Wet process detoxifying processing device and method for chromium slag and contaminated soil of chromium slag

A technology of wet detoxification and polluted soil, which is applied in the restoration of polluted soil, etc., can solve the problems of affecting resource utilization of waste residue, secondary pollution, and high cost of detoxification, and achieves convenient resource utilization, high degree of automation, and reduction effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

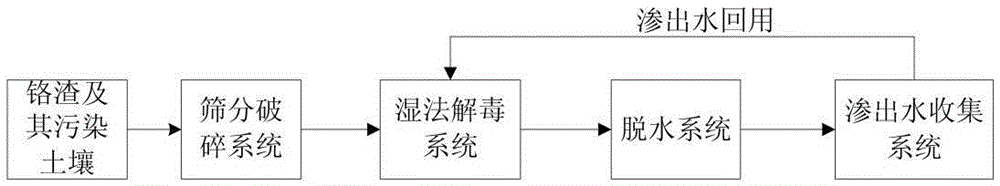

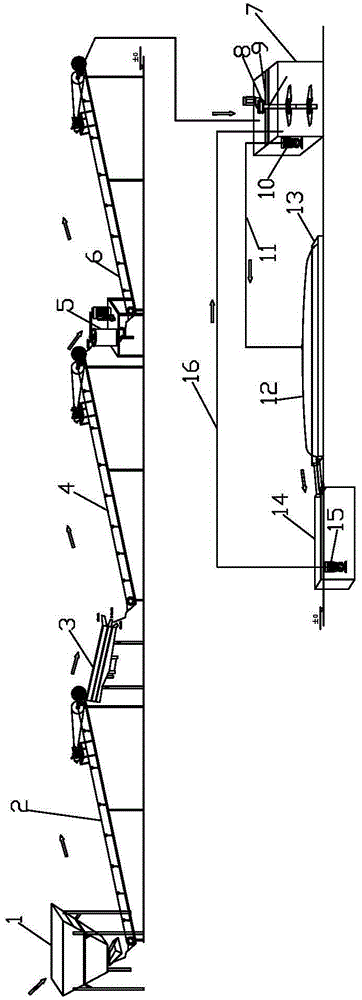

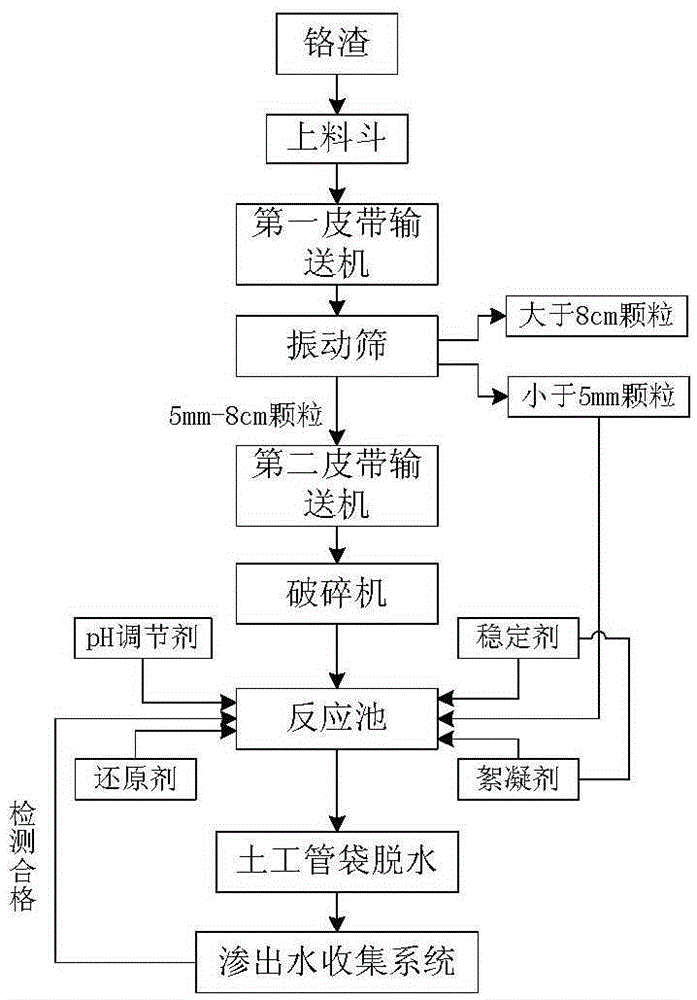

[0027] Such as figure 1 As shown, the wet detoxification treatment device for chromium slag contaminated soil of the present invention includes a screening and crushing system, a wet detoxification system, a dehydration system and a seepage water collection system connected in sequence through pipelines, and the seepage water collection system is transported through The tubing is connected to a wet detoxification system. The screening and crushing system is used to screen and crush the chromium slag and its polluted soil into allowable feed particle size, and the wet detoxification system is used to react the screened and crushed chromium slag and its polluted soil with chemicals Detoxification, the dehydration system is used to dehydrate the mixed slurry in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com