Toothbrush shear mechanical arm and working method thereof

A manipulator and grasping manipulator technology, applied in conveyors, metal processing, conveyor objects, etc., can solve problems such as increasing product scrap rate, wasting manpower, worker burns, etc., to reduce production scrap rate, reduce production costs, and ensure health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

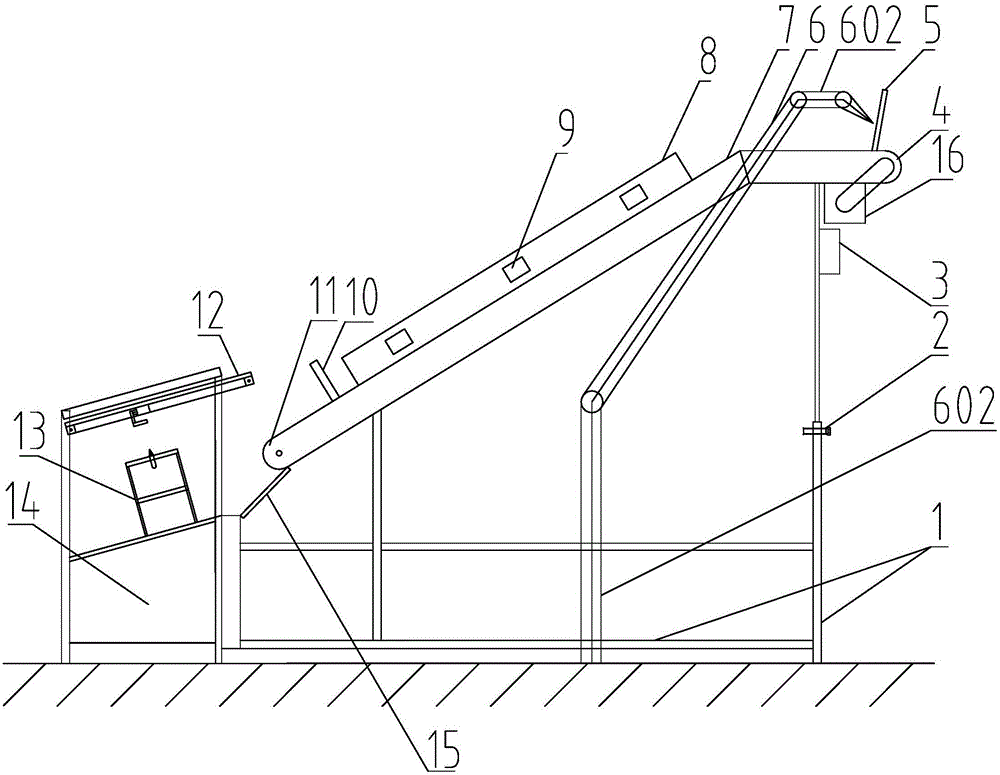

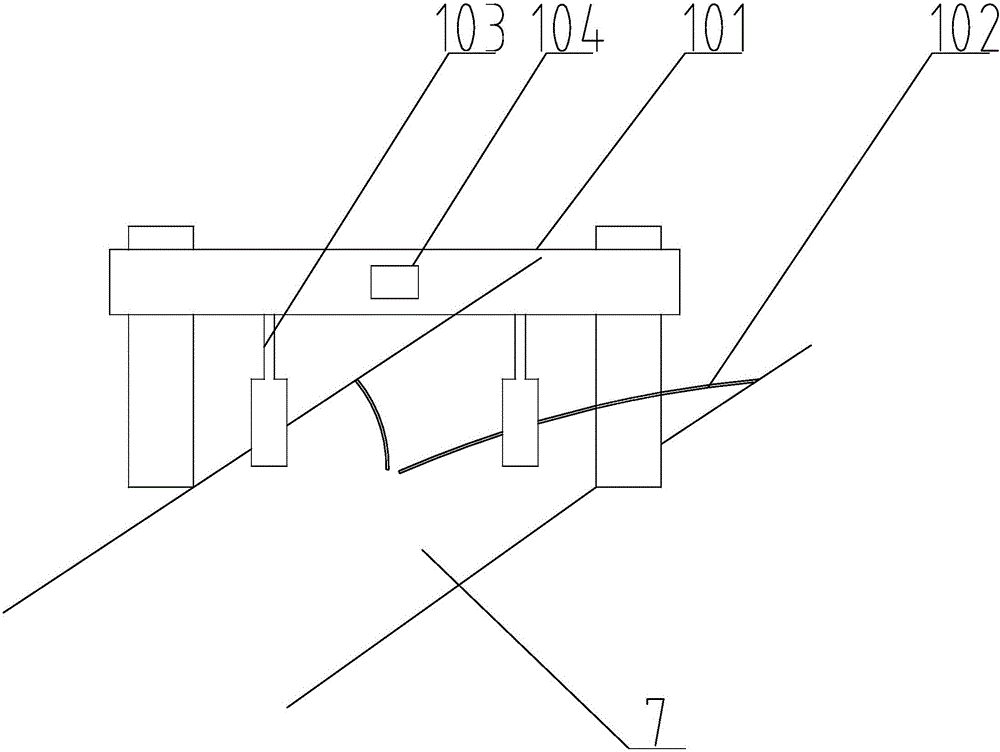

[0026] The invention as Figure 1-2 As shown, it includes a grabbing manipulator 6, a conveyor belt 7, a horizontal manipulator 12, a level adjustment device 10, pneumatic scissors 13 and an intelligent control module 14, and an oblique partition 5 is placed at the front end of the conveyor belt to enable the grabbing manipulator to grab the toothbrush handle Make sure that the nozzle is upward.

[0027] The grabbing manipulator 6 is placed above the conveyor belt 7, the horizontal manipulator 12 is placed at the lower end of the conveyor belt 7, and the horizontal adjustment device 10 is placed on the horizontal conveyor belt 7; the grabbing manipulator 6, the horizontal manipulator 12, the level adjustment device 10, and the pneumatic scissors 13 It is connected with the intelligent control module 14. The conveyor belt 7 is supported by the bracket 1, and includes the driving roller 4 and the driving roller 4 drives the driven roller 11 to rotate through the belt.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com