Smart glass using nano silver conducting layer and manufacturing method of smart glass

A technology of dimming glass and conductive glass, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased processing difficulty, fracture resistivity of conductive coating, waste of raw materials, etc., to reduce production scrap rate, high deformability Features, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

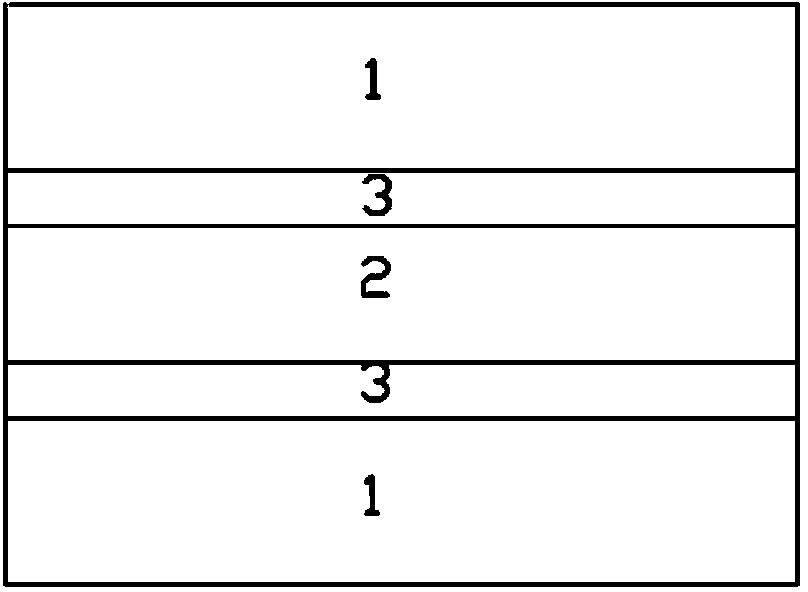

[0023] According to the mass fraction, 0.7% of nano-silver wire, 0.05% of nano-graphite sheet, 0.05% of carbon nanotube, 0.01% of carbon nanofiber, 0.5% of polyethylene oxide, 0.01% of polyvinyl alcohol, and 0.5% of polyvinylpyrrolidone, The balance is ethanol, mixed, and intermittently ultrasonically dispersed for more than 30 minutes to make a conductive paste, which is evenly coated on the float glass by roller coating to form a wet film of 20-30 μm. , Heated for 30 minutes to solidify the conductive paste and form a uniform 200-300nm conductive film layer on the glass to obtain conductive glass. The size of the conductive glass can be adjusted when coating as needed.

[0024] Print conductive silver glue on one side edge of two pieces of conductive glass, lead out the wiring circuit, glue the four side edges with glue, make the conductive film layers face each other, and form a layer of 0.2-0.3mm thick between the two conductive film layers Hollow layer, inject liquid cry...

Embodiment 2

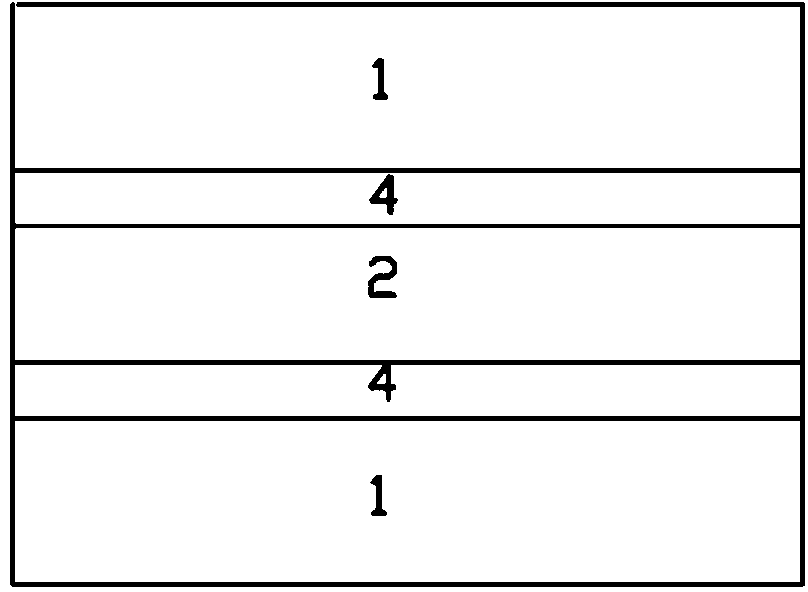

[0030] According to the mass fraction, 6% of nano-silver wire, 0.1% of nano-graphite sheet, 0.3% of carbon nanotube, 0.3% of carbon nanofiber, 1% of polyethylene oxide, 0.05% of polyvinyl alcohol, 1.8% of polyvinylpyrrolidone, Polyvinyl butyral 0.3%, the balance is ethanol, mixed, intermittent ultrasonic dispersion for more than 30min, to make a conductive paste, and evenly coat the conductive paste on the float glass by roller coating to form a 20 The wet film of ~30μm is heated at 90°C for 30 minutes to solidify the conductive paste and form a uniform layer of 400-500nm conductive film on the glass to obtain conductive glass.

[0031] Print conductive silver glue on one side edge of two pieces of conductive glass, lead out the wiring circuit, glue the four side edges with glue, make the conductive film layers face each other, and form a layer of 0.2-0.3mm thick between the two conductive film layers Hollow layer, inject liquid crystal into the hollow layer under vacuum condi...

Embodiment 3

[0038] According to the mass fraction, 0.1% of nano-silver wire, 2% of nano-graphite sheet, 1% of carbon nanotube, 0.2% of carbon nanofiber, 0.05% of polyethylene oxide, 1% of polyvinylpyrrolidone, and polyvinyl butyral 0.5%, the balance is ethanol, mixed, intermittent ultrasonic dispersion for more than 30min, to make a conductive paste, and evenly coat the conductive paste on the float glass by roller coating to form a 20-30μm wet film, Heating at 50°C for 60 minutes to solidify the conductive paste and form a uniform 400-500nm conductive film on the glass to obtain conductive glass.

[0039] Print conductive silver glue on one side edge of two pieces of conductive glass, lead out the wiring circuit, glue the four side edges with glue, make the conductive film layers face each other, and form a layer of 0.2-0.3mm thick between the two conductive film layers Hollow layer, inject liquid crystal into the hollow layer under vacuum conditions, and finally close the injection port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com