Tubular filter capable of automatically discharging slag for metal melt and working method of tubular filter

A technology of metal melt and working method, which is applied in the direction of fixed filter elements, chemical instruments and methods, and filtration circuits, can solve the problems of surface defects, poor mechanical properties of aluminum materials, and high filtration costs, so as to improve service life, The effect of reducing hydrogen content and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

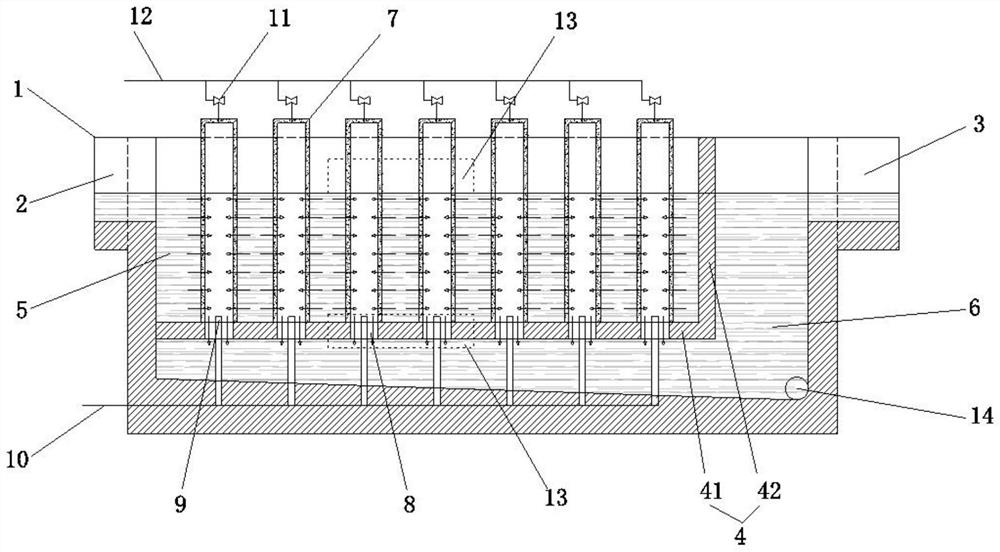

[0029] like figure 1 As shown, a self-slag-discharging tubular filter for metal melts includes a closed filter box 1; both ends of the filter box 1 are provided with flow channels along the flow direction of the metal melt from front to back and sequentially connected to the external launder. The molten metal inlet 2, the molten metal outlet 3; the inside of the filter box 1 is divided into a filter chamber 5 at the upper part and an underflow chamber 6 at the lower part by a partition 4; the molten metal inlet 2 is connected with the filter chamber 5 The metal melt outlet 3 communicates with the underflow chamber 6; the partition plate 4 is provided with a plurality of ceramic filter tubes 7 at intervals; the through hole 8 at the bottom of the ceramic filter tube 7 communicates with the underflow chamber 6; The through hole 8 is provided with a venting plug 9; the venting plug 9 communicates with the air intake pipe 10 connected to the outside; the top of the ceramic filter ...

experiment example 1

[0046] Casting 5052 aluminum alloy flat ingots, in which the online degassing purification equipment is a double-rotor online degasser + a self-discharging slag tube filter.

[0047] 5052 aluminum alloy in the melting furnace, Si0.102%, Fe0.290%, Cu0.024%, Mn0.059%, 2.5%, Cr0.18%, Zn0.02%, Ti 0.028%, the rest is aluminum and unavoidable of impurities.

[0048] On the converter process, the slag content is 0.68mm2 / kg and the hydrogen content is 0.262ml / 100gAl measured by the off-line slag measuring instrument; the off-line slag content is 0.52mm2 / kg, the hydrogen content is 0.11ml / 100gAl; the slag content is 0.011mm2 / kg, and the hydrogen content is 0.099ml / 100gAl measured by the off-line slag measuring instrument behind the self-slagging tubular filter;

experiment example 2

[0050] Casting 3003 aluminum alloy flat ingots, in which the online degassing purification equipment is a double-rotor online degasser + a self-discharging slag tube filter.

[0051] 3003 aluminum alloy in the melting furnace, Si0.102%, Fe0.450%, Cu0.074%, Mn1.06%, Mg0.02%, Cr0.003%, Zn0.02%, Ti 0.018%, the rest is aluminum and unavoidable impurities.

[0052] On the converter process, the slag content is 0.65mm2 / kg and the hydrogen content is 0.271ml / 100gAl measured by the off-line slag measuring instrument; the slag content is 0.51mm2 / off-line between the double-rotor degasser and the self-slagging tubular filter kg, the hydrogen content is 0.108ml / 100gAl; the slag content is 0.011mm2 / kg, and the hydrogen content is 0.095ml / 100gAl measured by the off-line slag measuring instrument behind the self-slagging tubular filter.

[0053] The invention removes the impurities adsorbed on the surface of the ceramic filter tube by blowing air during the filtering process and the end st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com