Method for reducing overflow in injection molding of IPM (Intelligent Power Module) and DBC substrate

A technology of injection molding and substrates, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reducing the cooling area of the module, reducing the reliability of the module, affecting the appearance and quality of the module, and reducing production. Even input and force balance, and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

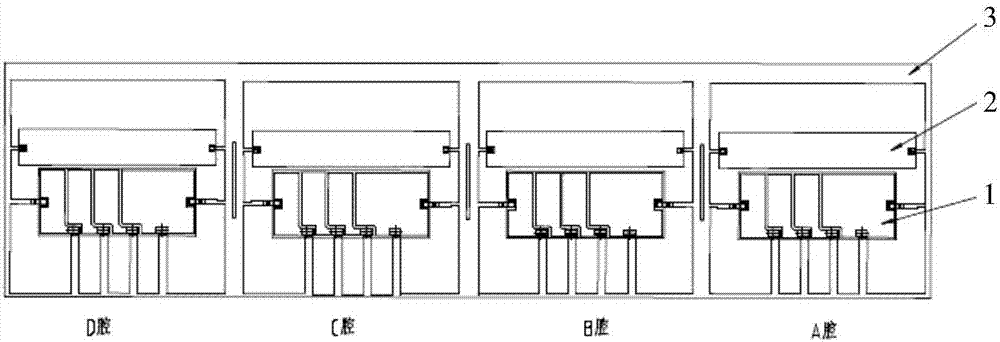

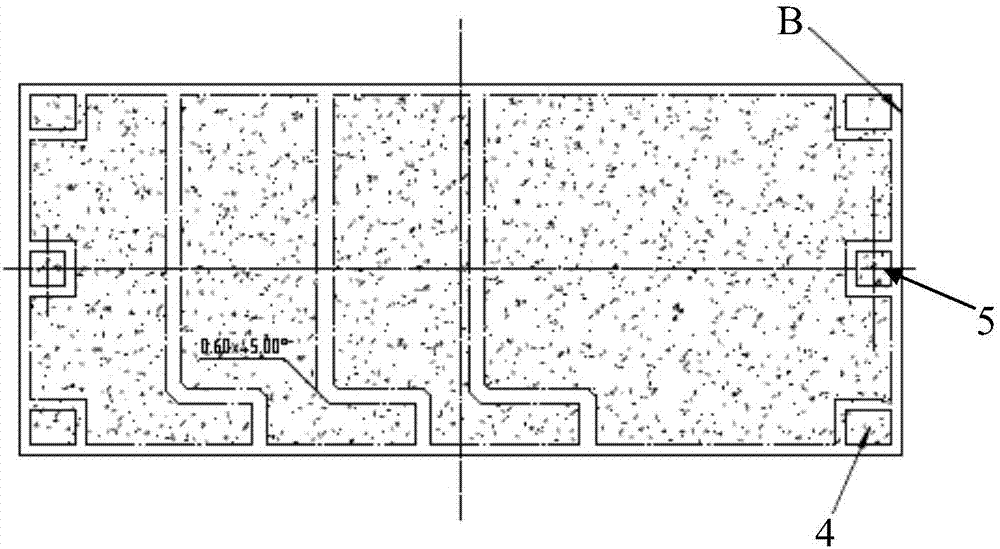

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] see Figure 2-Figure 4 : The present invention reduces the method for injection molding overflow of IPM module, changes the island design on the DBC substrate 1, makes the DBC substrate 1 be stressed in the injection molding process; and designs a "wedge-shaped" table top on the DBC back copper layer 7 on the back of the DBC substrate 1 The structure 10 forms a buffer platform for the flow rate of the injection material on the back of the DBC substrate 1, and reduces the overflow of the injection material to the back of the DBC substrate 1 when the DBC substrate 1 is uneven. Specifically:

[0024] In the layout design of the DBC substrate 1 , four second islands 4 are added at the four corners of the DBC substrate 1 . The ejector pin of the upper mold is directly pressed on the second island 4 added at the four corners of the DBC substrate 1; the original firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com