Lamination-vacuum pressure pouring process of micro conductive retractor collar

A conductive slip ring, vacuum pressure technology, applied in slip ring manufacturing, circuits, current collectors, etc., can solve the problems affecting the reliability of micro and small conductive slip ring components, the difference in the thickness of the filling layer, and the poor mutual insulation performance. Environmental adaptability and reliability of work, guarantee consistency and reliability of work, effect of good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings. ,

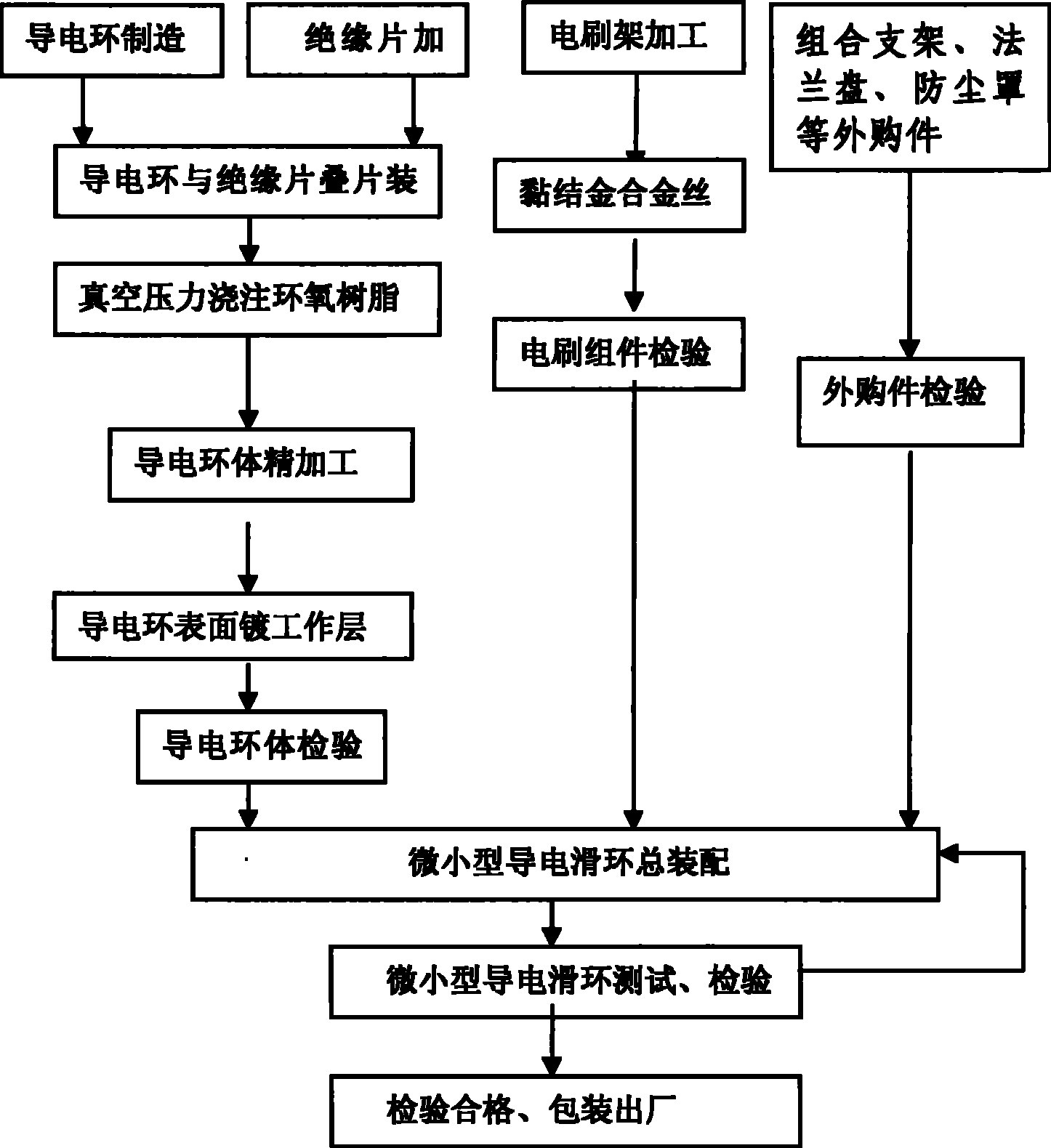

[0015] The present invention includes conductive ring processing technology, brush holder processing technology and miniature conductive slip ring assembly technology, wherein the conductive ring processing technology includes conductive ring manufacturing, insulating sheet processing, conductive ring body finishing, conductive ring surface plating working layer and Conductive ring body inspection and other steps. The brush holder processing technology consists of three steps: brush holder processing, bonding gold alloy wire and brush assembly inspection. After the conductive ring body inspection and brush assembly inspection, the combined bracket, Structural parts such as flanges and dust covers are inspected, and then the processed conductive ring body, brush holder assembly, combined bracket, flange, and dust cover a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com