PP-R pipe mould

A PP-R and mold technology, used in household appliances, tubular items, other household appliances, etc., can solve the problem of insufficient plasticization of plastic melt, achieve compact structure, simple production operation, and reduce production scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

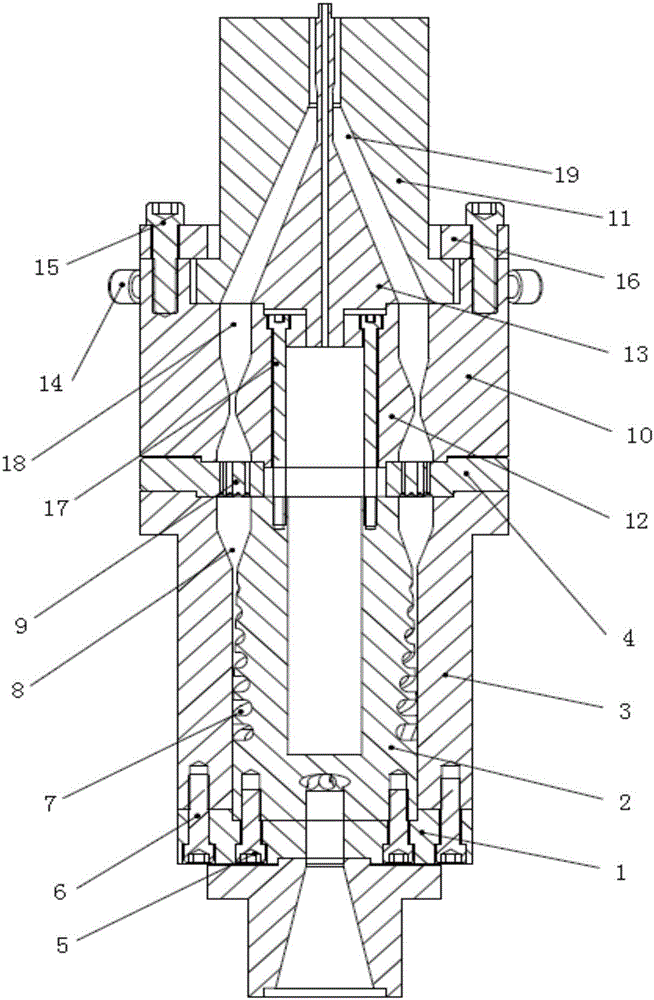

[0023] The present invention will be further explained below in conjunction with the accompanying drawings. The accompanying drawings are for illustrative purposes only, and cannot be construed as limiting the present invention; in order to better illustrate this embodiment, some parts in the accompanying drawings will be omitted, enlarged or reduced; for those skilled in the art, certain parts in the accompanying drawings It is understandable that some well-known structures and descriptions thereof may be omitted.

[0024] like figure 1 As shown, a PP-R pipe mold includes a mold connecting part, a mold plasticizing part and a mold forming part, and the mold connecting part, the mold plasticizing part and the mold forming part are sequentially connected. The plasticizing part of the mold includes a mold base 1, an outer mold body 3 and a spiral body 2 arranged on the mold base 1, a splitter plate 4 arranged on the outer mold body 3 and the spiral body 2, and the outer mold bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com