Method and device for applying liquid degasification

A degassing device and fluid technology, applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of time-consuming, adding new bubbles, increasing equipment investment, etc., so as to improve economic benefits and reduce production waste rate , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

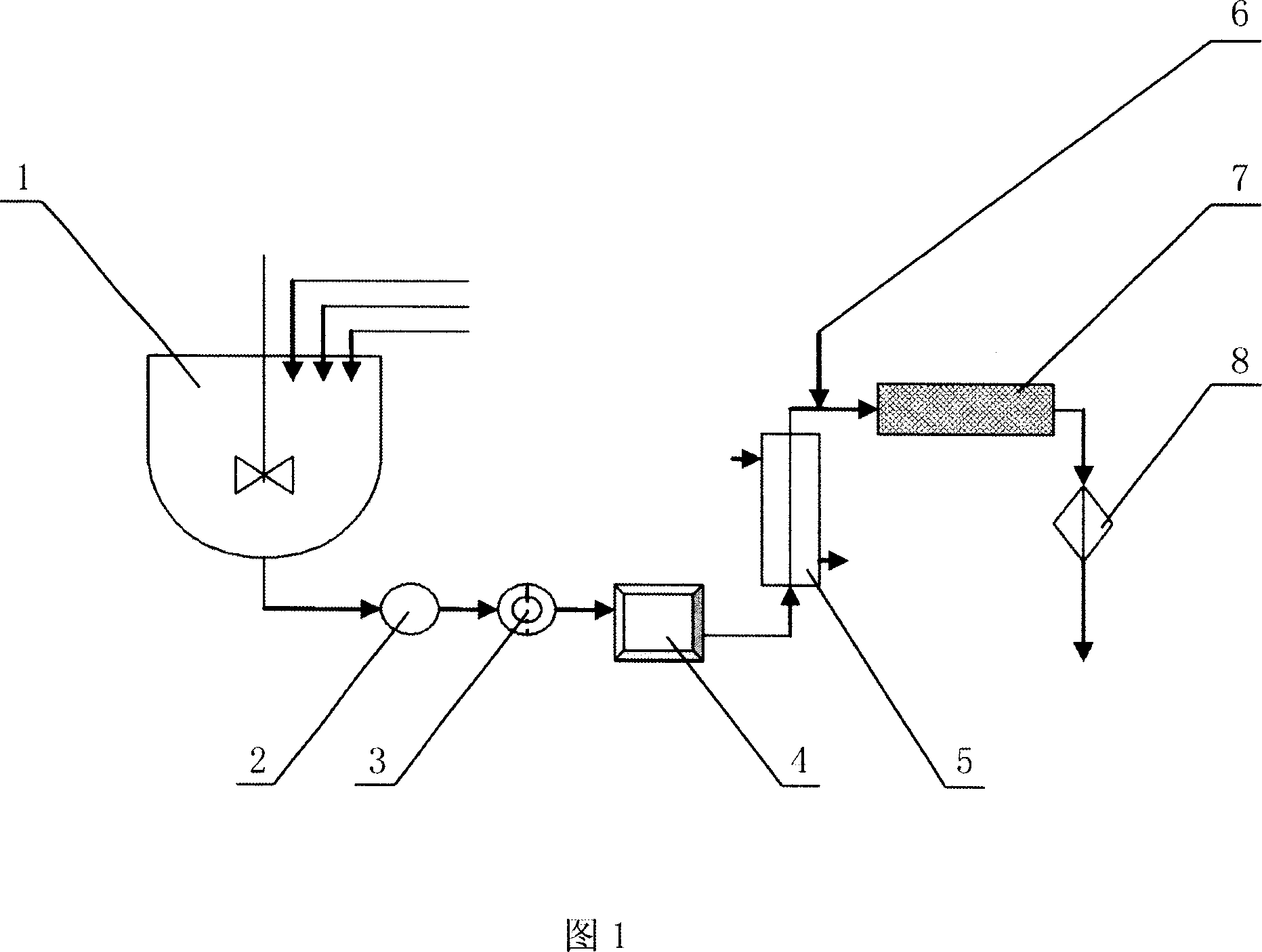

[0023] As shown in Figure 1, fluid preparation is an important part of the entire coating process, so the fluid preparation system is also very important. It includes various unit operations before coating, such as dissolving, stirring, conveying, filtering, degassing, mixing, temperature control, etc. These operations have a great impact on the quality of the final coated product. Firstly, the fluid is dissolved and stirred in the coating pot 1, and then sent to the filter device 3 by the power unit 2 for filtration, and then sent to the ultrasonic degasser 4 for degassing. After coming out of the ultrasonic degassing device 4, the fluid passes through the temperature control device 5 to adjust the temperature of the fluid, and then goes to the mixing device for mixing, and then passes through the online bubble detection instrument 8 for bubble detection, and finally can be sent to the applicator for coating .

[0024] The method for degassing the coating fluid in this prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com