Molten aluminum online vacuum degassing device and method

A technology of vacuum degassing device and molten aluminum, applied in the field of material metallurgy, can solve problems such as unstable degassing effect, and achieve the effects of stable degassing process and high degassing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

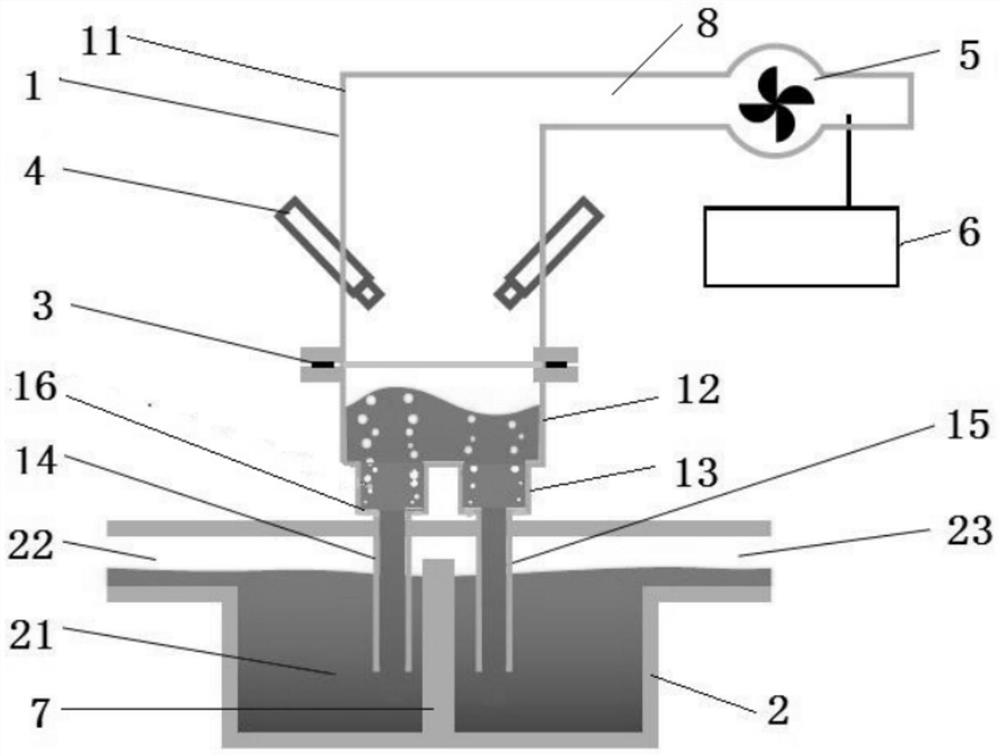

[0024] Such as figure 1 As shown, a device for online vacuum degassing of molten aluminum includes a vacuum furnace 1, a double-chamber tank 2 and a vacuum pump 5; the bottom of the vacuum furnace 1 is provided with two depressions 13; the two depressions 13 are respectively connected to the flow of aluminum liquid 21 The riser 14 of the vacuum furnace 1 and the molten aluminum 21 flow out of the downcomer 15 of the vacuum furnace 1; the two recesses 13 are provided with ventilating bricks 16 along the circumference of the riser 14 and the downcomer 15, so that The air-permeable brick 16 is used to provide inert gas; the two sides of the double-chamber tank 2 are respectively provided with the inlet 22 of the aluminum liquid flow tank and the outlet 23 of the aluminum liquid flow tank; The chamber tank 2 is divided into a liquid inlet tank and a liquid outlet tank; the liquid level of the aluminum liquid 21 on the side of the riser 14 in the double chamber tank 2 is higher tha...

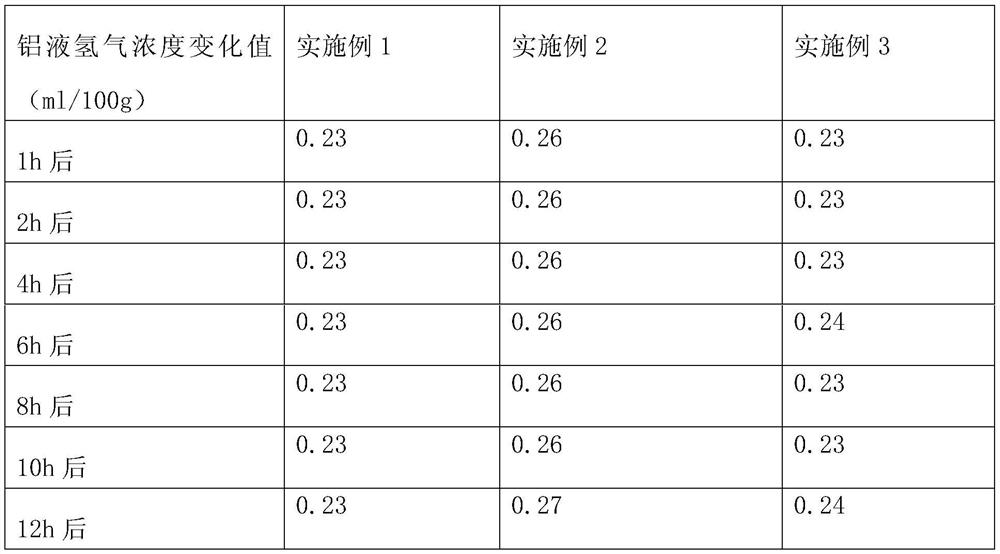

Embodiment 2

[0038] Adopt the device of the aluminum liquid online vacuum degassing of embodiment 1 to carry out degassing, degassing method comprises the following steps:

[0039] S1: Inject aluminum liquid 21 from the entrance 22 of the aluminum liquid flow tank into the double-chamber tank 2, lower the vacuum furnace 1, so that the riser 14 and downcomer 15 of the vacuum furnace 1 are respectively immersed in the aluminum liquid 21 of the double-chamber tank 2 , turn on the vacuum pump 5 to vacuumize, so that the air pressure in the vacuum furnace 1 is lower than the external pressure of the vacuum furnace 1, and the aluminum liquid 21 enters the vacuum furnace 1 under the effect of the air pressure difference between the inside and outside of the vacuum furnace 1 to start degassing;

[0040] S2: During the degassing process of the aluminum liquid 21, a small amount of inert gas is sprayed through the breathable brick 16, and the gas sprayed to the breathable brick 16 surrounding the ris...

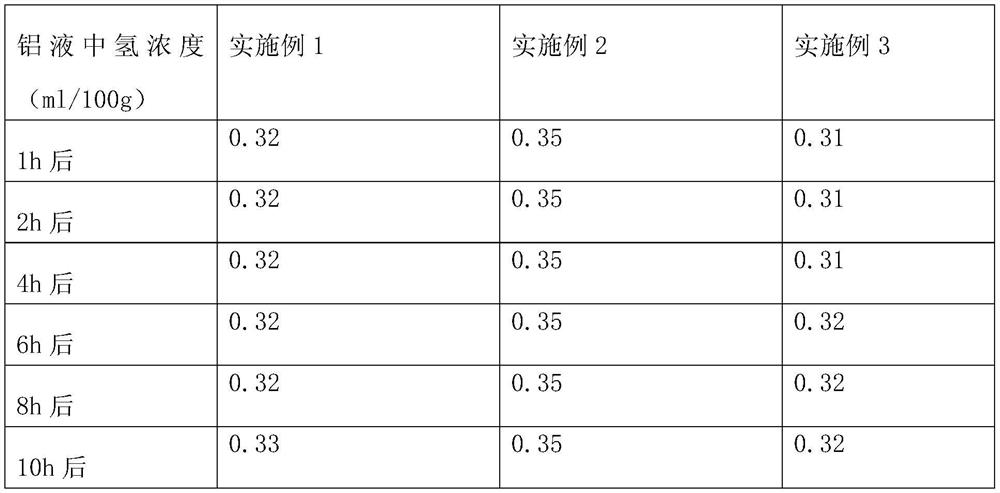

Embodiment 3

[0042] Adopt the device of the aluminum liquid online vacuum degassing of embodiment 1 to carry out degassing, degassing method comprises the following steps:

[0043] S1: Inject aluminum liquid 21 from the entrance 22 of the aluminum liquid flow tank into the double-chamber tank 2, lower the vacuum furnace 1, so that the riser 14 and downcomer 15 of the vacuum furnace 1 are respectively immersed in the aluminum liquid 21 of the double-chamber tank 2 , turn on the vacuum pump 5 to vacuumize, so that the air pressure in the vacuum furnace 1 is lower than the external pressure of the vacuum furnace 1, and the aluminum liquid 21 enters the vacuum furnace 1 under the effect of the air pressure difference between the inside and outside of the vacuum furnace 1 to start degassing;

[0044] S2: During the degassing process of the aluminum liquid 21, a small amount of inert gas is sprayed through the breathable brick 16, and the gas sprayed to the breathable brick 16 surrounding the ris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com