Automatic packaging equipment for integrated packaging products

A technology for automatic packaging and packaging products, which is applied in packaging, transportation, packaging, container manufacturing machinery, etc. It can solve the problems of insufficient pressing of cardboard and foam, affecting product quality, and weak bonding, etc., so as to avoid uneven and uneven gluing. Adequate, uniform glue, solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

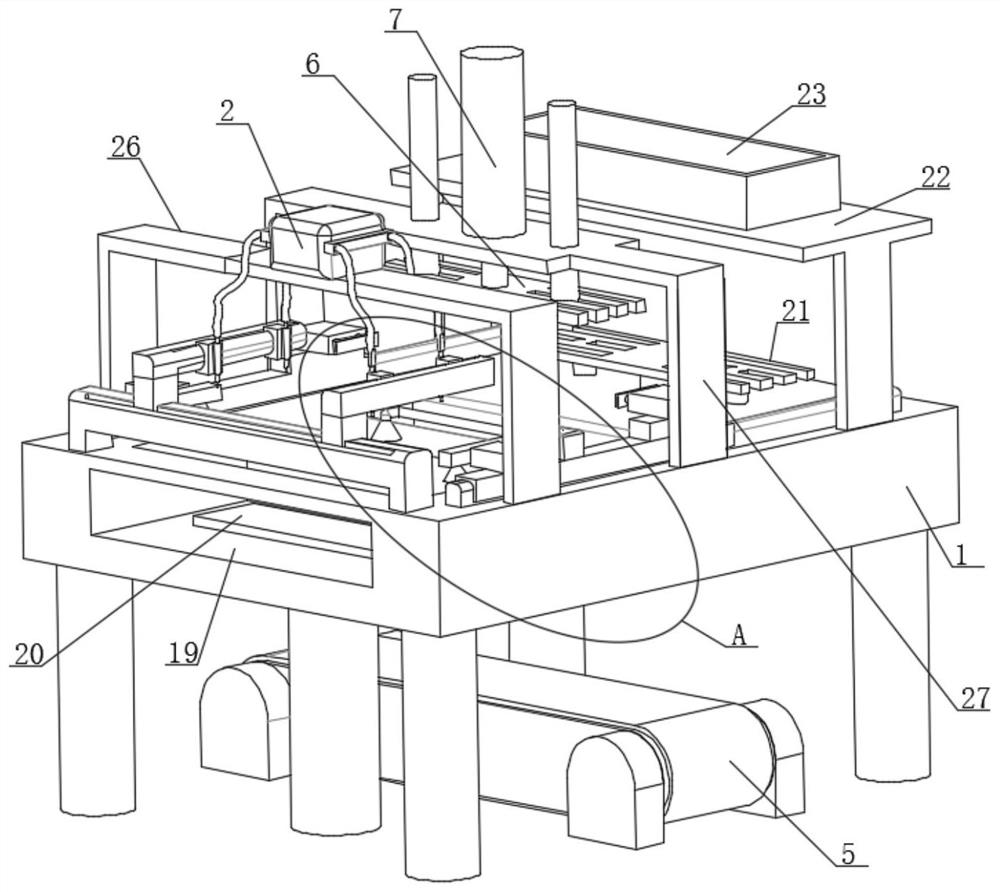

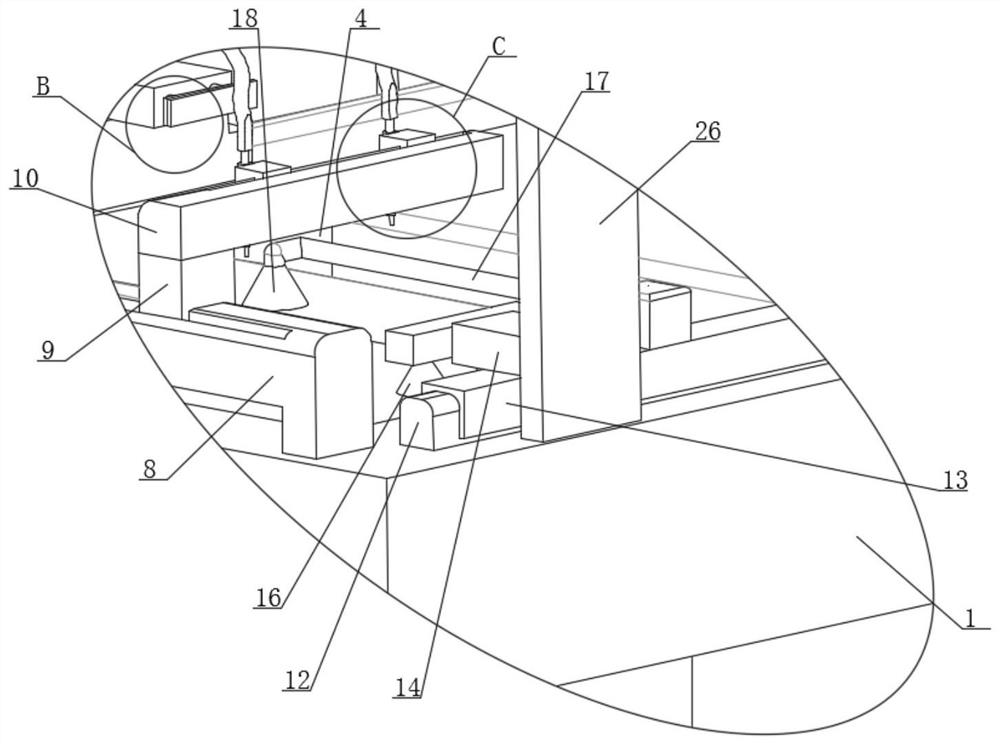

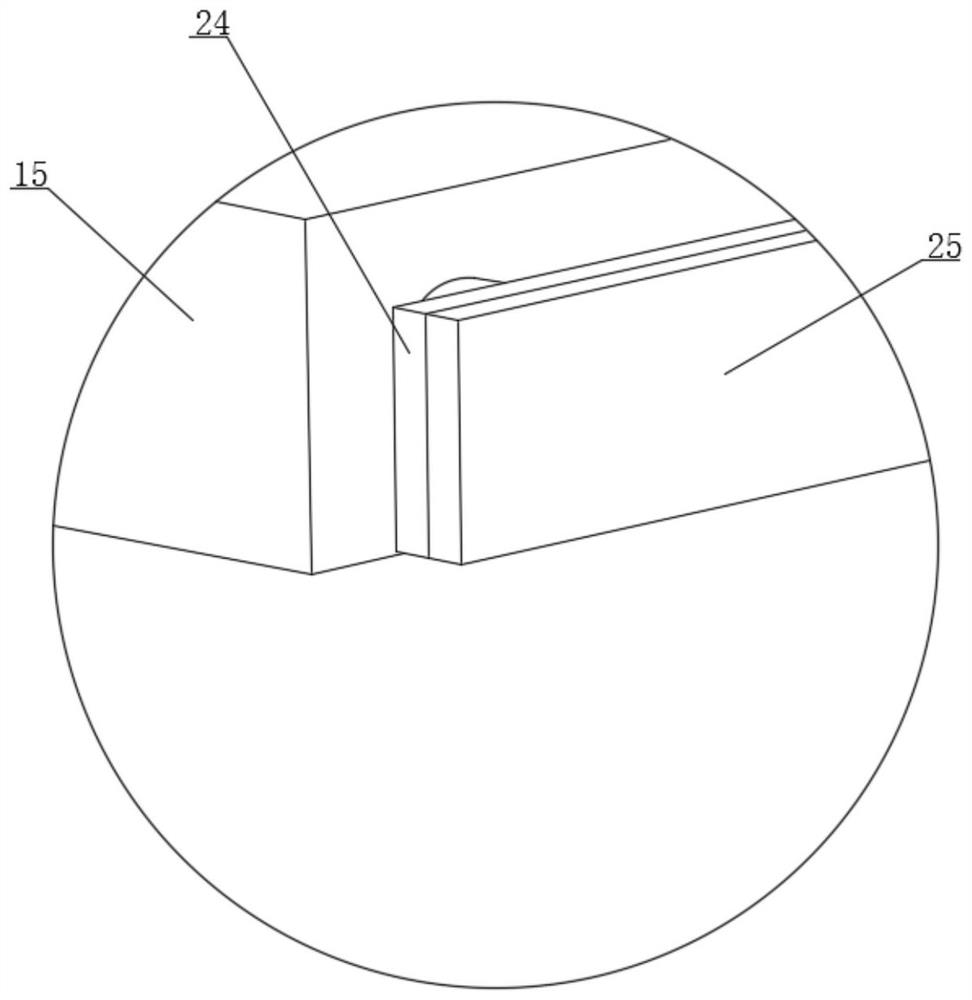

[0038] see Figure 1-6 As shown, the present invention is an automatic packaging equipment for integrated packaging products, including a workbench 1, a gluing assembly arranged on one side of the workbench 1, a pressing assembly arranged in the middle of the workbench 1, and an assembly arranged above the workbench 1 The feeding component on the side, the gluing component is used for cardboard gluing, and the cardboard is placed directly under the gluing component, the feeding component transports the foam and the cardboard after gluing to the pressing component for pressing and molding, the bottom of workbench 1 Conveyor 5 is fixedly installed; the glue-making component is used to automatically glue the cardboard, and the foam and glued cardboard are automatically transported to the pressing component through the feeding component for pressing and forming, and the automatic pressing operation of the pressing component forms an assembly line packaging The automatic production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com