Machining technology for reducing deformation of thin-wall parts

A processing technology and technology of thin-walled parts, which is applied in the field of processing technology to reduce the deformation of thin-walled parts, can solve problems such as poor flatness and parallelism, related size deviation, and deformation, so as to reduce production time and scrap rate, The effect of reducing the amount of deformation and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described and understood by non-limiting examples below.

[0018] The invention provides a processing technology for reducing the deformation of thin-walled parts, which specifically includes the following steps:

[0019] (1) Rough machining of parts: process qualified rough parts, reserve 0.25 for the finished size, remove excess material, and process clamping positioning holes at the four corners of the parts;

[0020] (2) Tempering to relieve stress: Put the rough-machined parts into a box-type tempering furnace and heat for 2 hours at a heating temperature of 200°C. After heating, take the parts out and place them on a cooling tray, and cool them naturally in the air;

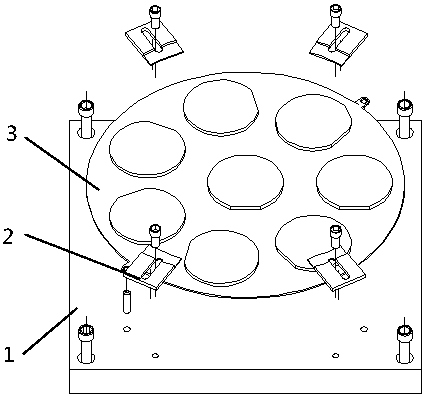

[0021] (3) Parts finishing: such as figure 1 , the positioning pin is inserted into the positioning hole to fix the reverse side of the part on the tooling plate 1, press the 4 corners of the part 3 with the pressure plate 2, tamp it with a rubber hammer, and then us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com