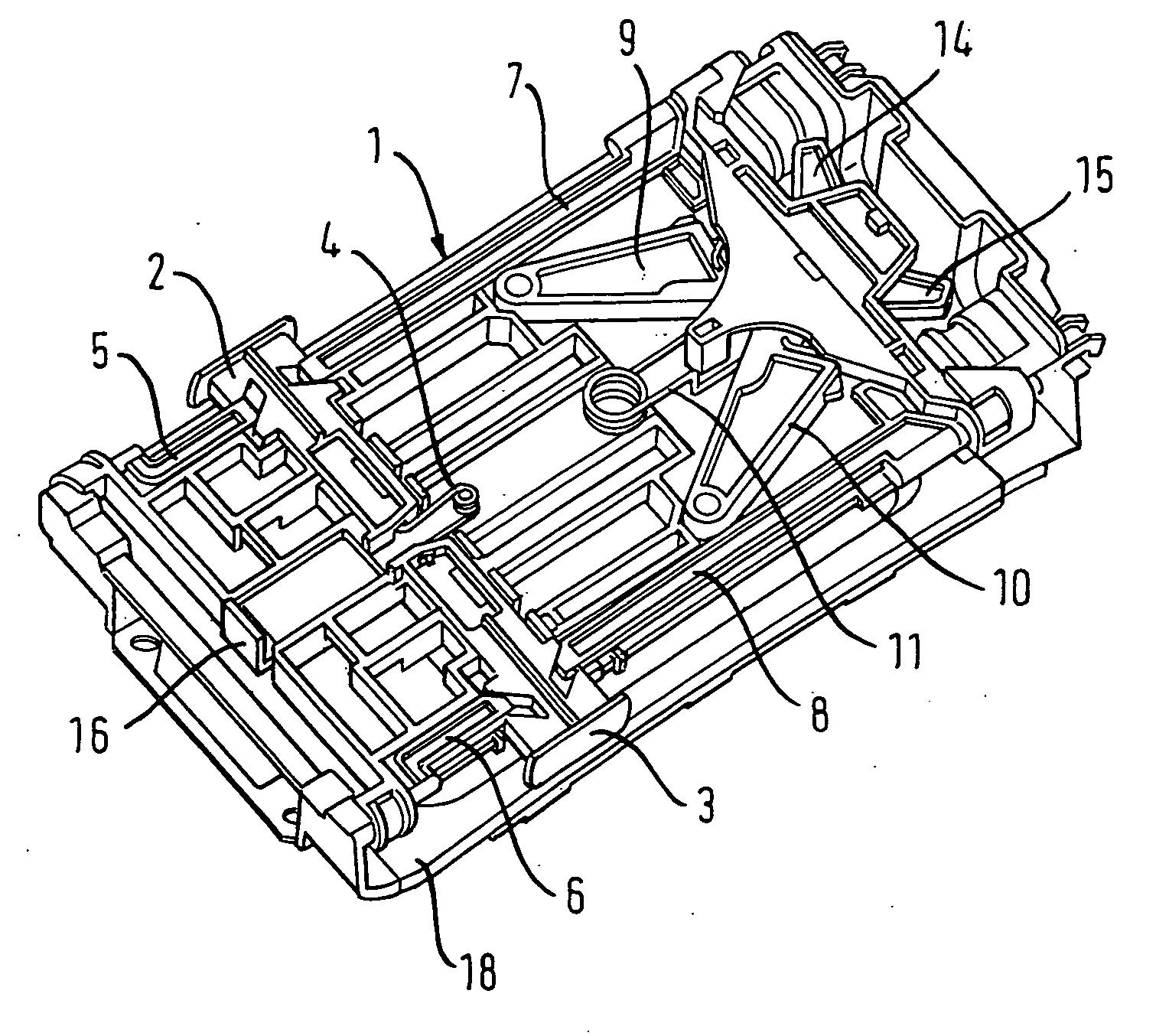

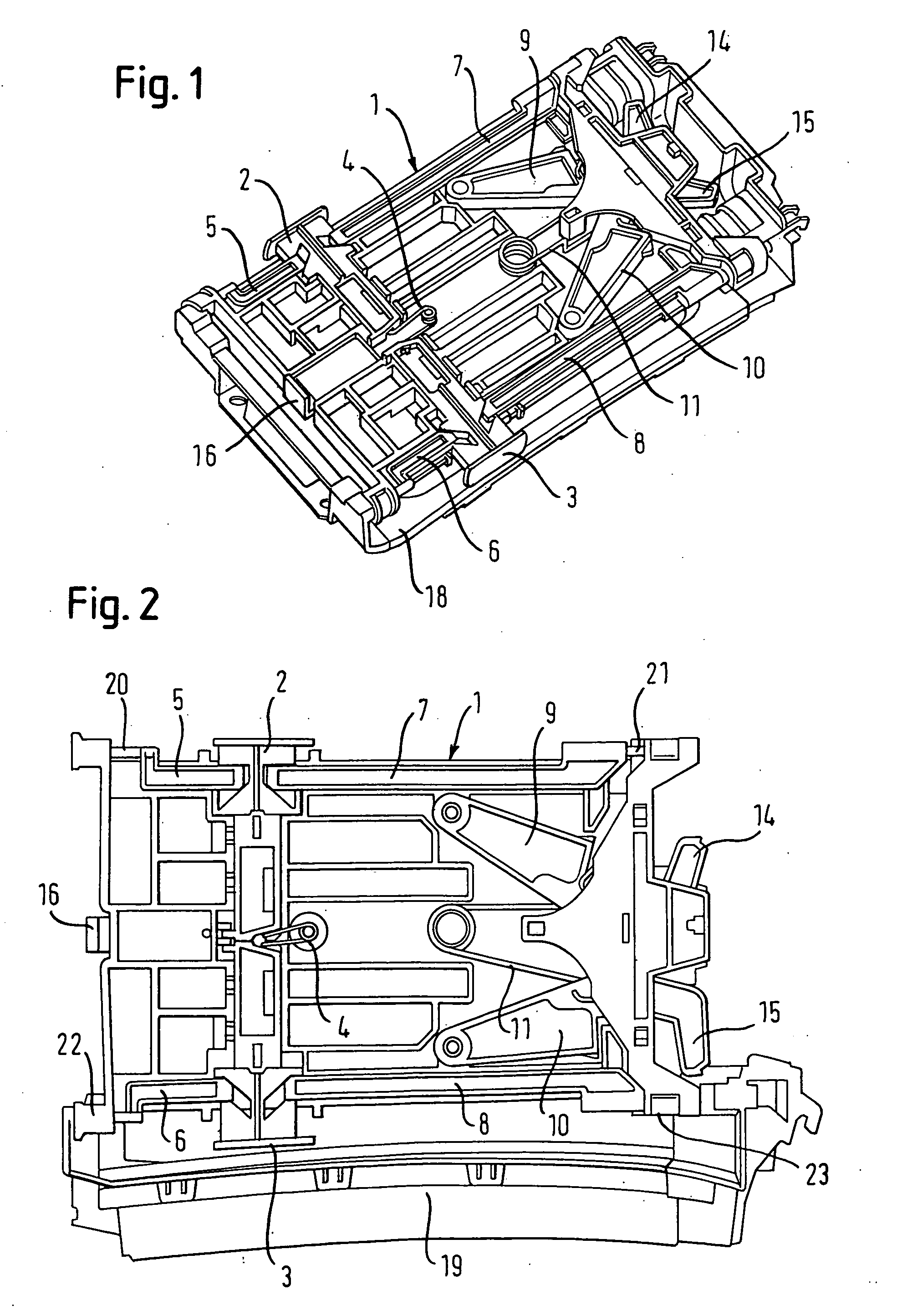

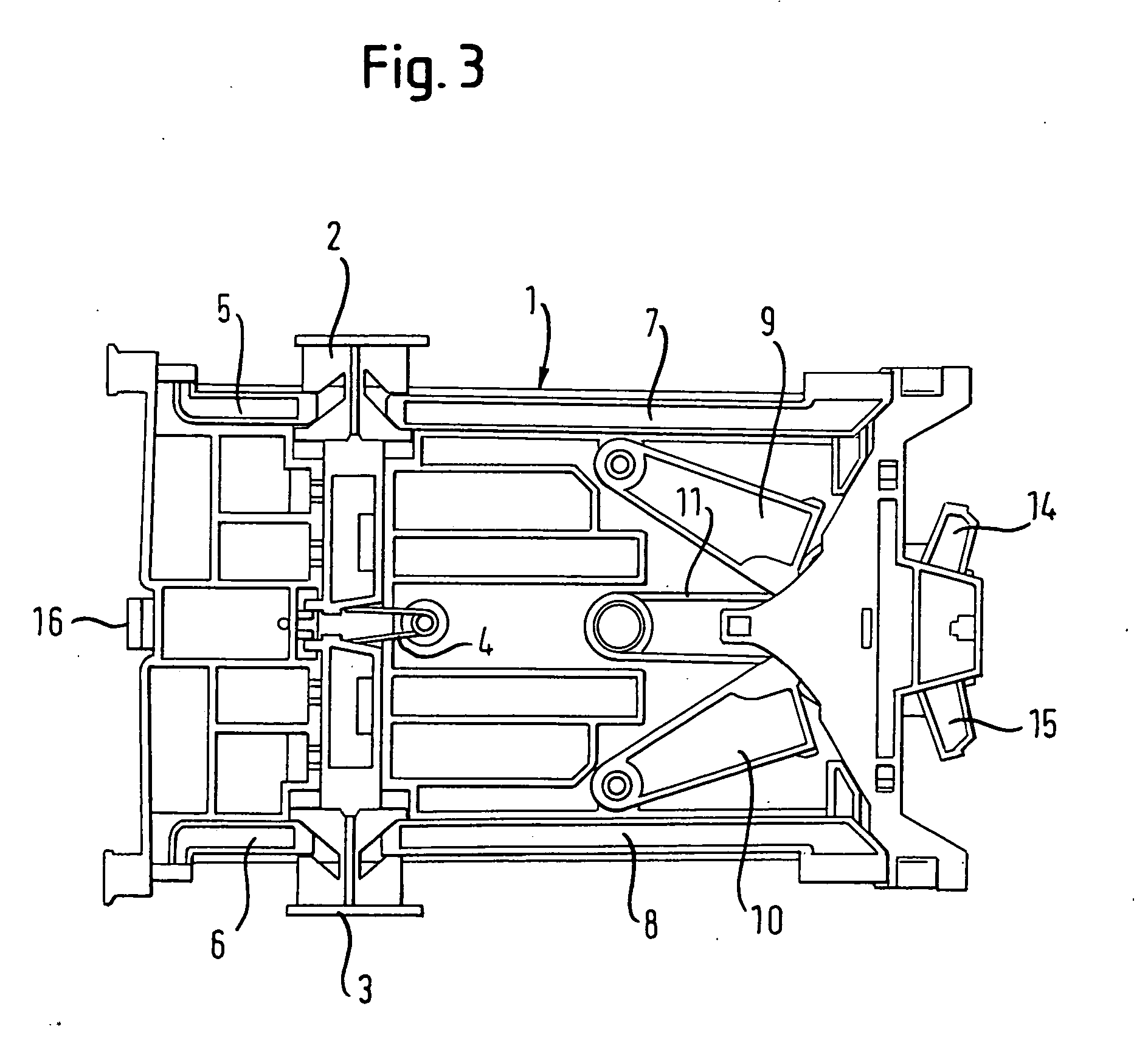

Housing with lid and kinematic frame

ActiveUS7870984B2Easy to produceReduce production scrap rateLidsNon-removalbe lids/coversEngineeringMechanical engineering

The invention relates to a device for holding objects, preferably a telephone, in particular for use in a center arm rest and / or the center console of a vehicle, with a frame or receptacle and a reversibly closable lid which is mounted so that it may be swiveled in each case about one of the rotary axes arranged in the region of the upper closing edges of the side walls of the frame or container and lying essentially parallel to the closing edges. The lid has an opening and closing mechanism which is arranged in a function carrier frame that may be connected to the lid. In addition, the invention relates to a method for the production of a device for holding objects, in particular for use in a center arm rest and / or the center console of a vehicle.

Owner:LISA DRAXLMAIER GMBH

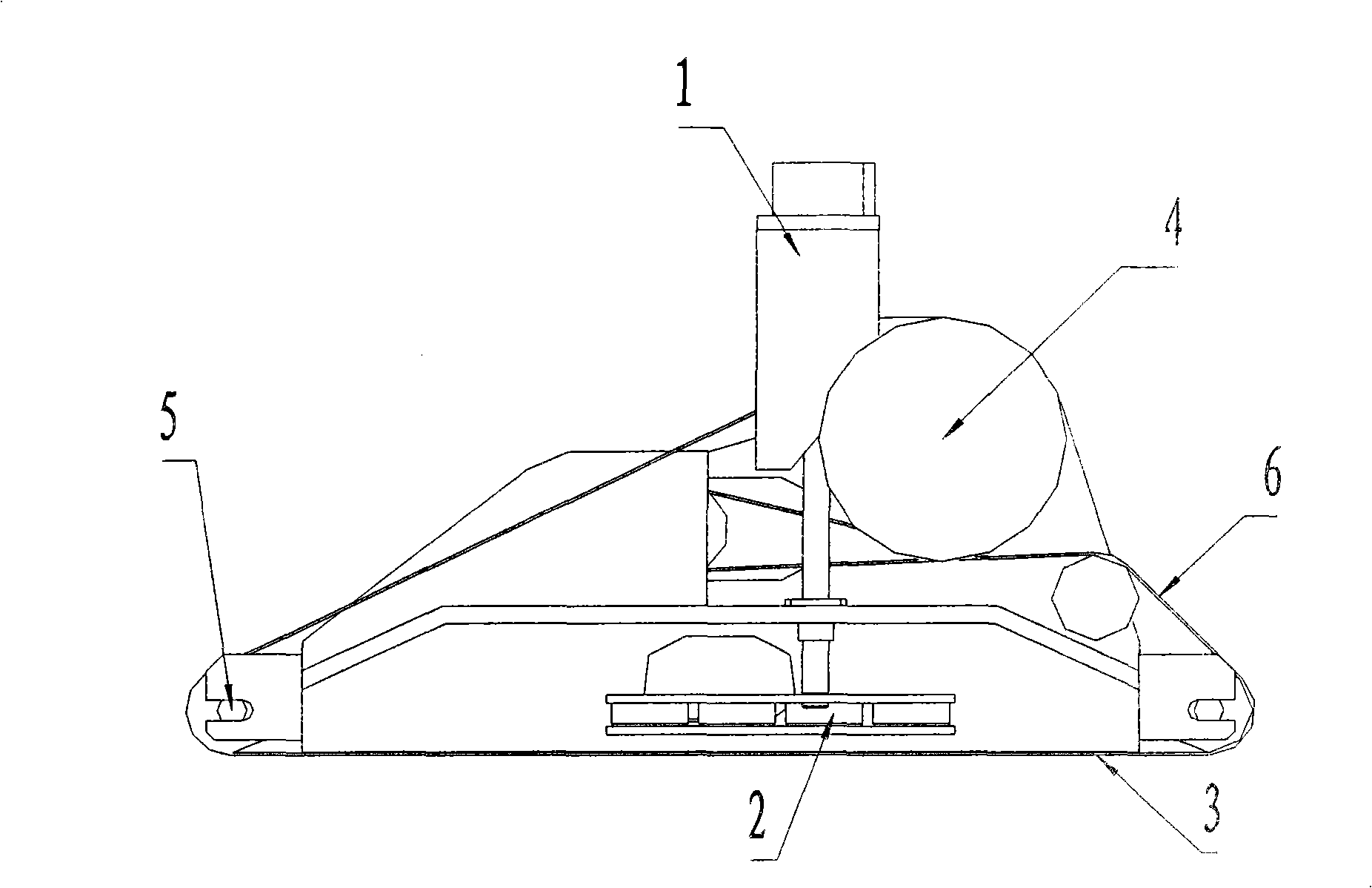

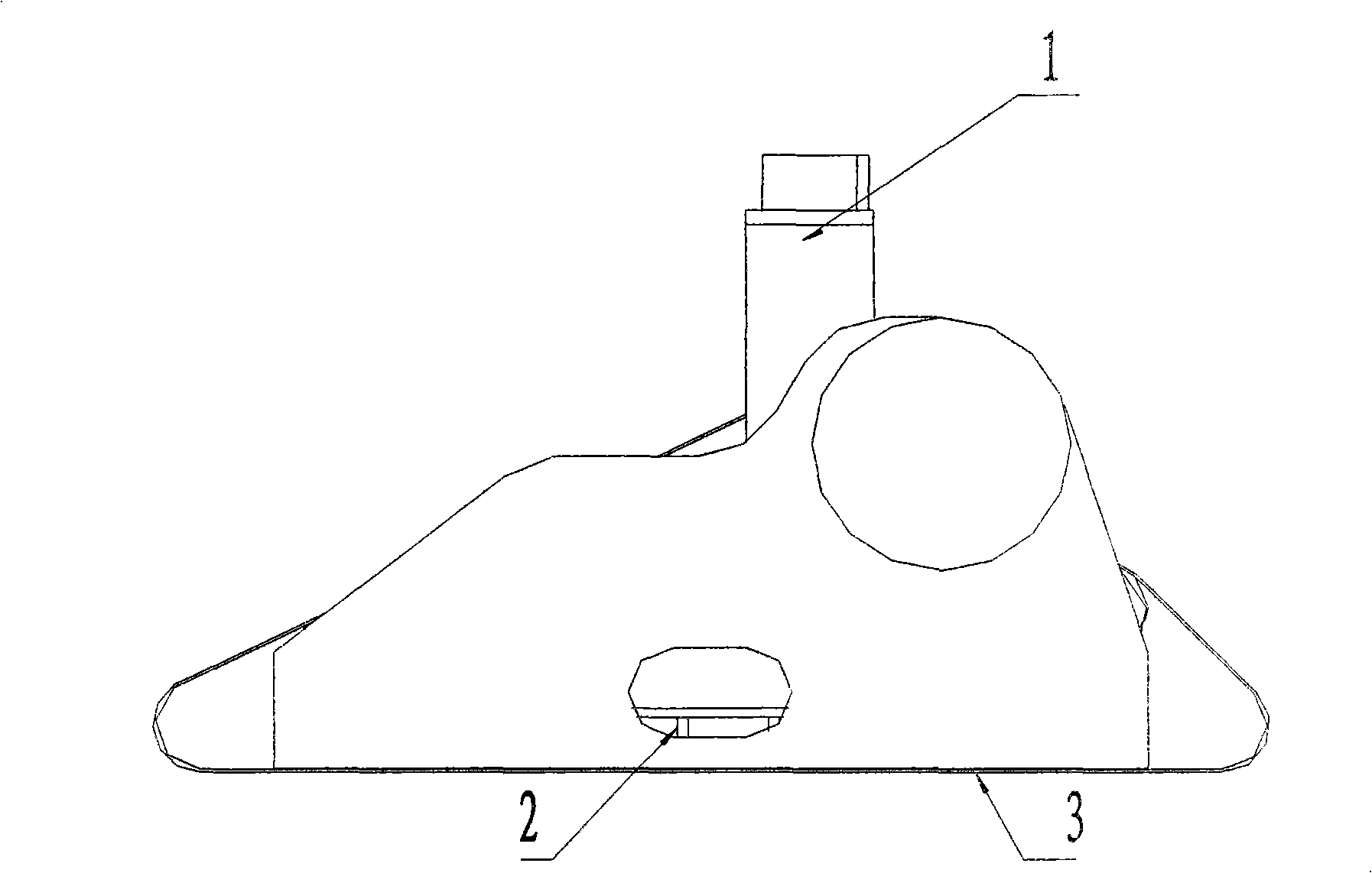

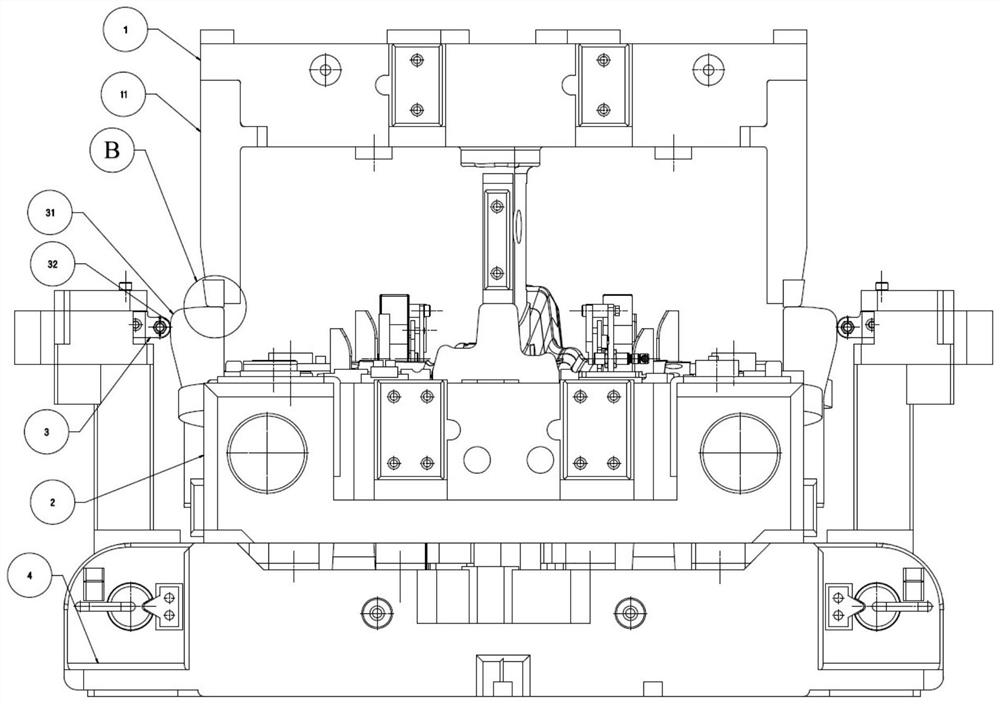

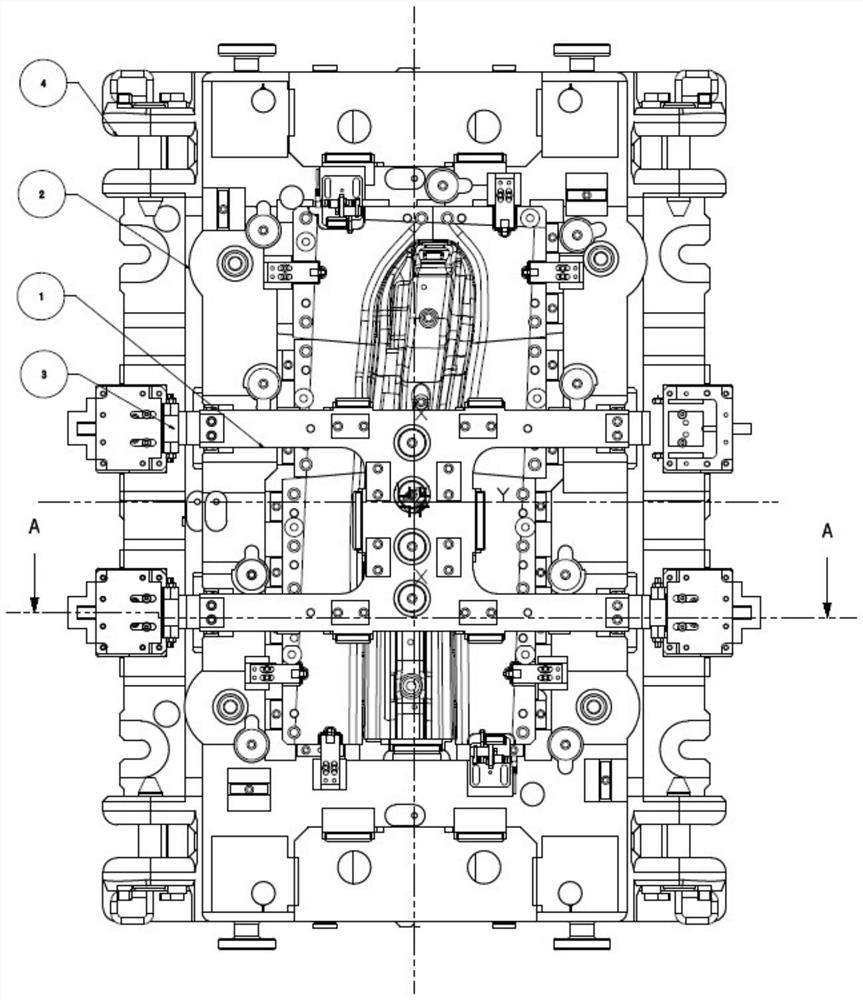

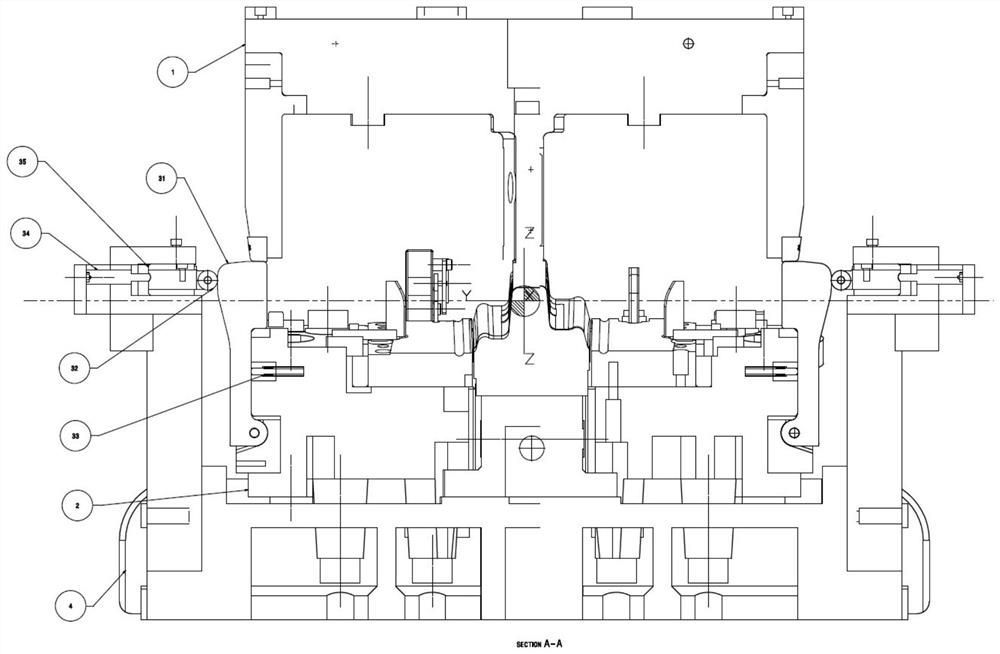

Mechanical mechanism for delayed release of upper die core of drawing die

PendingCN113579074AGuarantee processing qualityReduce production scrap rateShaping toolsWaste productStructural engineering

The invention provides a mechanical mechanism for delayed release of an upper die core of a drawing die. The mechanical mechanism comprises delay units (3). The delay units (3) comprise supporting rollers capable of horizontally reciprocating and rotary supporting blocks abutting against the supporting rollers. Supporting boxes are distributed on a lower die holder (4) at equal intervals, the supporting rollers (32) are arranged in the supporting boxes, the rotary supporting blocks (31) are hinged to the peripheral side of a blank holder (2), the peripheral side of the upper die core (1) extends downwards to form protruding blocks (11), and when the die is closed, the lower surfaces of the protruding blocks (11) abut against the upper surfaces of the rotary supporting blocks (31). According to the mechanical mechanism for delayed release of the upper die core of the drawing die, the mode that the rotary supporting blocks and the protruding blocks are matched with each other is adopted, it is guaranteed that the upper die core cannot be released immediately after die opening, the effect of delayed release is achieved, the machining quality of parts is guaranteed, waste products are avoided, and good economical efficiency is achieved.

Owner:TIANJIN MOTOR DIES

Housing with lid and kinematic frame

ActiveUS20050199664A1Facilitates functional checkFacilitates of individual partLidsNon-removalbe lids/coversEngineeringHandrail

The invention relates to a device for holding objects, preferably a telephone, in particular for use in a centre arm rest and / or the centre console of a vehicle, with a frame or receptacle and a reversibly closable lid which is mounted so that it may be swivelled in each case about one of the rotary axes arranged in the region of the upper closing edges of the side walls of the frame or container and lying essentially parallel to the closing edges. The lid has an opening and closing mechanism which is arranged in a function carrier frame that may be connected to the lid. In addition, the invention relates to a method for the production of a device for holding objects, in particular for use in a centre arm rest and / or the centre console of a vehicle.

Owner:LISA DRAXLMAIER GMBH

PP-R pipe mould

InactiveCN106079359ACompact structureEasy to operateTubular articlesRejection rateComposite material

The invention relates to a PP-R pipe mould which comprises a mould connecting part, a mould plastifying part and a mould forming part; the mould connecting part, the mould plastifying part and the mould forming part are sequentially connected. The mould connecting part, the mould plastifying part and the mould forming part are formed into an integer, plastic melt enters the mould from the mould connecting part and spirally moves in an axial direction in the mould plastifying part, so that plastic melt plastifying effect is strengthened, and finally formed pipe blank leaves the mould from the mould forming part. The PP-R pipe mould is compact in structure, is simple in production operation, effectively improves the problem that a PP-R pipe easily generates confluence lines, air pores and crystal points, can be suitable for production use of PP-R pipe products of the same type, is extremely high in production stability, effectively improves product quality and reduces a production rejection rate.

Owner:GUANGDONG LIANSU TECH INDAL

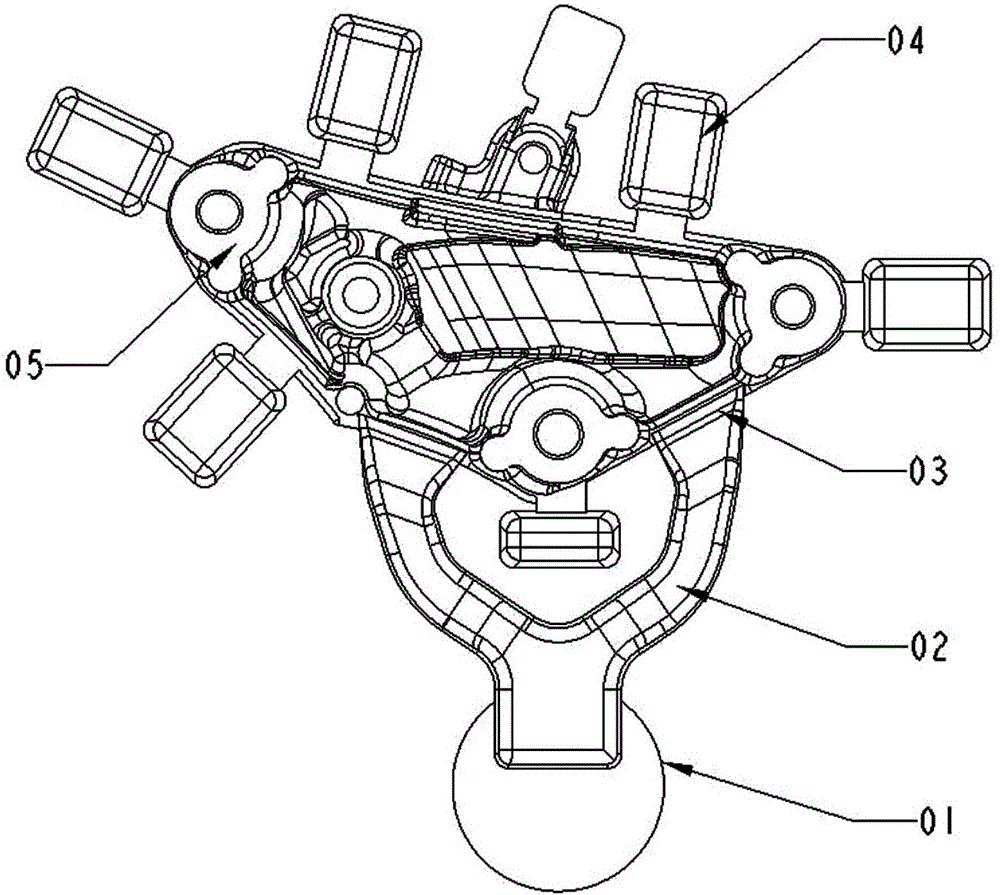

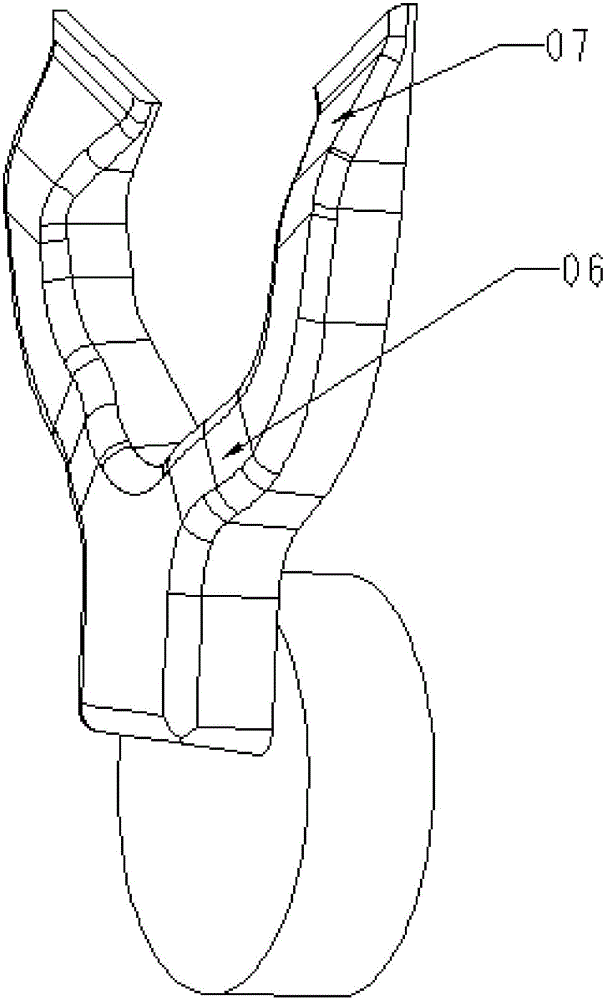

Pouring device for high-pressure casting mold

The invention provides a pouring device for a high-pressure casting product. The pouring device comprises a material cake (01), a cross gate (02), an inner sprue (03) and slag accumulating ladles (04). The pouring device is characterized in that the inner sprue (03) is in lap joint with the surfaces of cast parts (05) and is arranged with the shape changed along the surfaces of the cast parts (05); the cross gate (02) comprises the input end connected to the material cake (01) and the two output ends connected with the inner sprue (03) correspondingly; and the cross sectional area, in the direction of the inner sprue (03), of the cross gate (02) is decreased step by step. The pouring device used for an aluminum alloy pressure casting mold has the advantages that washing of liquid aluminum to a mold core is avoided in the mold filling process, and pulling damage defects of products and the mold are reduced; meanwhile, the flowing smoothness of the liquid aluminum in a cavity is guaranteed, the exhausting performance of the cavity is good, and pore defects of the cast parts are remarkably reduced; and the pouring gate and exhausting structural design is reasonable, the quality of the products and the mold is guaranteed, and the production effects are improved.

Owner:CITIC DICASTAL

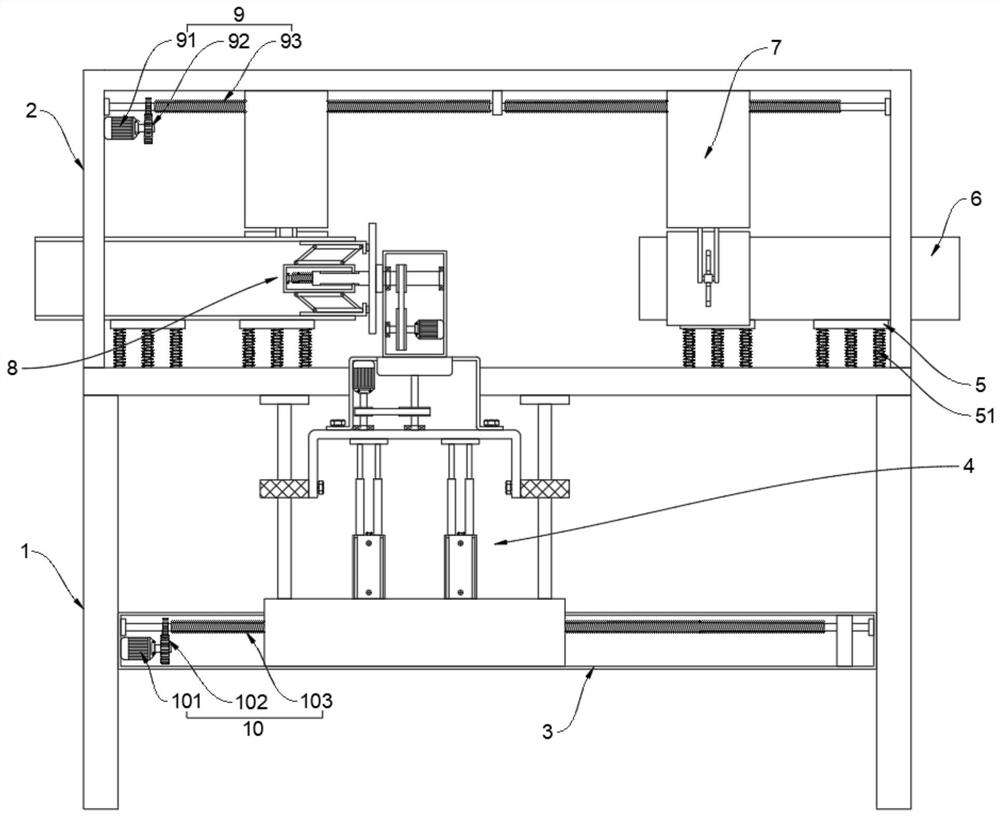

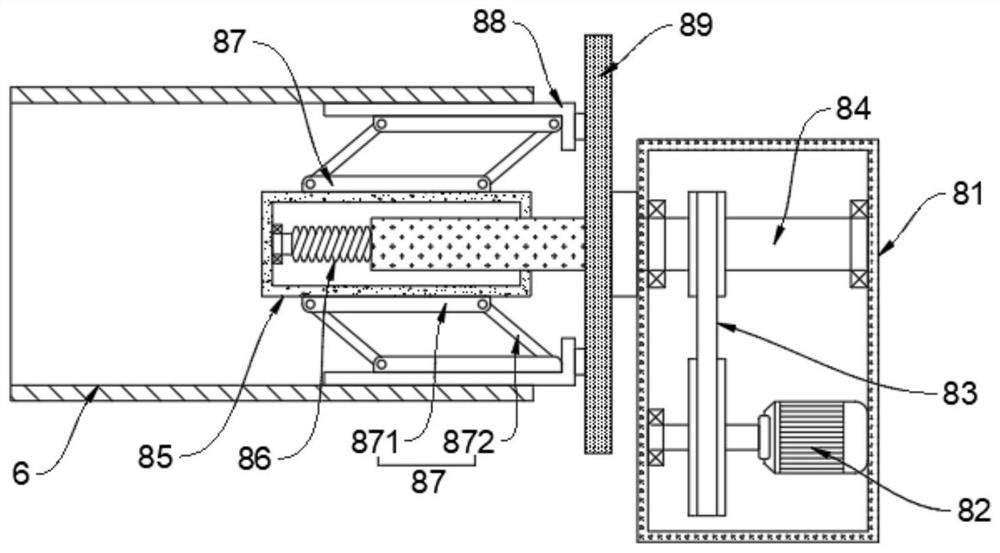

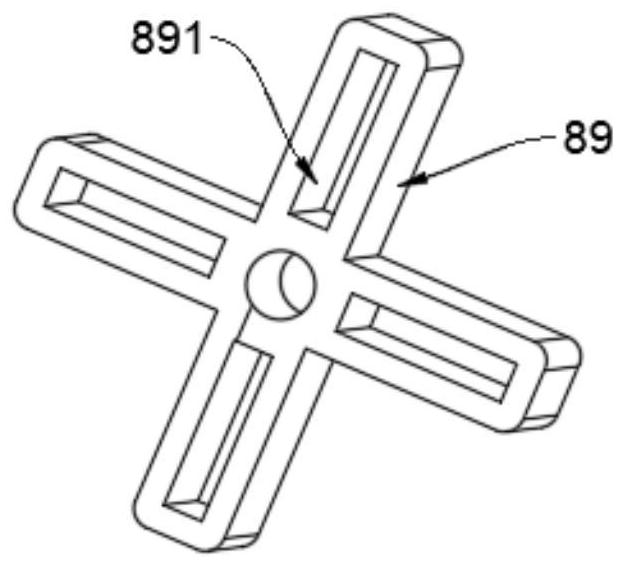

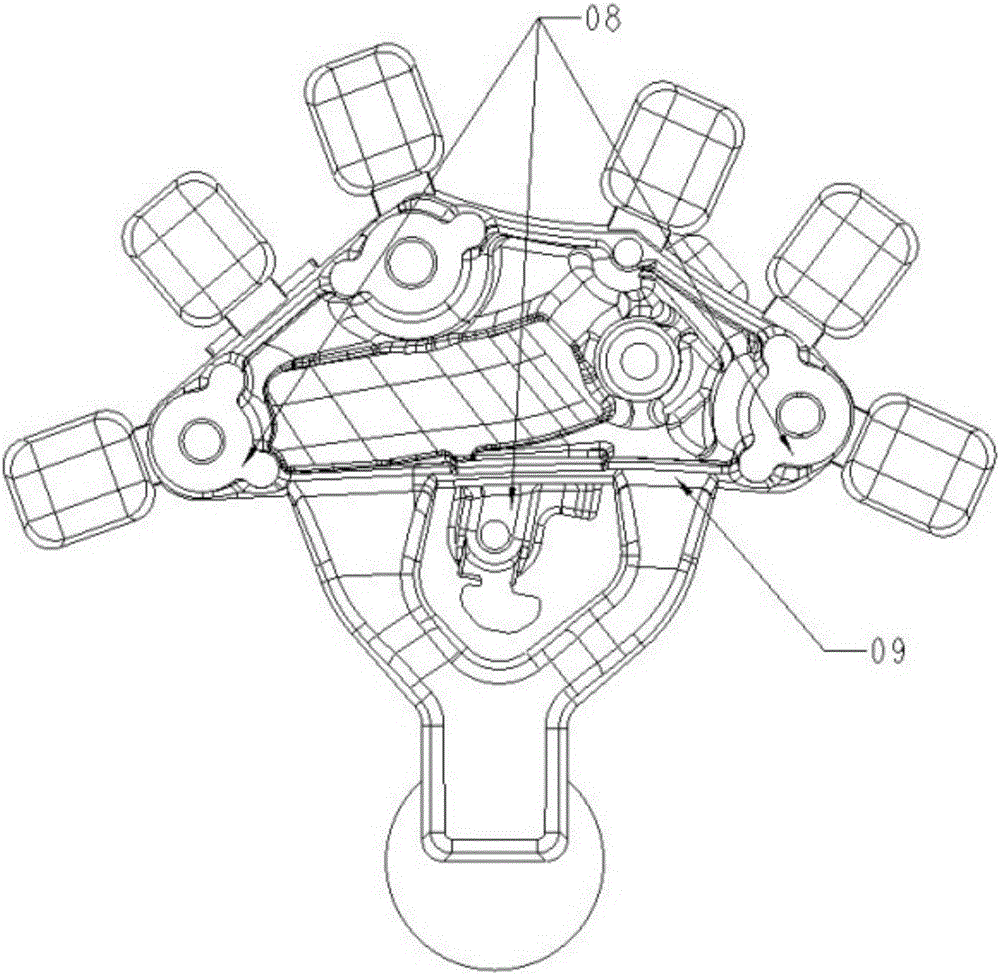

An air cushion floating non-contact waxing mechanism

ActiveCN111318411BReduce scratchesReduce production scrap rateLiquid surface applicatorsCoatingsPhysicsCoating

The invention relates to an air-cushion floating non-contact wax coating mechanism which is characterized in that a wax coating spindle penetrates through axial center holes of a first expansion sleeve and a second expansion sleeve sequentially; an air distribution hub is arranged on the profile surface of the first expansion sleeve in an embedding manner; a star wheel hub is arranged on the profile surface of the second expansion sleeve in an embedding manner; a wax coating star wheel is fixedly connected with the star wheel hub; air guide holes are formed in the edge of the wax coating starwheel; a closed space is formed among the air distribution hub, a star wheel hub and a wax coating star wheel; vacuum spacing blocks and compressed air spacing blocks are arranged inside the closed space; the closed space is divided by the vacuum spacing blocks and the compressed air spacing blocks into vacuum adsorption areas and compressed air action areas; and the vacuum adsorption areas or thecompressed air action areas in the closed space communicate through the air guide holes. According to the technical scheme, pop-top cans are prevented from being in contact with a metallic wax coating star wheel body when coated with wax, the rejection rate during the production can be reduced, the structure can be simplified, the maintenance cost can be reduced, the downtime can be shortened, and the production efficiency can be improved.

Owner:PACIFIC CAN SHENYANG CO LTD

Centrifugal casting method and device of magnesium alloy hub

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die anda lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

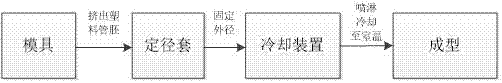

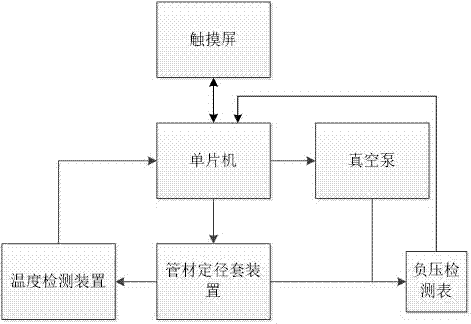

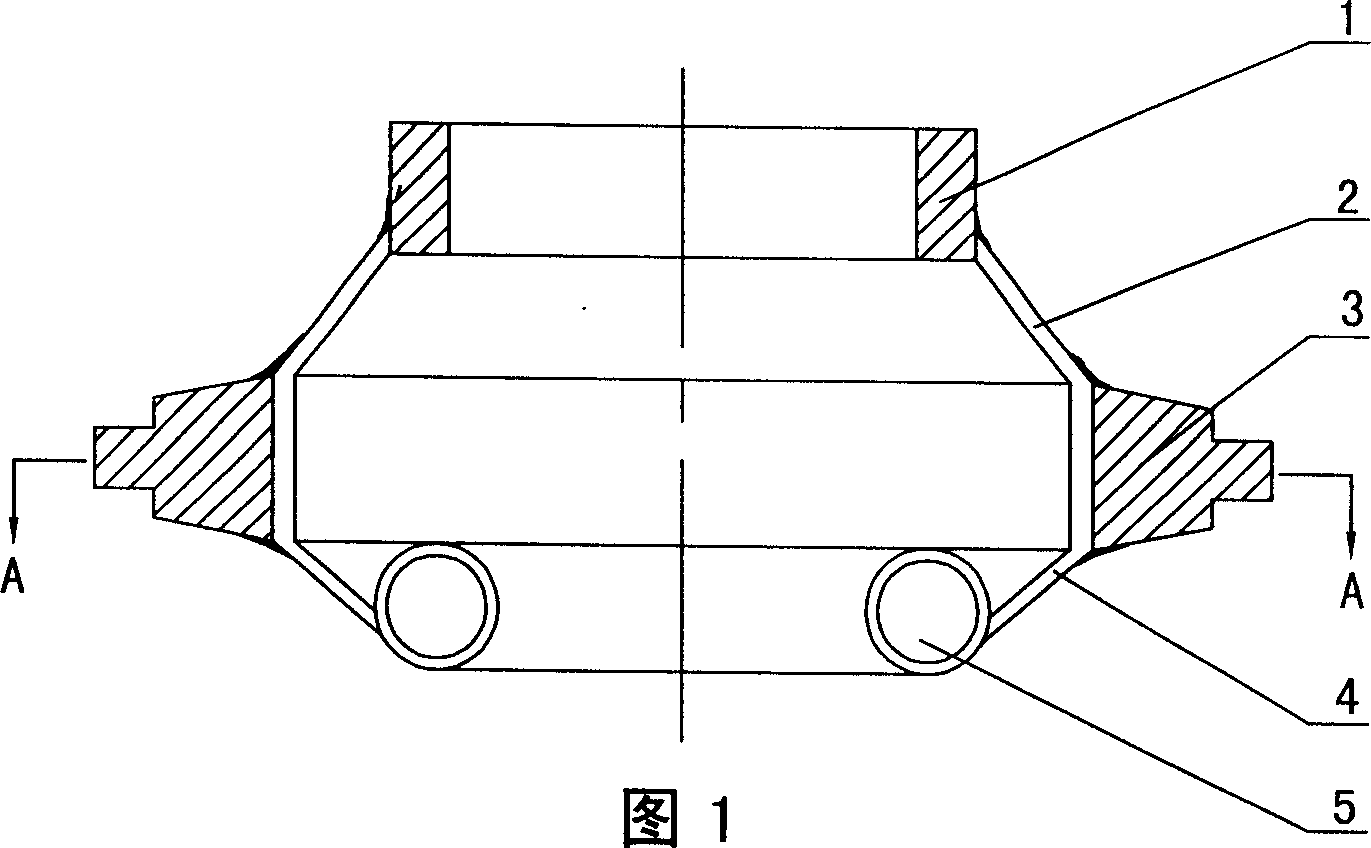

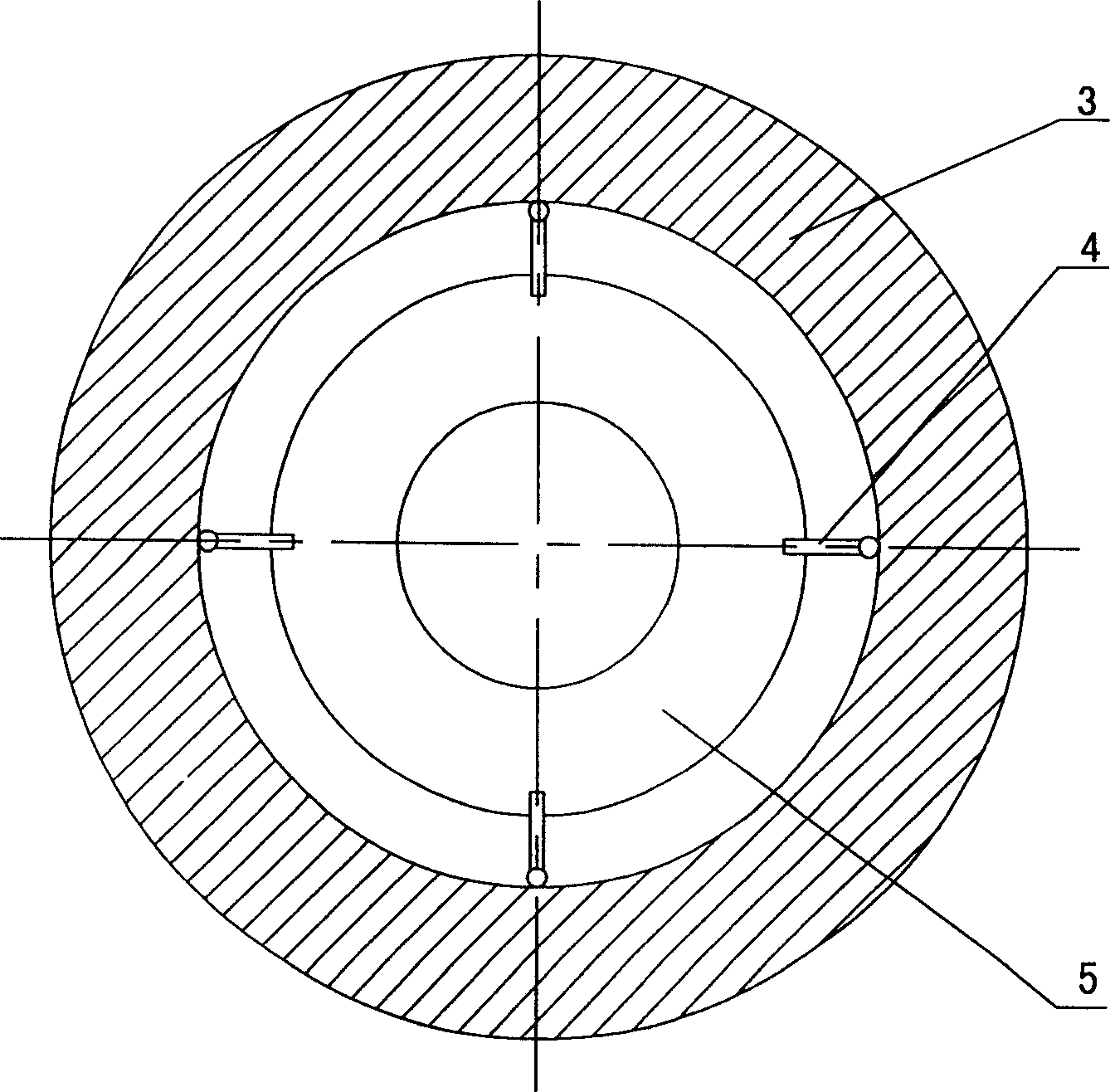

An automatic control system for pipe outer diameter

The invention discloses an automatic pipe outer diameter control system. The automatic pipe outer diameter control system comprises a negative pressure detection gauge, a temperature detection device, a single-chip microcomputer, a touch screen, a vacuum pump, a negative pressure pipeline, a pipe sizing sleeve device and an alarm device. The vacuum pump is connected with the pipe sizing sleeve device through the negative pressure pipeline, the negative pressure detection gauge is installed on the negative pressure pipeline, the touch screen is installed on the single-chip microcomputer in a connected mode, and the single-chip microcomputer is connected with the negative pressure detection gauge, the temperature detection device, the vacuum pump and the alarm device. The pipe sizing sleeve device comprises a sizing sleeve shell, a pipe sizing sleeve, a spray cooling mechanism and a sealing mechanism. By additionally arranging the negative pressure detection gauge and other devices, the pipe outer diameter sizing process is automatically regulated and controlled, manual work is reduced, and the rejection rate of production is reduced; meanwhile, an alarm can be given to remind operators to carry out emergency processing when changes beyond the automatic regulation and control capability of the system happen, and thus the safety coefficient of production is increased; by arranging a frequency converter, the vacuum degree of the vacuum pump can be regulated, and meanwhile electric energy can be saved.

Owner:CHENGDU CHUANXING TECH PLASTICS INDUSRTY CO LTD

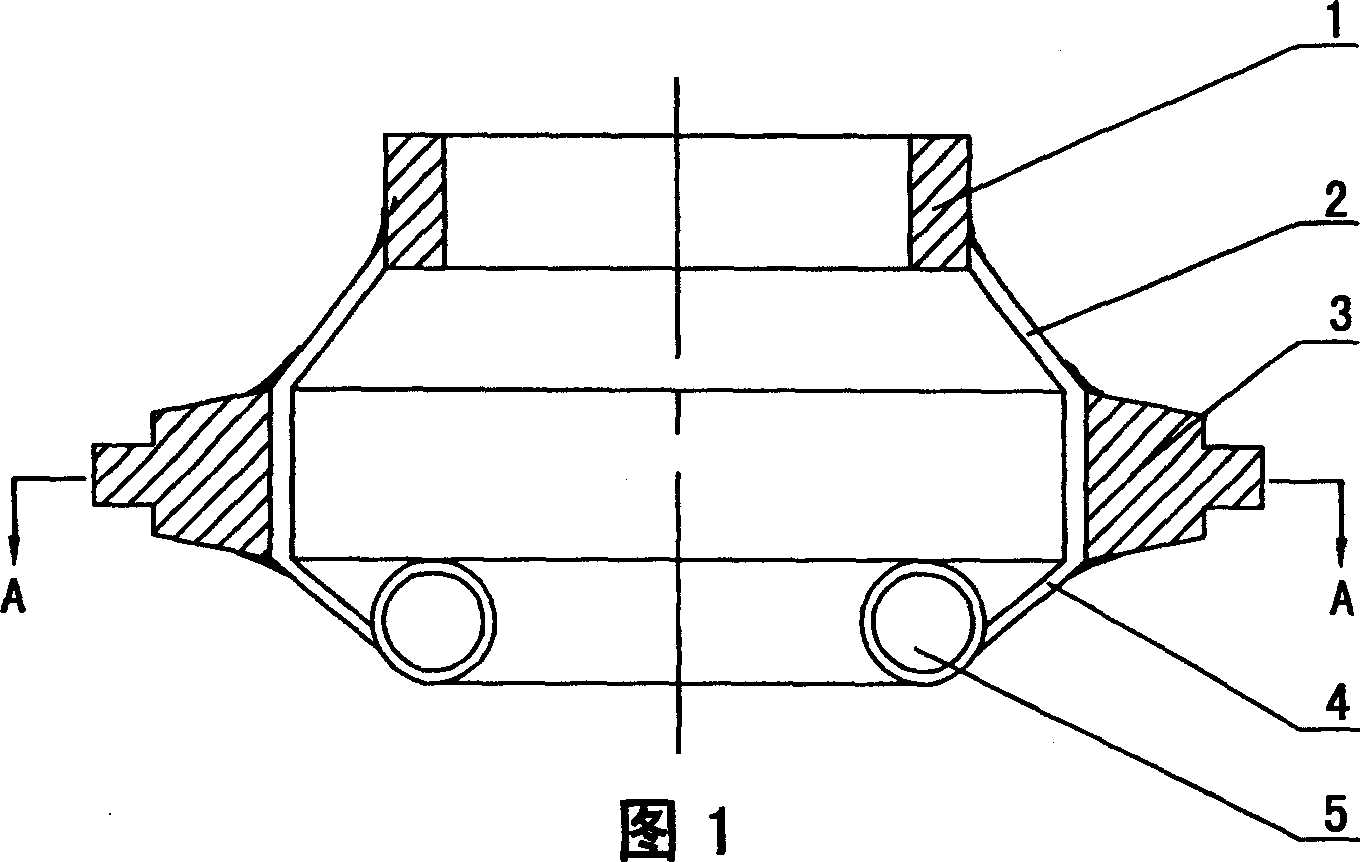

Novel aluminium piston wearable collar and method for manufacturing piston

InactiveCN1485536AAvoid bulkyReasonable structureMachines/enginesPistonsCombustion chamberInternal combustion engine

The invention relates to an improved aluminum piston wear resisting inlaid ring and the method for making the piston using the wear resisting inlaid ring, wherein the wear resisting inlaid ring is used in the diesel engine piston, including a wear resisting inlaid ring and an internal cooling channel, the wear resisting inlaid ring and the internal cooling channel are in fixed connection through a support stand, the wear resisting inlaid ring connects with a combustion chamber larynx aperture guard ring through the support stand, the internal cooling channel is in fixed connection with the wear resisting ring through the support stand and they are cast into the piston body integrally. The invention realizes simplified structure and easy production.

Owner:苏道胜

Printing machine automatic adjusting system and method based on UVW platform and machine vision

ActiveCN114393915ASmall changesImprove response rateRotary pressesOther printing apparatusVisual monitoringMachine vision

The invention relates to a printing machine automatic adjusting system based on a UVW platform and machine vision, the printing machine automatic adjusting system comprises an automatic alignment platform, and a printing head and a vision monitoring device which are connected with the automatic alignment platform, the printing head is embedded in the upper end face of the automatic alignment platform, and the vision monitoring device is connected with the outer side face of the automatic alignment platform through an adjusting mechanism. The using method comprises the two steps of equipment assembling and machining operation. On one hand, various automatic alignment platforms on the market can be effectively operated in a matched mode according to use requirements; and on the other hand, human eye judgment can be replaced by industrial camera photographing, and the current data volume needing to be translated and rotated is accurately calculated, so that the working precision of machining operation is greatly improved, meanwhile, the difficulty of equipment production learning and operation is effectively reduced, and the production rejection rate is reduced.

Owner:昆山市和博电子科技有限公司

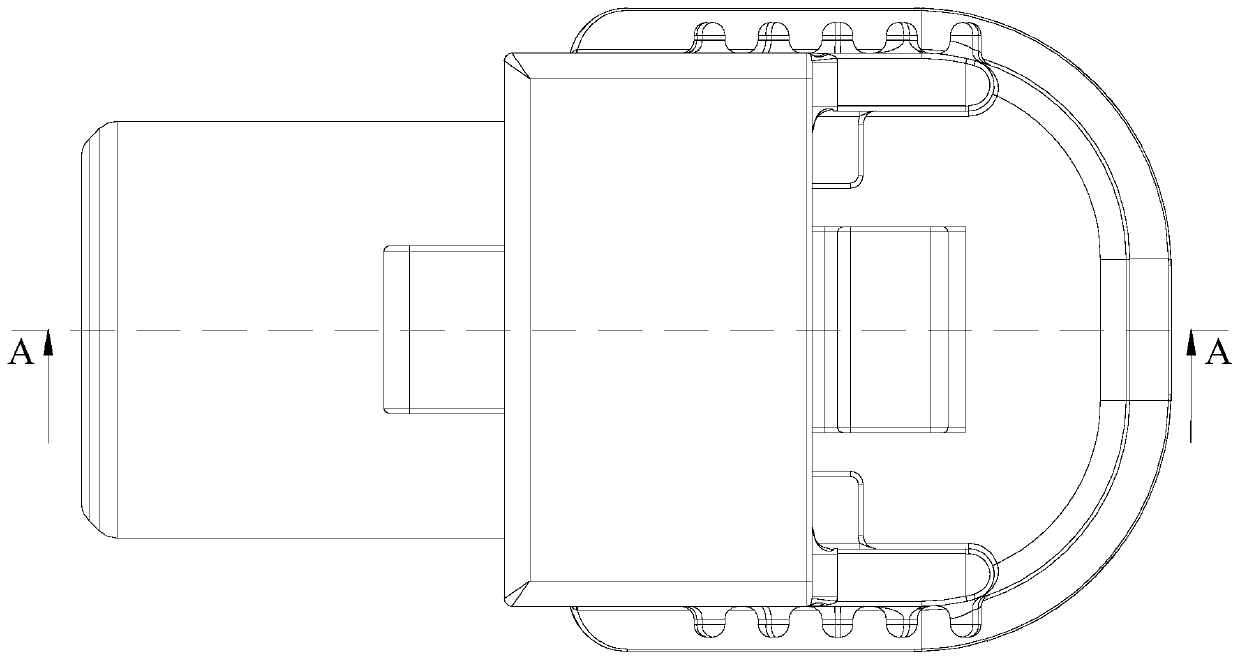

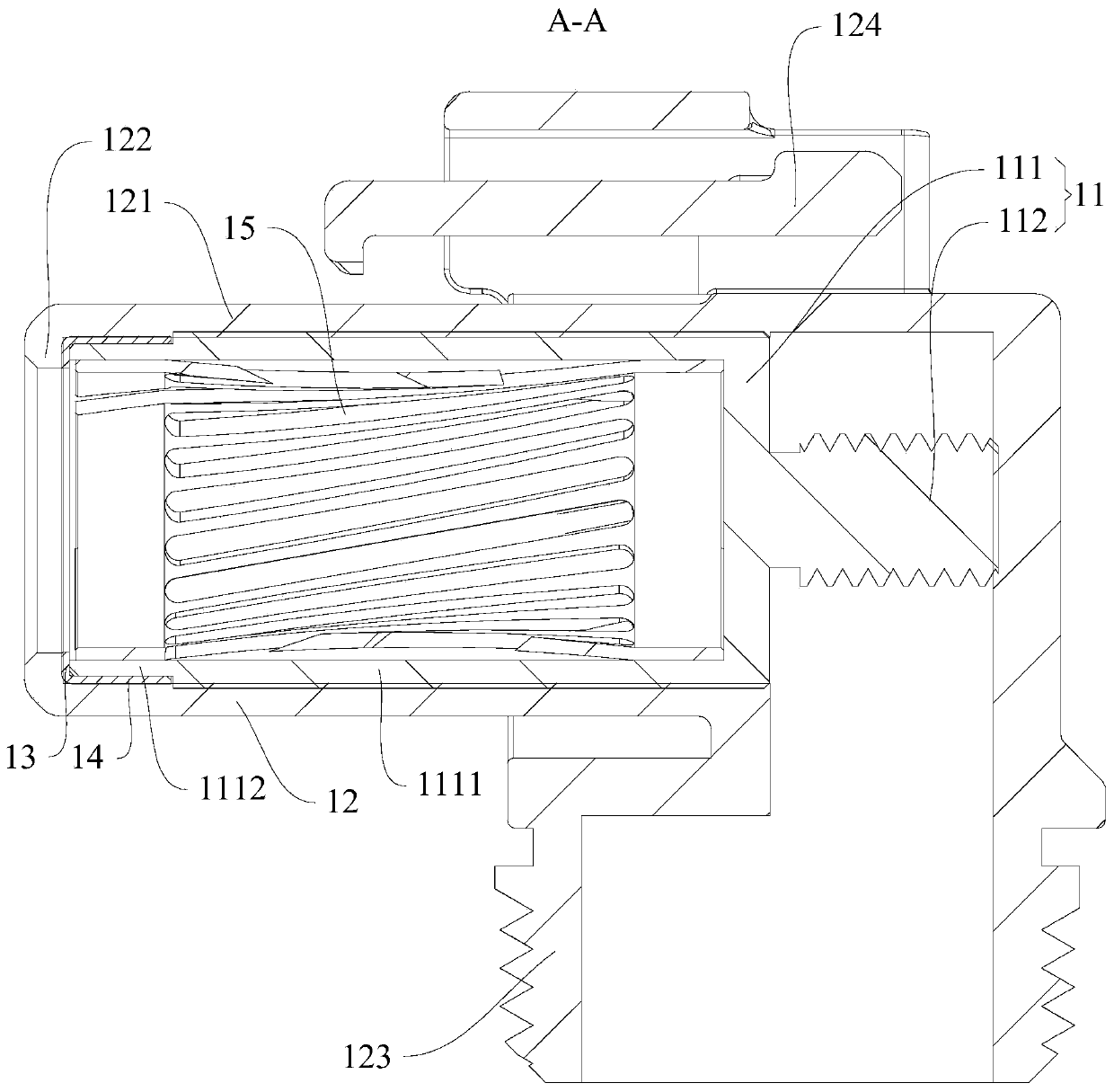

Electrical connector

PendingCN109861023AReduce production scrap rateReduce manufacturing costCouplings bases/casesElectrical connectionBiomedical engineering

The invention relates to the technical field of electrical connectors, and provides an electrical connector. The electrical connector comprises a conductive sleeve, an encapsulating outer casing and amaterial blocking ring. The conductive sleeve comprises an insertion portion and a wiring portion, one end of the insertion portion is provided with an insertion hole, and the other end of the insertion portion is electrically connected with the wiring portion; the encapsulating outer casing comprises a housing main body and an anti-off snap ring, one side of the housing main body is provided with an insertion holding hole, the other side thereof is provided with a wiring holding hole, and the anti-off snap ring is formed by extending inwards from the port edge of the hole port of the insertion holding hole. The electrical connector further comprises a material blocking ring arranged in the insertion holding hole and located between the anti-off snap ring and the insertion portion, wherein the inner ring diameter of the material blocking ring is smaller than the hole diameter of the insertion hole. The electrical connector is provided with the material blocking ring at the insertion hole of the conductive sleeve to block an insulation material from being incident to a matching portion of the conductive sleeve in the late process for forming the encapsulating outer casing so as toguarantee the assembling and electrical connection conduction of the conductive sleeve and a plug pin in the late phase without the influence of the insulation material.

Owner:株洲时代龙友科技有限公司

Automatic packaging equipment for integrated packaging products

PendingCN114434870AReduce production scrap rateImprove product qualityPaper-makingBox making operationsProcess engineeringAssembly line

The invention discloses automatic packaging equipment for integrated packaging products, and belongs to the field of packaging product production.The automatic packaging equipment comprises a workbench, a gluing assembly arranged on one side of the workbench, a pressing assembly arranged in the middle of the workbench and a feeding assembly arranged on the edge side of the upper portion of the workbench, the gluing assembly is used for gluing paperboards, and the pressing assembly is used for pressing the paperboards; a paperboard is placed under the gluing assembly, the feeding assembly conveys the paperboard subjected to foaming and gluing to the pressing assembly to be pressed and formed, a conveyor is fixedly arranged at the bottom of the workbench, and the gluing assembly comprises a gluing machine fixedly installed above the workbench and a gluing gun connected to the glue outlet end of the gluing machine through a glue outlet pipe. By means of automatic and assembly line type production, the problems that in manual production operation, the production efficiency of packaging products is low, and manpower is consumed are solved, the problem that due to misoperation caused by manual operation, the product quality is affected is solved, and through pressing of the forming opening, paperboards and foam are firmly bonded in the packaging product production process.

Owner:安徽艾柯泡塑股份有限公司

Novel aluminium piston wearable collar and method for manufacturing piston

InactiveCN1266376CPrecise positioningReasonable structureMachines/enginesPistonsCombustion chamberEngineering

The invention relates to an improved aluminum piston wear resisting inlaid ring and the method for making the piston using the wear resisting inlaid ring, wherein the wear resisting inlaid ring is used in the diesel engine piston, including a wear resisting inlaid ring and an internal cooling channel, the wear resisting inlaid ring and the internal cooling channel are in fixed connection through a support stand, the wear resisting inlaid ring connects with a combustion chamber larynx aperture guard ring through the support stand, the internal cooling channel is in fixed connection with the wear resisting ring through the support stand and they are cast into the piston body integrally. The invention realizes simplified structure and easy production.

Owner:苏道胜

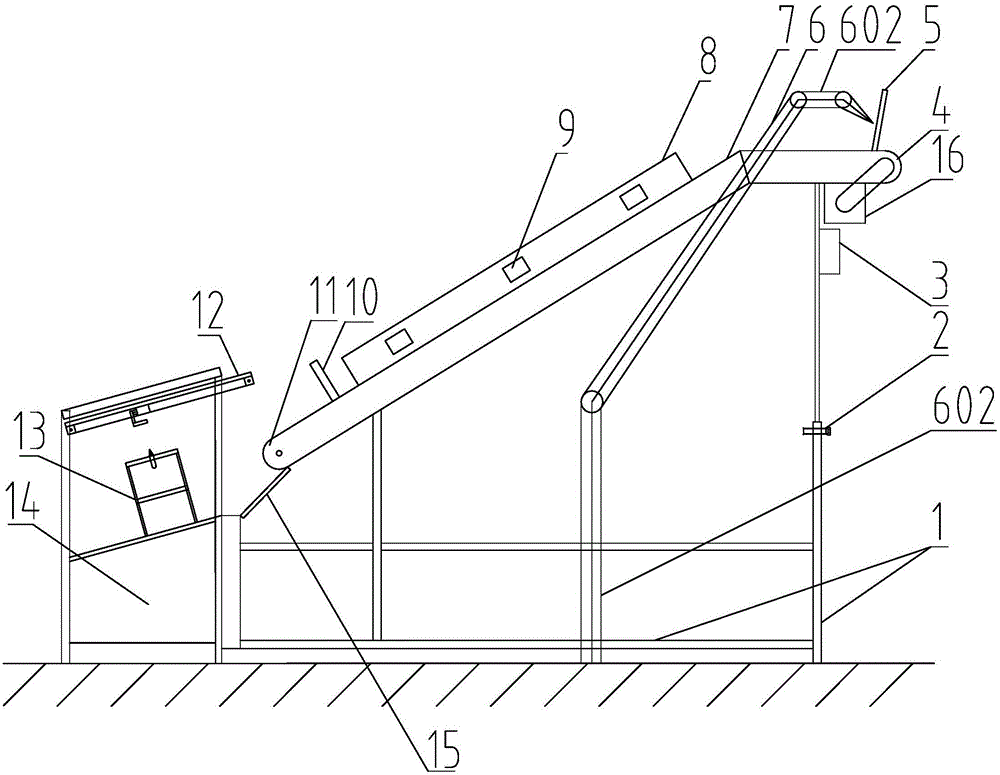

High-efficiency closing compactor at the filter bowl filter screen end of automobile engine oil collector

ActiveCN104785665BReduce labor intensityHigh degree of automationEngine componentsRejection ratePiston rod

The invention belongs to a high-efficiency closing compactor at a filter bowl filter screen end of a vehicle engine oil strainer. The compactor comprises a main pressure cylinder (5), and is characterized in that the end of a piston rod of the main pressure cylinder (5) is fixedly connected with a main pressure cylinder mounting base (6); a slide table (11) is movably mounted on the lower surface of a device fixing plate (3); the two ends of the slide table (11) are fixedly connected with reciprocating slide bases (8); the reciprocating slide bases (8) are movably mounted on a device slide way (4); a mold head fixing table (13) is mounted below the reciprocating slide base (8); a closing mold head (12) is mounted on the lower surface of the left side of the mold head fixing table (13), and a compacting mold head (10) is mounted on the lower surface of the right side; and the left end of the slide table (11) is connected with a piston rod of a driving cylinder (1). The compactor is high in automation degree, reduces the labor intensity of workers, doubles the production efficiency, and reduces the rejection rate by 80%.

Owner:DALIAN XINGANG HYDRAULIC PIPE FITTING

Toothbrush shear mechanical arm and working method thereof

InactiveCN105752677AAccurate locationPrevent fallingConveyorsControl devices for conveyorsMode controlManipulator

The invention relates to a mechanical device and a working method thereof, in particular to an automatic toothbrush handle water gap shear-off device and a working method thereof.The toothbrush shear mechanical arm is provided with a sheath, can automatically place toothbrush handles on a conveying belt and can automatically correct the positions of the toothbrush handles.An obliquely-placed partition plate is arranged at the front end of the conveying belt, and a grabbing mechanical arm is arranged above the conveying belt.A horizontal mechanical arm is arranged at the lower end of the conveying belt.A horizontal adjusting device is arranged on the horizontal conveying belt.The grabbing mechanical arm, the horizontal mechanical arm, the horizontal adjusting device and a pneumatic shear are connected with an intelligent control module.The conveying belt comprises a driving roller and a driven roller.The driving roller and the driven roller are separately arranged at the two ends of the conveying belt.The conveying belt is supported by a support.The support is provided with a conveying belt speed controller and a conveying belt drive motor.Intelligent mode control is adopted, intelligence is achieved in the whole course, labor is saved, and production cost is reduced.

Owner:JIANGSU ASK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com