Charge type vacuum oil filter

A vacuum oil purifier, electric charge technology, applied in the direction of filtration separation, filtration loop, separation method, etc., can solve the problems of low filtration precision, low degree of automation and purification efficiency, slow water evaporation, etc., to improve work efficiency and improve dehydration. and degassing efficiency, the effect of improving filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

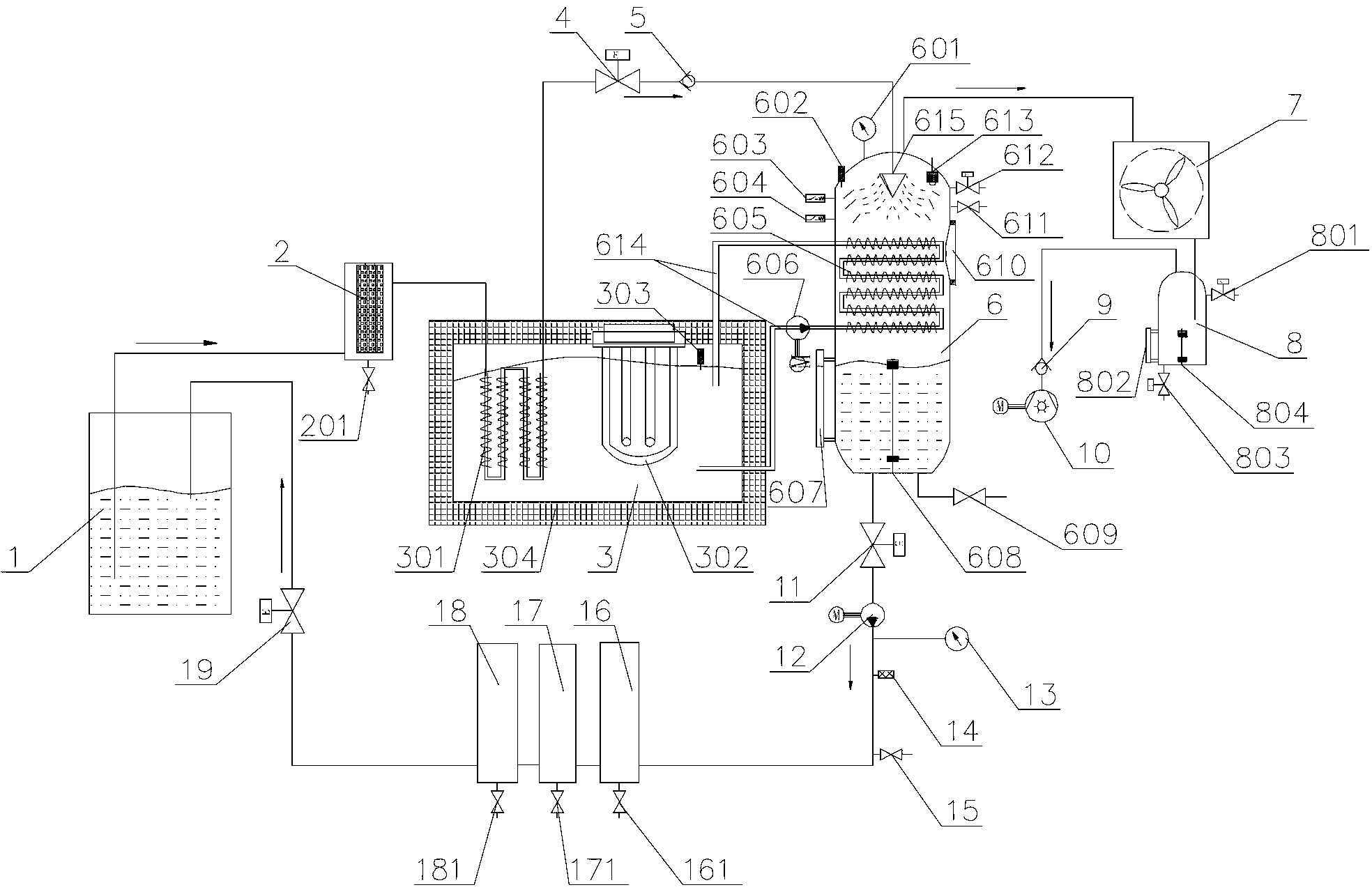

[0019] like figure 1 Shown is a charge-type vacuum oil filter, including an oil circuit and a heat transfer oil circuit.

[0020] The oil circuit includes an oil tank 1 containing oil, a coarse filter 2, a heat exchanger A301, an atomizer 615, a vacuum chamber 6, a pre-filter 16, a charging mixer 17, a collector 18 and oil pipelines , the oil outlet of the oil tank 1 is connected to the oil inlet of the coarse filter 2 through the oil pipeline, and the oil outlet of the coarse filter 2 is connected to the oil inlet of the heat exchanger A301 through the oil pipeline The oil outlet of the heat exchanger A301 communicates with the oil inlet of the atomizer 615 through the oil pipeline, and the atomizer 615 is arranged on the top of the vacuum chamber 6, and the vacuum chamber 6 The oil outlet communicates with the pre-filter 16 , the charging mixer 17 and the collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com