Full-automatic deflating machine for plastic balls

A degasser, fully automatic technology, applied in balls, sports accessories, inflatable hollow balls, etc., can solve the problems of high labor intensity and low degassing efficiency of workers, reduce labor intensity, improve degassing efficiency, and facilitate packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

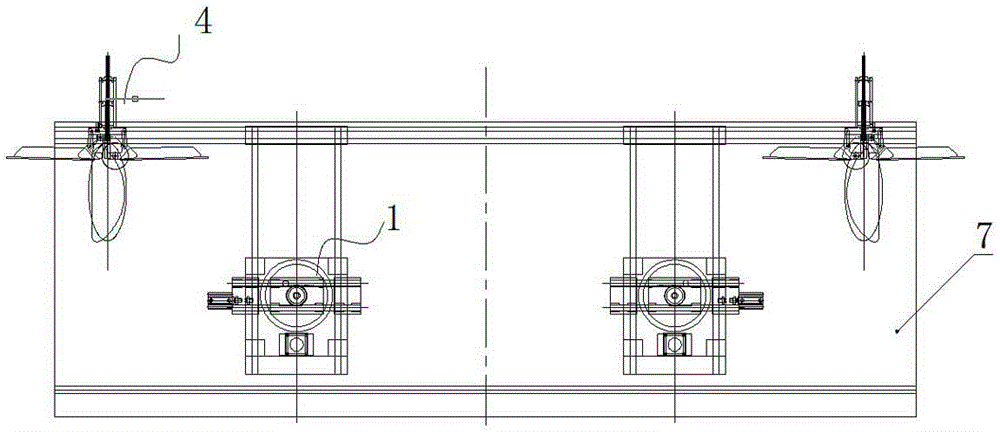

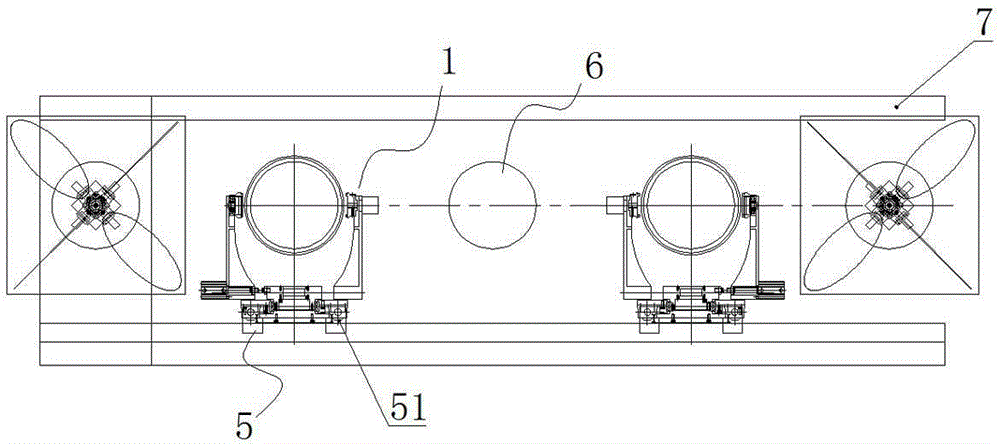

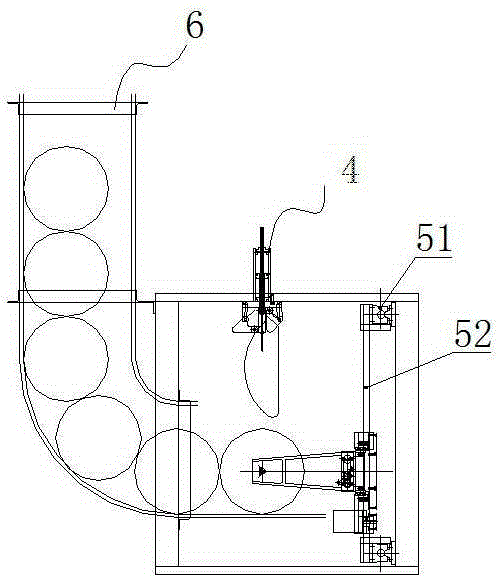

[0050] Such as Figure 4~6 As shown, the valve finding mechanism includes a symmetrically arranged plastic ball clamping arm, a synchronously driven clamping mechanism for the clamping arm, a rotating clamping head arranged oppositely, a swinging mechanism for the clamping arm, and a valve camera identification component. A pair of symmetrically arranged plastic ball clamping arms 11, the pair of plastic ball clamping arms 11 are driven by the clamping arm synchronous clamping drive mechanism to move synchronously in the opposite direction or in the opposite direction to realize closing and opening actions; the clamping arms synchronously drive the clamping mechanism Specifically include: clamping arm mounting seat 12, clamping drive cylinder 13, synchronous gear 14, pull rod A15 and pull rod B16; wherein, the clamping arm mounting seat 12, the center of the clamping arm mounting seat 12 is built with a synchronous Gear 14, pull rod A15 and pull rod B16 are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com