Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

358results about How to "Extrude evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

The invention discloses a method for a preparing low density polypropylene foam section or beads by two-step extrusion molding, which comprises the following steps that: expandable master batch is prepared from 30 to 80 portions of polypropylene, 10 to 40 portions of foaming agent, 0 to 15 portions of foaming accelerant, 0 to15 portions of dispersant and 0 to 10 portions of nucleating agent at a temperature below the decomposition temperature of the foaming agent and above a viscous flow temperature of the polypropylene; 20 to 99 portions of polypropylene with high melt strength, 0 to 70 portions of common polypropylene and 1 to 10 portions of expandable master batch are plasticizated and extruded together; supercritical gas is added to perform the blending of the plasticizated and extruded mixture; and the product obtained is made to generate foamcores in a foaming nucleation apparatus to form the section or beads finally. A chemical foaming agent is partially decomposed and foamed during the plasticization and extrusion, so that the viscosity of fused mass is reduced, the dissolution and dispersion of the supercritical gas are facilitated, and a problem that a foam imploding is likely to happen in a secondary forming process so as to influence the quality and appearance of secondarily formed product is solved as the chemical foaming agent retained in molding beads can be decomposed and foamed again during the secondary processing.

Owner:SICHUAN UNIV

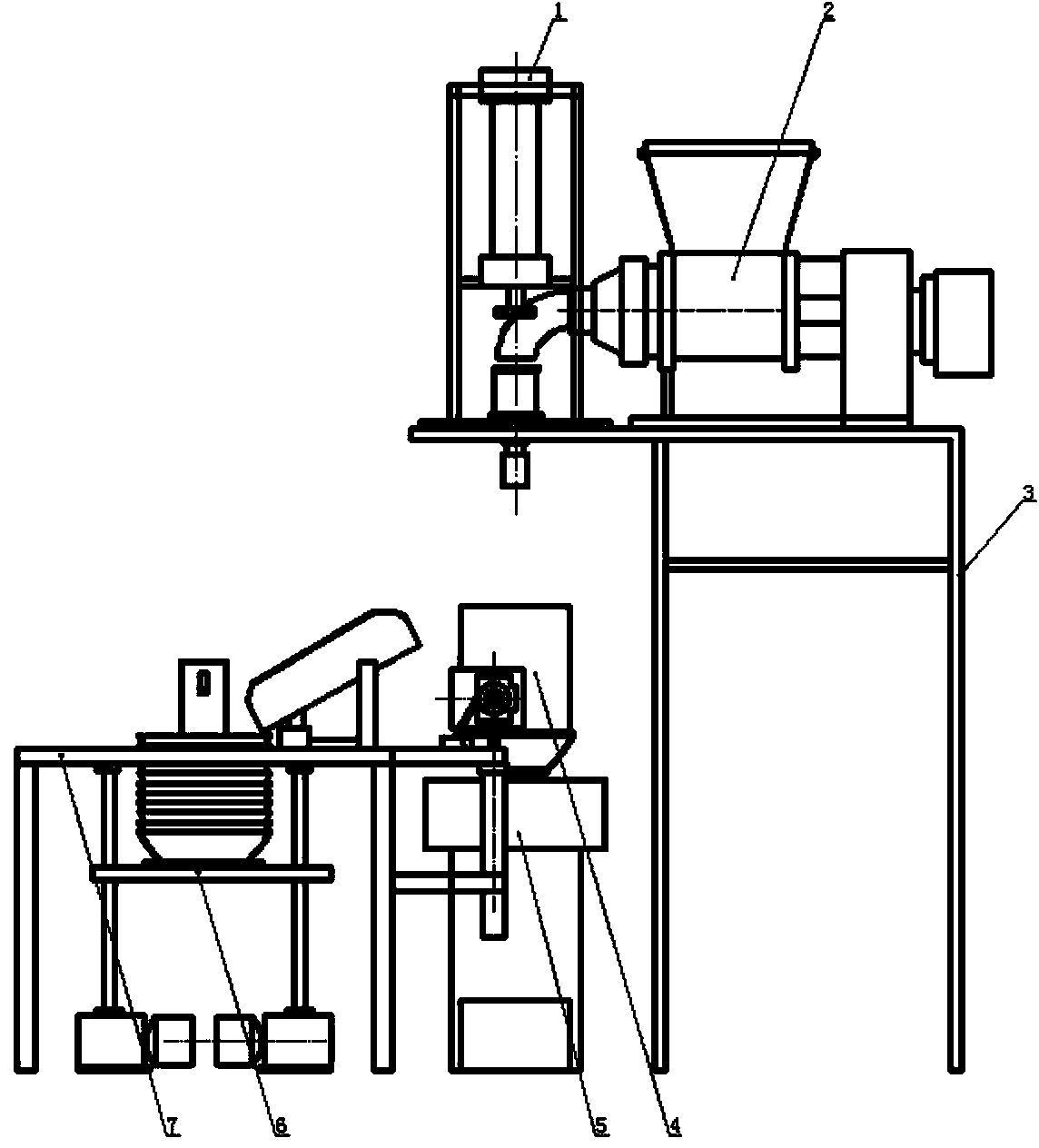

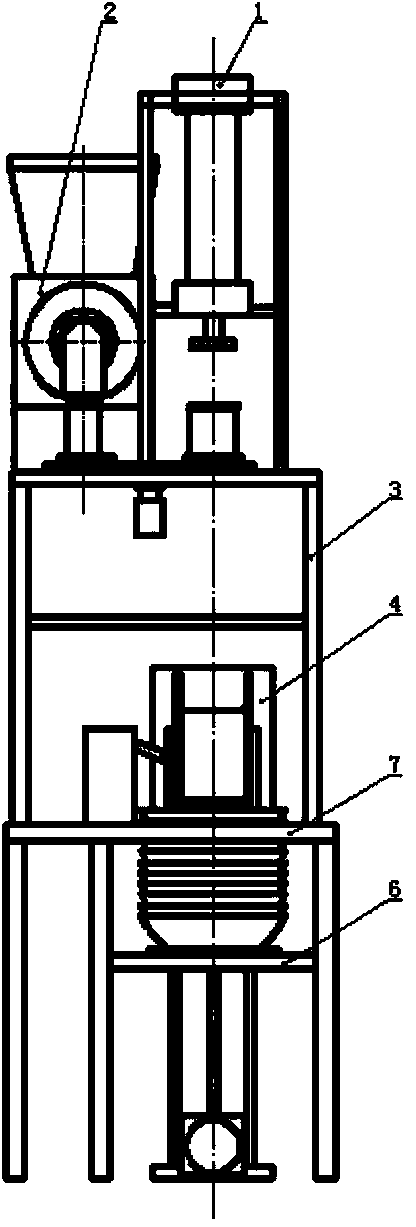

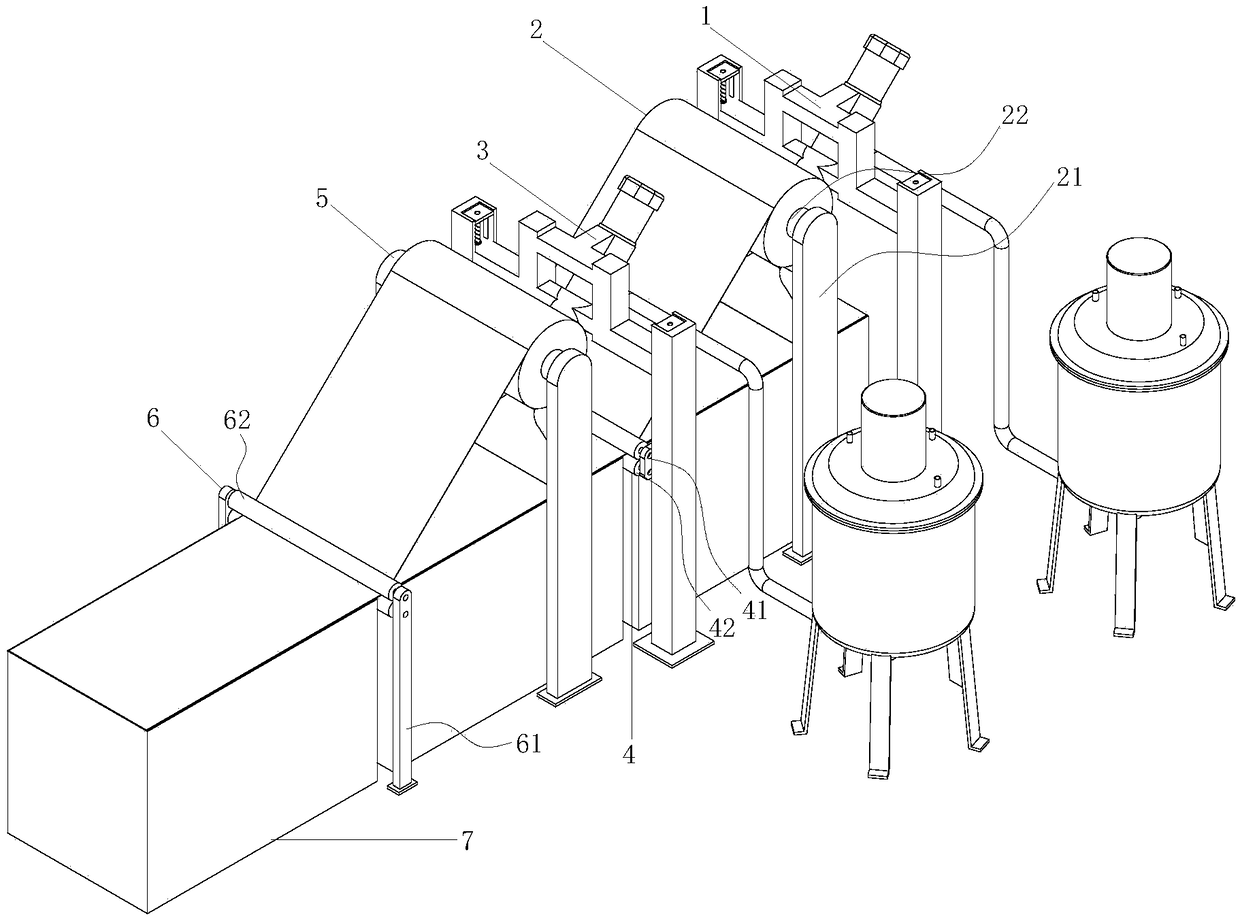

Full-automatic noodle cooking machine and application method thereof

ActiveCN103750082AReasonable structureDesign scienceCooking vesselsDough extruding machinesEngineeringMechanical engineering

The invention relates to a full-automatic noodle cooking machine and an application method thereof. The full-automatic noodle cooking machine comprises a dough kneading device, a dough pressing device, a hopper, a noodle cooking furnace, a worktable and a hoisting supporting frame, wherein the dough kneading device and the dough pressing device are mounted on the bracket; the dough kneading device, the dough pressing device, the hopper, the noodle cooking furnace and the worktable are sequentially mounted; the hoisting supporting frame is mounted in the middle below the workable; the hoisting supporting frame is used for supporting a plurality of noodle bowls for containing noodles and is driven by a worm and worm rod structure to be hoisted. The whole process is finished by a full-automatic machine and a worker only needs to set the time of each step through a controller; the worker does not need to contact noodles from the step of putting flour to the step of forming the noodles, so that a noodle processing process is safe and sanitary and the food health is guaranteed.

Owner:于敬伟

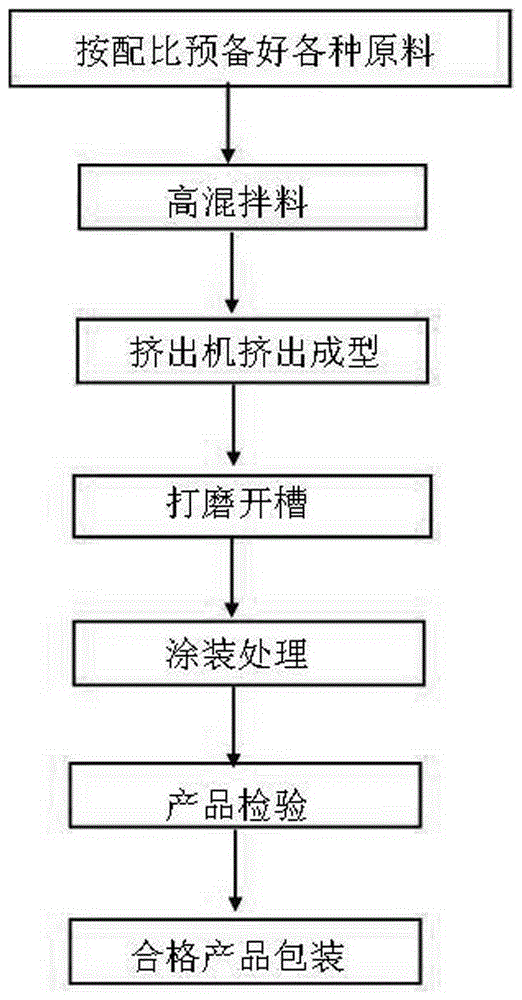

Stone-wood floor and production technology and laying method thereof

The invention belongs to the technical field of indoor and outdoor building decorative materials and production technologies thereof, and provides a stone-wood floor and a production technology and laying method thereof. The stone-wood floor is prepared from, by weight, 90-100 parts of ground limestone, 30-35 parts of PVC, 0.3-0.6 part of stearic acid, 2-2.5 parts of chlorinated polyethylene, 0.5-1.0 part of a foaming agent, 6-7 parts of a foaming control agent and 2-3 parts of a stabilizer. The raw materials are highly mixed and stirred, extruded, molded, ground, slotted and coated to obtain a finished product. The processing procedures are simplified, the cost is lowered, the product quality is improved, the hardness, abrasion resistance and flexibility of the produced product are improved, PVC is foamed to generate pores through the foaming technology, and the pores are filled with microstructures such as the ground limestone, so that the product density reaches 1.2 g / cm<3> which is close to that of a pure wood floor, and the cheap and fine stone-wood floor can be truly obtained.

Owner:南召县磊鑫钙业新型材料科技有限公司

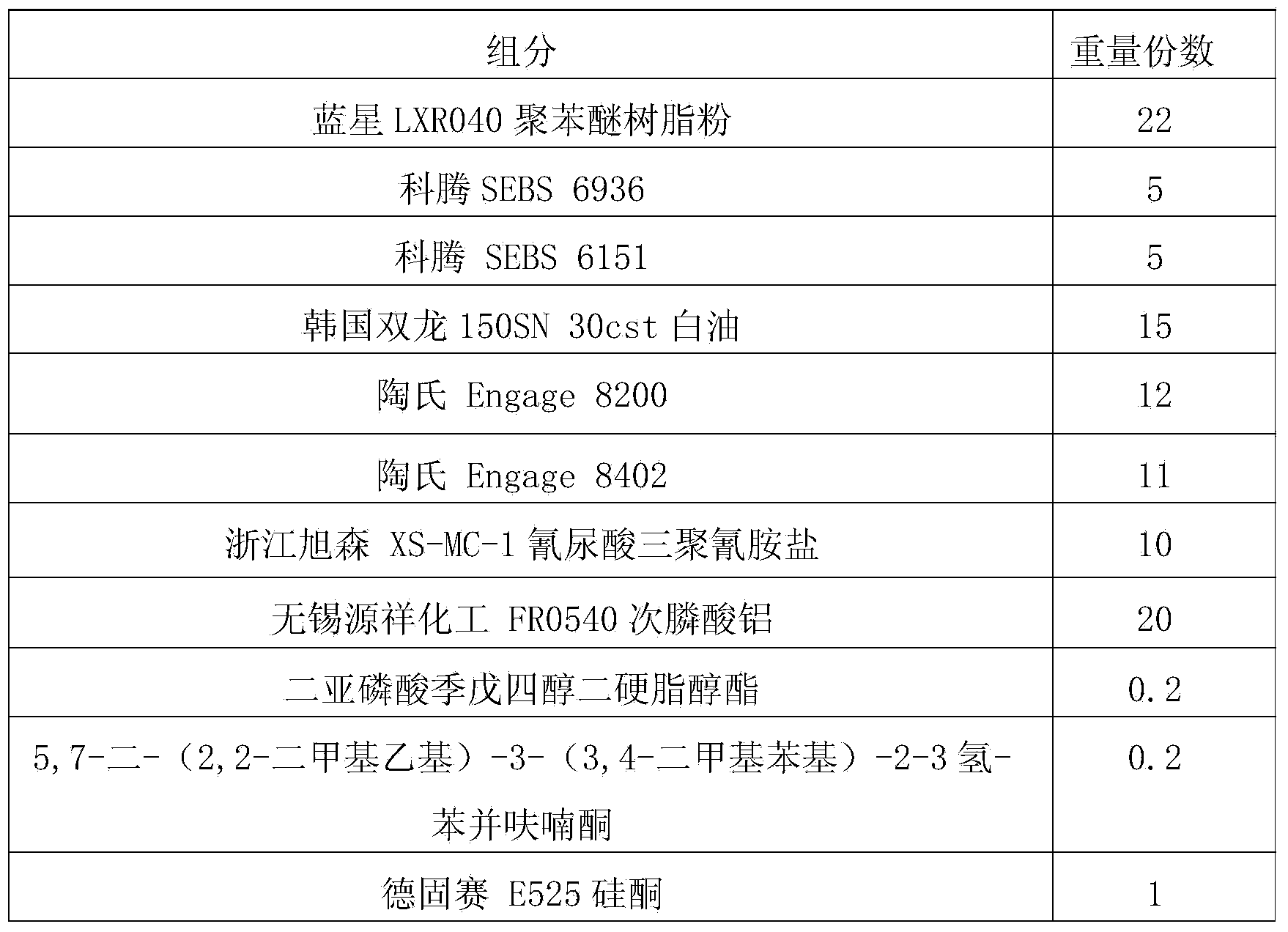

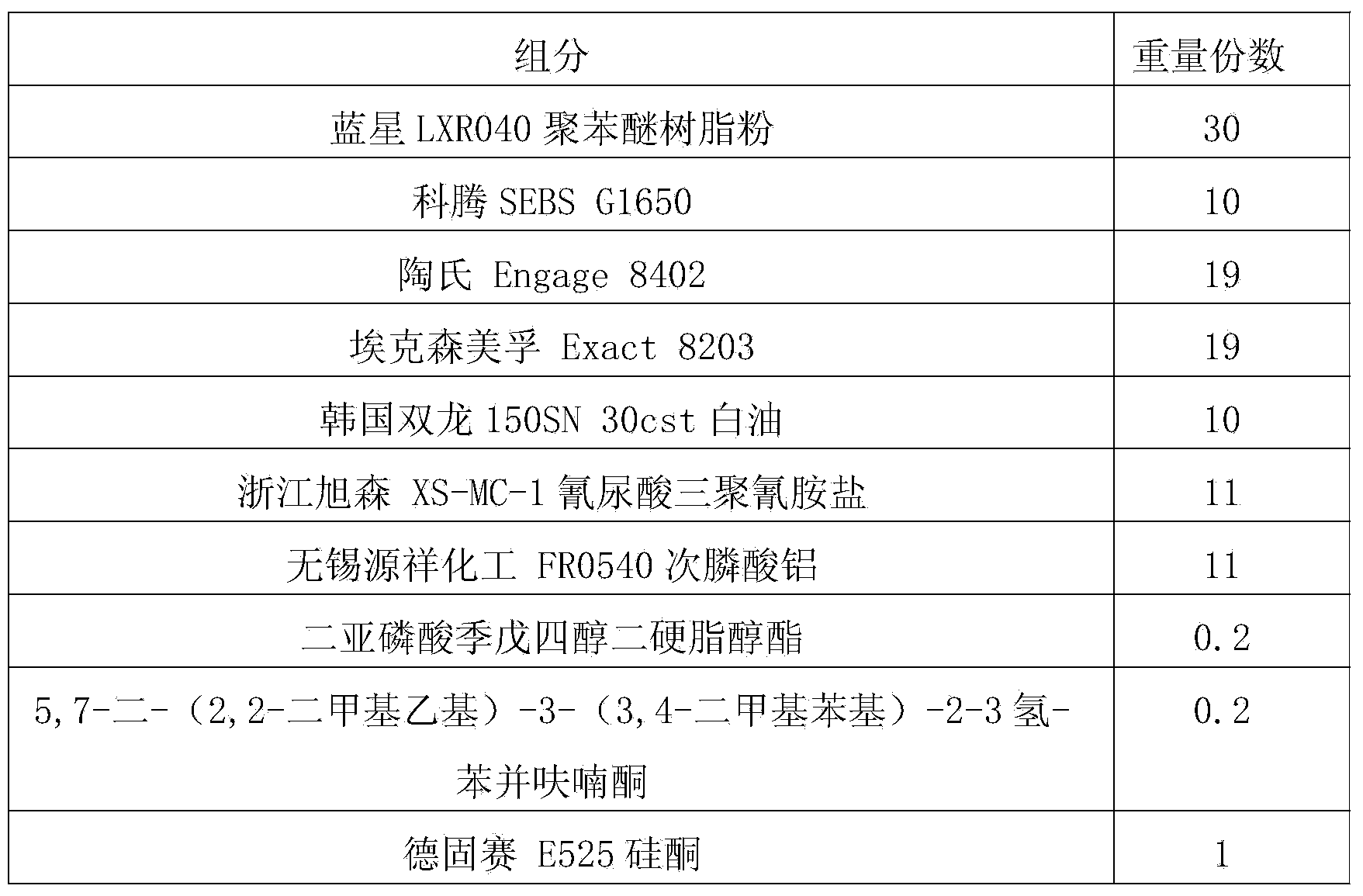

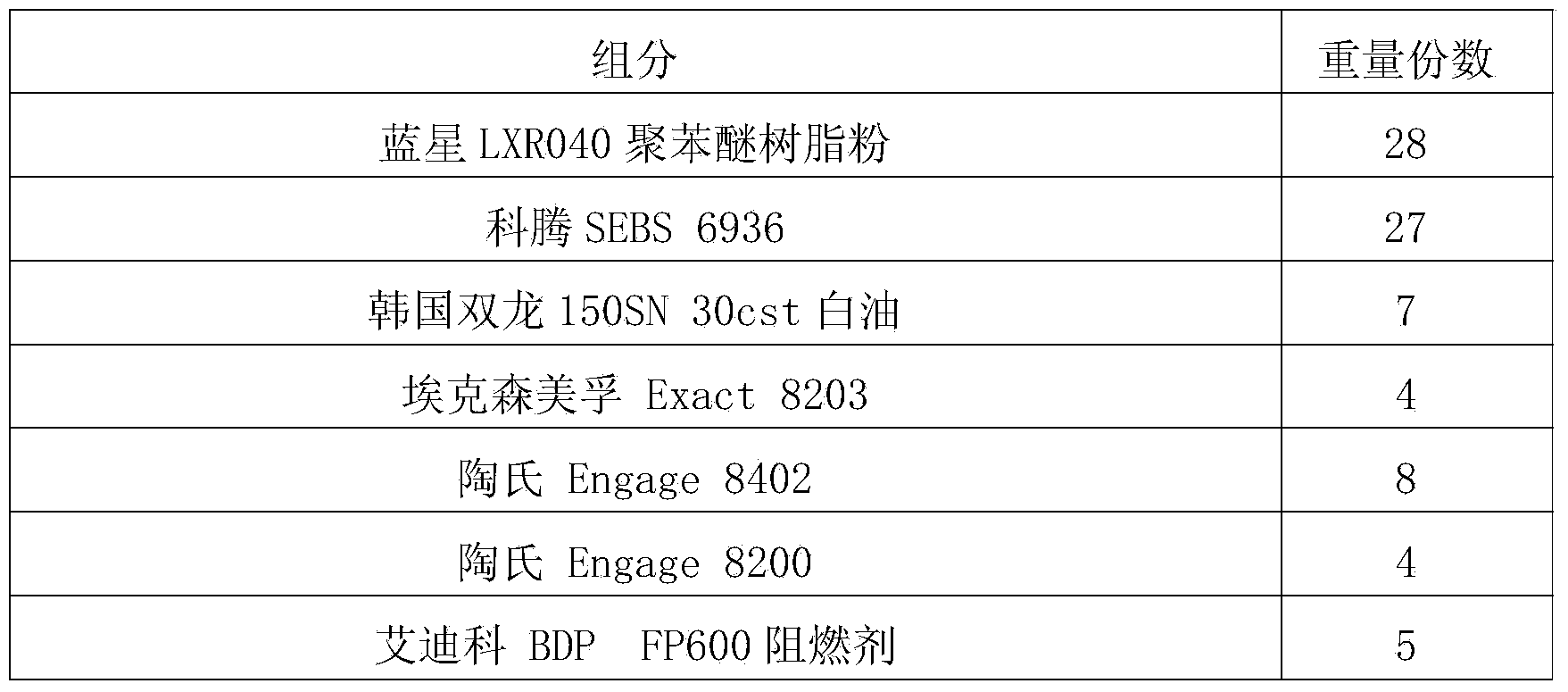

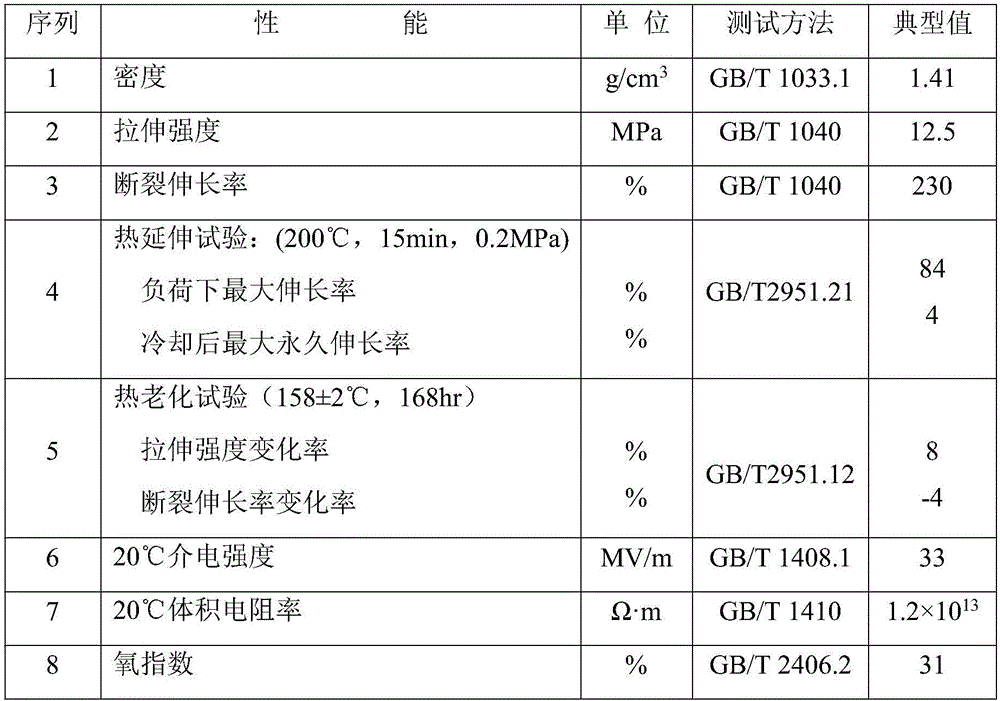

Thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and preparation method thereof

ActiveCN103910990ASimplify the proportioning processSimplify the manufacturing processThermoplasticElastomer

The invention discloses a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and a preparation method thereof. The cable material is used for a soft type electric wire and cable coating, and comprises the following components: polyphenyl ether resin powder, styrene-series elastomers, a plasticizer, a polyolefin elastomer, a compound phosphor-nitrogen flame retardant, an antioxidant and a lubricant. The material components are uniformly stirred in a high-speed mixer, extruded by a twin-screw extruder, pelletized in water, dried and then packaged to obtain a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material finished product. The thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material designed by the invention has excellent performance such as good processing performance, halogen-free and flame-retardant performance, low density, high tensile strength, good scraping resistance, good softness, good low temperature resistance, capacity of being extruded at a processing temperature of 200 DEG C-280 DEG C and not decomposed, free of cracks on a sample sheet for seven days under a high-temperature high-humidity environment with 98% humidity and a temperature of 85 DEG C, free of precipitates on surface, and the like.

Owner:JIANGSU LINRY NEW MSTAR TECH

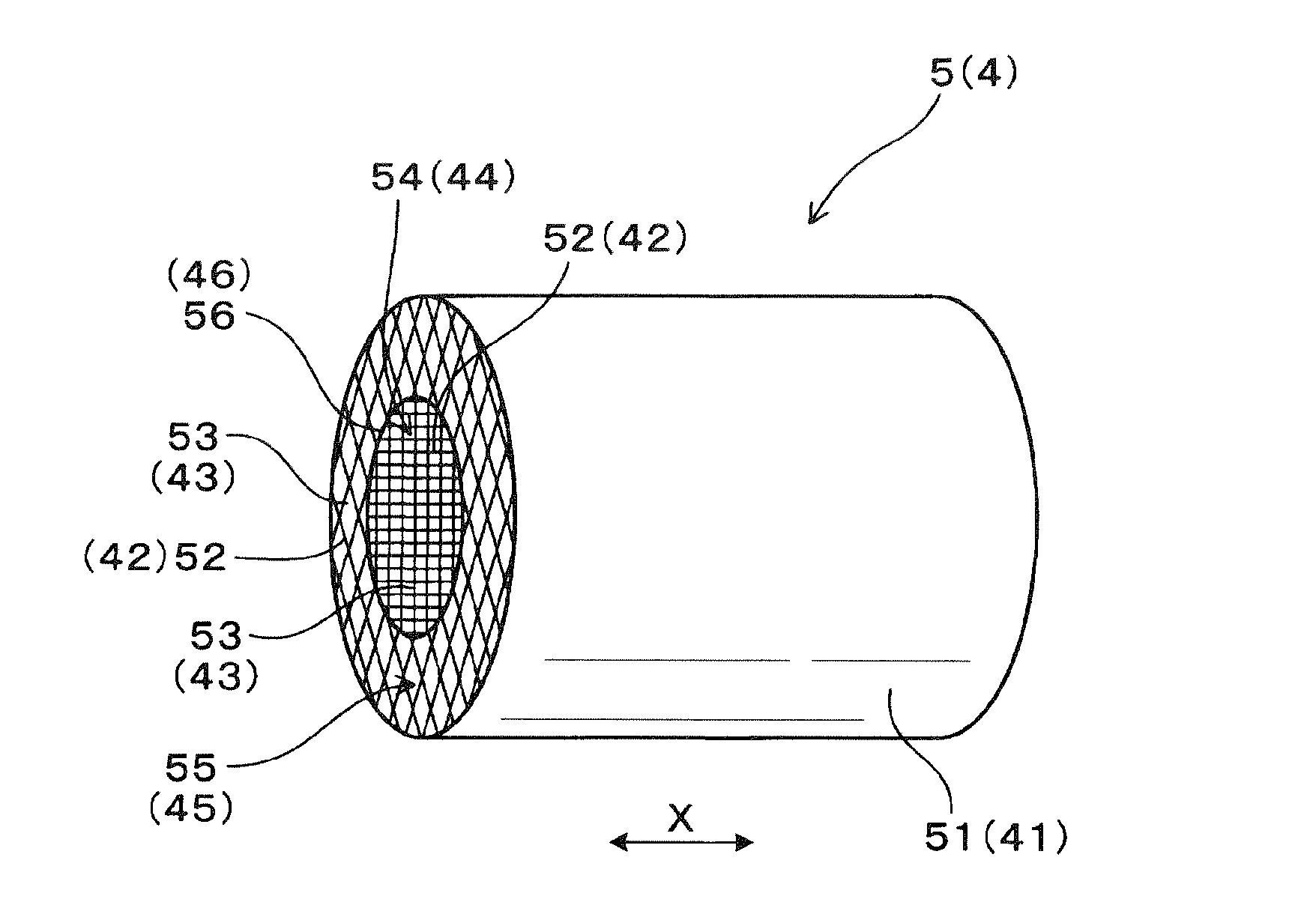

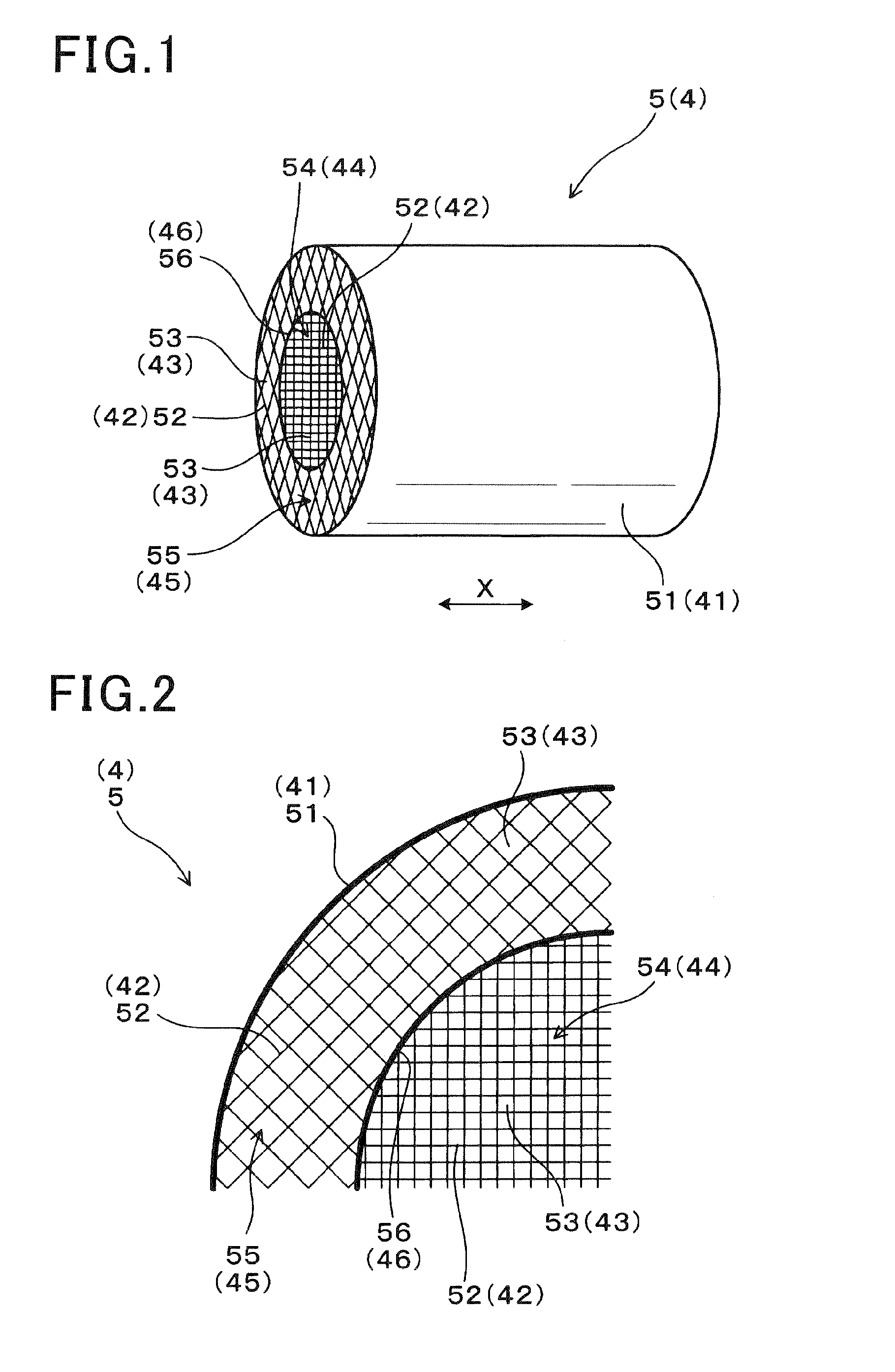

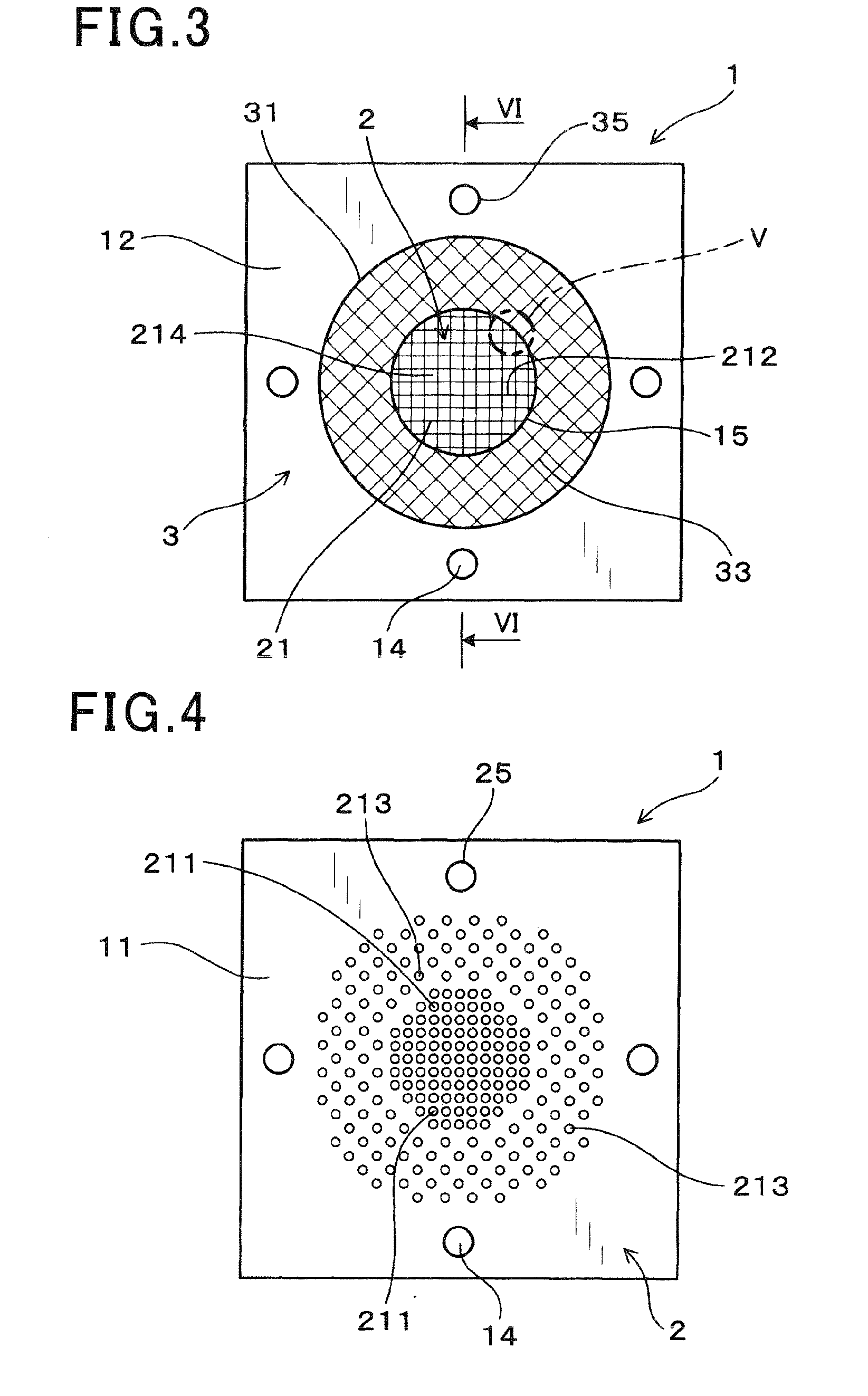

Method of producing honeycomb structural body

ActiveUS20150137431A1Suppress generation of localIncrease production capacityDispersed particle filtrationTransportation and packagingHoneycomb structureMetal

A method feeds raw material into a metal die and extrudes the raw material to produce a honeycomb molded body. The method fires the honeycomb molded body to make a honeycomb structural body. The metal die has a first metal die and a second metal die arranged at an upstream side of an extrusion direction of the raw material and a second metal die arranged at a downstream side of the extrusion direction of the raw material. The first metal die has a projection section and the second metal die has a penetration hole. The projection section is fitted to the penetration hole to assemble the first metal die and the second metal die. Communication holes formed in the second metal die communicate with raw material second feeding holes formed in the first metal die.

Owner:DENSO CORP

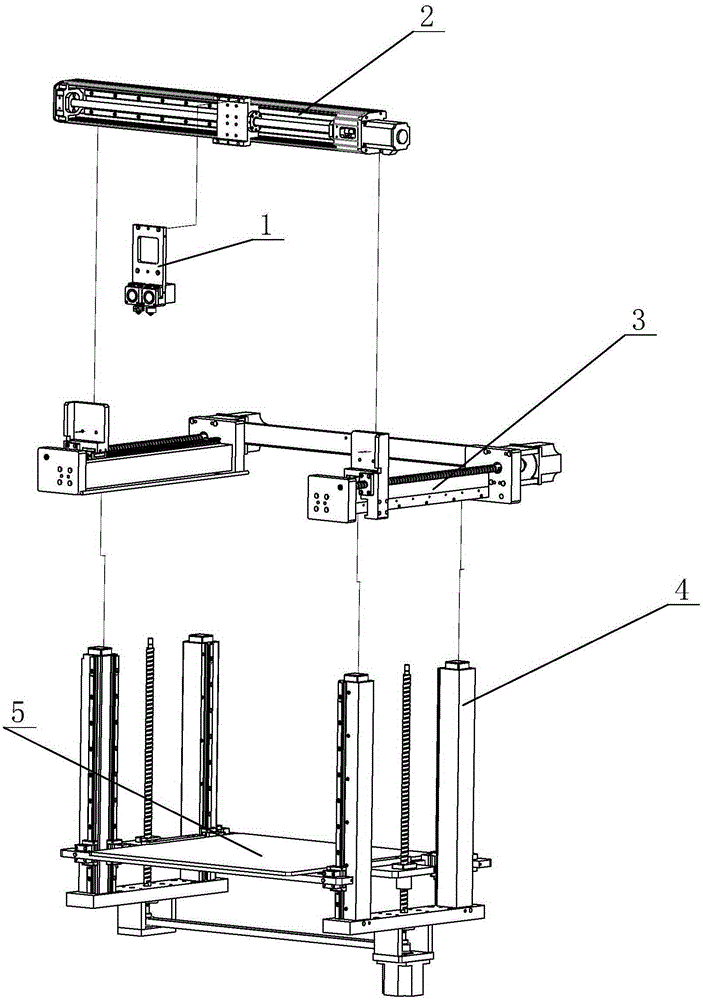

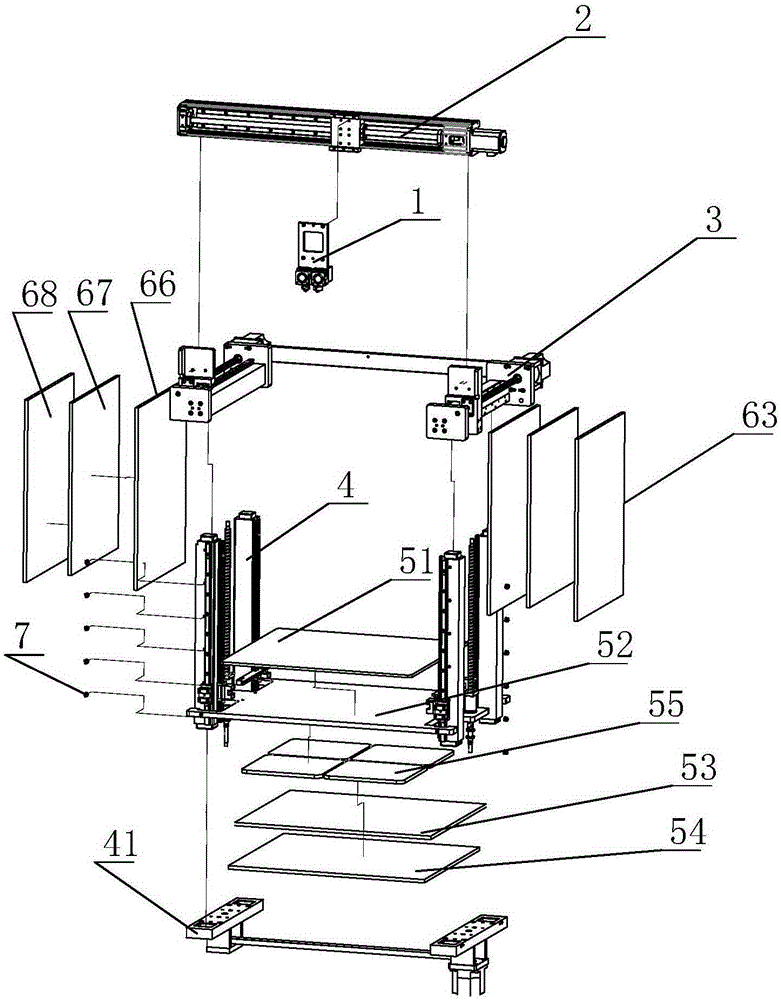

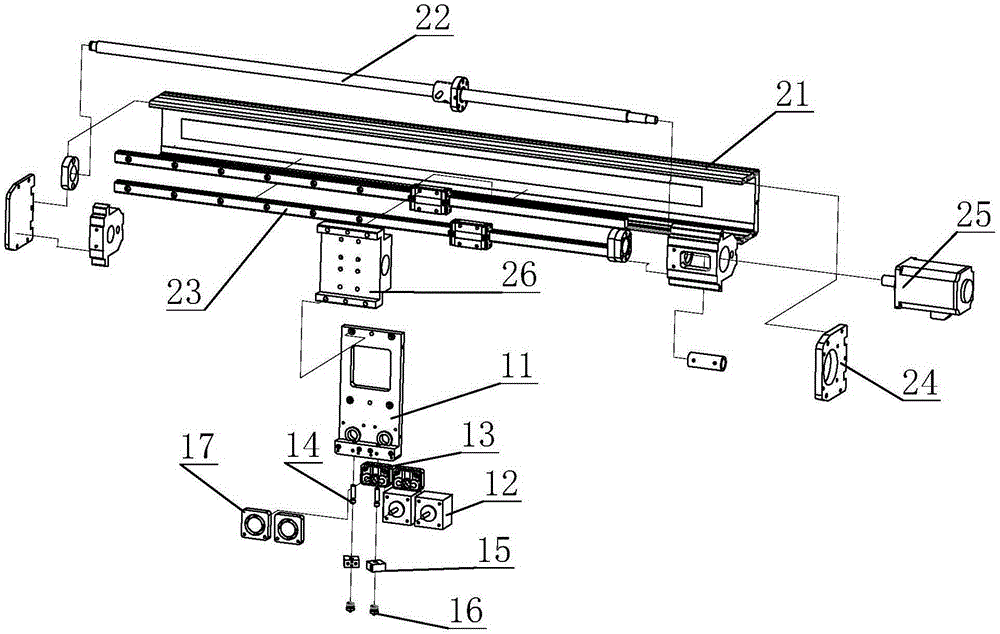

High-speed high-precision 3D printer

ActiveCN105235222AImprove rigidityImprove stabilityAdditive manufacturing apparatusBall screwEngineering

The invention discloses a high-speed high-precision 3D printer and mainly relates to the technical field of 3D printing. The high-speed high-precision 3D printer comprises an X-axis module, a Y-axis module, a Z-axis module, an extrusion mechanism, a platform mechanism and a machine casing; the Z-axis module comprises two retaining plates; a Z-axis ball screw and two Z-axis uprights are arranged on the retaining plates; the Z-axis uprights are in pin connection with the machine casing through a plurality of positioning pins; two Z-axis linear guide rails are mounted on the Z-axis uprights; a nut of the Z-axis ball screw and sliders of the Z-axis linear guide rail all are fixed on the platform mechanism; the Y-axis module is fixed at the top ends of the Z-axis uprights; the X-axis module comprises an X-axis upright that is in sliding connection with the Y-axis module in a Y-axis direction; an X-axis ball lead and two X-axis linear guide rails are mounted on the X-axis upright; the extrusion mechanism is mounted on a nut of the X-axis ball screw and the sliders of the two X-axis linear guide rails. The high-speed high-precision 3D printer has the beneficial effects of stable transmission, high mechanical strength, and remarkable increase of precision and speed.

Owner:WUHU AISANDI ELECTRONICS TECH CO LTD

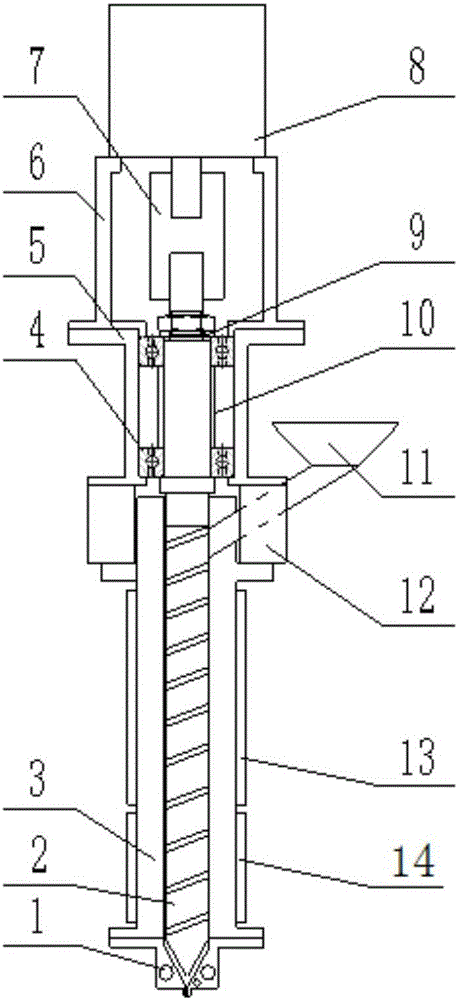

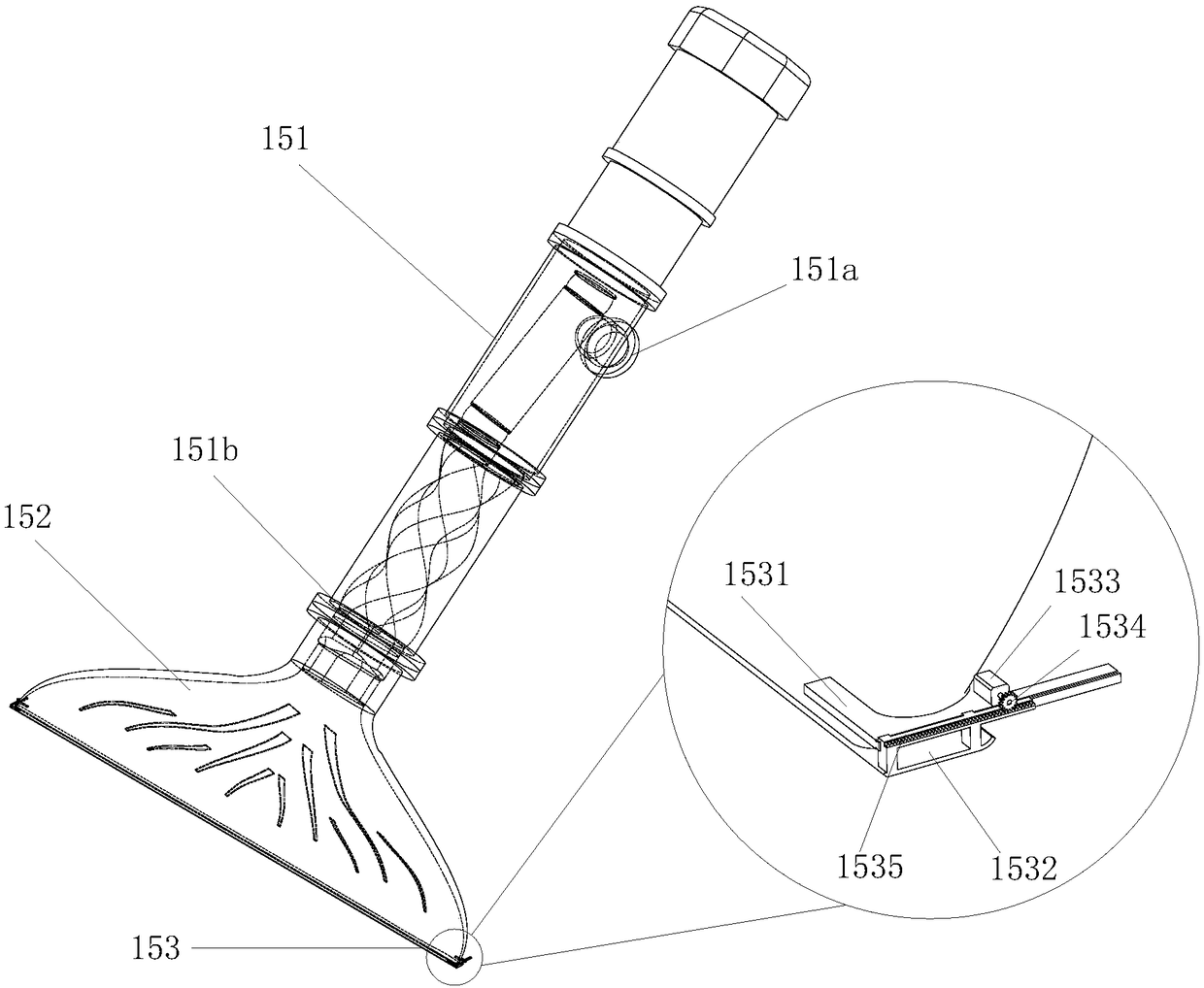

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

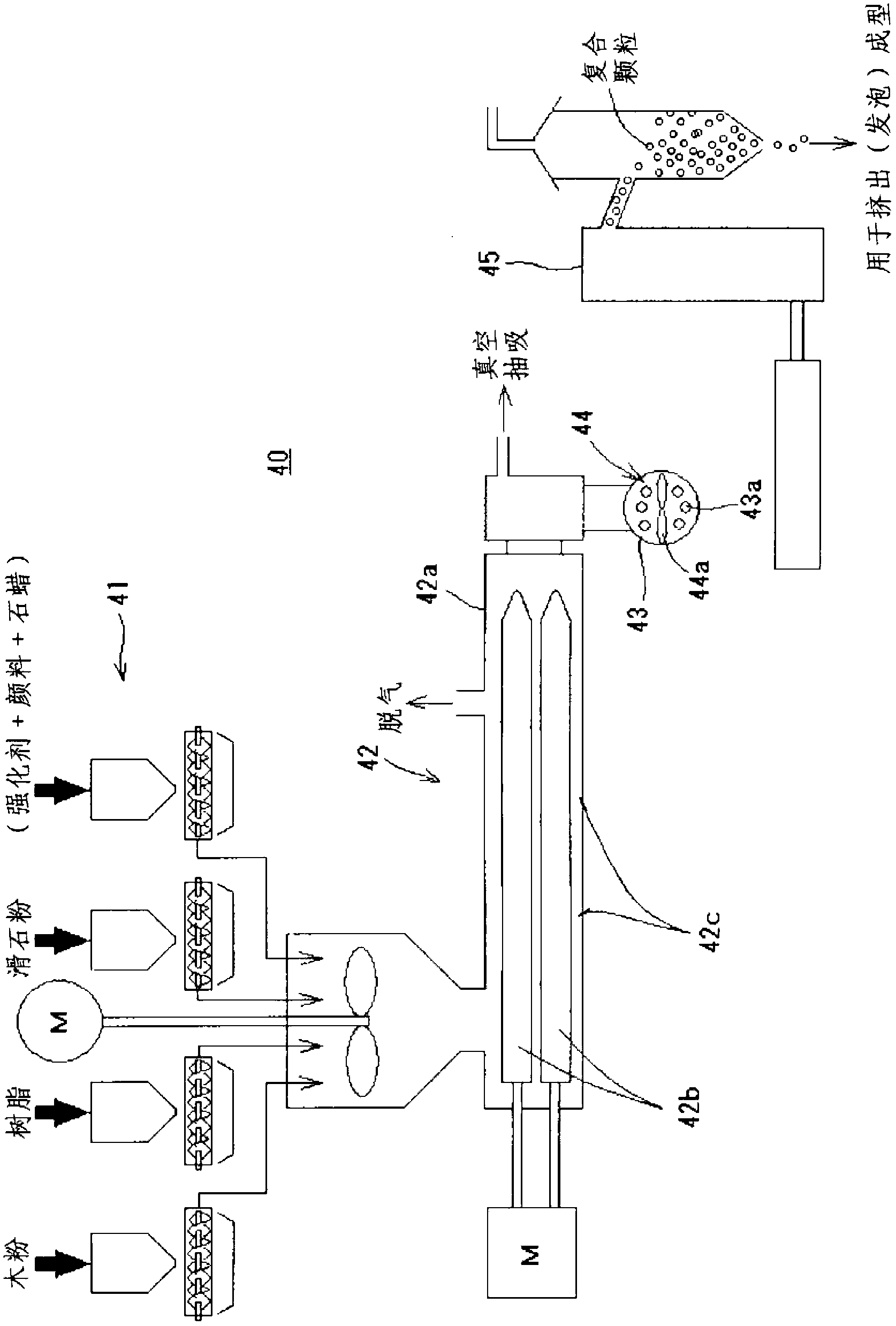

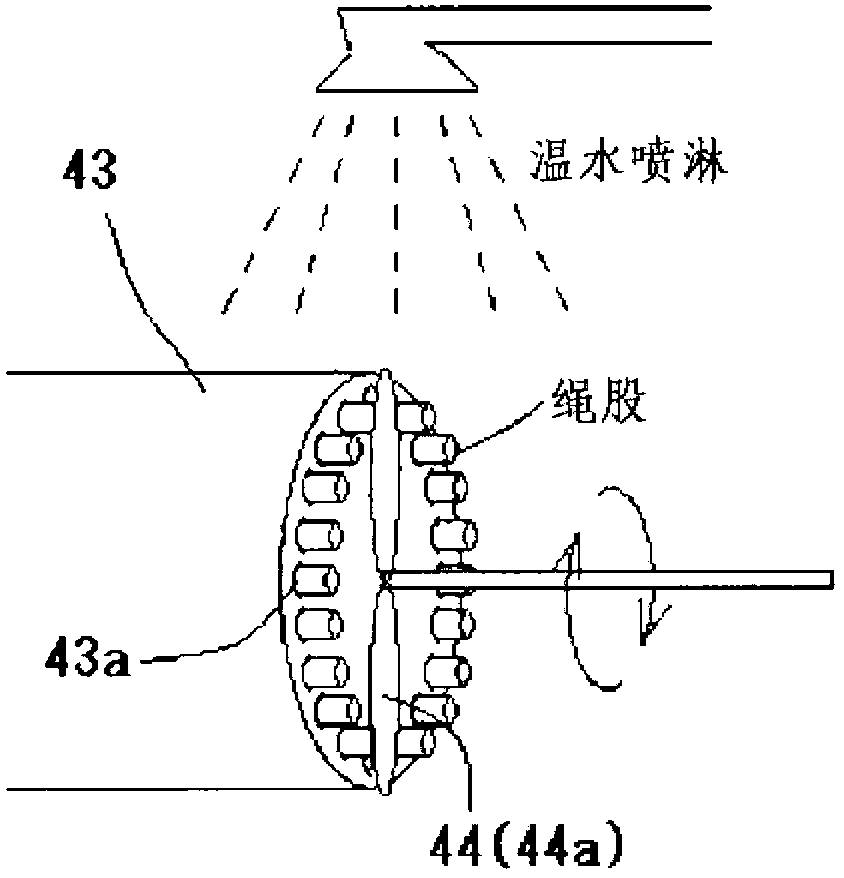

Method for producing composite pellet for extrusion molding, and composite pellet for extrusion molding produced by the method

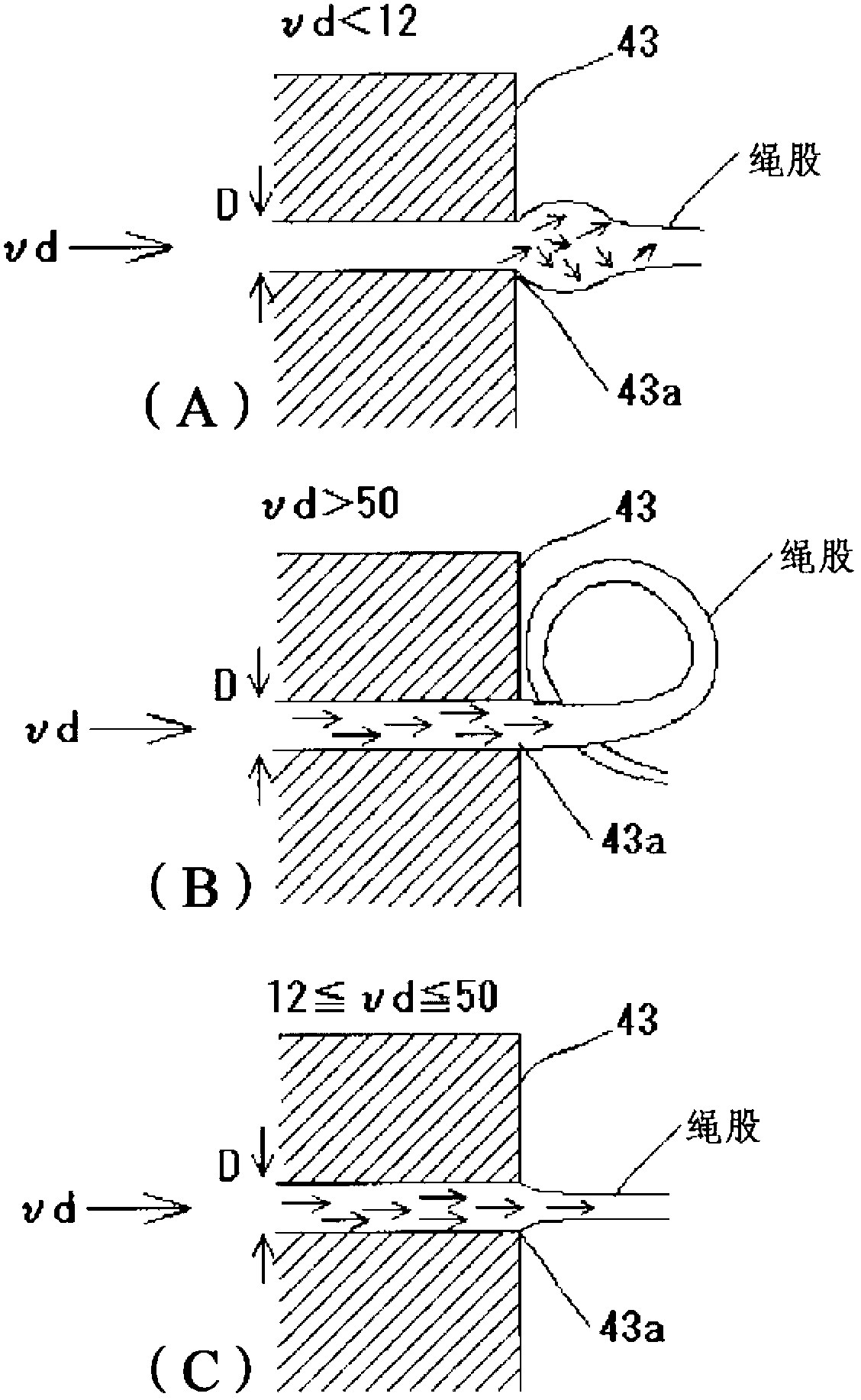

InactiveCN102869484AInhibit swellingAvoid contactFlat articlesDomestic articlesHydroxystearic AcidVolumetric Mass Density

Disclosed are composite pellets for extrusion molding wherein fusion does not occur between the pellets, and there is no variation in size and density. A molten material obtained by an extruder for a raw material containing a thermoplastic resin and wood powder is extruded into a strand shape through a die nozzle of the extruder, and cut into a predetermined length to form a pellet. At this time, the extrusion amount, the diameter of each nozzle hole, and the number of nozzle holes are adjusted so that the linear velocity (vd) of the molten material in each nozzle hole of the die nozzle is in the range of 12 to 50 cm / sec. Further, regardless of the variations in particle diameter, etc., a stable amount of the composite pellets are supplied to the extruder, and smoothly introduced to a screw of the extruder. The composite pellets and 12-hydroxystearic acid containing a metal of Ca, Mg, or Zn are agitated together, and 0.03 to 0.4 mass% of the 12-hydroxystearic acid is attached to the periphery of 100 mass% of the composite pellet, and the pellets are used for extrusion molding.

Owner:WPC CORP

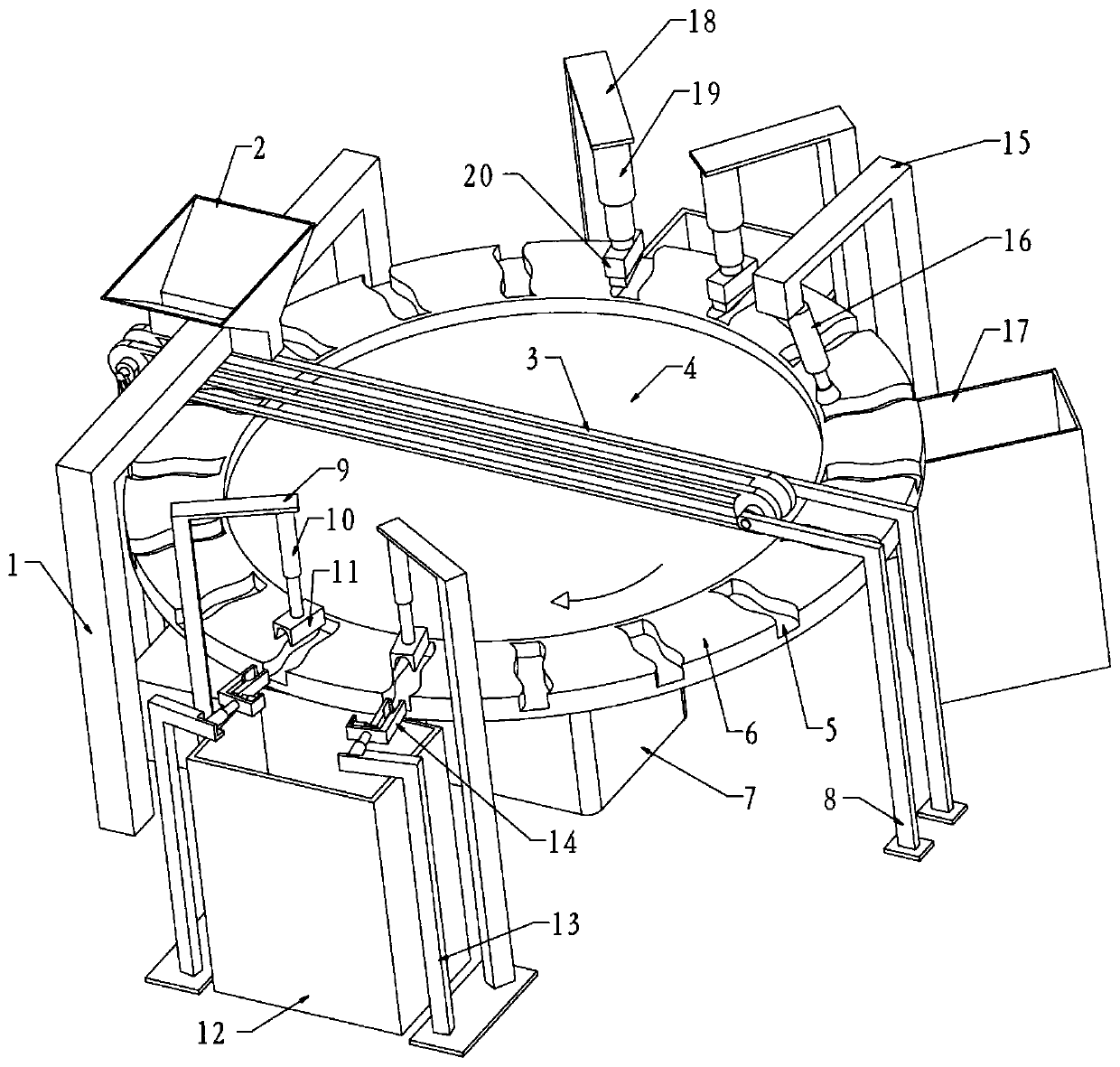

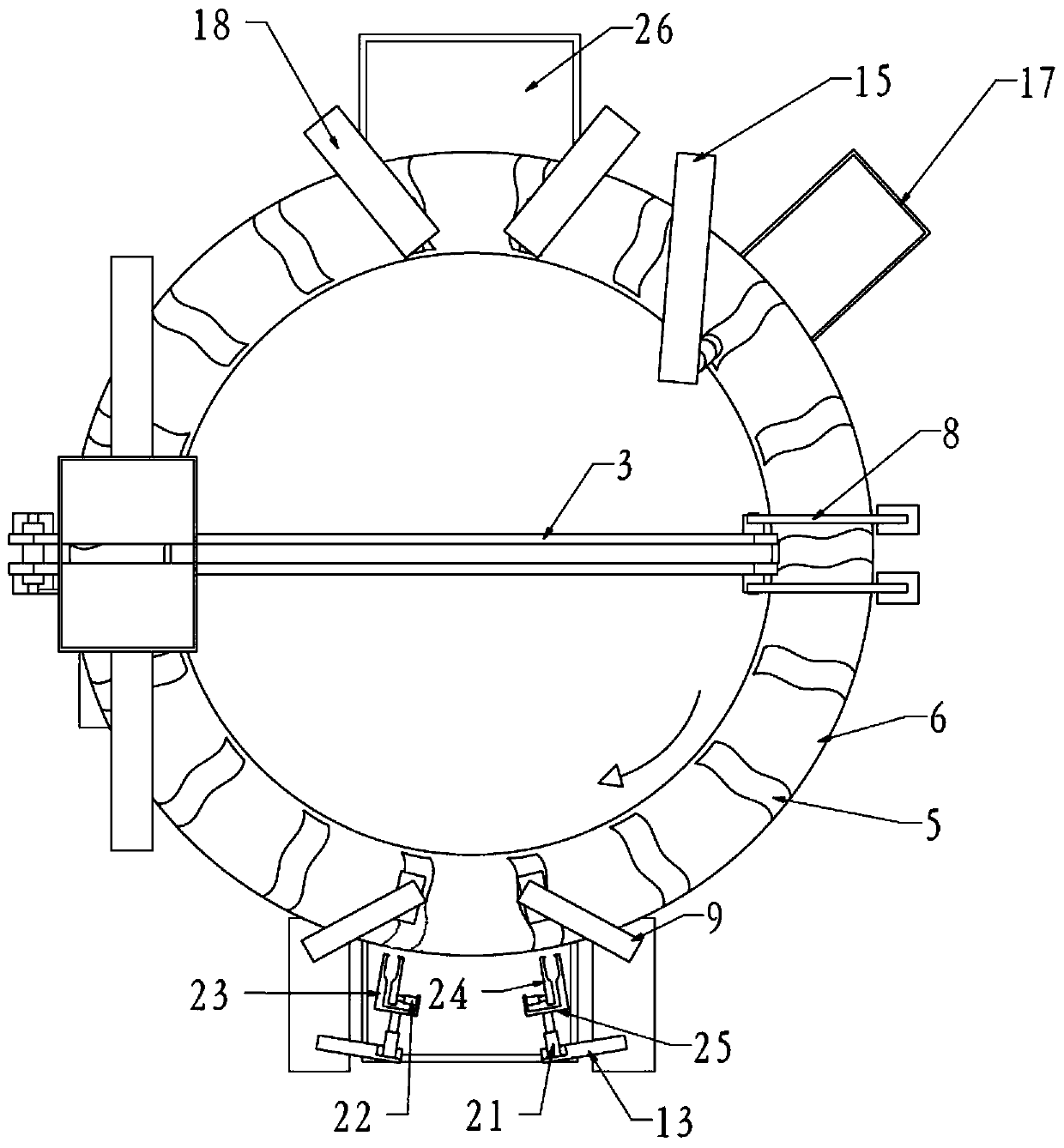

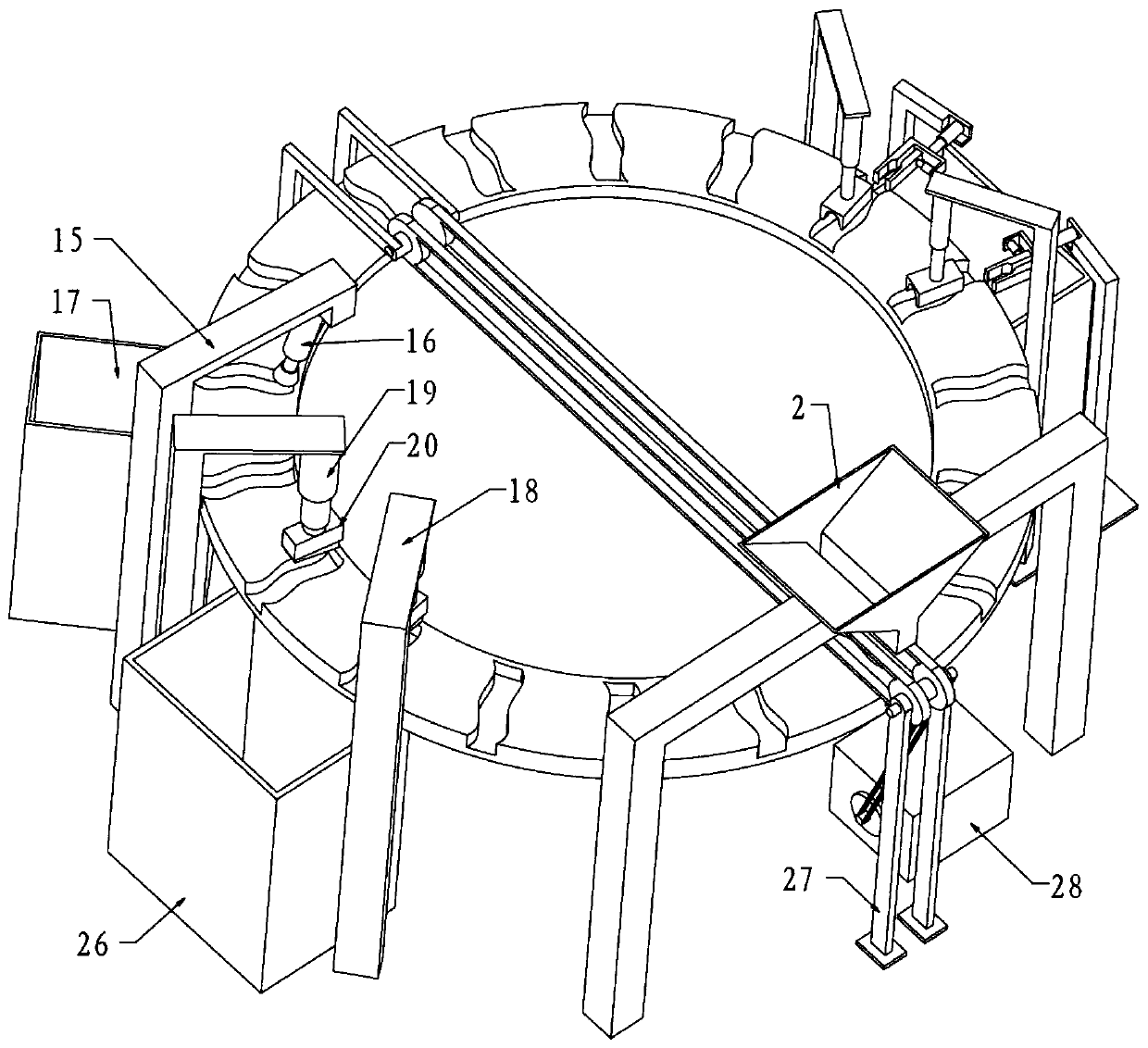

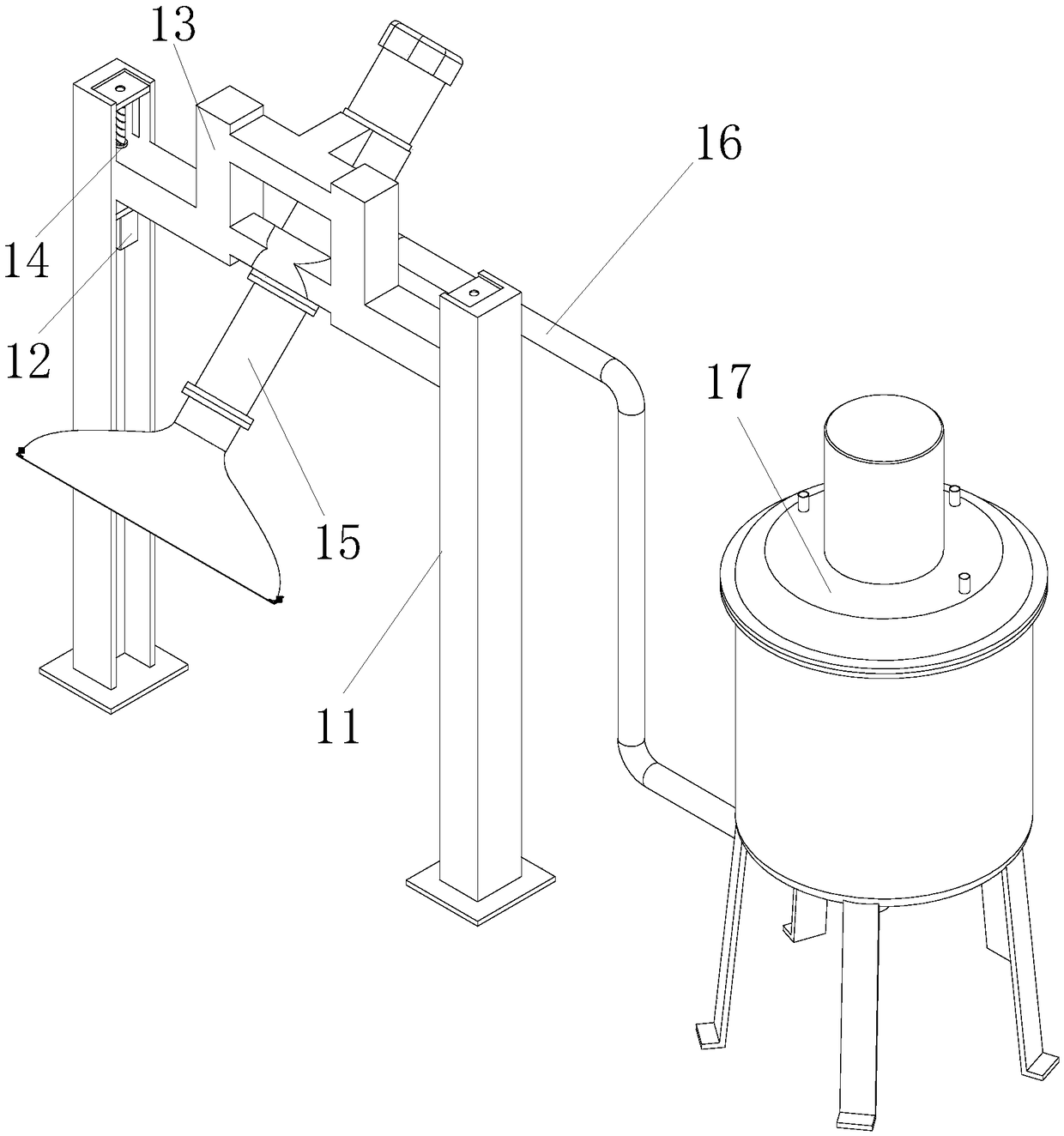

Crayfish shell removing device

PendingCN111011465AImprove convenienceSmall space requirementShrimp/lobster processingShrimpEngineering

The invention discloses a crayfish shell removing device, and belongs to the field of crayfish processing devices. The crayfish shell removing device comprises a rotating disc, a boss is arranged on the rotating disc, grooves are formed in the boss in an annular array, and a conveying belt is arranged above the rotating disc; a clamping device is movably arranged above the boss, the clamping device is connected to a piston rod of a first air cylinder, and the first air cylinder is installed on a third support; a head removing device is movably arranged on the outer side of the boss, the head removing device is connected to a piston rod of a third air cylinder, and the third air cylinder is installed on a fourth support; an extrusion device is movably arranged above the boss, the extrusiondevice is connected to a piston rod of a second air cylinder, and the second air cylinder is installed on a sixth support; an air spraying pipe is arranged above the boss and installed on a fifth support. According to the crayfish shell removing device, shrimp heads and shrimp lines can be synchronously removed, the rotating disc type annular integrated design is adopted, the space requirement ofa workshop is reduced, meanwhile, overall management and operation are facilitated, and the production efficiency is further improved.

Owner:国联(益阳)食品有限公司

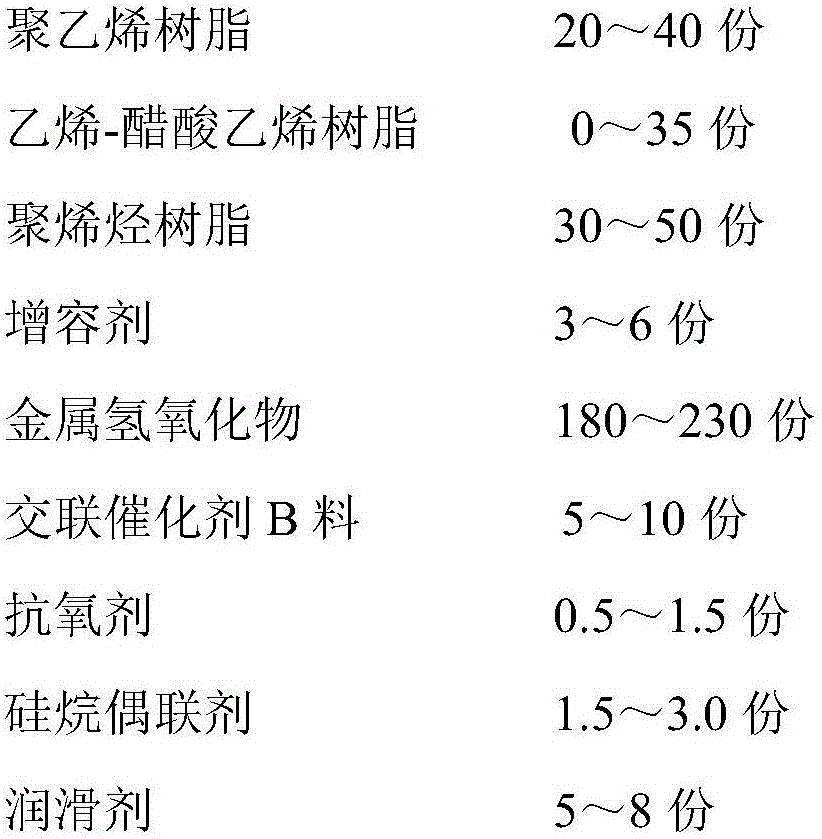

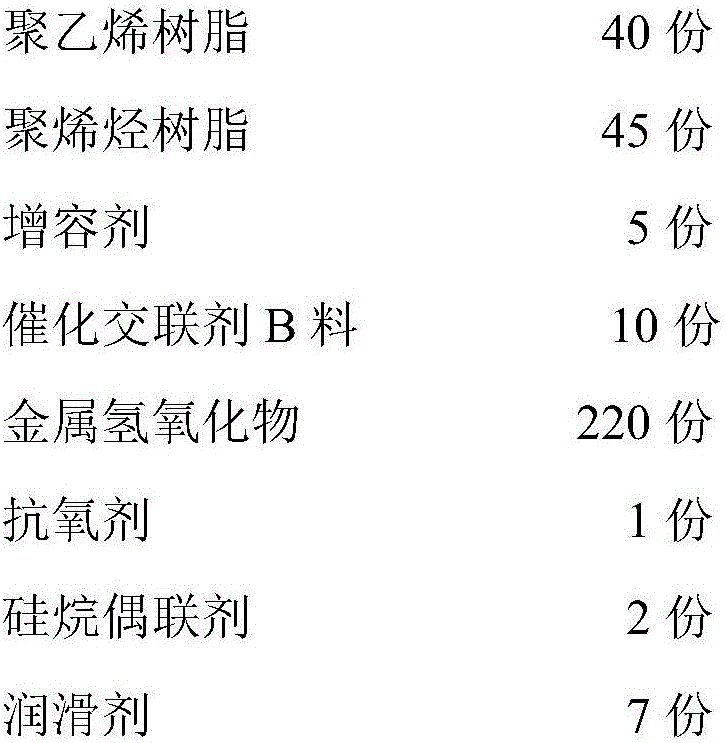

Two-step process silane crosslinking low-smoke halogen-free flame-retarding polyolefin cable material and manufacturing method of same

The invention discloses a two-step process silane crosslinking low-smoke halogen-free flame-retarding polyolefin cable material and a manufacturing method of same. The cable material is composed of a silane grafted polyethylene material A and a low-smoke halogen-free flame-retarding polyolefin master batch containing a crosslinking catalyst material B, wherein the mass ratio of the silane grafted polyethylene material A to the low-smoke halogen-free flame-retarding polyolefin master batch containing the crosslinking catalyst material B is 12-25:88-75. The manufacturing method is simple, has low energy consumption and is easy to control. The cable material has good stability and high resin flowability and can be extruded smoothly during pay-off. The preparation process of an electric wire cable is free of pre-crosslinking, so that continuous pay-off is allowed and the cable has high surface smooth degree. The manufacturing method improves processability and surface smooth degree during the pay-off processing of the electric wire cable.

Owner:上海新上化高分子材料有限公司

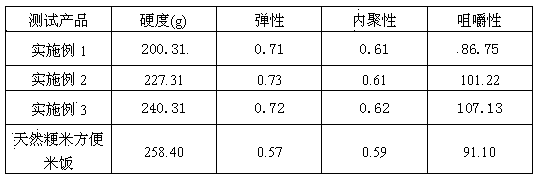

Preparation method of moisturizing instant rice

ActiveCN103519056ATraits that are easy to controlImprove adaptabilityFood thermal treatmentMulti-step food processesRice dishesBroken rice

The invention discloses a preparation method of moisturizing instant rice. By taking broken rice as a raw material, the moisturizing instant rice is prepared by the following steps: pre-cooking; drying; crushing; carrying out twin-screw extrusion; cutting and moulding; packaging; sealing; and sterilizing. In the pre-cooking step, the degree of gelatinization is controlled at 40-60%. In the drying step, the water content is controlled at 20-25%. According to the invention, the moisturizing instant rice is processed and prepared by adopting pre-cooking step combined with twin-screw extrusion, so that the moisturizing instant rice prepared is full in particle, glittering and translucent in color and luster, appropriate in hardness and chewiness and durable in storage, and the quality of the moisturizing instant rice is close to that of natural rice.

Owner:JIANGNAN UNIV

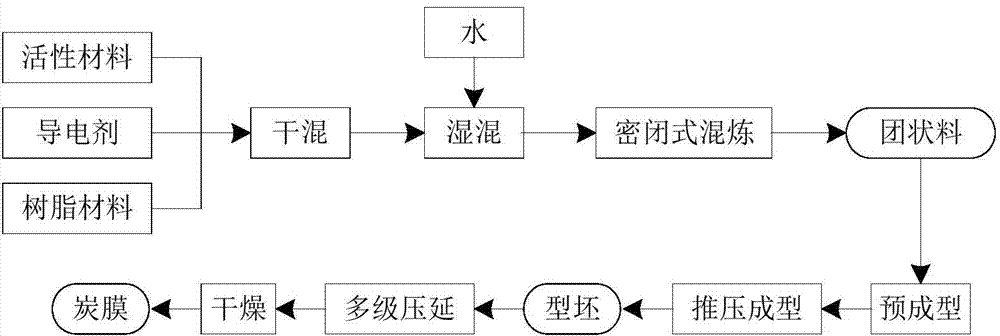

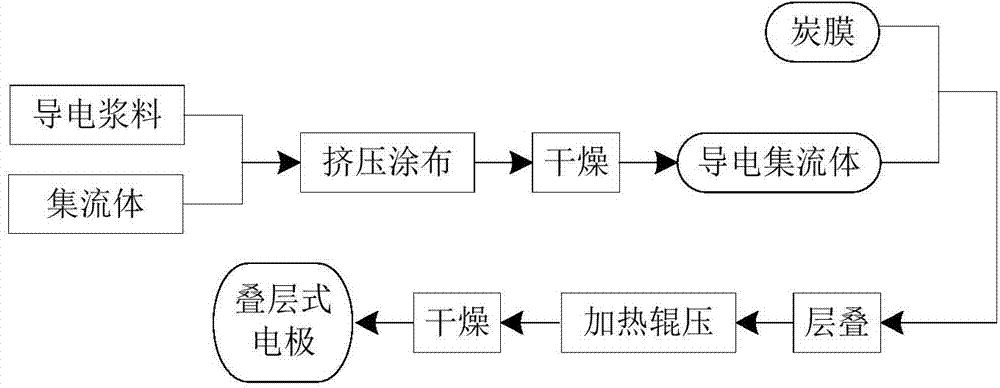

Manufacturing method for laminated electrode, carbon film and manufacturing method for carbon film

ActiveCN104715937AImprove dispersion uniformityStrengthen the effect of fibrosisHybrid capacitor electrodesHybrid/EDL manufactureCarbon filmCurrent collector

The invention discloses a manufacturing method for a laminated electrode, a carbon film and a manufacturing method for the carbon film. According to the manufacturing method for the carbon film of the laminated electrode, dry mixing, wet mixing, closed mixing, pushing-pressing forming, calendaring and drying are performed on active material, conductive additives and adhesion agents, the manufactured carbon film of the laminated electrode and a conductive current collector are laminated to form the laminated electrode, and the laminated electrode is suitable for a super capacitor. According to the manufacturing method for the carbon film, the raw materials are sufficiently and evenly mixed through the steps of dry mixing, wet mixing and closed mixing, and then through the follow-up machining technology, the carbon film which has good strength, toughness, bending resistance and other mechanical properties and is high in bulk density and capable of being continuously manufactured is formed. The carbon film obtained through the manufacturing method is laminated on the conductive current collector, so that the manufactured laminated electrode has the advantages of being high in loading capacity of active matter, low in internal resistance, high in chemical stability, long in service life and the like.

Owner:TIG TECH CO LTD

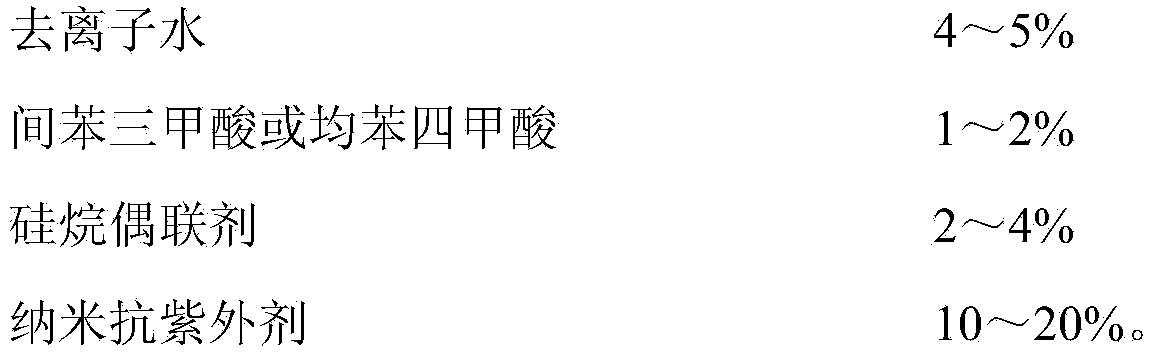

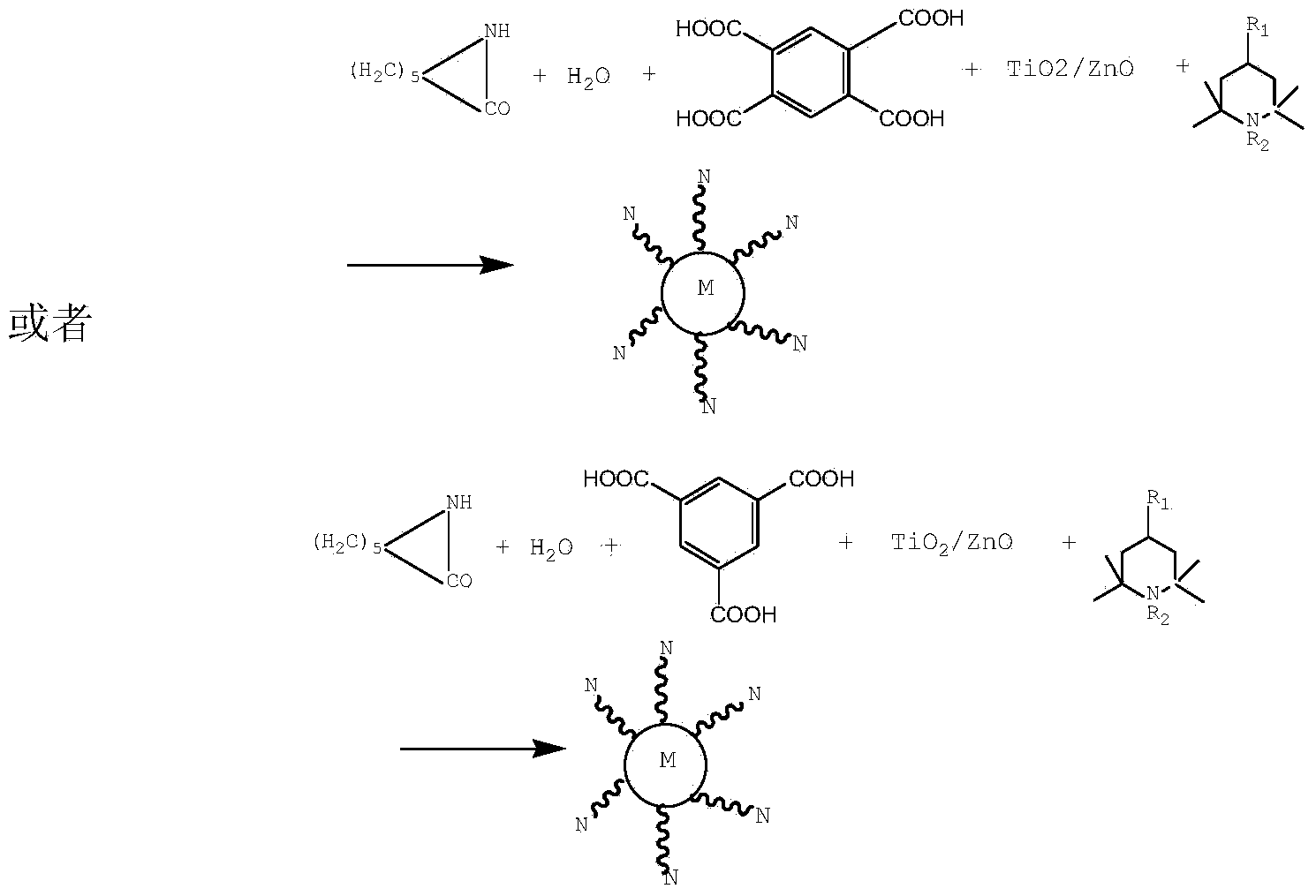

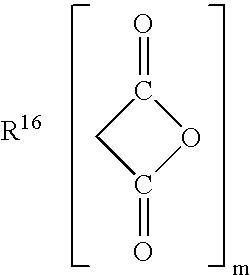

Uvioresistant nylon-6 fiber for ultrathin and light fabric and preparation method thereof

ActiveCN103774272AImprove liquidityBarrier transmissionMelt spinning methodsArtifical filament manufactureIn situ polymerizationNylon 6

The invention relates to an uvioresistant nylon-6 fiber for an ultrathin and light fabric and a preparation method of the uvioresistant nylon-6 fiber. The uvioresistant nylon-6 fiber is formed by branched-chain nylon-6 functional master batches and conventional nylon-6 chips through blending and spinning, wherein the branched-chain nylon-6 functional master batches account for 6-10% in weight percentage; the preparation method comprises the steps of firstly, preparing the branched-chain nylon-6 functional master batches through in-situ polymerization or blending; secondly, crystallizing and drying the branched-chain nylon-6 functional master batches and the conventional nylon-6 chips respectively and mixing, and then performing vacuum drying to obtain blended chips; and finally, performing melt spinning to the blended chips with melt spinning equipment. The using amount of ultraviolet absorbents is reduced, the fiber spinnability is improved, the uvioresistant and the ultraviolet aging resistant effects are ensured; the fabric can strongly absorbing ultraviolet radiation while light weight is ensured, and is suitable for developing thin and light clothes in summer.

Owner:中国化学纤维工业协会

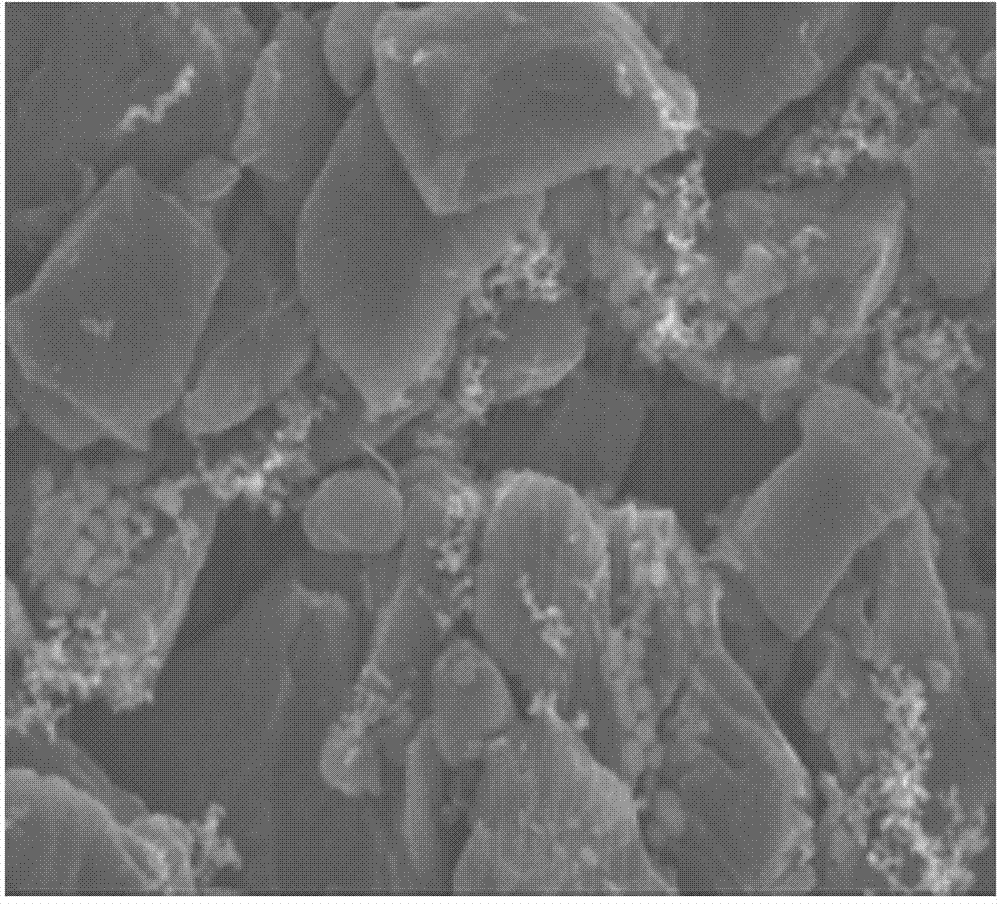

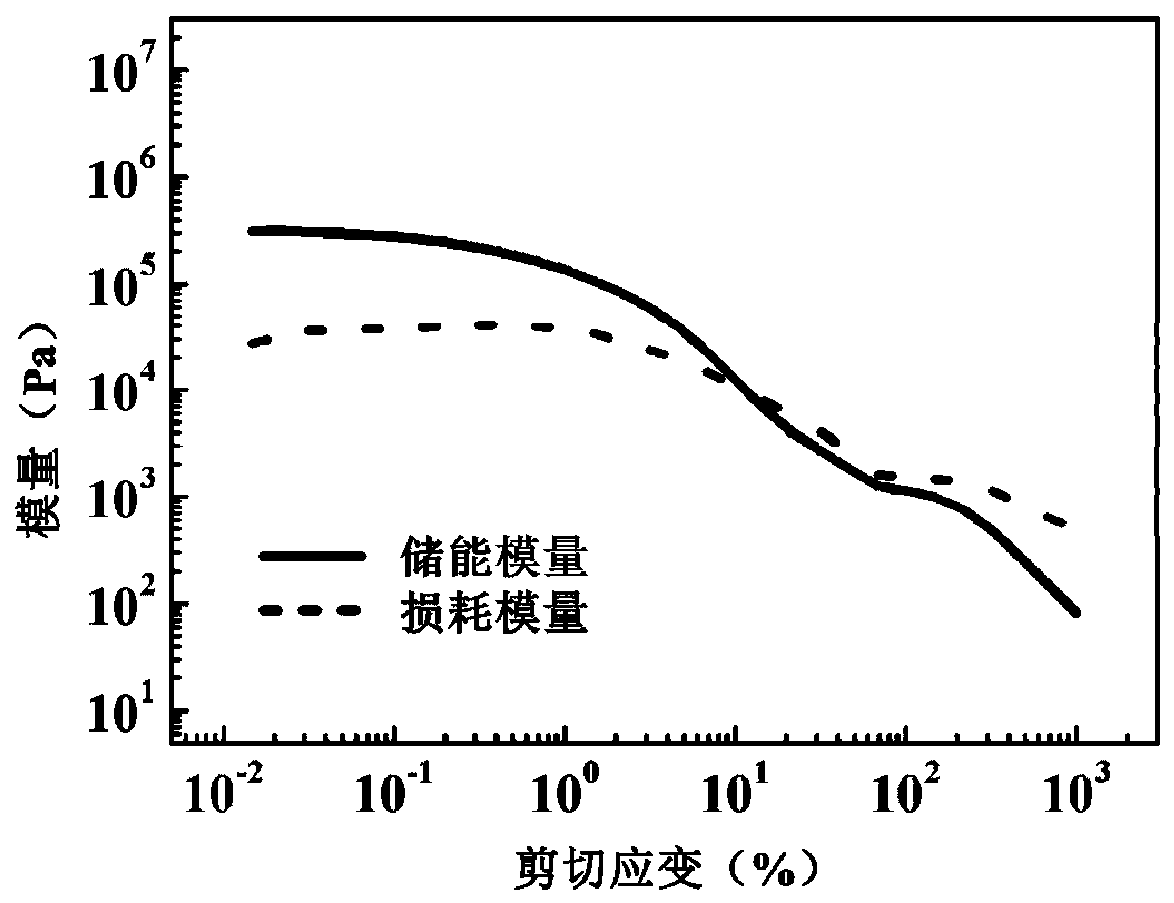

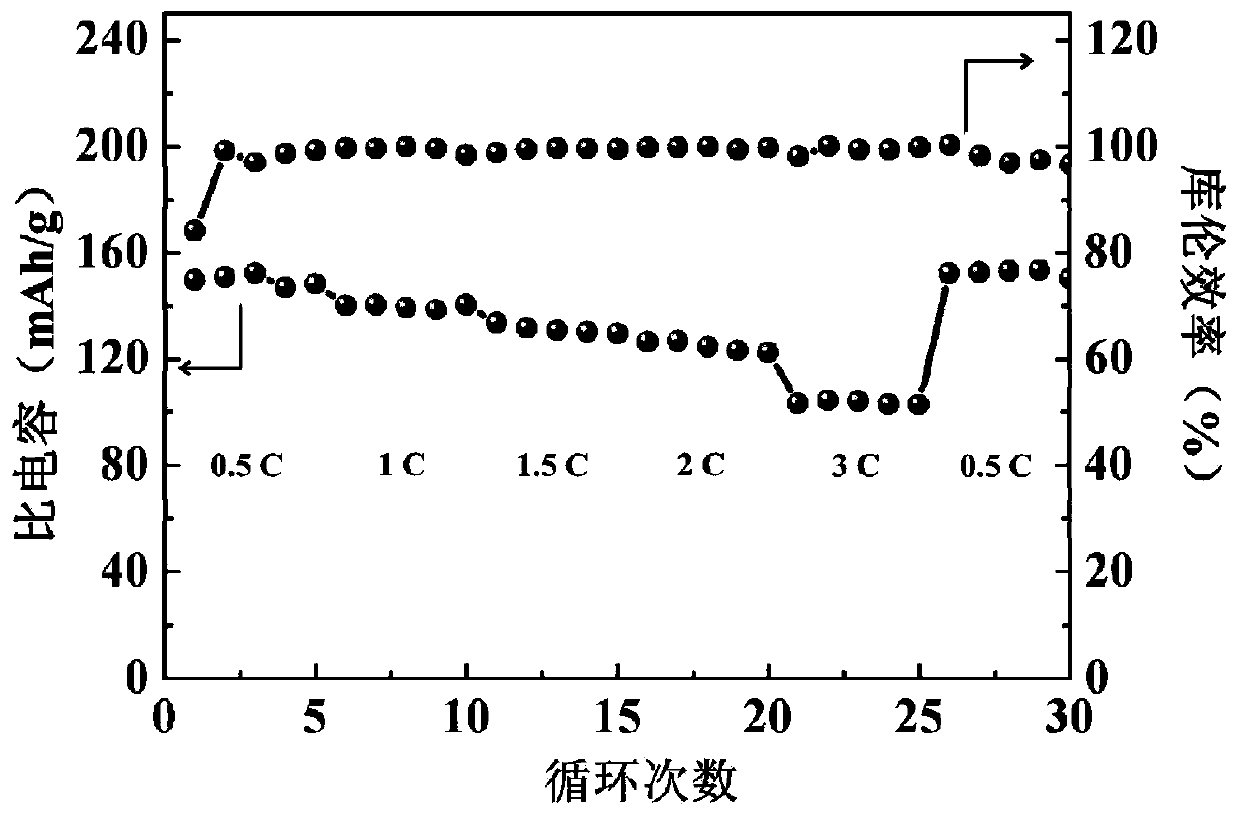

Universal 3D printing nano electrode slurry and preparation method thereof

ActiveCN110752354AExtrude evenlyEvenly dispersedCell electrodesSecondary cellsNanotechnologyElectrically conductive

The invention discloses universal 3D printing nano electrode slurry. The universal 3D printing nano electrode slurry is prepared from the following components: a nano electrode active material, a conductive agent, a binding agent and a dispersant, wherein the weight ratio of the nano electrode active material to the conductive agent to the binding agent is (5 to 7) to (2 to 4) to 1; the ratio of the volume of the dispersant to the total weight of the nano electrode active material, the conductive agent and the binding agent is (2 to 5 mL) to 1 g. The invention further provides a preparation method of the universal 3D printing nano electrode slurry. The universal 3D printing nano electrode slurry disclosed by the invention has the beneficial effects that the rheological property and the material dispersity of the 3D printing nano electrode slurry are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

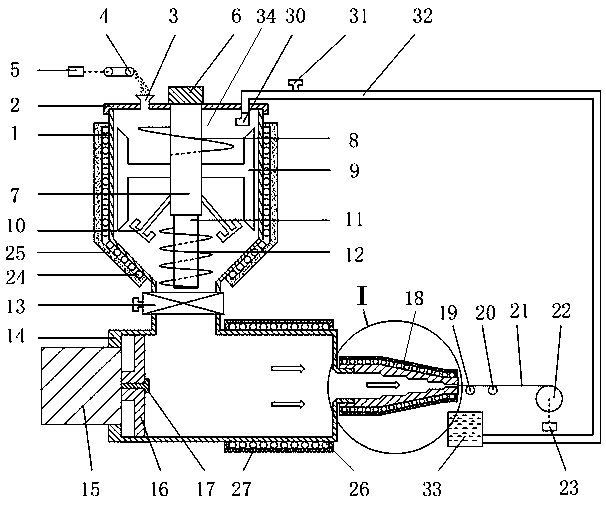

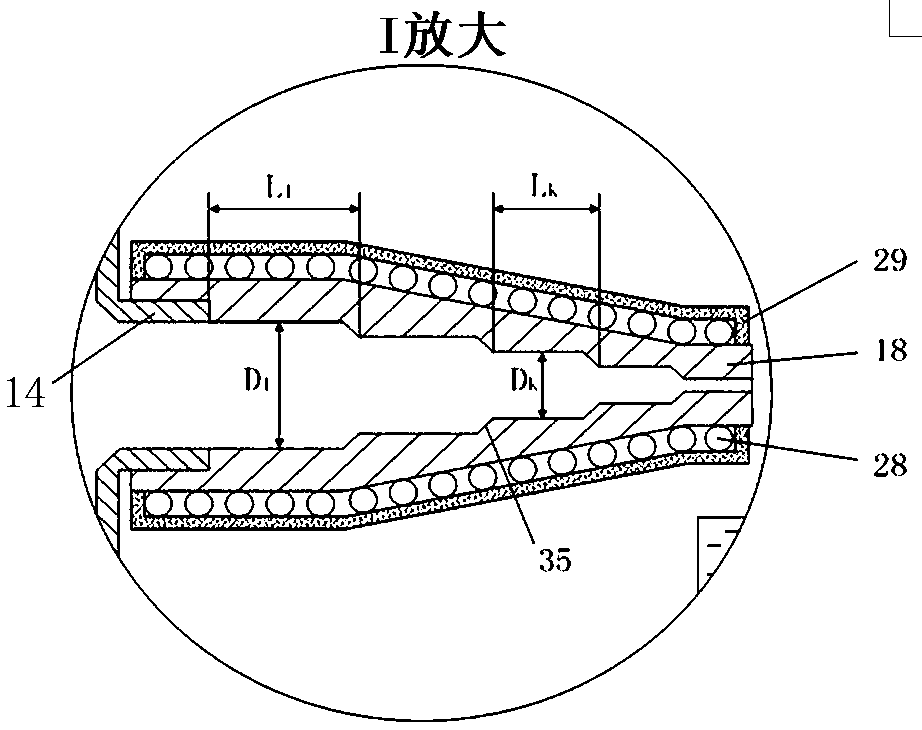

Extrusion device and method for oriented chopped carbon fiber reinforced thermoplastic composite

ActiveCN109177106AAchieve recyclingAvoid massive agglomerationDomestic articlesYarnHydraulic cylinder

The invention discloses an extrusion device and method for an oriented chopped carbon fiber reinforced thermoplastic composite, and belongs to the field of composite processing. A multifunctional stirring device is arranged in the middle of the interior of a melting chamber; the bottom of the melting chamber is connected to an extrusion chamber horizontally arranged left and right by a gate valve;a telescopic hydraulic cylinder which is horizontally arranged is located at the left side of the extrusion chamber; the right end of the telescopic hydraulic cylinder is connected to a first-stage sleeve piston; a second-stage sleeve piston is coaxially connected to the first-stage sleeve piston; a right end outlet of the extrusion cavity is coaxially connected and communicates with a tapered stepped pipe type nozzle; the interior of the tapered stepped pipe type nozzle is provided with multiple-stage tapered stepped pipes from left to right; and the inner diameters of pipelines of the tapered stepped pipes decrease in sequence from left to right, and the left and right lengths sequentially decrease from left to right. The extrusion device and method integrate the three processes of blanking, stirring and extruding, guide chopped carbon fiber yarns to be directionally arranged in a thermoplastic resin matrix in a material extrusion direction, and directly process the chopped carbon fiber yarns and thermoplastic resin matrix raw materials into continuous wires.

Owner:JIANGSU UNIV

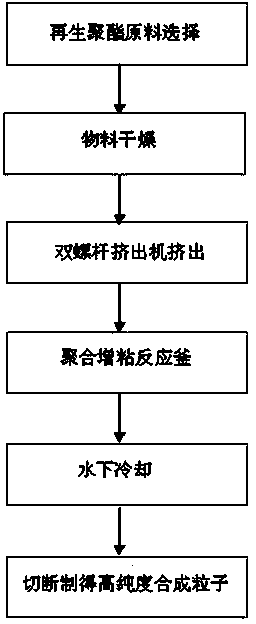

Method for preparing recycled polyester high-purity synthetic particle

The invention relates to a method for preparing recycled polyester high-purity synthetic particle. The method comprises the following steps: firstly, selecting recycled polyester raw materials, drying the materials, melting and extruding the recycled polyester raw materials through a double-screw extruder, putting in a viscosity increasing reaction kettle to carry out viscosity increasing reaction, filtering out small-particle impurities in the high viscosity melt after the reaction through a melt filter and carrying out underwater cooling and pelletizing to obtain the recycled polyester high-purity synthetic particle. The method disclosed by the invention has the advantages that the phenomena such as filament break and filament ossification in fore-spinning process of fiber can be reduced and the fiber finished product quality is increased, so that the production cost is saved and the purposes of low carbon and environmental protection are realized; when being used for spinning recycled multifunctional polyester staple fiber products, the recycled polyester high-purity synthetic particle produced by adopting the method is capable of reducing the phenomena such as the filament break and the filament ossification and in the fore-spinning process of fiber and increasing the quality index of fiber finished products; in the meantime, the method disclosed by the invention is capable of effectively utilizing various recycled chemical fibers and textile wastes, so that the cost is reduced and the purposes of comprehensive utilization of resources and more environmental protection are realized.

Owner:扬州天富龙集团股份有限公司

Method of forming fiber-aluminum alloy composite part

ActiveCN110143034AExtrude in timeOut in time, fromLamination ancillary operationsLaminationEpoxyFiber

The invention provides a method of forming a fiber-aluminum alloy composite part. The method comprises the following steps: 1, cutting an aluminum alloy plate and a fiber cloth according to a shape ofthe part; 2, subjecting the aluminum alloy plate to solid solution treatment, and immediately subjecting the aluminum alloy plate from the solid solution treatment to pre-pressing treatment, allowingfor uniform distribution of gridded grooves on a surface, glued to the fiber cloth, of the aluminum alloy plate, and then subjecting the pre-pressed aluminum alloy plate to quenching treatment; 3, subjecting the quenched aluminum alloy plate to degreasing treatment, and subjecting the fiber cloth to pre-impregnation treatment in an epoxy resin glue solution; 4, forming a sandwich plate in the order of aluminum alloy plate, fiber prepreg and aluminum alloy plate, and pre-pressing the sandwich plate; and 5, putting the obtained sandwich plate into a stamping die, closing the die and holding thetemperature, and then carrying out solidification to obtain the fiber-aluminum alloy composite part. The method overcomes the shortcoming of low elongation rate during the formation of a fiber material and improves the strength of the composite material part.

Owner:WUHAN UNIV OF TECH

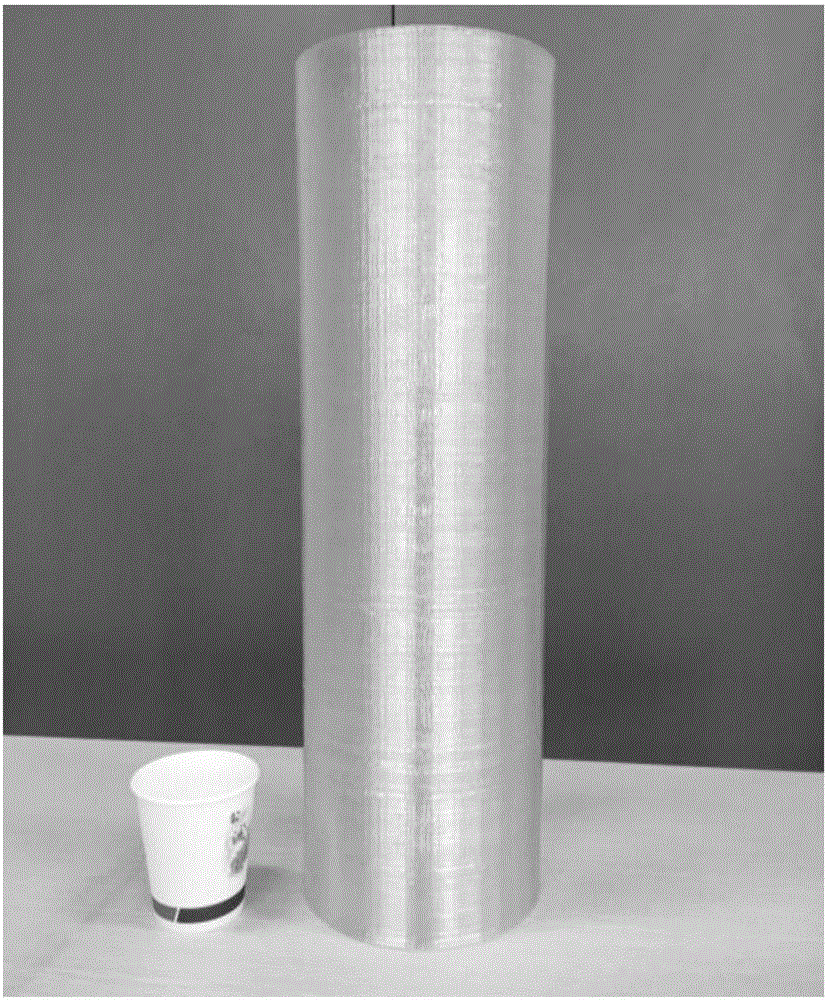

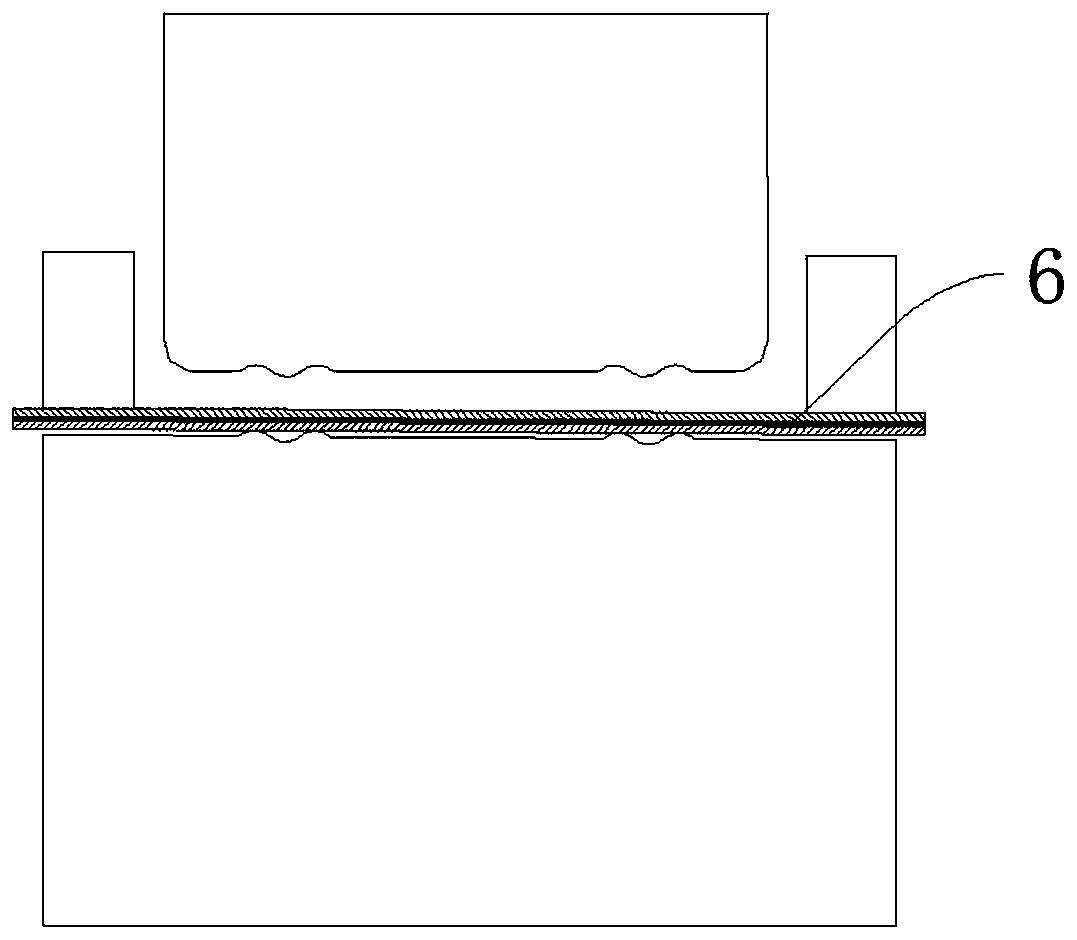

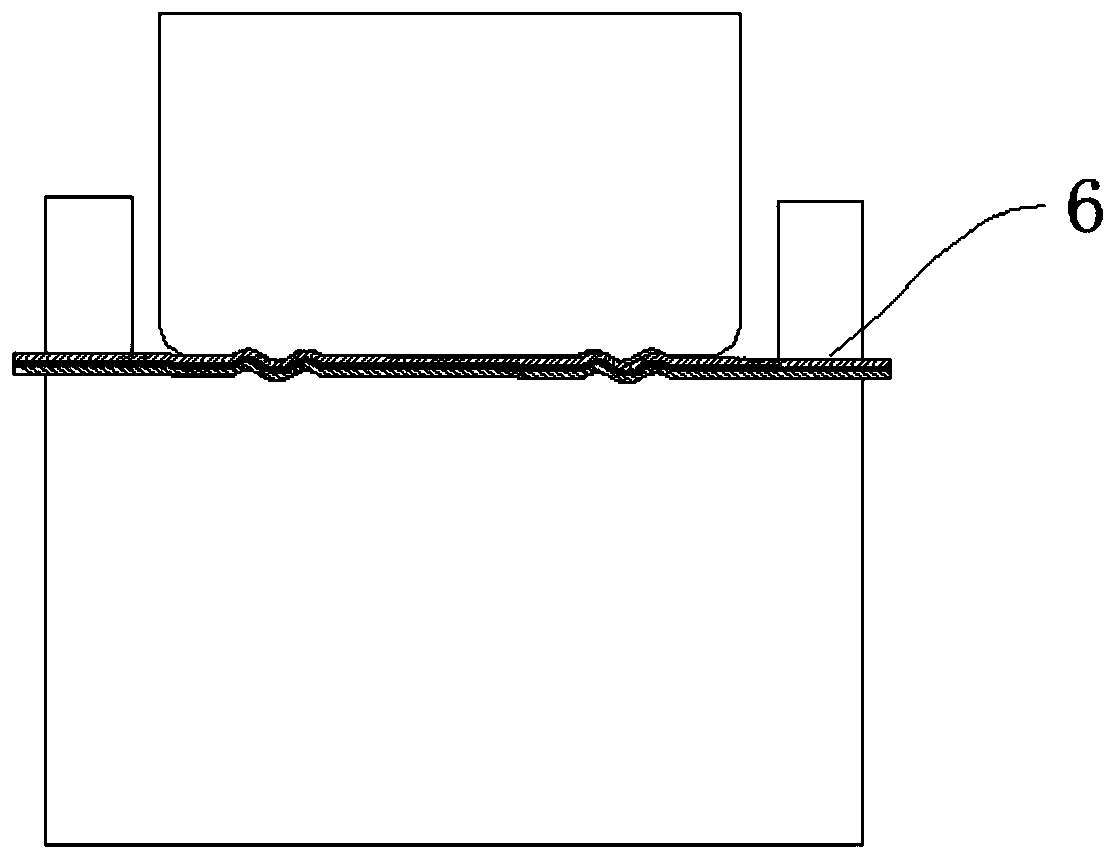

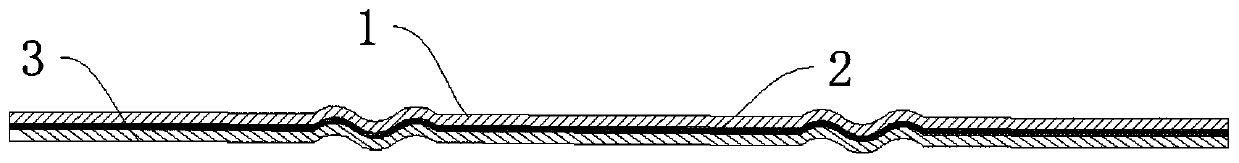

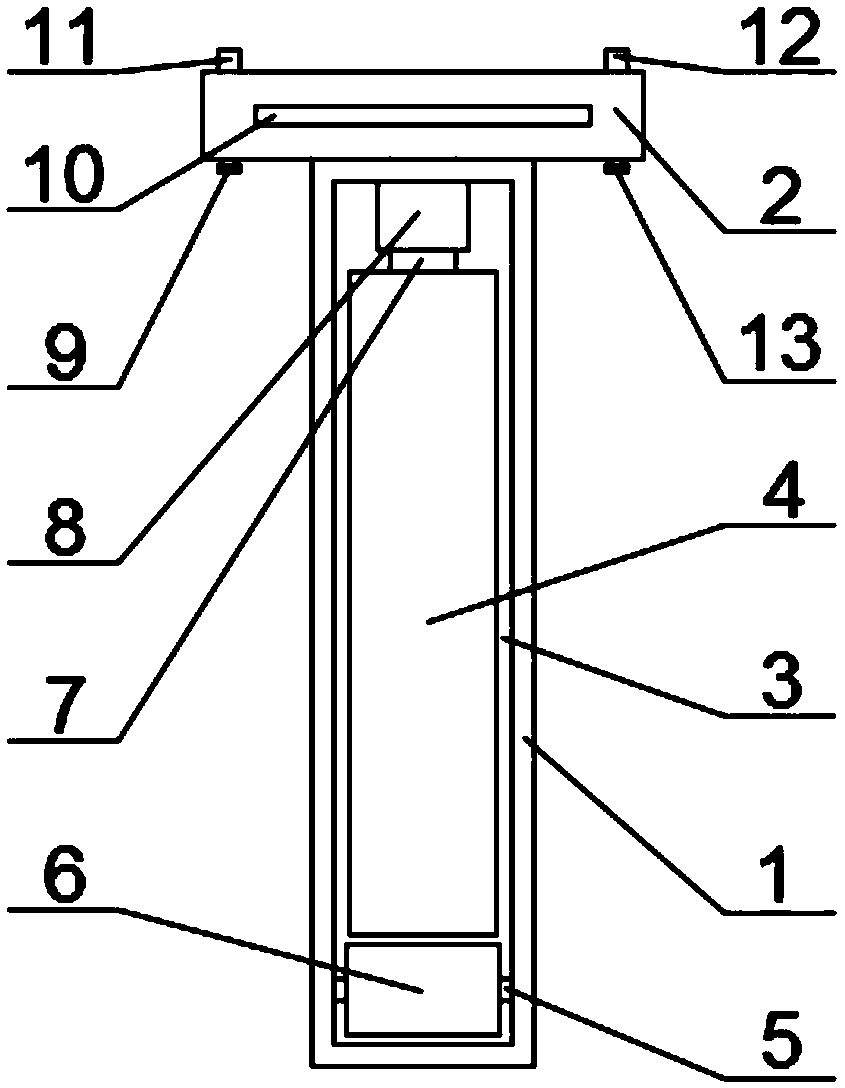

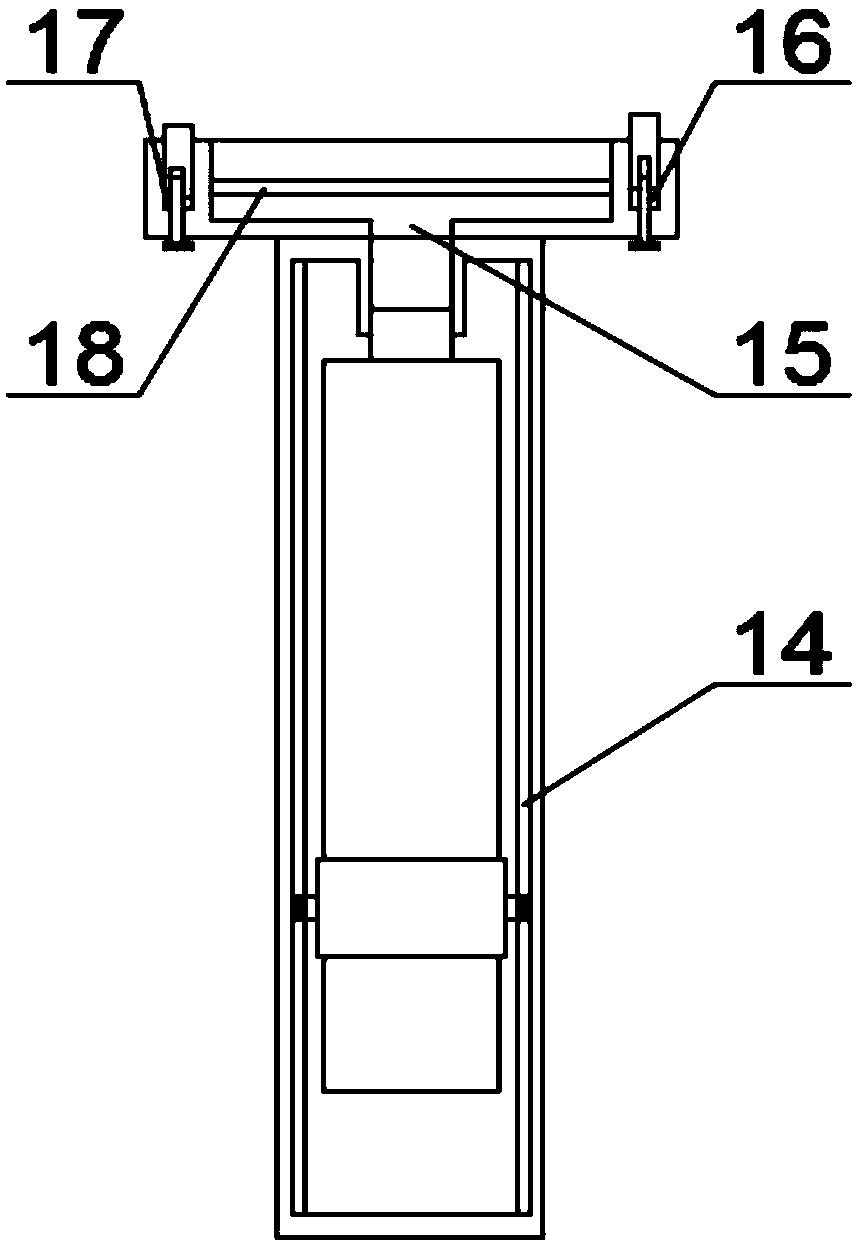

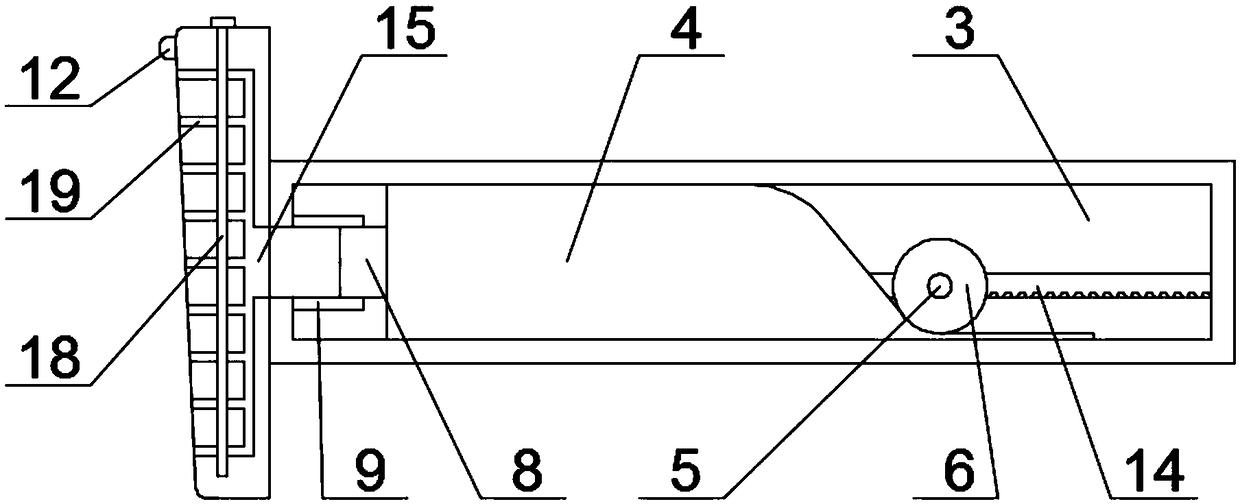

Continuity testing method of cement mortar for 3D (Three Dimensional) printing of building

InactiveCN108444867AExtrude evenlySolving Continuity Testing IssuesFlow propertiesContinuity testConstruction 3D printing

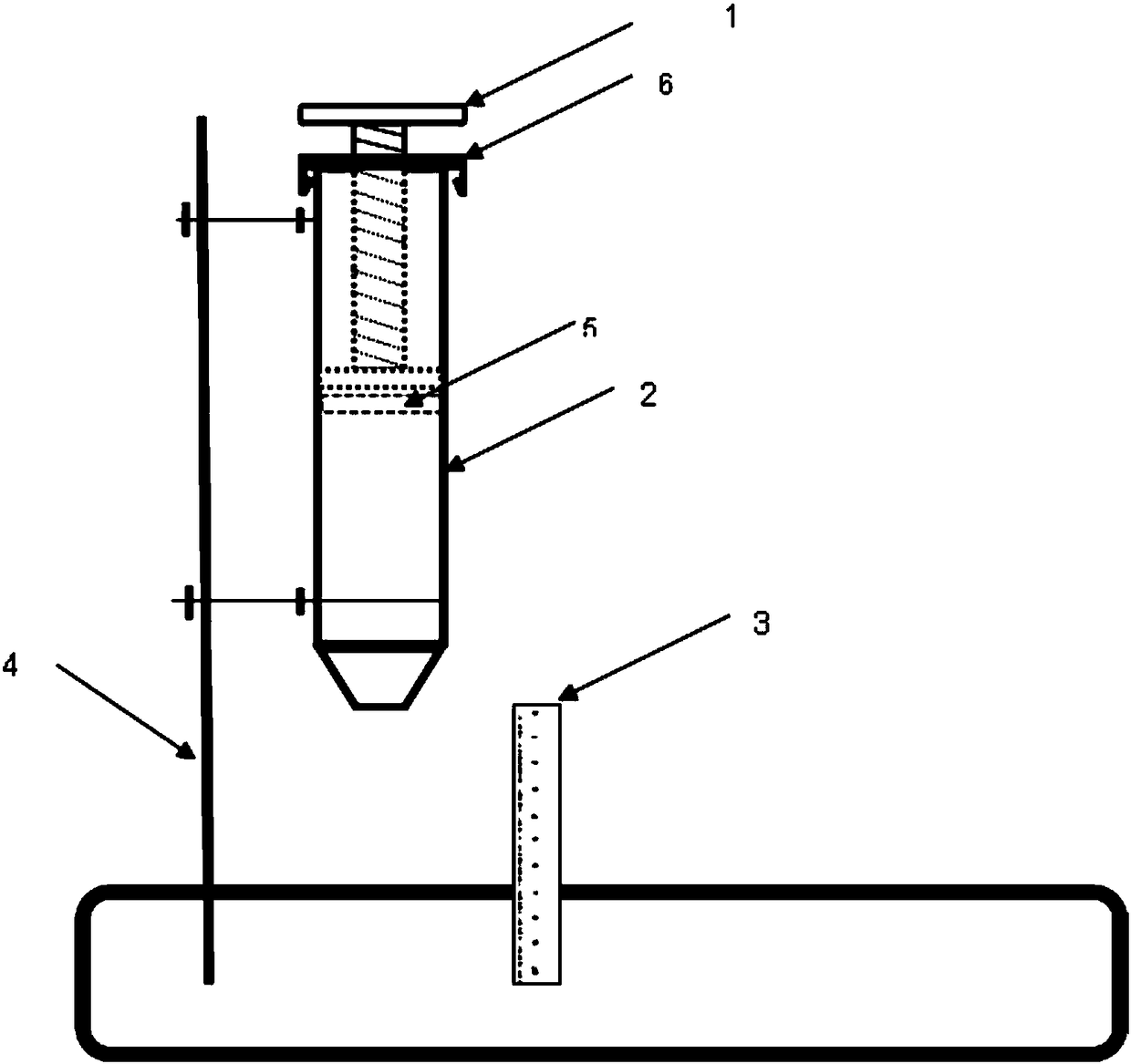

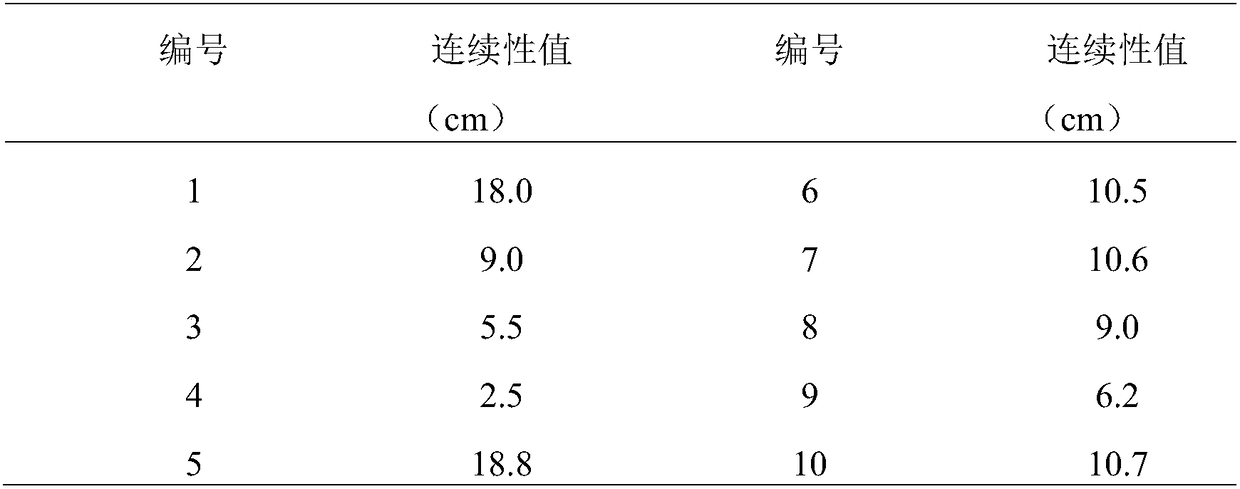

The invention provides a continuity testing method of cement mortar for 3D (Three Dimensional) printing of a building. A device for the continuity testing method is vertically arranged and comprises apushing rod (1) in an extruding barrel and a rear cover (6) which sleeves the pushing rod (1), wherein the pushing rod (1) is pushed into the extruding barrel (2); a gasket (5) is put into the extruding barrel (2) before the pushing rod (1) is put; the rear cover (6) is fixed at the upper end of the extruding barrel (2); the extruding barrel (2) is fixed on a fixed bracket (4); a straight ruler (3) is fixed on the fixed bracket (4); a zero scale line of the straight ruler (3) and the lower end of an extruding nozzle of the extruding barrel are located on the same horizontal line. Compared with the prior art, the cement mortar for the 3D printing of the building is tested and a quantification numerical value index related to continuity performance can be obtained; the continuity of the mortar for the 3D printing is accurately evaluated. The continuity testing method has the advantages that the proportion of the cement mortar for the 3D printing is easy to design, the blending time of amaterial before printing is shortened, wastes of the material are reduced and the working efficiency is improved.

Owner:BEIJING UNIV OF TECH

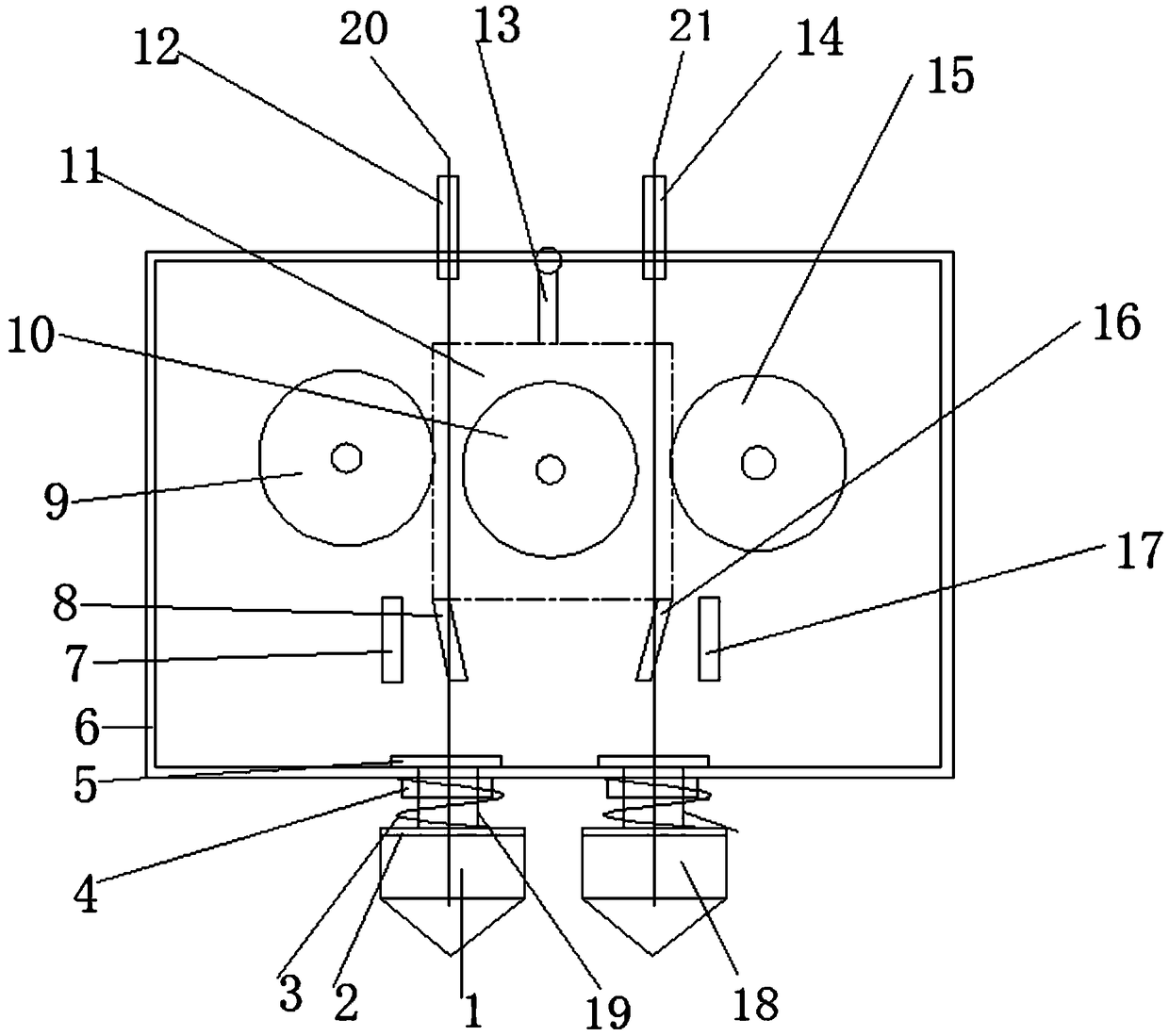

Efficient polishing equipment for metal plate production

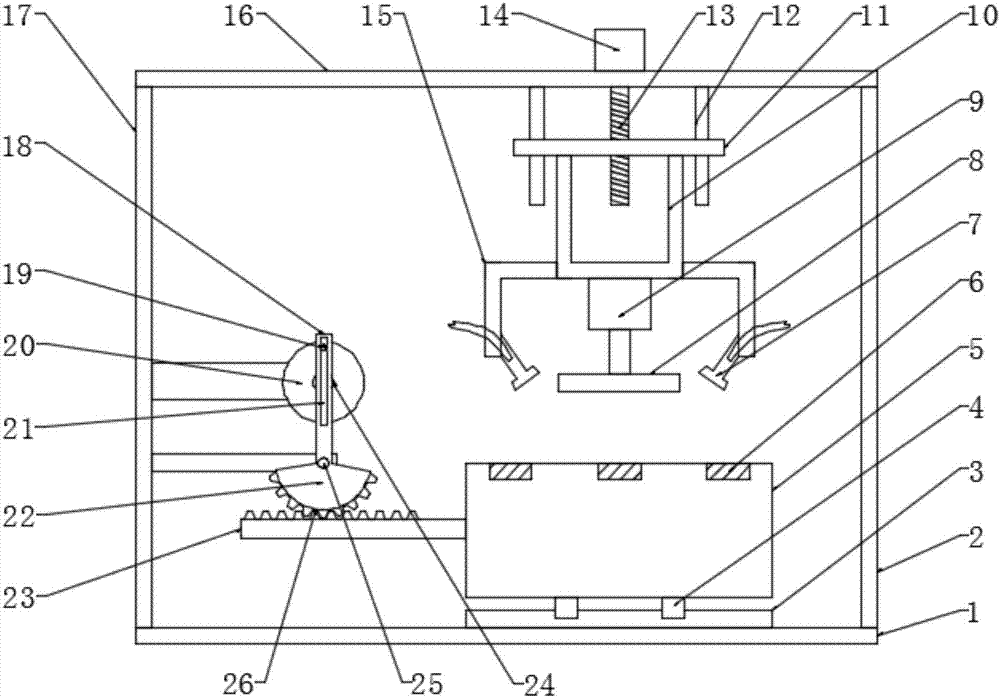

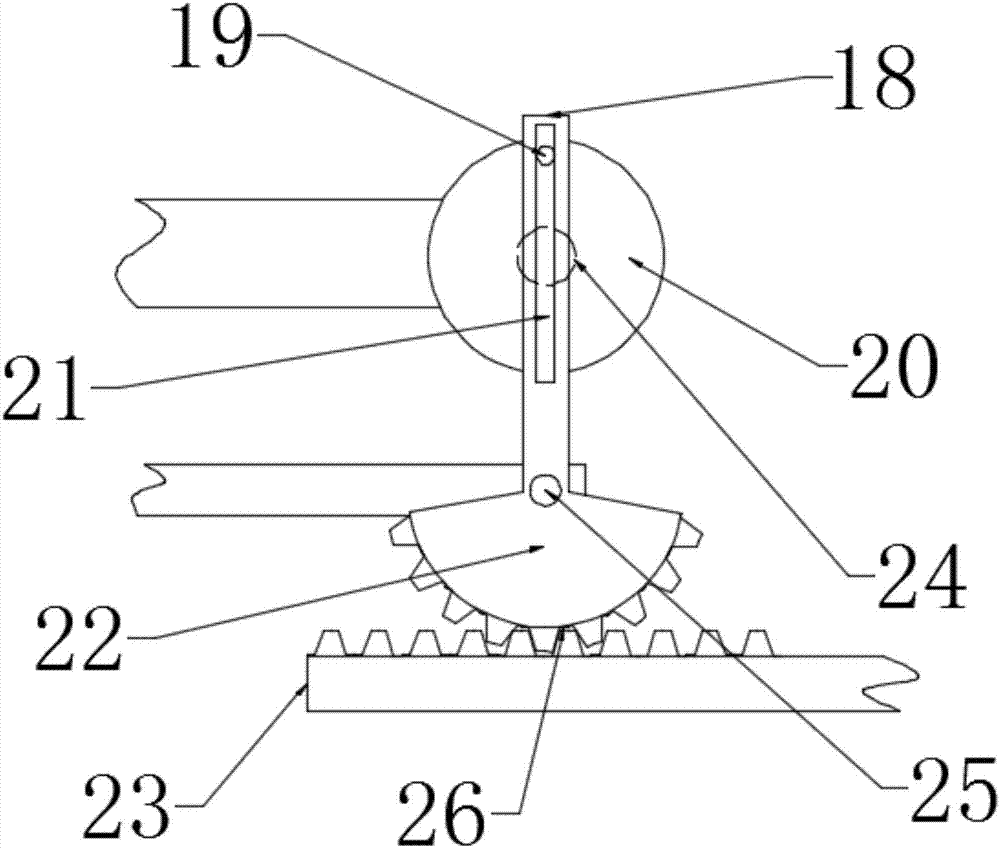

InactiveCN107160283AAchieve polishExtrude evenlyPolishing machinesGrinding drivesCircular discElectric machinery

The invention discloses efficient polishing equipment for metal plate production. The efficient polishing equipment comprises a bottom plate, a left side plate, a right side plate, a top plate, a worktable, sliding blocks, a sliding rail, a power mechanism, a second motor, a thread rod, a supporting plate, a U-shaped plate, a third motor, a polishing wheel, a fixed rod and polishing agent extruding nozzles. The power mechanism is arranged and comprises a first motor, a disc, a connecting rod, a fan-shaped gear and a rack, a plate is overall polished through matching of the parts, and polishing efficiency is high; the second motor, the thread rod and the U-shaped plate are arranged, the parts are matched to adapt metal plates with different thicknesses, and the different plates can be polished; and the polishing agent extruding nozzles are arranged, polishing agents are extruded in a uniform speed through the polishing agent extruding nozzles at the time of polishing, the polishing agents are uniformly and sufficiently extruded while the working efficiency is improved, and the polishing effect is good.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

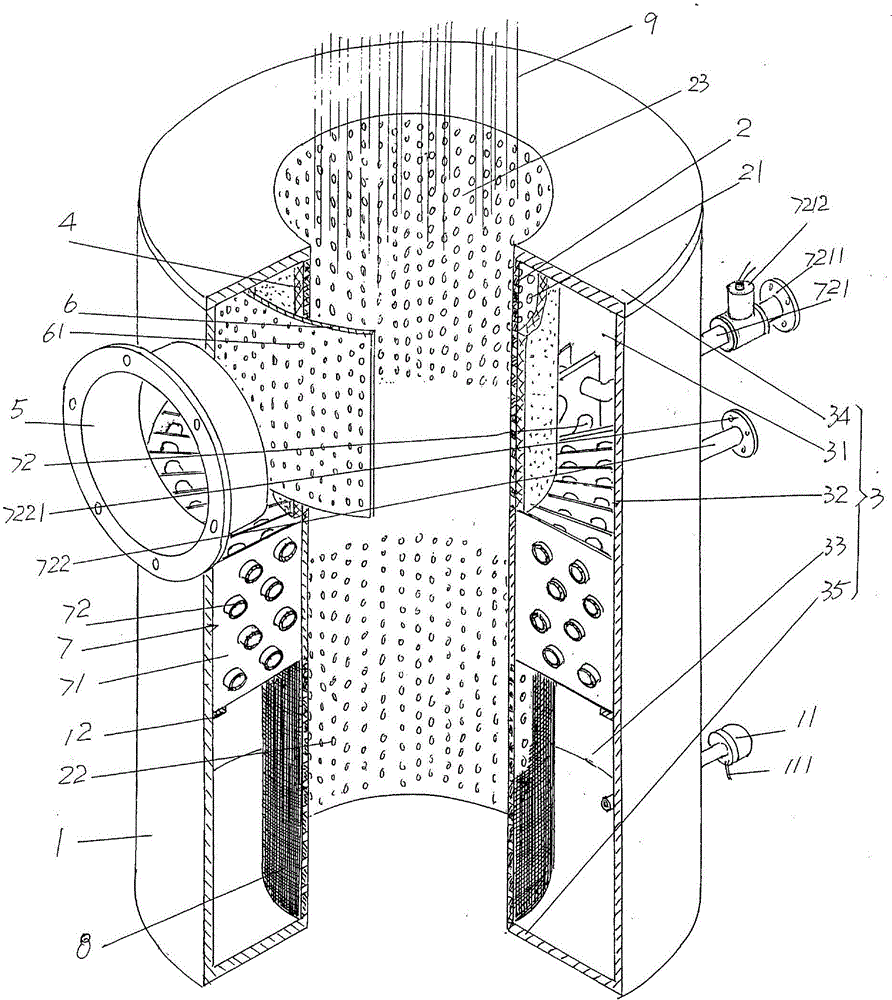

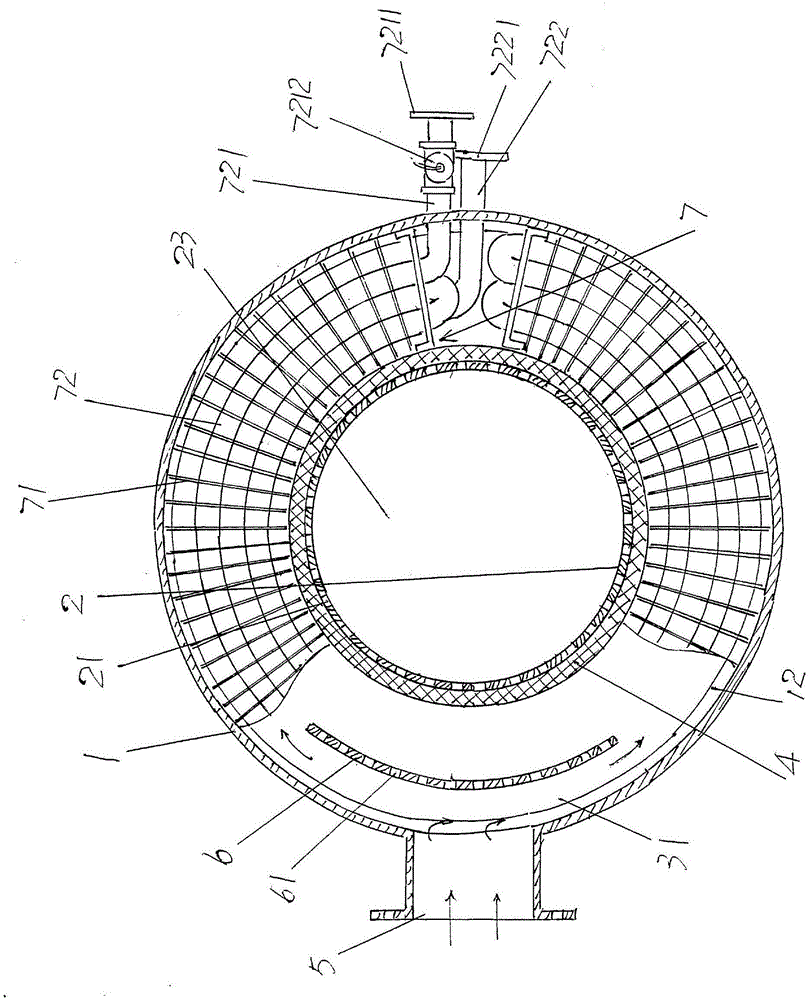

Gradient circular blowing cooling device used for polylactic acid short-fiber super-high speed spinning

ActiveCN106192029AMeet rapid cooling requirementsExtrude evenlyFilament/thread formingWater circulationSynthetic fiber

Provided is a gradient circular blowing cooling device used for polylactic acid short-fiber super-high speed spinning, pertaining to the technical field of synthetic fiber production equipment. The device comprises a cooling drum and a flow-guide inner sleeve. The cooling drum is arranged below a spinneret plate. The flow-guide inner sleeve is arranged in the cooling drum and a sleeve separation cavity is arranged on the inner wall of the cooling drum. The upper part of the sleeve separation cavity is an upper cooling cavity. The middle of the sleeve separation cavity is a surface air cooler cavity. The lower part of the sleeve separation cavity is a lower cooling cavity. The device further comprises a filter sleeve and a surface air cooler, as well as a filter net sleeve. The filter sleeve is arranged in the upper cooling cavity. An air-conditioning wind import interface is fixed on the cooling drum and communicates with the upper cooling cavity. A flow distribution plate is arranged in the upper cooling cavity and fixed with one side, upwardly facing the upper cooling cavity, of a top sealing cover of a sleeve separation cavity. Ventilation holes are arranged in the flow distribution plate. The surface air cooler is arranged between the cooling drum and the flow-guide inner sleeve and connected with a cooling water circulation heat-exchanging device. The filter net sleeve is arranged in a lower cooling cavity. Therefore, the spinneret plate can be used for smoothly extruding polylactic acid melt filaments in order to meet the rapid cooling requirement for acid melt filaments. Therefore, super-high speed spinning can be carried out.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

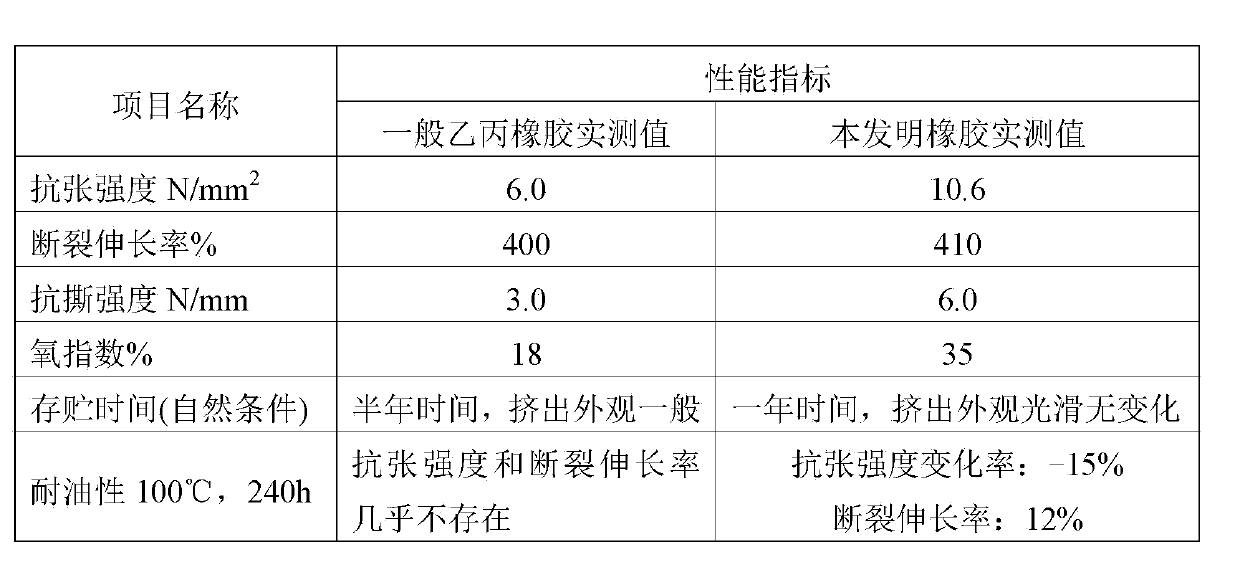

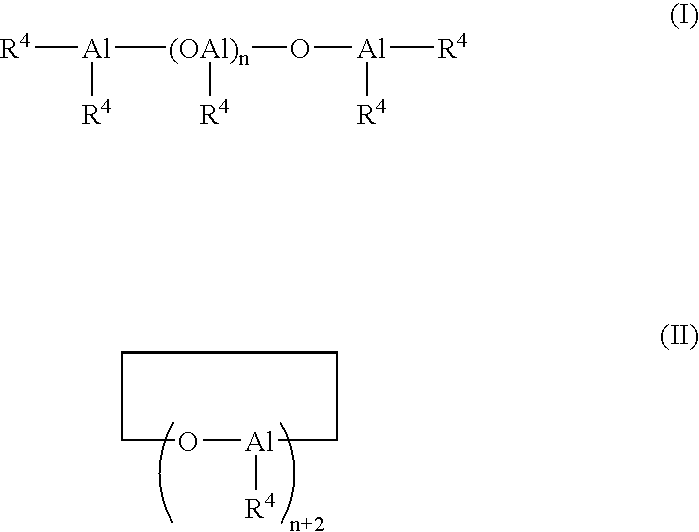

High performance crosslinked elastomeric insulation material

InactiveCN103396615AImprove flame retardant performanceExtended storage timePlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a high performance crosslinked elastomeric insulation material, which is composed of the following raw materials by weight part: 90-100 of chlorinated polyethylene CPE135B, 3-5 of a curing agent DCBP, 2-4 of triallyl isocyanurate, 8-15 of magnesium oxide, 100-110 of 1250-mesh talcum powder, 10-15 of precipitated white carbon black, 10-15 of kaolin, 2-3 of polypropylene adipate, 3-4 of bisphenol A phosphite, 1-2 of dibutyltin dilaurate, 1-2 of dibasic lead phosphite, 15-20 of chlorinated paraffin 52, 4-6 of ethylene bis stearamide, 2-4 of hydrated zinc borate, 8-10 of diethylene glycol dibenzoate, 50-55 of light calcium carbonate, 1-2 of an antiager AW, and 10-15 of an auxiliary filler. The insulation material produced in the invention has good oil resistance, high strength, strong tear resistance, good flame retardance, and superior overall performance.

Owner:安徽龙庵电缆集团有限公司

Golf ball

InactiveUS7067572B2Efficient preparationGood rebound characteristicsFibre treatmentOrganic dyesPolymer sciencePtru catalyst

A golf ball is manufactured by molding and vulcanizing a rubber composition comprising 100 pbw of a base rubber composed primarily of a polybutadiene having a cis-1,4 content of at least 60 wt % and a Mooney viscosity of at least 30 and synthesized using a rare-earth catalyst, 15–50 pbw of an unsaturated carboxylic acid and / or a metal salt thereof, at least 2 pbw of a processing aid having a highest melting point of up to 115° C., and 1–5 pbw of an organic peroxide. The golf ball can be efficiently manufactured and has excellent rebound characteristics.

Owner:BRIDGESTONE SPORTS

Rubber accelerator TMTM predispersion master batch and preparation method thereof

The invention discloses a rubber accelerator TMTM predispersion master batch which is composed of the following components in parts by weight: 75-85 parts of tetramethylthiuram monosulfide, 10-20 parts of rubber matrix, 1-10 parts of rubber oil and 1 part of fatty acid alcohol ester. The preparation method is simple and easy to operate. The rubber matrix is previously compounded and prepared to effectively shorten the compounding time required by the subsequent master batch preparation process. The prepared master batch has no impurity or dust, can effectively maintain the original activity of TMTM, does not cake at room temperature, is easy for proportioning and compounding, has the advantages of favorable flowability, no flying dust and high utilization ratio of raw materials, and can not cause skin allergy of operating personnel. The master batch is dispersed uniformly in the rubber product after proportioning and compounding, can ensure the production efficiency and quality of the rubber product, and has important meanings for sustainable development of rubber manufacturing industry.

Owner:NINGBO ACTMIX POLYMER

Dermatological ointment applying device

InactiveCN109498979AEasy to controlAvoid pollution and wasteMedical devicesMedical applicatorsBiomedical engineeringMedical treatment

The invention relates to a dermatological ointment applying device, and belongs to the technical field of medical instruments. The dermatological ointment applying device comprises a handle and an ointment applying head which are fixedly connected, a second through hole and a plurality of second ointment outlets communicated with the second through hole are formed in the ointment applying head, anointment slot is formed in the handle, a connecting tube is mounted in the ointment slot and connected with the second through hole, a groove is further formed in the ointment applying head, an adjusting plate is mounted in the groove, and a bolt connected with the adjusting plate in a threaded manner is mounted on the adjusting plate, penetrates the ointment applying head and extends to the outside. By the aid of the adjusting plate, an ointment applying thickness is conveniently controlled, a geared compression roller is matched with a plurality of adjustable ointment outlets to supply ointments, so that the ointments are more uniformly squeezed out, ointment squeeze-out quantity is more easily controlled, ointment pollution and waste are avoided, and the ointments are more uniformly applied.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

Telescopic double-nozzle FDM-3D printer nozzle assembly controlled by electromagnetic

ActiveCN108790145AReduce weightReduce control difficulty3D object support structuresManufacturing auxillary operationsWire rodDrive wheel

The invention provides a telescopic double-nozzle FDM-3D printer nozzle assembly controlled by electromagnetic. The assembly comprises a fixing frame, a motor and a driving wheel; when a first nozzleworks, the motor rotates, a second electromagnet is electrified, and a third iron sheet is attracted to tight compress the driving wheel and a second driven wheel to convey a first wire rod; and whena second nozzle works, the motor is rotated reversely, a third electromagnet is electrified, and the third iron sheet is attracted to tight compress the driving wheel and the second driven wheel to convey a second wire rod. The motor is driven to swing towards the two sides, the driving wheel is driven to cooperate with the two driven wheels on the two sides correspondingly, so that the two wire rods can be extruded out, and the two nozzles can be fed; and on the premise that the basic function of a nozzle assembly is guaranteed, the weight of one motor and the weight of one friction wheel arereduced greatly, so that the control difficulty is reduced, and the printing precision and the surface precision are improved.

Owner:XI AN JIAOTONG UNIV

Copper-clad plate production equipment and copper-clad plate processing method

ActiveCN109435422ASolve problems such as low production yieldGuaranteed continuous productionLamination ancillary operationsLaminationEngineeringCopper

The invention relates to the field of copper-clad plate production, and particularly discloses copper-clad plate production equipment and a copper-clad plate processing method. The equipment comprisesa first coating device, a first roller, a second coating device, a first rolling device, a second roller and a second rolling device which are arranged front the front part to the rear part in sequence, wherein baking devices are arranged on the front side of the first rolling device, between the first rolling device and the second device, and on the rear side of the second rolling device; the structure of the first coating device is the same with that of the second coating device; the structure of the first roller is the same with that of the second roller. Through the copper-clad plate production equipment and the copper-clad plate processing method, the problem, in the prior art, of low copper-clad plate production yield caused by defects like air bubble inclusion and nonuniform prepreg components during reinforcing material glue dipping and glue solution curing processes can be solved.

Owner:安徽鸿海新材料股份有限公司

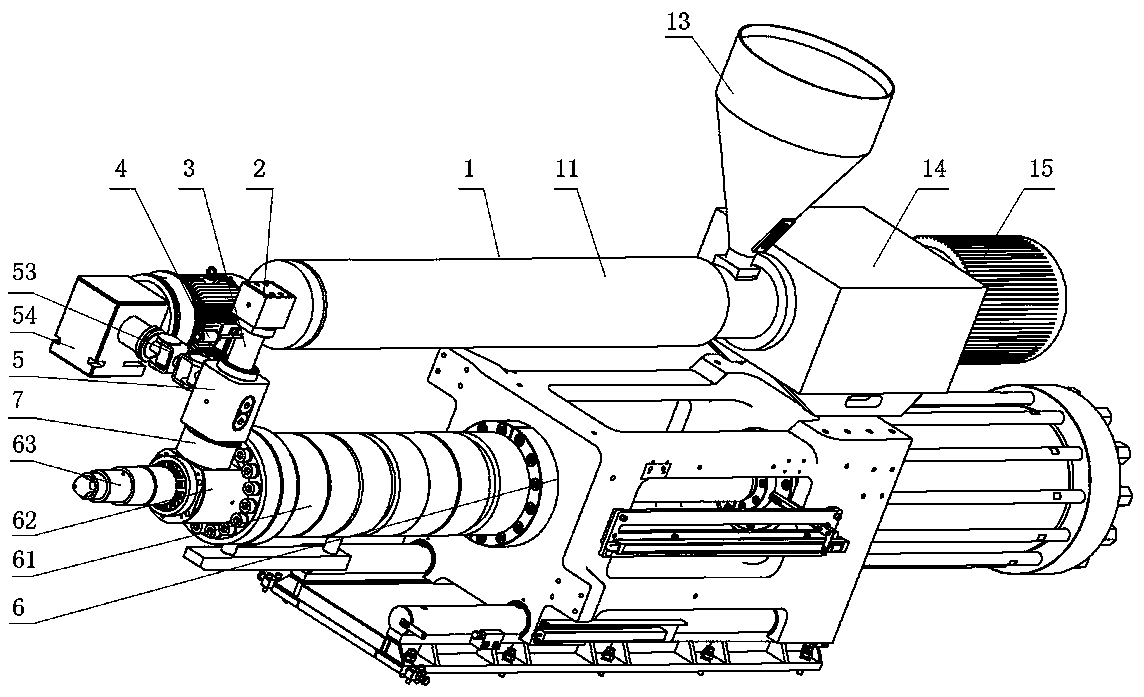

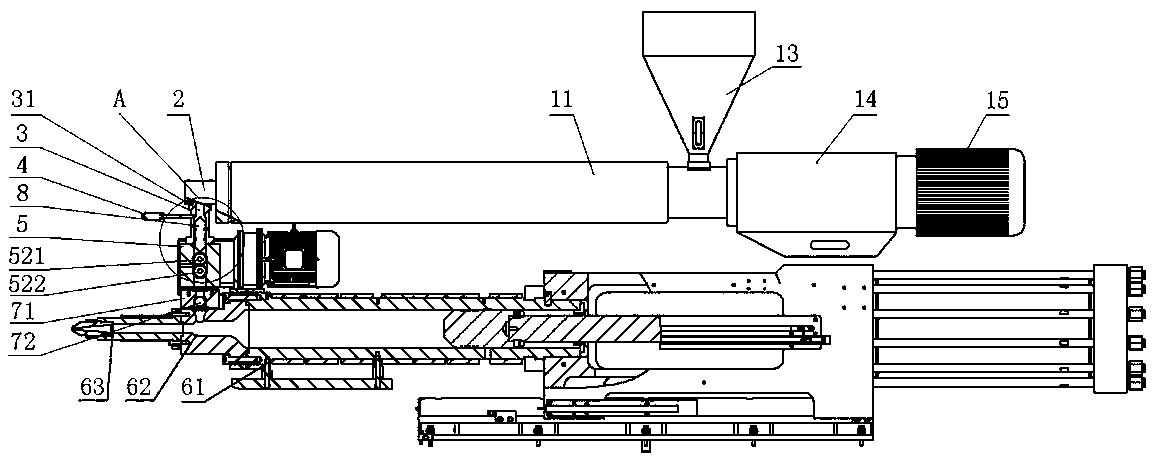

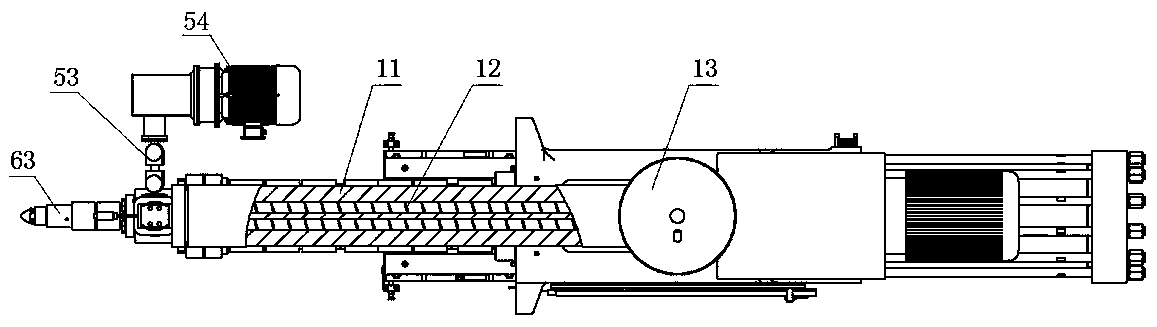

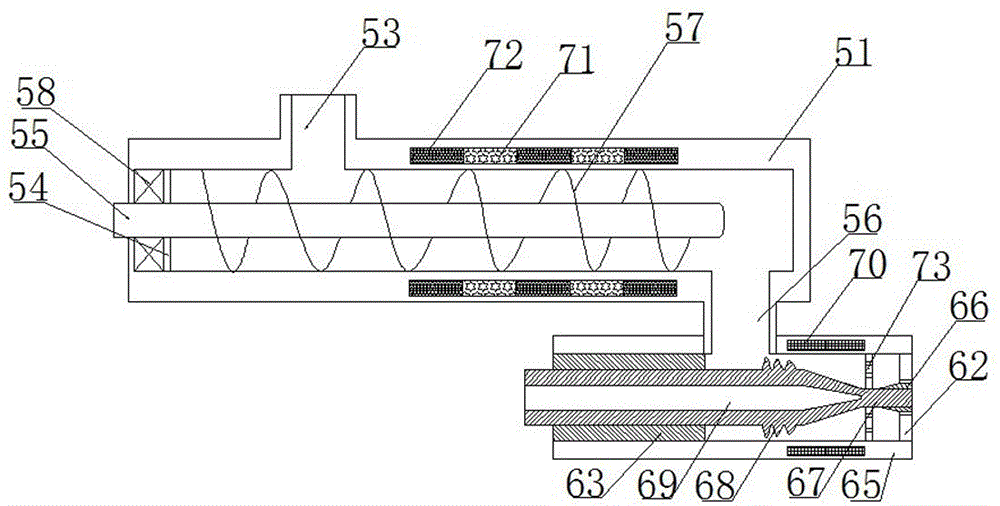

Wood plastic physical micro-foaming squeezing type injection molding machine and molding process

The invention relates to a wood plastic physical micro-foaming squeezing type injection molding machine and a molding process, and belongs to the field of wood plastic production equipment. The machine comprises a dual-screw extruder and an injection machine and is characterized in that the dual-screw extruder comprises a material cylinder, two screws are arranged in the material cylinder, a hopper is arranged at the input end of the material cylinder, a material cylinder front body is arranged at the output end of the material cylinder, a connecting body is arranged below the material cylinder front body, a supercutical fluid injector is arranged at the side end of the connecting body, a first cavity is formed in the connecting body, the upper end of the connecting body communicates withthe material cylinder front body through the first cavity, the side end of the connecting body communicates with the supercutical fluid injector through the first cavity, a gear pump is arranged belowthe connecting body, the injector comprises an injection oil cylinder, an injection cylinder front body, and a nozzle, and the lower portion of the gear pump is connected with the injection cylinderfront body through a check valve. The problems that a wood plastic product is not uniform in size, product molding is large in brittleness, compactness is poor, cracking is prone, and density is largecan be solved. The machine is simple in whole structure and convenient to machine.

Owner:山东通佳智能装备有限公司

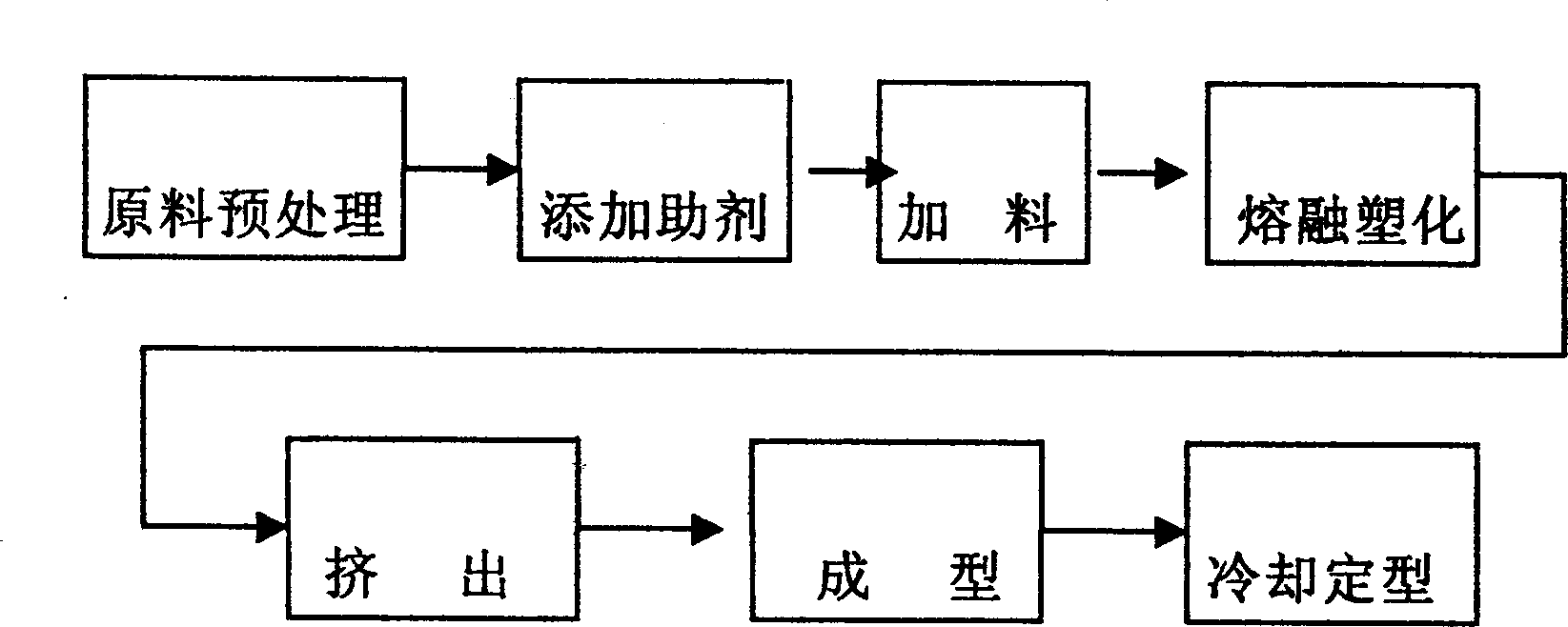

Method for producing super high molecular weight polyvinyl products by screw extruder

InactiveCN1377762AReduce manufacturing costIncrease productivityLiquid crystal compositionsHigh volume manufacturingEngineering

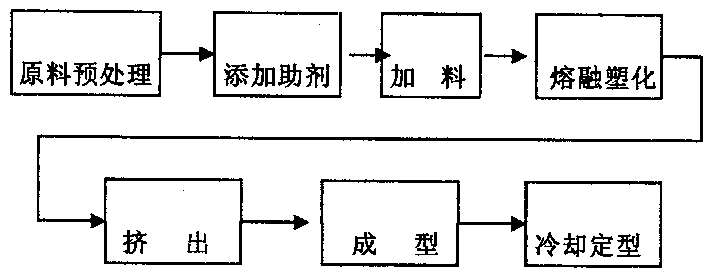

The process of producing superhigh molecular weight polyethylene product includes the steps of: material pre-treatment; adding LCP as modifying assistant into superhigh molecular weight polyethylene;feeding the mixture material into feeding port of the double screw extruder; smelting and denaturing the mixture material inside the double screw extruder; and extruding through the double screw extruder and one single screw extruder connected serially to the double screw extruder. The said production process has low production cost and high production efficiency and it is suitable for mass industrial production.

Owner:王明荣

Novel rubber pipe extruding machine

InactiveCN106426848AAchieve changeAvoid replacementTubular articlesEngineeringMechanical engineering

The invention discloses a novel rubber pipe extruding machine which comprises a feeding barrel, a bearing, a shell and a rotary shaft. The rotary shaft is connected with the feeding barrel through the bearing in a matched mode; one end of the feeding barrel is provided with a feed inlet, and the other end of the feeding barrel is provided with a discharge outlet; the shell is internally provided with an annular barrel fixedly connected with the inner wall of the shell, and a mold core is connected in the annular barrel through a thread in a matched mode and penetrates through the shell; one end of the mold core stretches out of the shell, and the other end of the mold core penetrates through a through hole of a mold sleeve and aligned with the mold sleeve; the inner surface of the mold sleeve and the outer surface of the mold core form a discharge hole; a thread is arranged on the outer circular face of the mold core, and a mold core sleeve connected with the mold core through a thread in the matched mode is arranged on the outer circular face of the mold core; and the shell is provided with a hot water heat conduction layer and internally provided with a porous plate, and through holes are fully distributed in the porous plate. The novel rubber pipe extruding machine can improve the production efficiency.

Owner:成都市红鑫科技有限公司

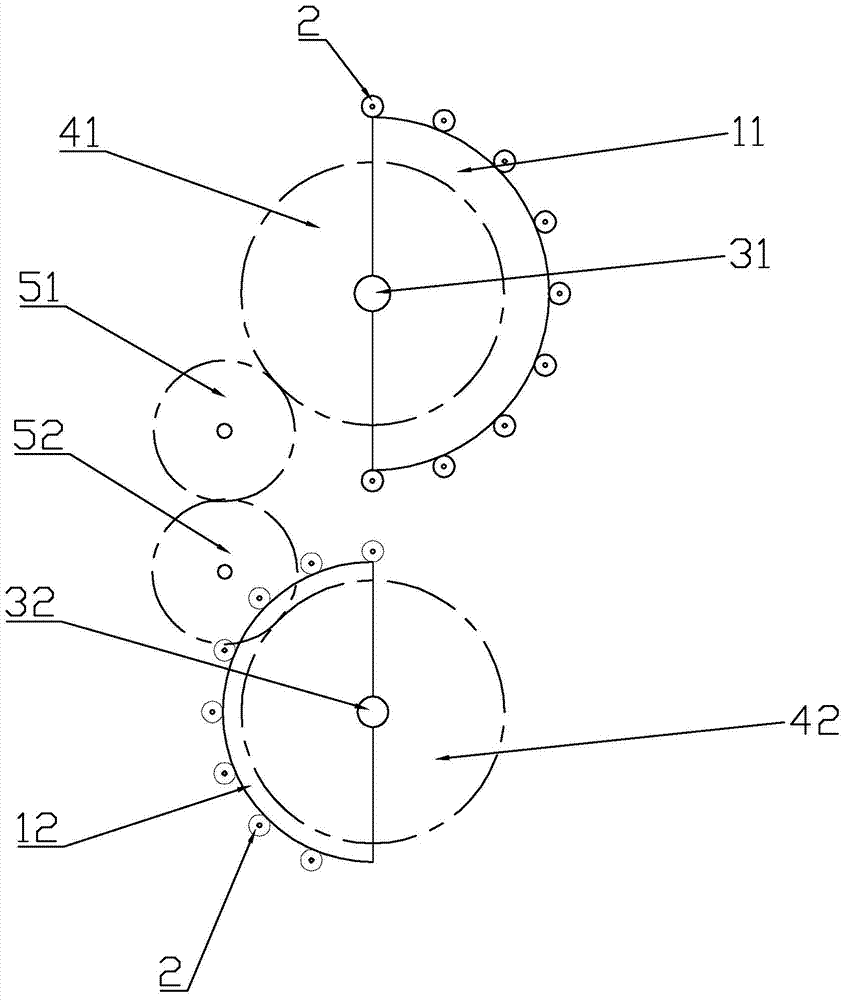

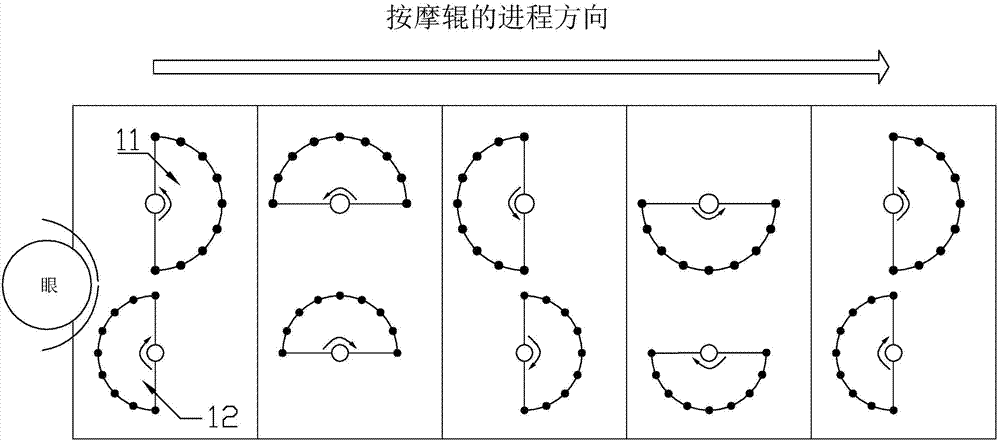

Intermittent massage mechanism used for eye meibomian gland massage

InactiveCN103610573AEasy to operateAvoid discomfortRoller massageEye treatmentMeibomian glandPhase difference

The invention relates to an intermittent massage mechanism used for eye meibomian gland massage. Two message rollers are included, wherein each massage roller is a semicircular roller, and the phase difference exists between the massage rollers. The intermittent massage mechanism has the advantages that the intermittent massage mechanism is not influenced by experience of a doctor and is easy and convenient to operate, and treatment can be conducted on a patient at home; the intermittent massage mechanism is even in pressing, injuries to the conjuctiva can not be caused, and the discomfort produced after massage is conducted on the patient is avoided; the massage difficulty is low, the efficiency is high, and safety and the comfort degree are improved; the defect that a non-anti-phase intermittent massage mechanism may enable the upper eyelids and the lower eyelids to be squeezed toward the middle portion to cause discomfort can be effectively overcome through the anti-phase message mechanism, and obstructions in the eye meibomian gland can be smoothly extruded.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com