Testing system of side-by-side arrangement of high-speed pump and low-speed pump

A test system, high and low speed technology, applied in the direction of pump test, liquid variable displacement machinery, machine/engine, etc., can solve the problems of not meeting the test conditions, difficult maintenance, not thorough degassing, etc., to eliminate the interference of dissolved air bubbles , Improve the effect of precision, high reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

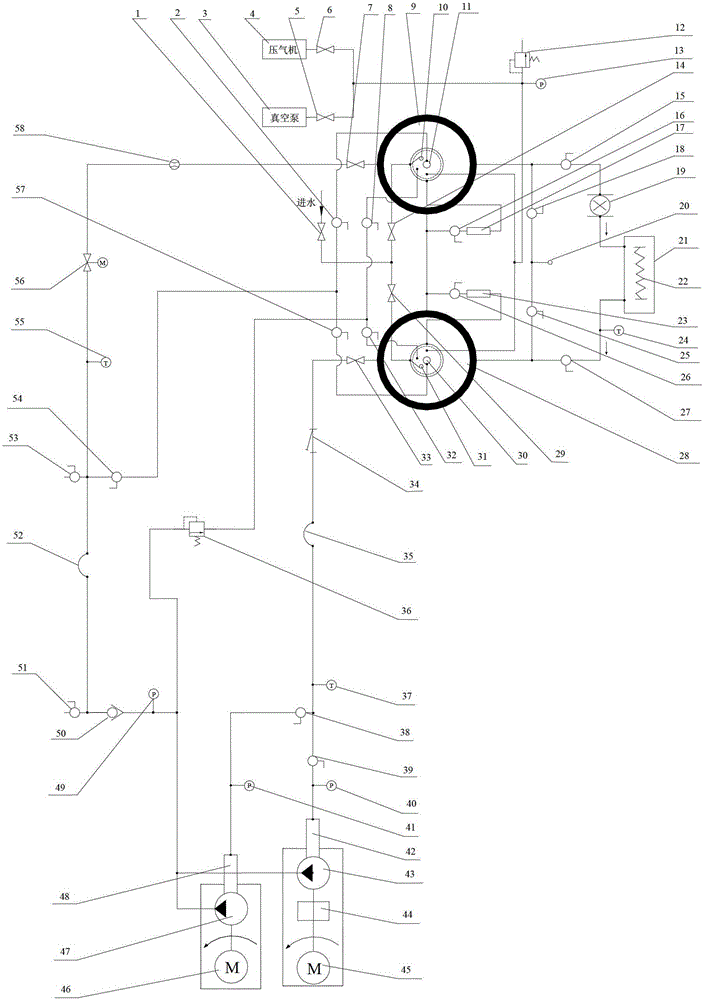

[0036] A kind of high and low speed pump test system arranged side by side of the present invention, such as figure 1 As shown, a closed circulation system is adopted, including the first shut-off valve 1, the fourteenth ball valve 2, the vacuum pump 3, the compressor 4, the fourth shut-off valve 5, the fifth shut-off valve 6, the seventh shut-off valve 7, and the ninth ball valve 8. Return water tank 9, first float valve 10, first nozzle 11, first safety valve 12, first pressure sensor 13, second stop valve 14, third ball valve 15, first ball valve 16, first liquid level Meter 17, fourth ball valve 18, water pump 19, water outlet 20, temperature control water tank 21, heating wire 22, second liquid level gauge 23, first temperature sensor 24, fifth ball valve 25, second ball valve 26, sixth ball valve 27. Outlet water tank 28, third stop valve 29, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com