High performance crosslinked elastomeric insulation material

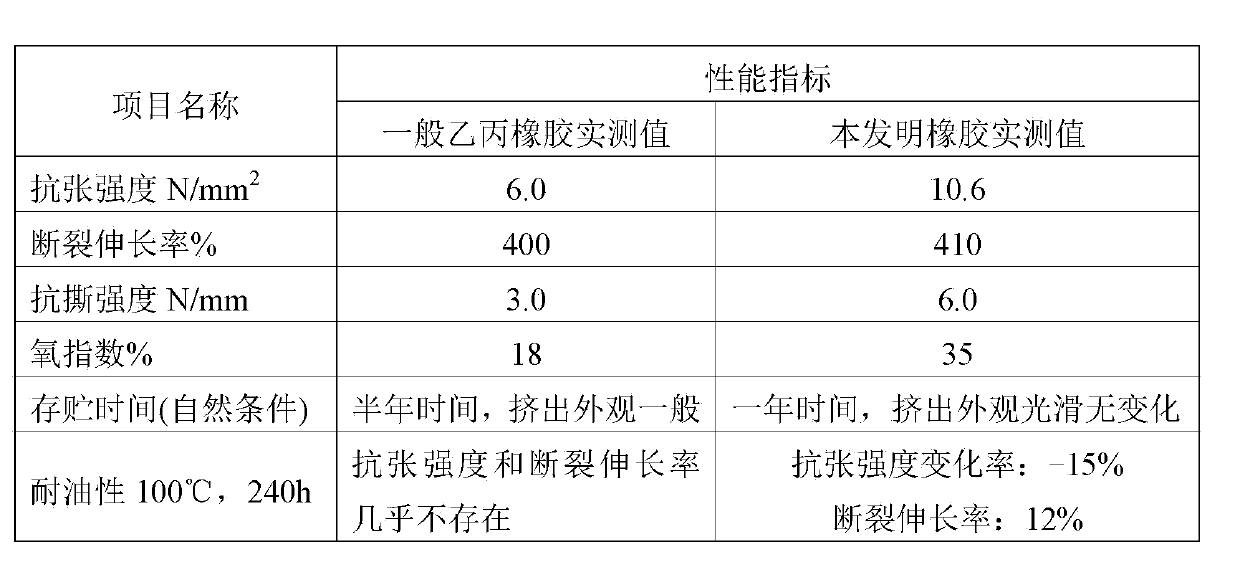

A technology of cross-linked elastomers and insulating materials, which is applied in the field of materials, can solve the problems of large decline in mechanical and physical properties, poor operating process performance, and slow vulcanization speed, so as to reduce production costs, improve oil resistance and use range, and vulcanize fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A high-performance cross-linked elastomer insulating material is characterized in that it is composed of the following raw materials in parts by weight (kg):

[0019] Chlorinated polyethylene CPE135B 100, vulcanizing agent DCBP 5, triallyl isocyanurate 2, magnesium oxide 15, talcum powder 110, precipitated silica 15, kaolin 15, propylene glycol adipate polyester 2, sub Bisphenol A Phosphate 4, Dibutyltin Dilaurate 2, Dibasic Lead Phosphite 2, Chlorinated Paraffin 52 20, Ethylene Bis Stearamide 6, Hydrated Zinc Borate 4, Diethylene Glycol Dibenzoate 10 , light calcium carbonate 55, anti-aging agent AW 1, auxiliary filler 15;

[0020] Described auxiliary filler is made up of the raw material of following weight part:

[0021] Nano silica 60, aluminum hydroxide powder 6, polyamide wax micropowder 7, sorbitan monooleate 0.6, stearic acid 2, propyltrimethoxysilane 2;

[0022] Add the above-mentioned nano-silica to 3 times the water, stir and disperse, add sorbitan monoolea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com