Mechanical mechanism for delayed release of upper die core of drawing die

A delayed release, drawing die technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of waste products, deformation of parts, damage to economic benefits, etc., to achieve the best economy, reduce production scrap rate, Ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

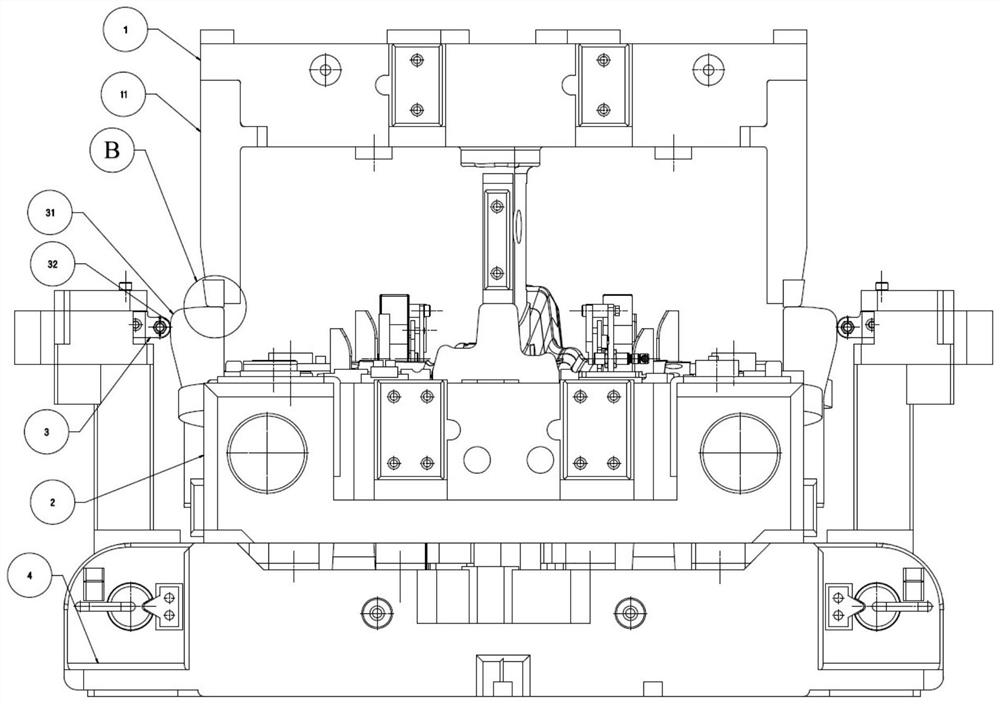

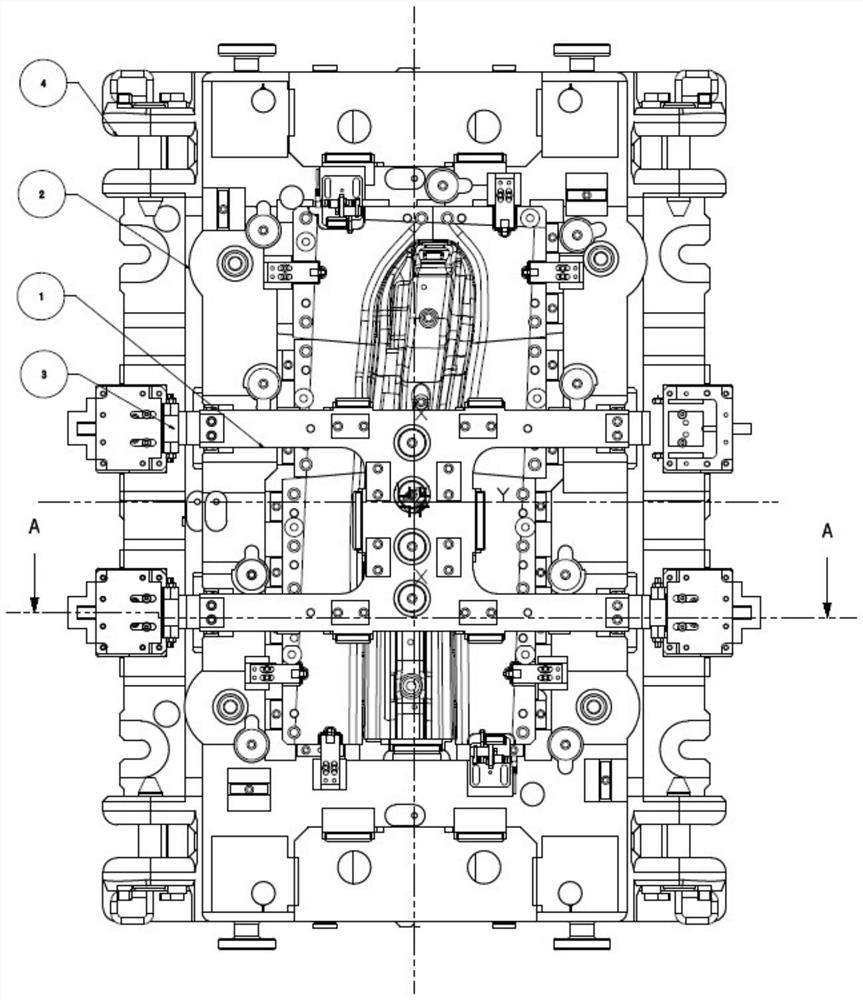

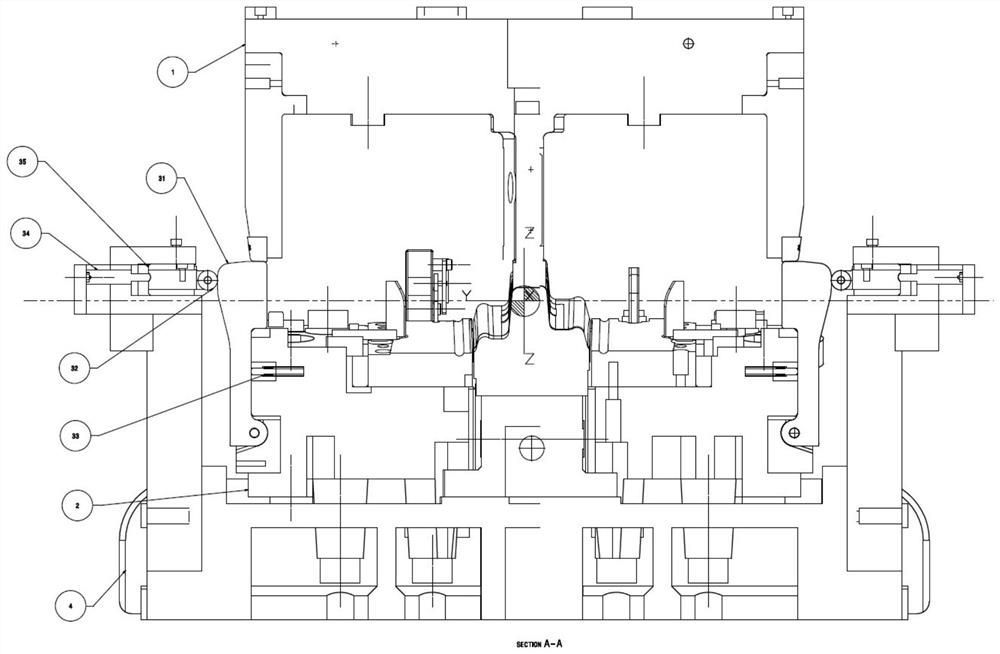

[0035] When the mold is closed, the rotary support block 31 descends with the blankholder 2, and the rotary support block 31 is supported by the supporting roller 32 and rotates directly below the raised block 11 during the descent process, and finally the upper surface of the rotary support block 31 is aligned with the raised block 11. The blocks abut against each other.

[0036] When the mold is opened, the blank holder 2 is lifted, and the ejector pin 33 pushes out the rotary support block 31, and the rotary support block 31 moves upward along the support roller 32, and a slide plate 35 and a nitrogen cylinder 34 are provided on the rear side of the support roller 32, so that the support The movement range of the roller 32 will not be too large, and it will have a buffering effect on the lifting of the rotating support block 31. The angle between the rotating support block 31 and the blank holder 2 will gradually increase, and the upper mold core 1 will be released when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com