Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Continuity test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, a continuity test is the checking of an electric circuit to see if current flows (that it is in fact a complete circuit). A continuity test is performed by placing a small voltage (wired in series with an LED or noise-producing component such as a piezoelectric speaker) across the chosen path. If electron flow is inhibited by broken conductors, damaged components, or excessive resistance, the circuit is "open".

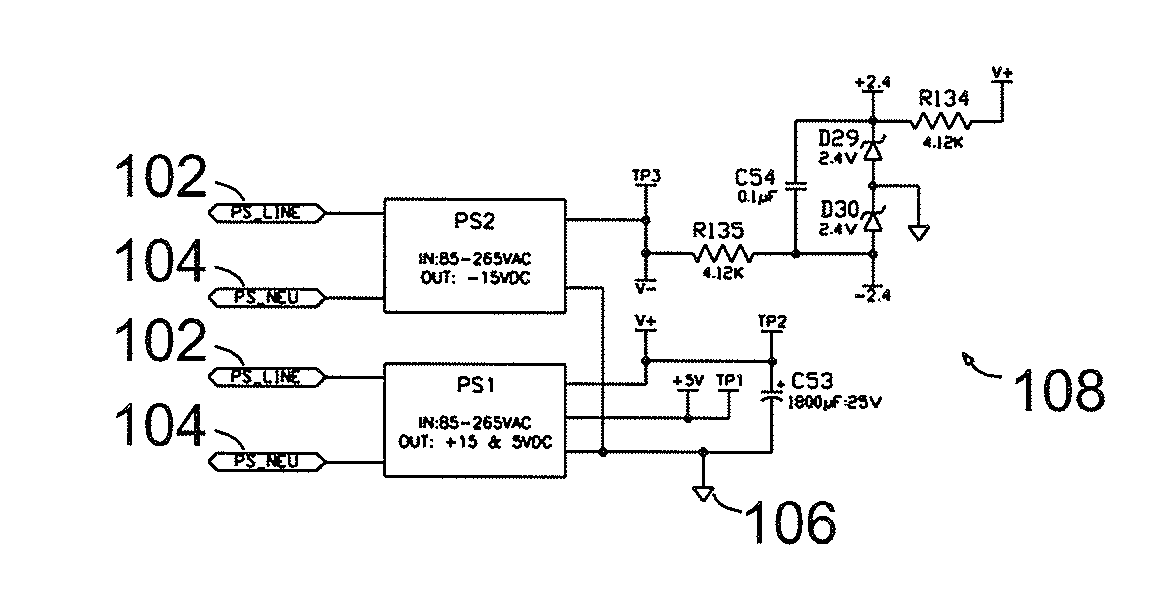

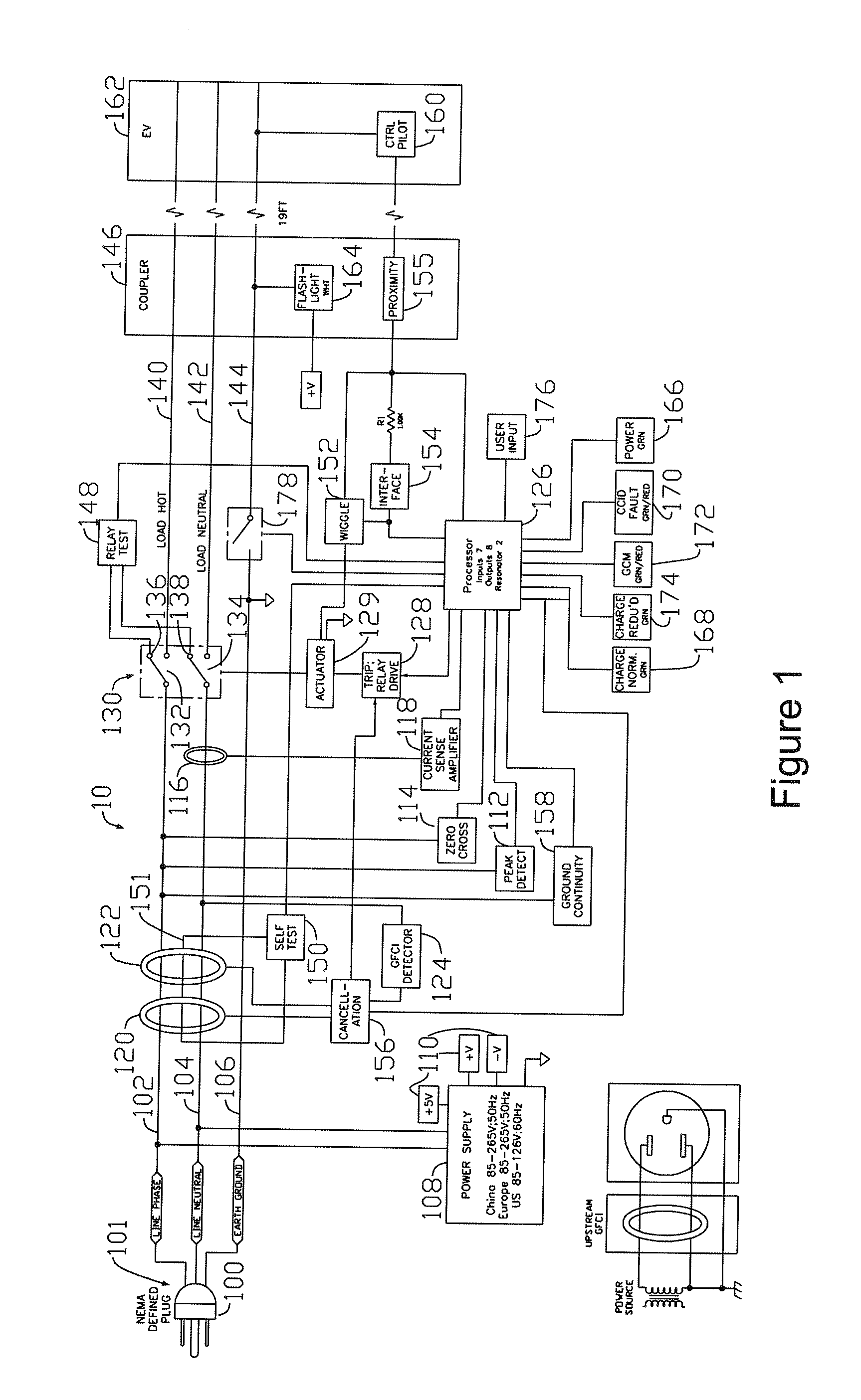

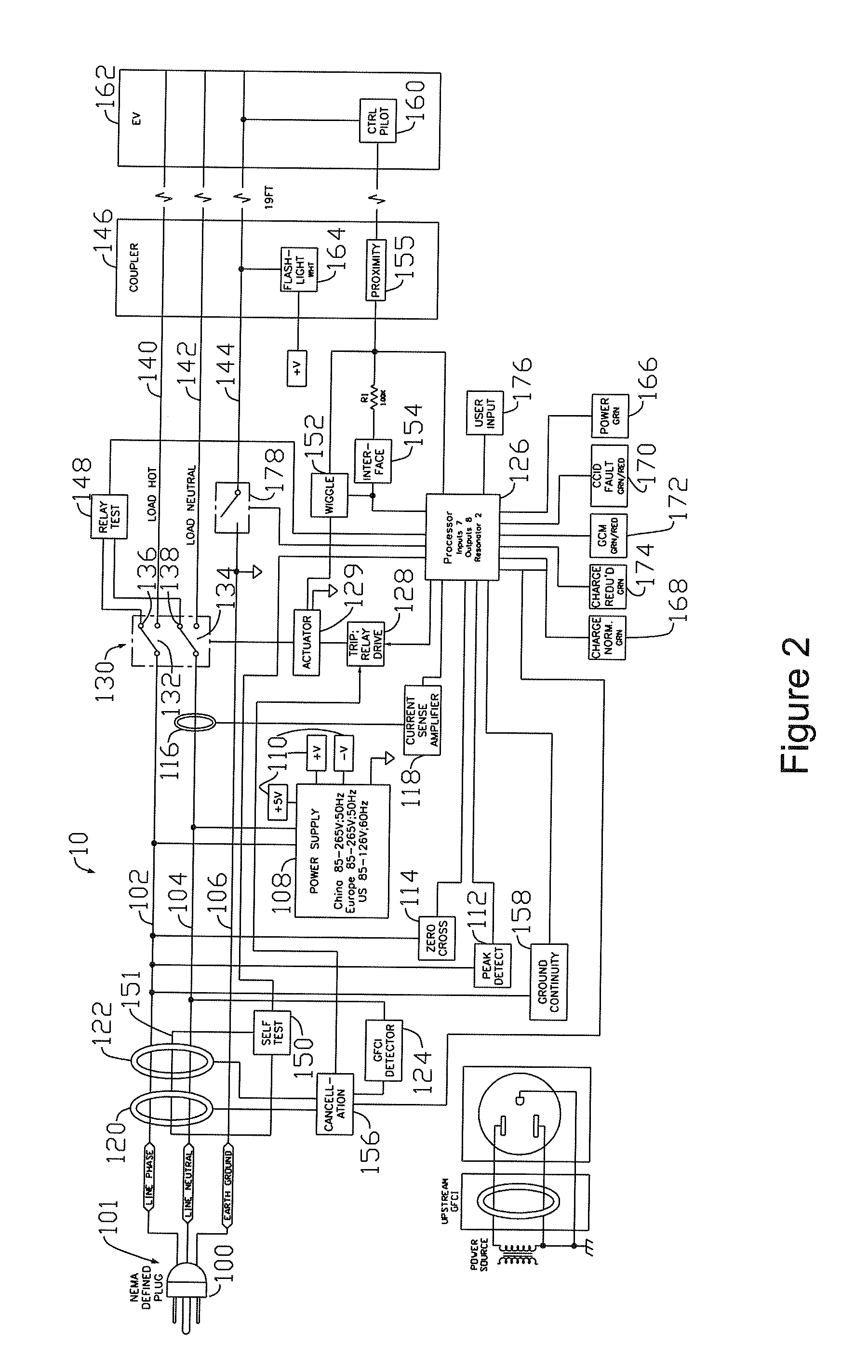

Protective device for an electrical supply facility

The present invention is directed to a protective device configured to be coupled between an AC power source and an electrical load. A ground continuity monitor is coupled to the ground conductor, the ground continuity monitor being configured to detect a ground discontinuity condition in the ground conductor. A circuit interrupter mechanism is configured to interrupt electrical continuity in a tripped state and establish electrical continuity in a reset state. A self-test circuit is coupled to the ground continuity monitor and configured to perform a simulated ground continuity test that simulates the ground discontinuity condition. The self-test circuit provides a test failure signal when the ground continuity monitor fails to provide an output signal in response to the simulated ground continuity test. The test failure signal is configured to trip the circuit interrupter mechanism.

Owner:PASS SEYMOUR

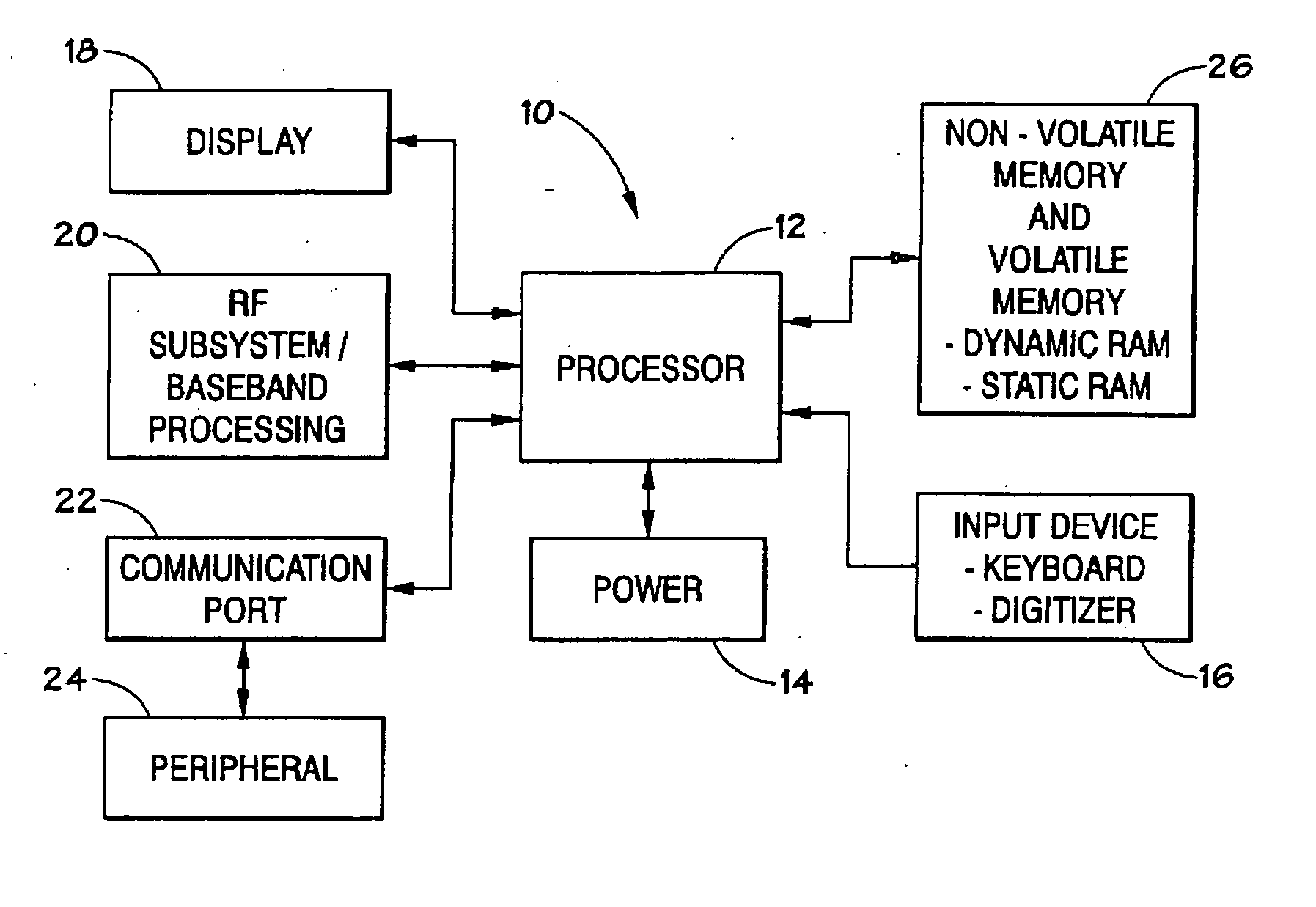

Compliant printed circuit socket diagnostic tool

InactiveUS20120268155A1Improve performanceIncrease valueElectronic circuit testingContinuity testingContact padElectrical devices

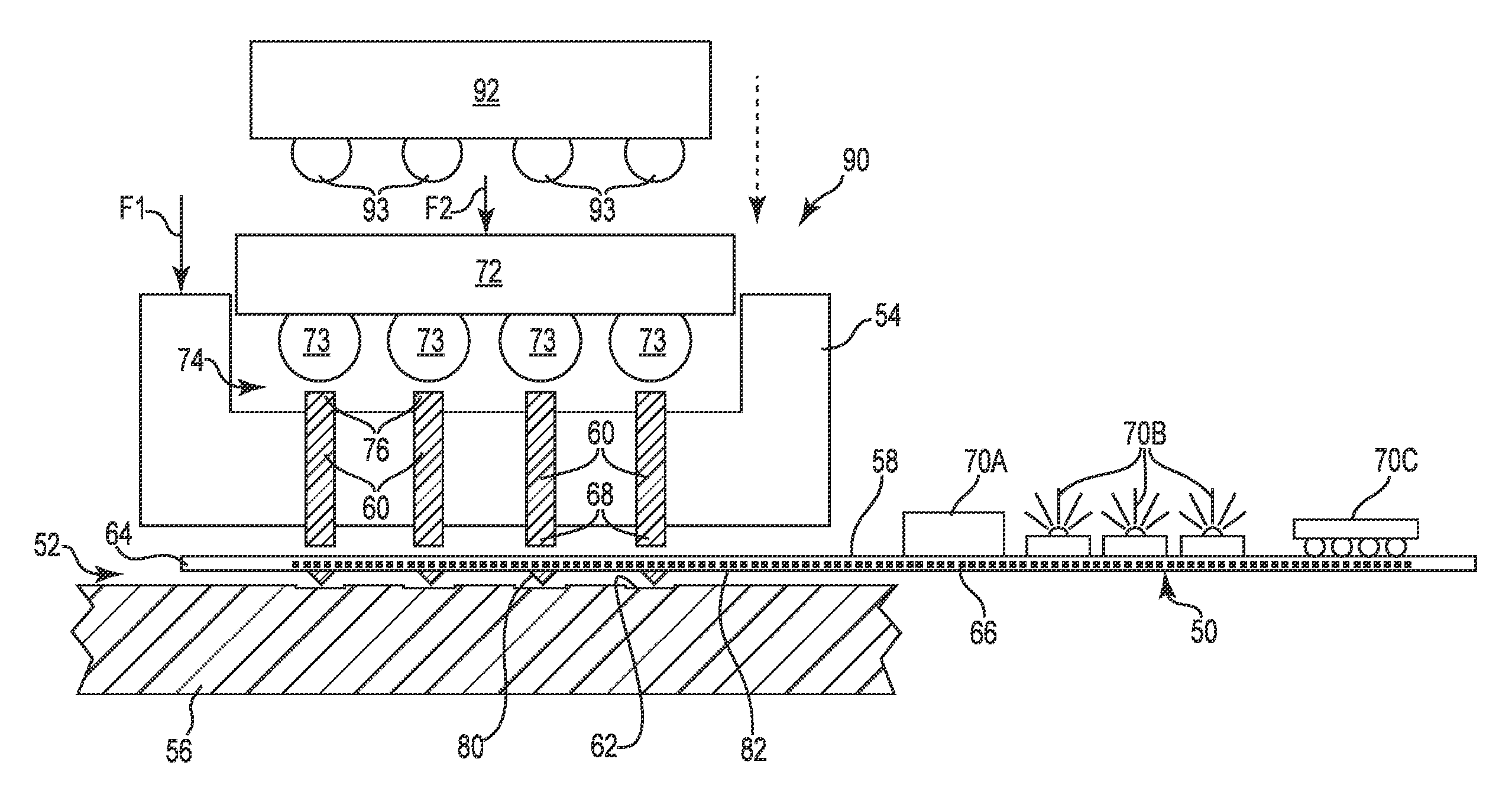

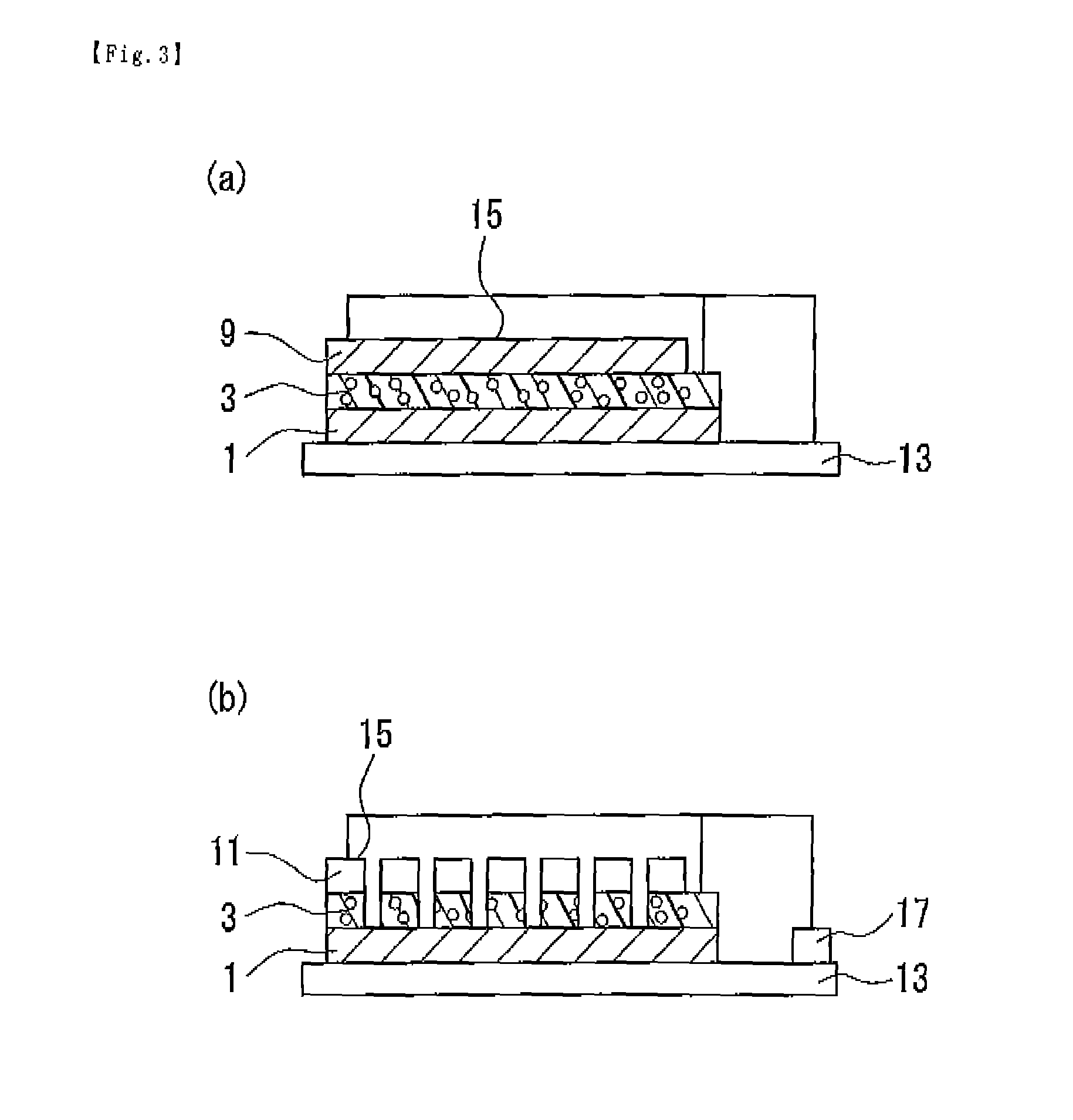

Diagnostic tools for testing integrated circuit (IC) devices, and a method of making the same. The first diagnostic tool includes a first compliant printed circuit with a plurality of contact pads configured to form an electrical interconnect at a first interface between proximal ends of contact members in the socket and contact pads on a printed circuit board (PCB). A plurality of printed conductive traces electrically couple to a plurality of the contact pads on the first compliant printed circuit. A plurality of electrical devices are printed on the first compliant printed circuit at a location external to the first interface. The electrical devices are electrically coupled to the conductive traces and programmed to provide one or more of continuity testing at the first interface or functionality of the IC devices. A second diagnostic tool includes a second compliant printed circuit electrically coupled to a surrogate IC device.

Owner:HSIO TECH

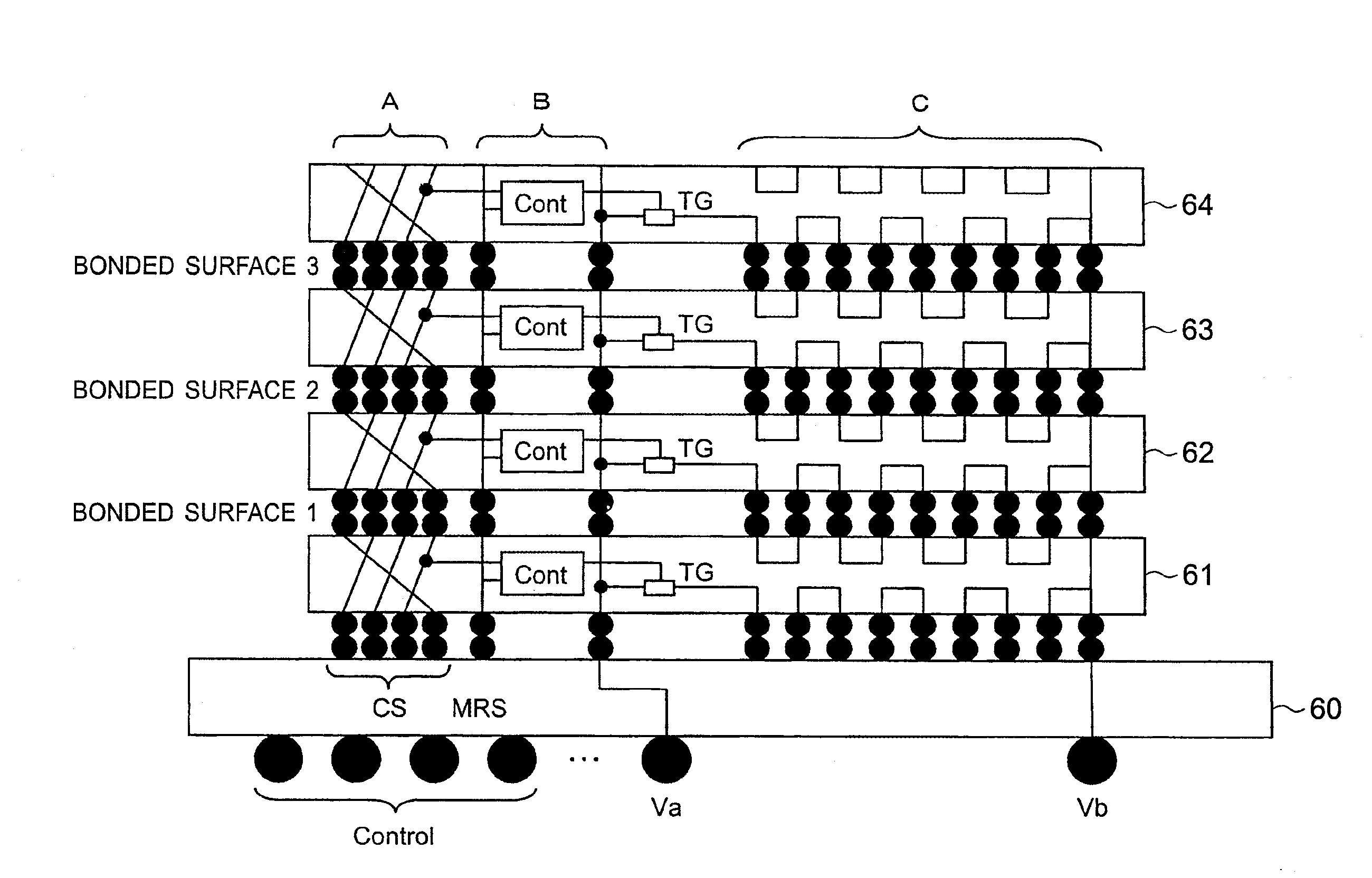

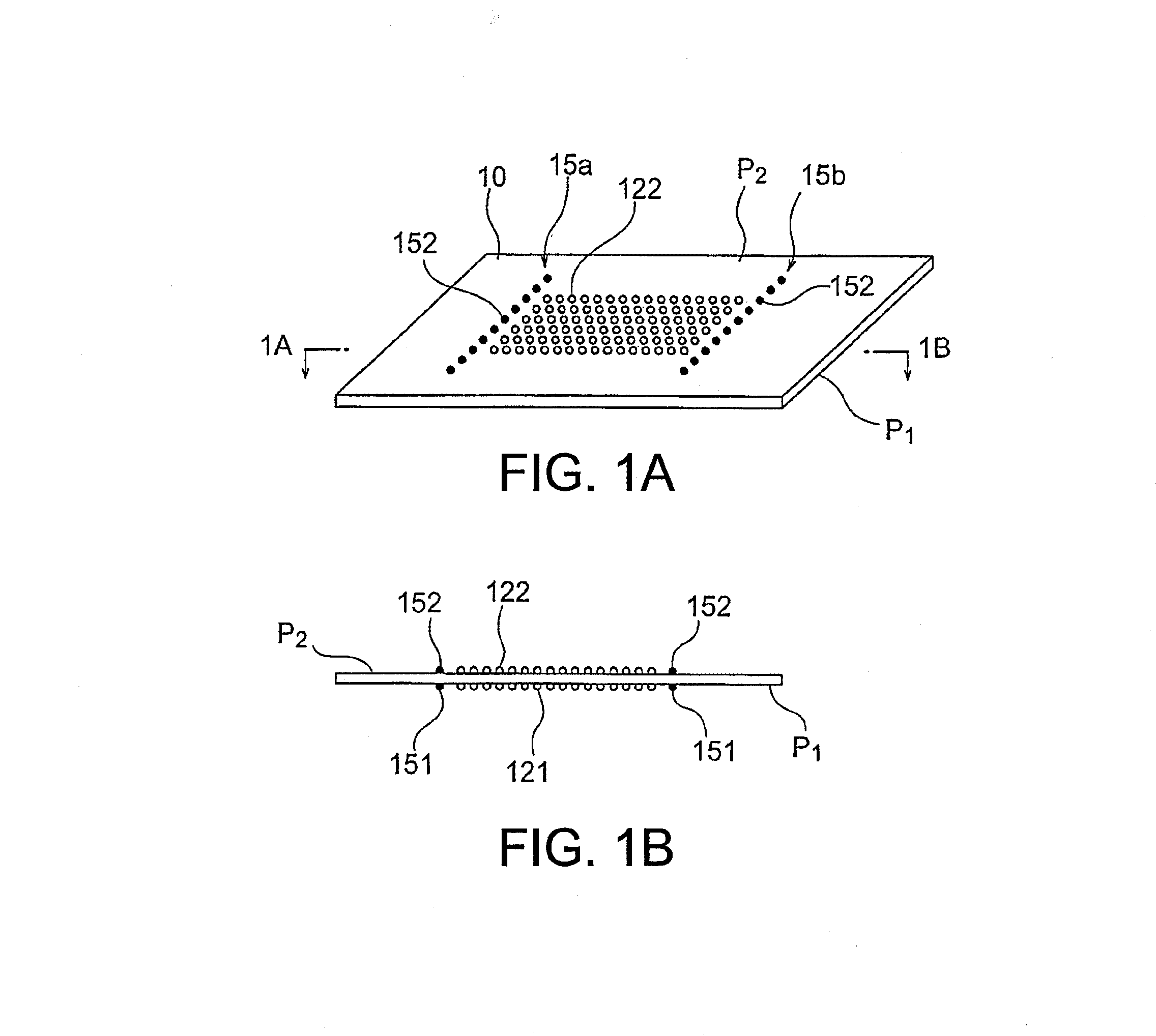

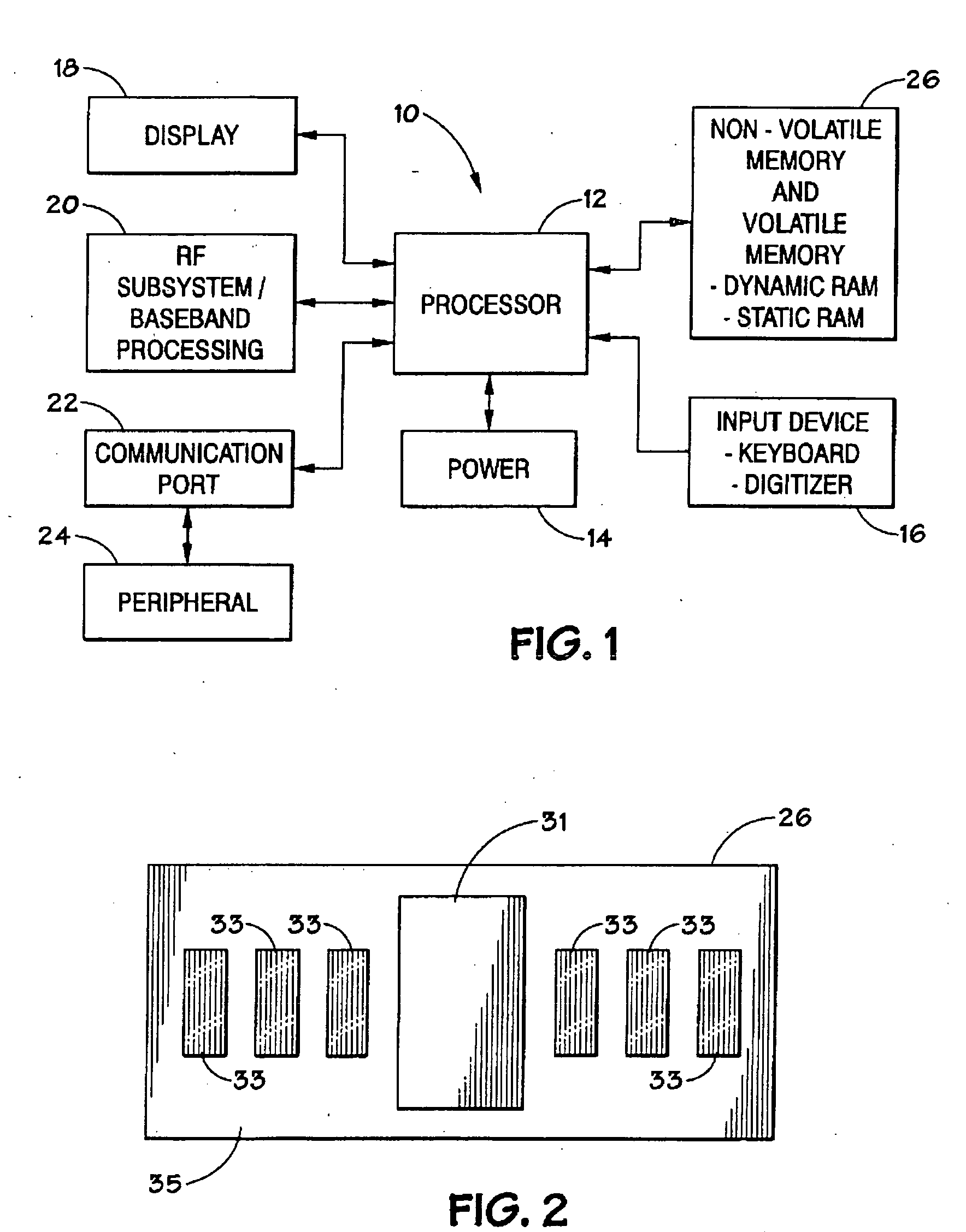

Compliant printed circuit wafer probe diagnostic tool

InactiveUS20120062270A1Improve performanceIncrease valueElectrical measurement instrument detailsSolid-state devicesContact padElectrical devices

Diagnostic tools for testing wafer-level IC devices, and a method of making the same. The first diagnostic tool can include a first compliant printed circuit with a plurality of contact pads configured to form an electrical interconnect at a first interface between distal ends of probe members in the wafer probe and contact pads on a wafer-level IC device. A plurality of printed conductive traces electrically couple to a plurality of the contact pads on the first compliant printed circuit. A plurality of electrical devices are printed on the first compliant printed circuit at a location away from the first interface. The electrical devices are electrically coupled to the conductive traces and are configured to provide one or more of continuity testing or functionality of the wafer-level IC devices. A second diagnostic tool includes a second compliant printed circuit electrically coupled to a dedicated IC testing device. A plurality of electrical devices are printed on the second compliant printed circuit and electrically coupled to the dedicated IC device.

Owner:HSIO TECH

Compliant printed circuit socket diagnostic tool

InactiveUS8928344B2Improve performanceIncrease valueContinuity testingIndividual semiconductor device testingContact padElectrical devices

Diagnostic tools for testing integrated circuit (IC) devices, and a method of making the same. The first diagnostic tool includes a first compliant printed circuit with a plurality of contact pads configured to form an electrical interconnect at a first interface between proximal ends of contact members in the socket and contact pads on a printed circuit board (PCB). A plurality of printed conductive traces electrically couple to a plurality of the contact pads on the first compliant printed circuit. A plurality of electrical devices are printed on the first compliant printed circuit at a location external to the first interface. The electrical devices are electrically coupled to the conductive traces and programmed to provide one or more of continuity testing at the first interface or functionality of the IC devices. A second diagnostic tool includes a second compliant printed circuit electrically coupled to a surrogate IC device.

Owner:HSIO TECH

Compliant printed circuit wafer probe diagnostic tool

InactiveUS8912812B2Improve performanceIncrease valueElectrical measurement instrument detailsSolid-state devicesElectricityContact pad

Owner:HSIO TECH

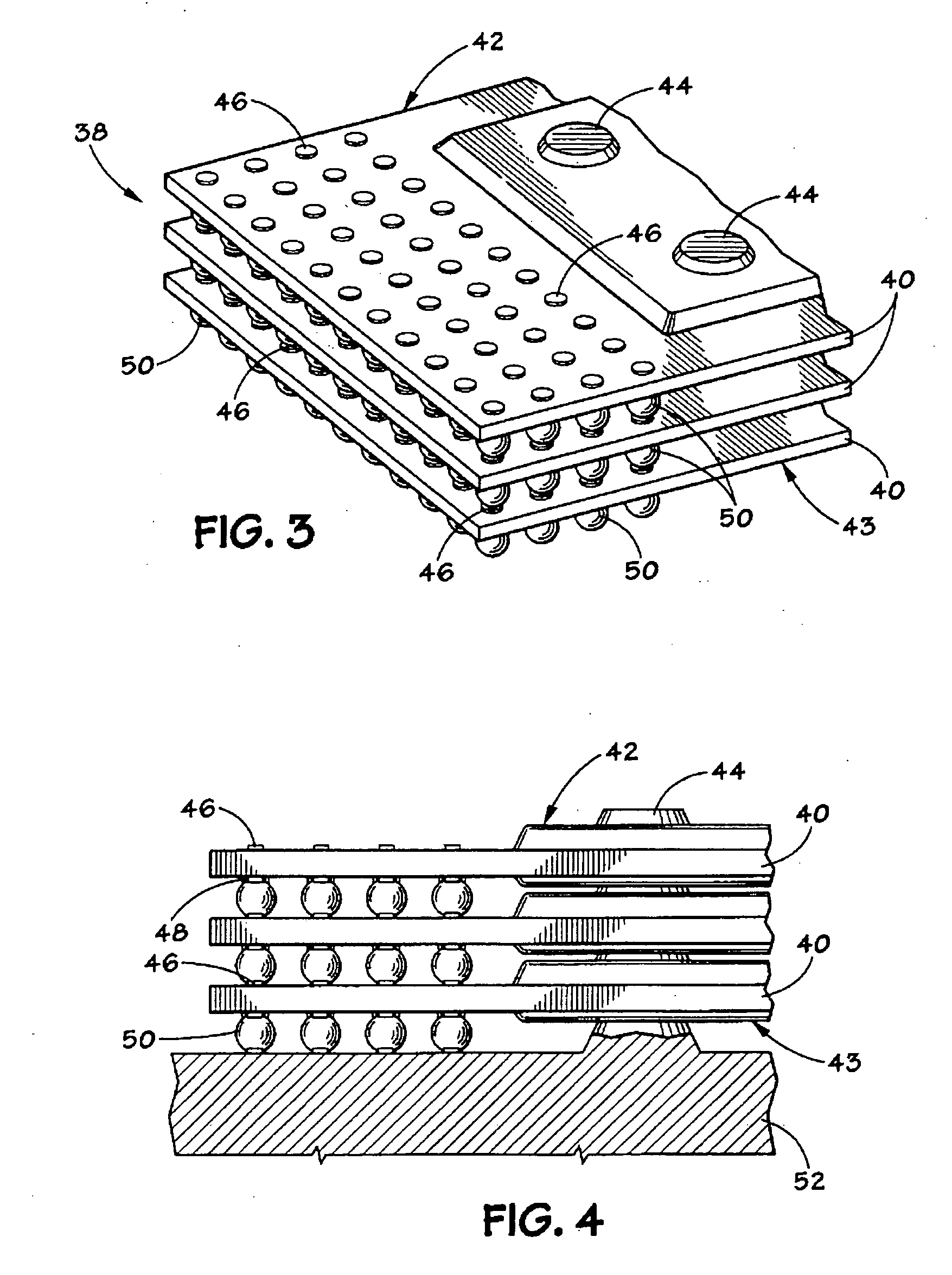

Packaging method for an electronic element

InactiveUS7459345B2Low costImprove productivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsResistHigh density

A packaging method for an electronic element has: etching portions of a top surface of a metal board to form recesses between raised unetched segments and filling the recesses with a dielectric material of high density polymer; forming multiple solder balls respectively on the raised unetched segments; coating the solder balls with a thin flux layer; bonding contacts on a die respectively to the solder balls with the thin flux layer; injecting an encapsulant between the die and the metal board; sealing the die with an outer encapsulant; etching a bottom surface of the metal board to form multiple metal leads; coating the bottom surface of the metal board other than the metal leads with a solder resist; and conducting a continuity test. The solder balls are not formed directly on the fragile die so the packaging method can be used with any types of dies and has a good applicability.

Owner:MUTUAL PAK TECH

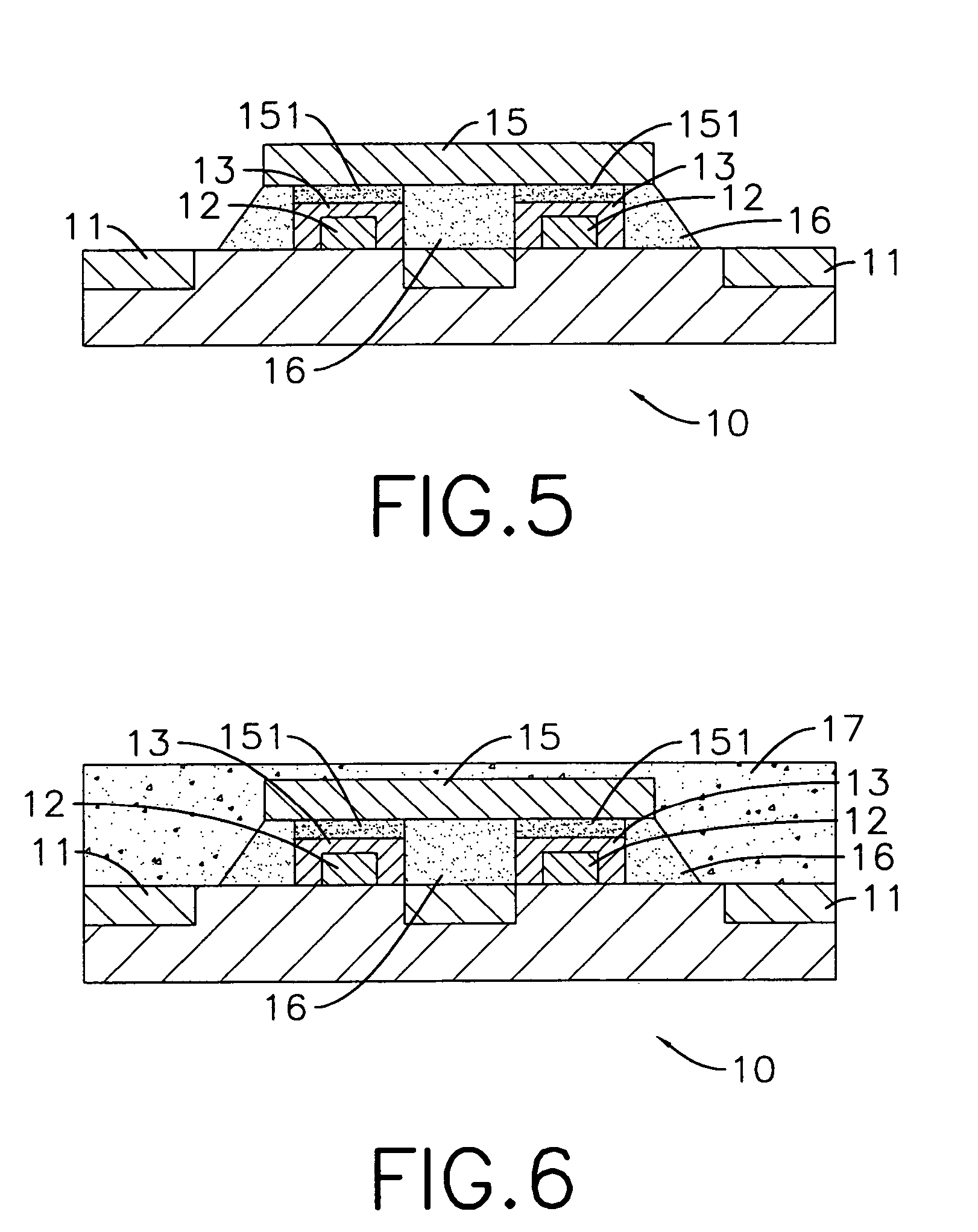

Semiconductor chip, semiconductor device, and method of measuring the same

ActiveUS20130076387A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipContinuity test

In a semiconductor device in which semiconductor chips having a number of signal TSVs are stacked, a huge amount of man-hours have been required to perform a continuity test for each of the signal TSVs. According to the present invention, no continuity test is performed directly on signal TSVs. Dummy bumps are arranged in addition to signal TSVs. The dummy bumps of the semiconductor chips are connected through a conduction path that can pass the dummy bumps between the semiconductor chips with one stroke when the semiconductor chips are stacked. A continuity test of the conduction path allows a bonding defect on bonded surfaces of two of the stacked semiconductor chips to be measured and detected.

Owner:LONGITUDE LICENSING LTD

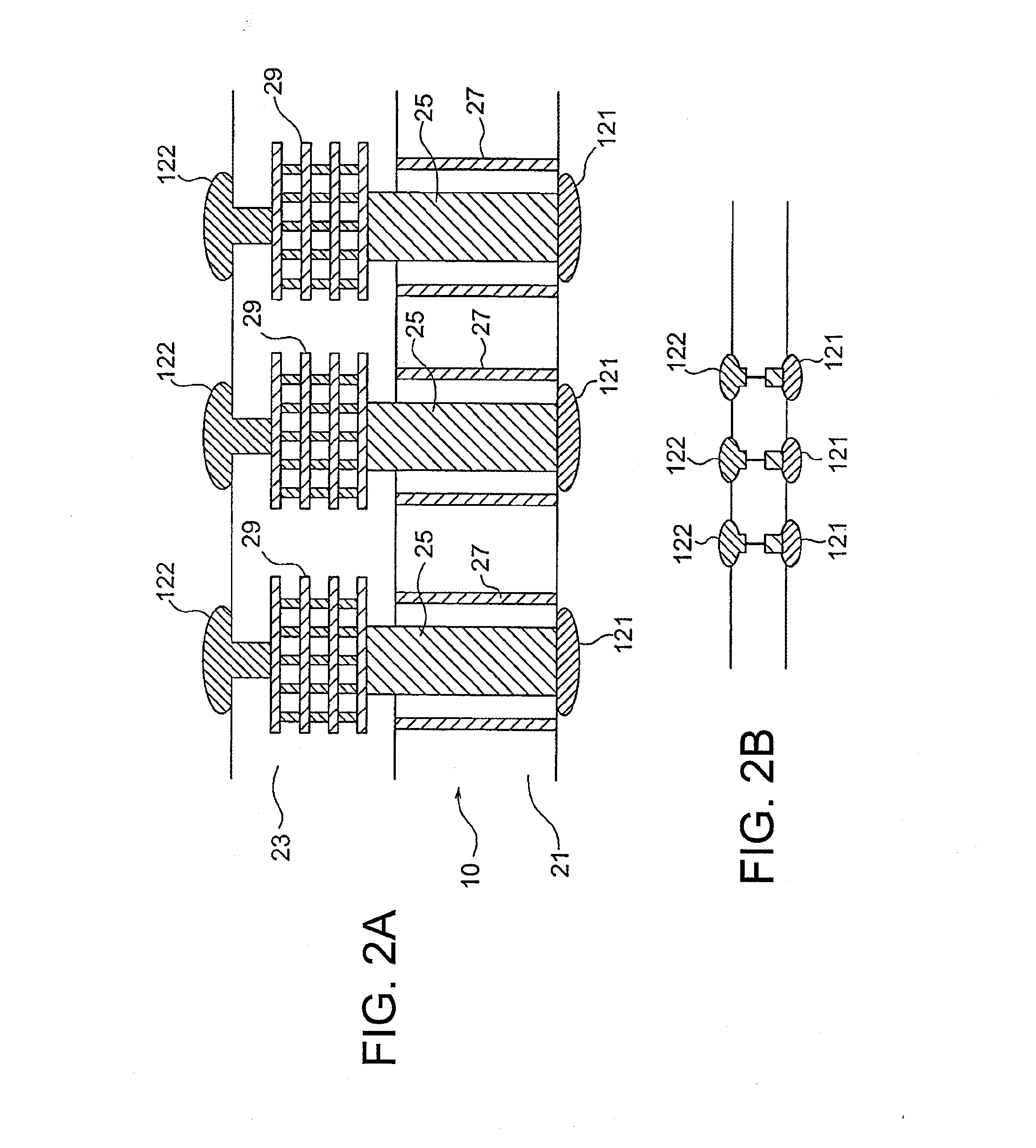

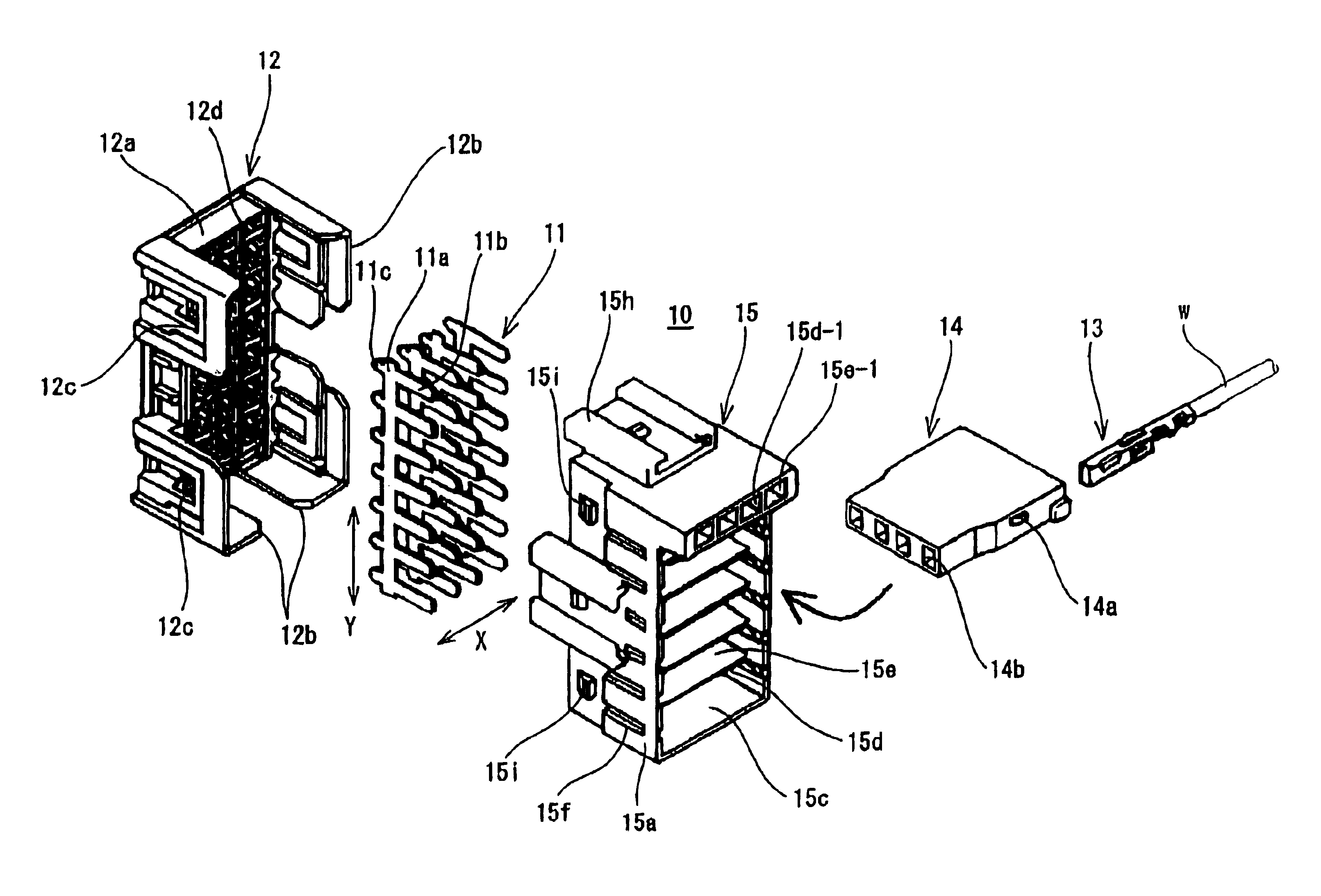

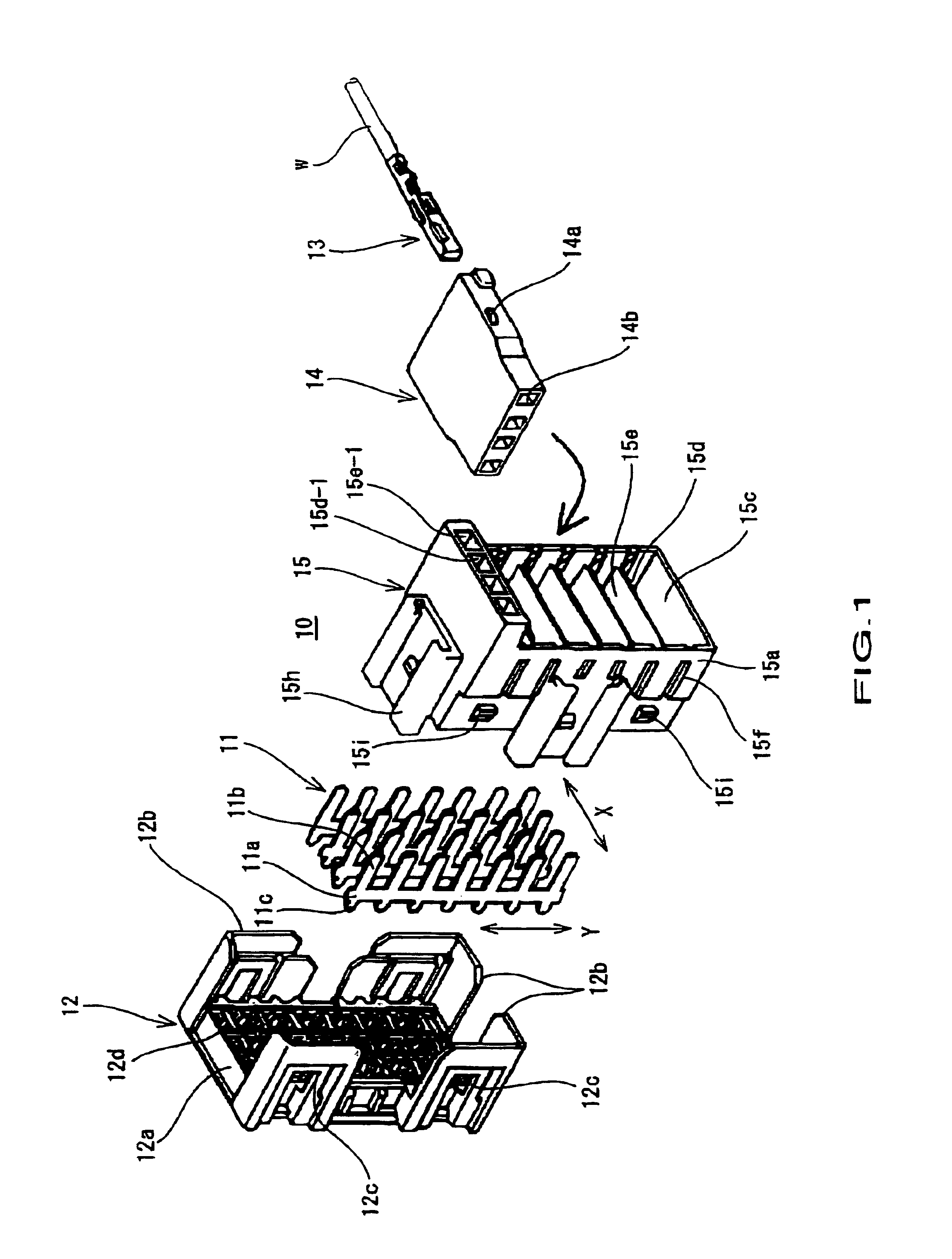

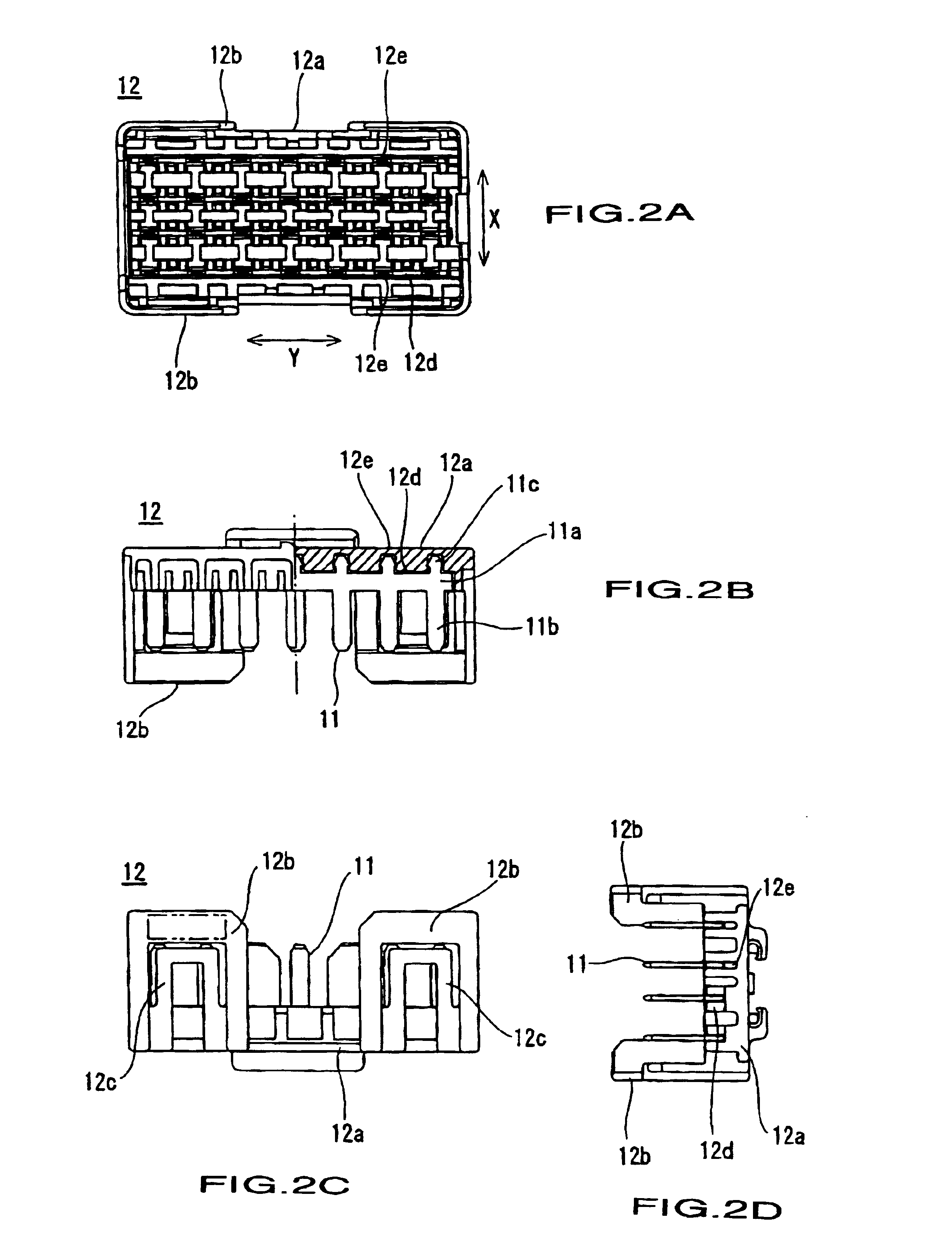

Electrical connector box and assembly method thereof

InactiveUS6840820B2Easy to changeReduce in quantityCoupling device detailsTwo-part coupling devicesElectricityContinuity test

An electrical connector box that provides multiple electrical circuit connections, simplifies alterations to circuit connection patterns, and allows for convenient continuity testing. The electrical connector box includes a housing and a holder that contains multiple vertically stacked receptacles. Multiple bus bars, of which multiple bus bar tabs are an integral part thereof, are press fit into the housing at uniform intervals, a block connector is inserted into each of vertically stacked receptacles in the holder, and the housing and holder are locked together during which the bus bar tabs in the housing are inserted into female terminal connectors held within the block connectors in the holder.

Owner:SUMITOMO WIRING SYST LTD

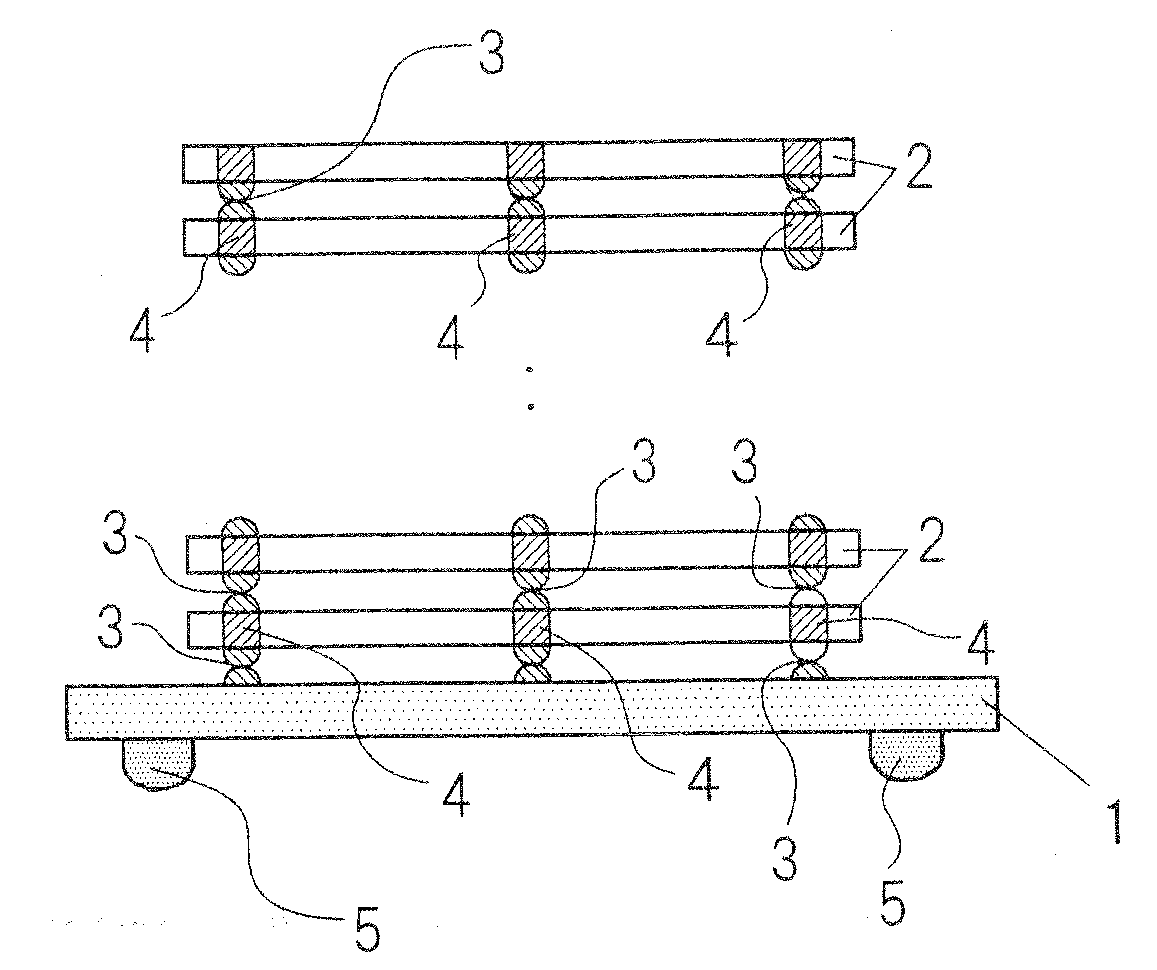

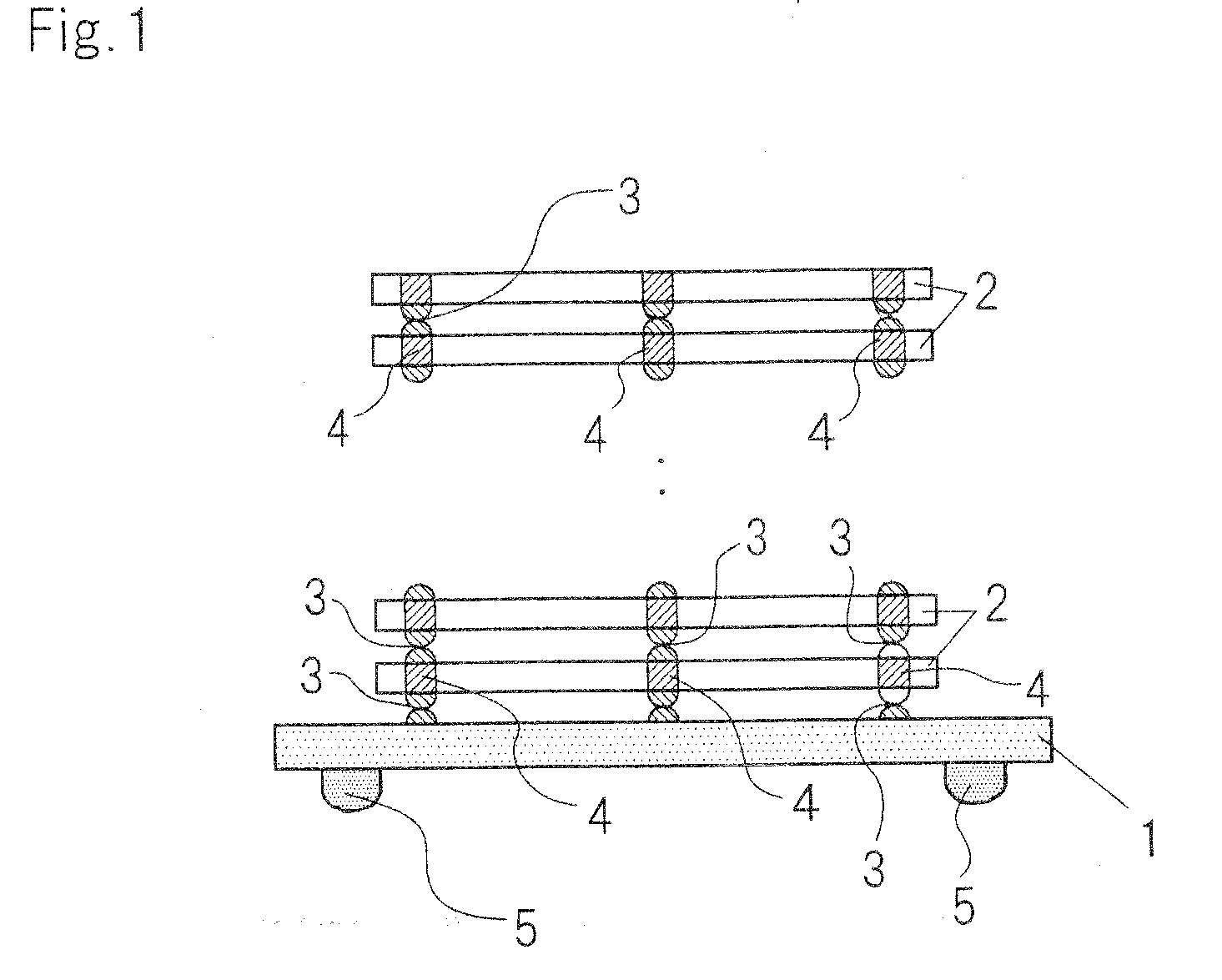

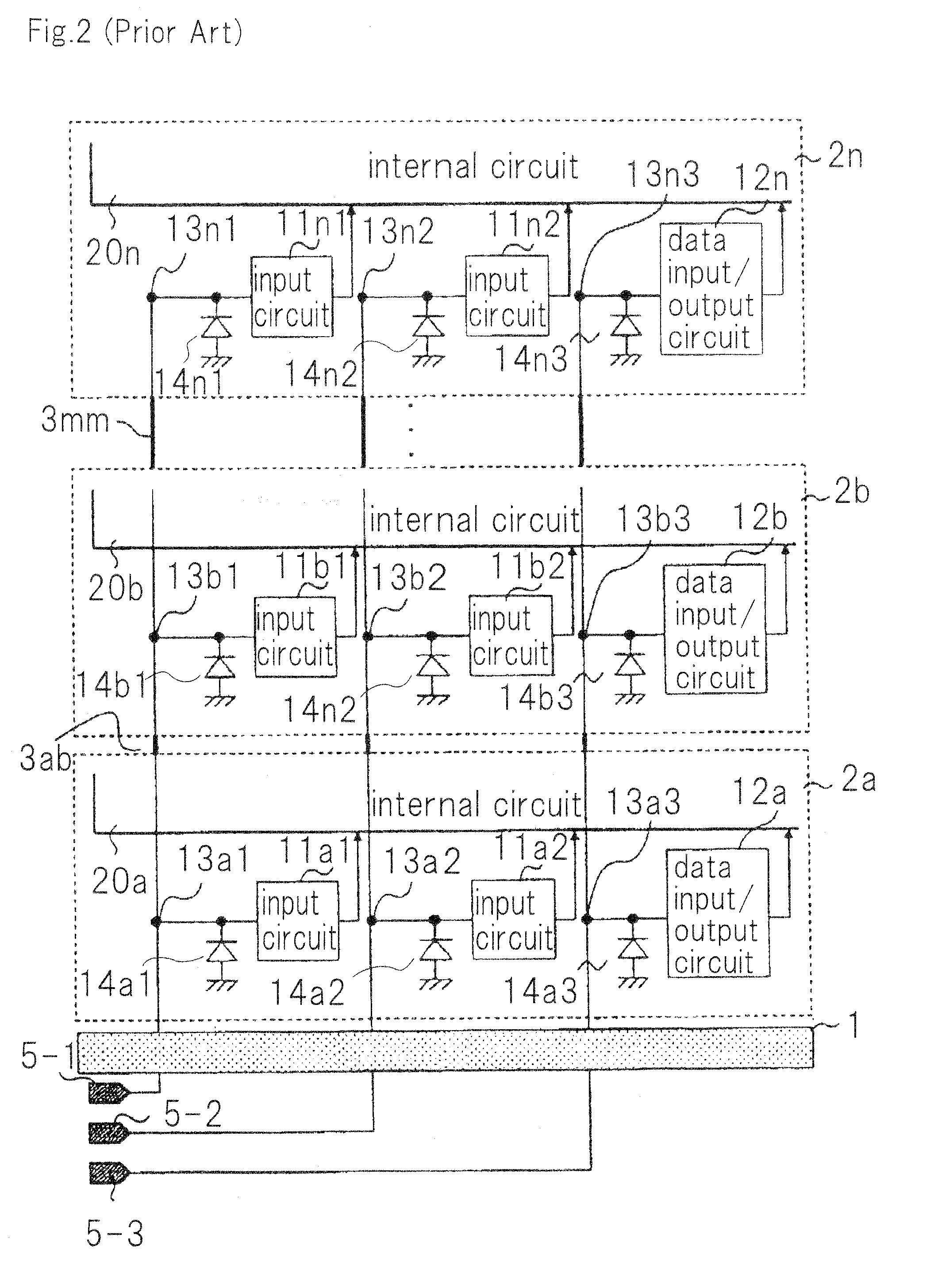

Separate testing of continuity between an internal terminal in each chip and an external terminal in a stacked semiconductor device

InactiveUS20090153177A1Easy to identifySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsContinuity testEngineering

A stacked semiconductor device is disclosed which is capable of conducting a test to determine whether or not there is continuity between an external terminal and a corresponding internal terminal in each chip, on an internal terminal-in each chip basis. The semiconductor device includes continuity test dedicated terminals for each chip, and continuity test elements each connected between an internal terminal in each chip and a continuity test dedicated terminal associated with the chip. A voltage is applied between an external terminal associated with an internal terminal whose connection status is to be checked and a continuity test dedicated terminal associated with a chip which includes the internal terminal such that a continuity test element associated with the internal terminal is rendered conductive. Thereafter, the value of current that flows through the continuity test element is measured to determine the connection status of the internal terminal.

Owner:LONGITUDE LICENSING LTD

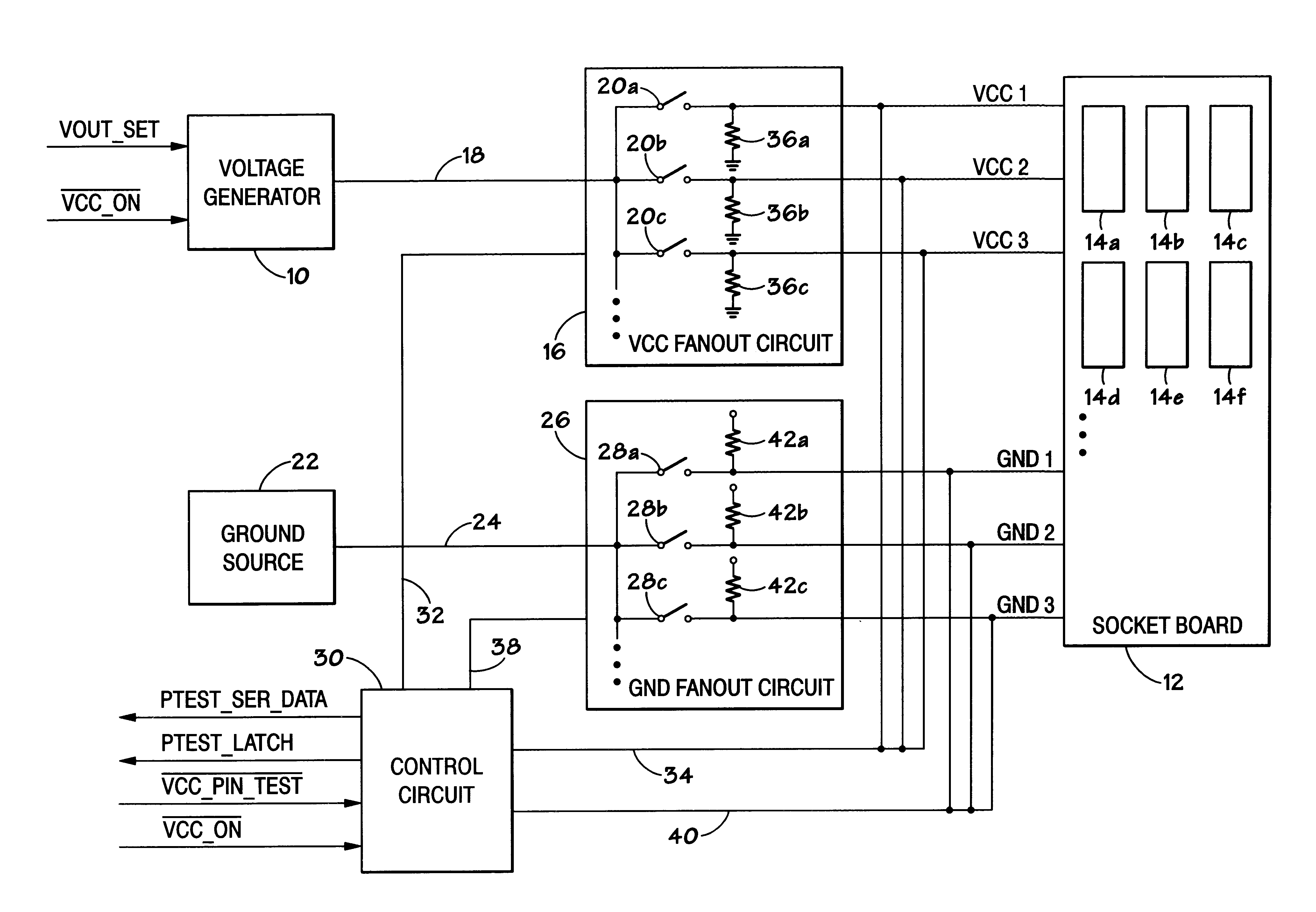

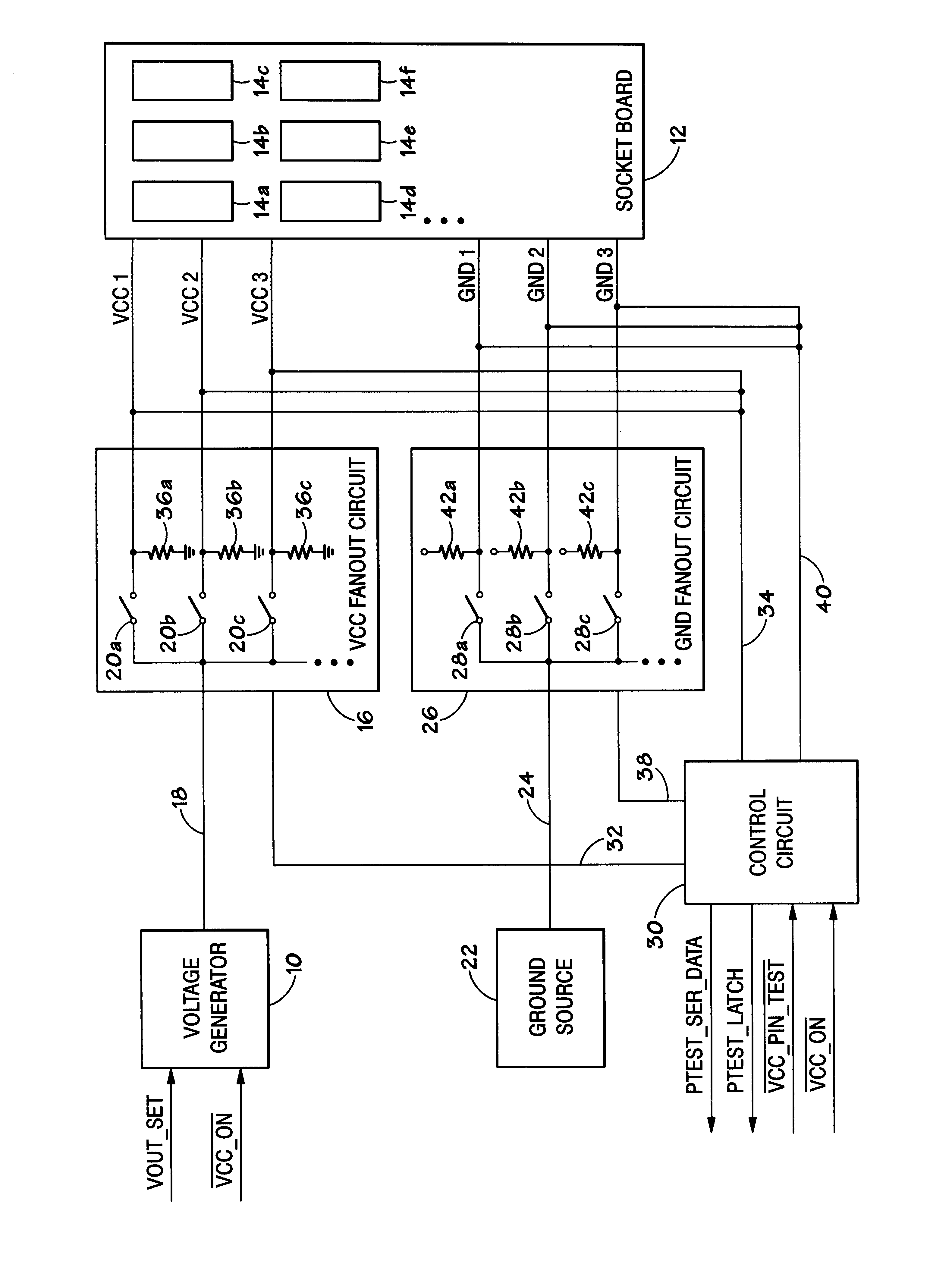

Method and apparatus of testing memory device power and ground pins in an array assembly platform

InactiveUS6545497B2Electrical measurement instrument detailsIndividual semiconductor device testingEngineeringContinuity test

An apparatus and technique for performing continuity tests of power and ground pins on a packaged integrated circuit. The technique includes using a first and second fanout circuit each including a number of signal paths. Each signal path includes a switch and corresponds to a power or ground socket on a board configured to hold a number of integrated circuit packages. The fanout circuits allow full device testing, as well as testing of individual pins. By controlling the state of the switches, power and ground may be selectively supplied to power and ground pins to check the continuity of the signals from the integrated circuit device within the package to the external pins provided to route the signal to an external device.

Owner:MICRON TECH INC

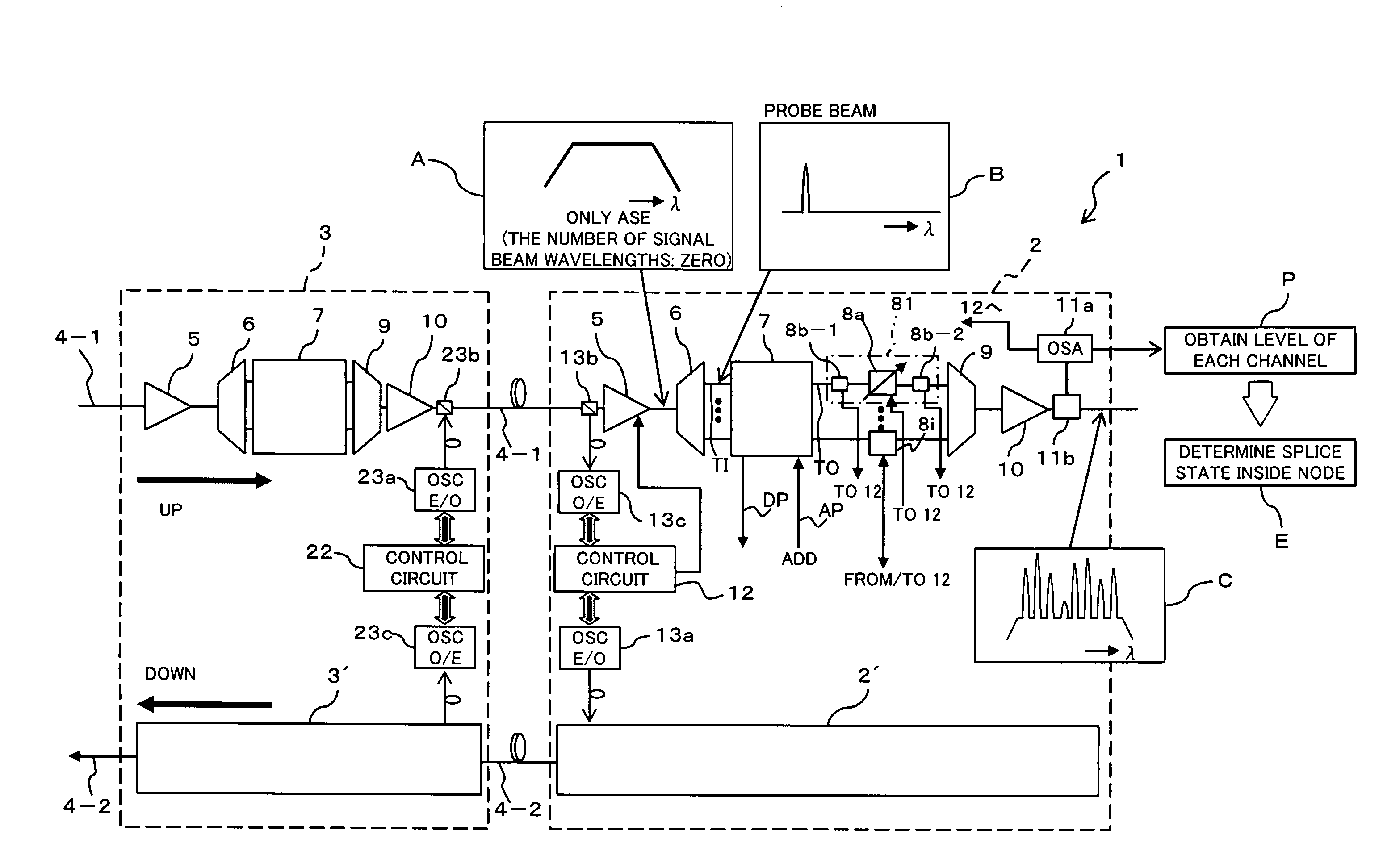

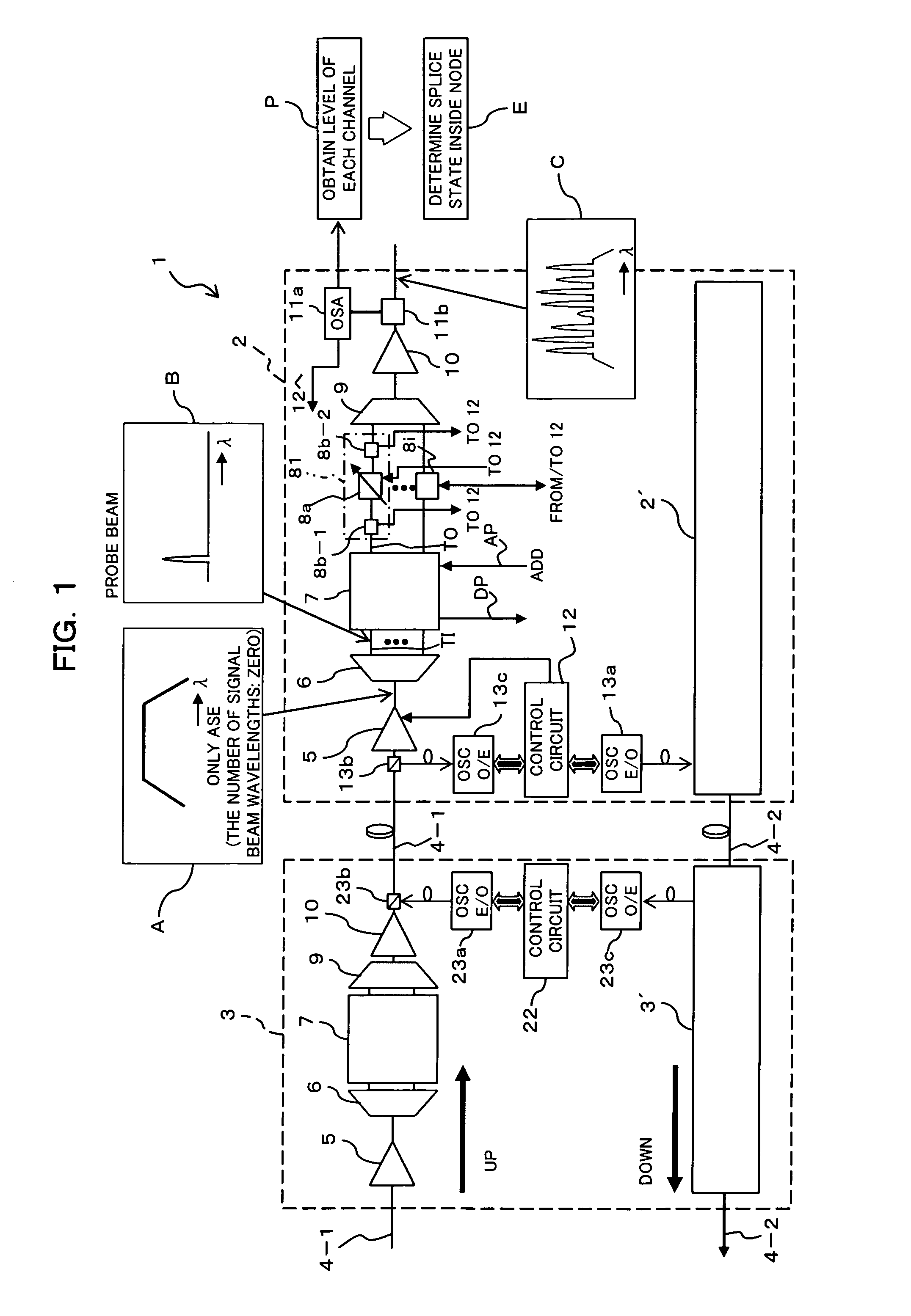

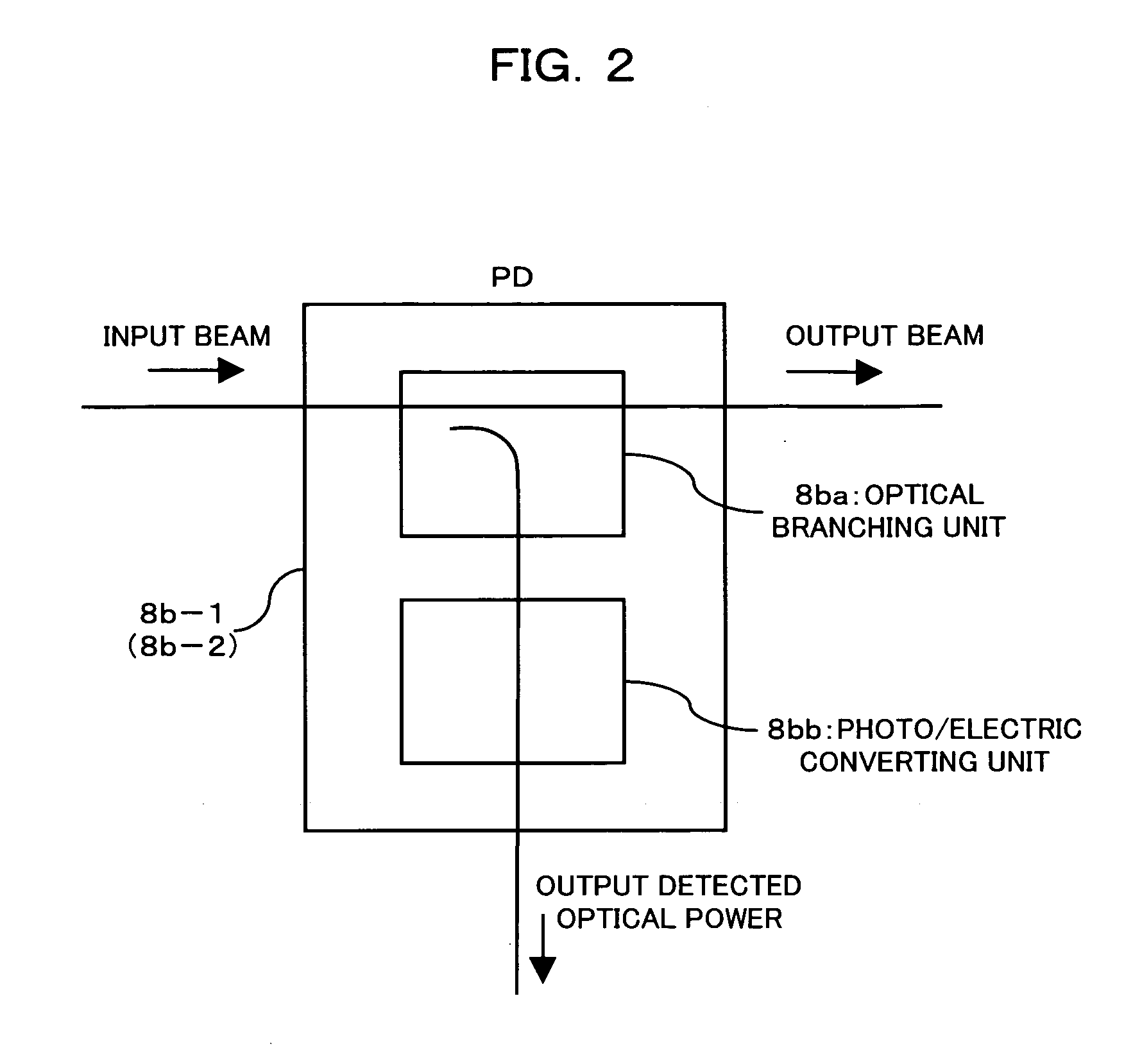

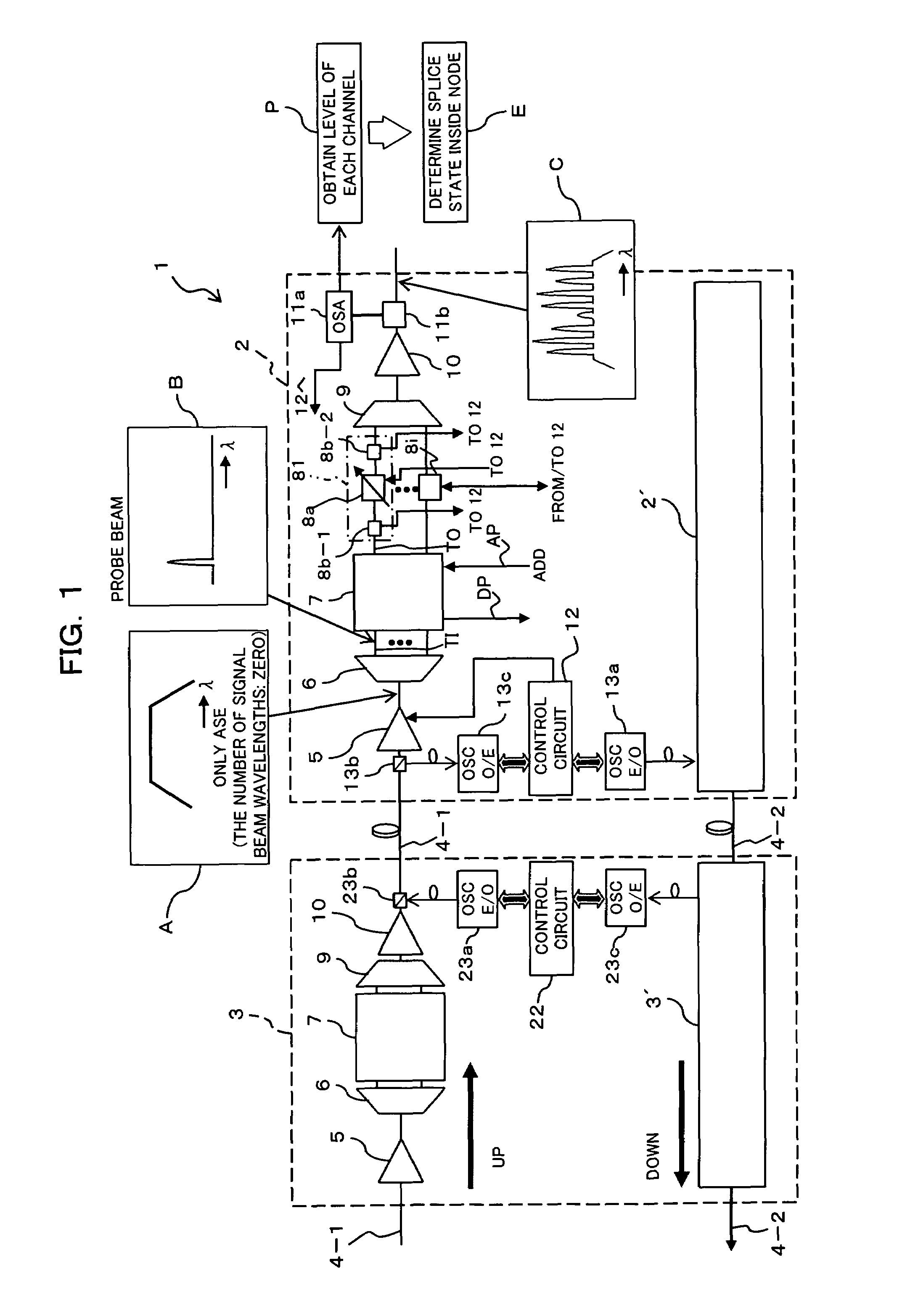

Optical transmission apparatus, continuity testing method therein, and optical transmission system

InactiveUS20060269284A1Short timeLow costRing-type electromagnetic networksWavelength-division multiplex systemsOptical propagationContinuity test

An optical transmission apparatus comprises a preamplifier controlling unit for controlling a preamplifier so that amplified spontaneous emission including all wavelength bands of a wavelength-multiplexed signal beam is outputted toward a wavelength demultiplexing unit, with the wavelength-multiplexed signal beam not inputted, power monitors for monitoring optical powers of the amplified spontaneous emission fed from the preamplifier and wavelength-demultiplexed by the wavelength demultiplexing unit, and a determining unit for determining the continuity state of an optical propagation path of each wavelength component on the basis of a result of monitoring by the power monitors. The optical transmission apparatus allows the continuity test on optical propagation paths of channels including a channel not used at the time of a start of the operation to be made easier than the known techniques.

Owner:FUJITSU LTD

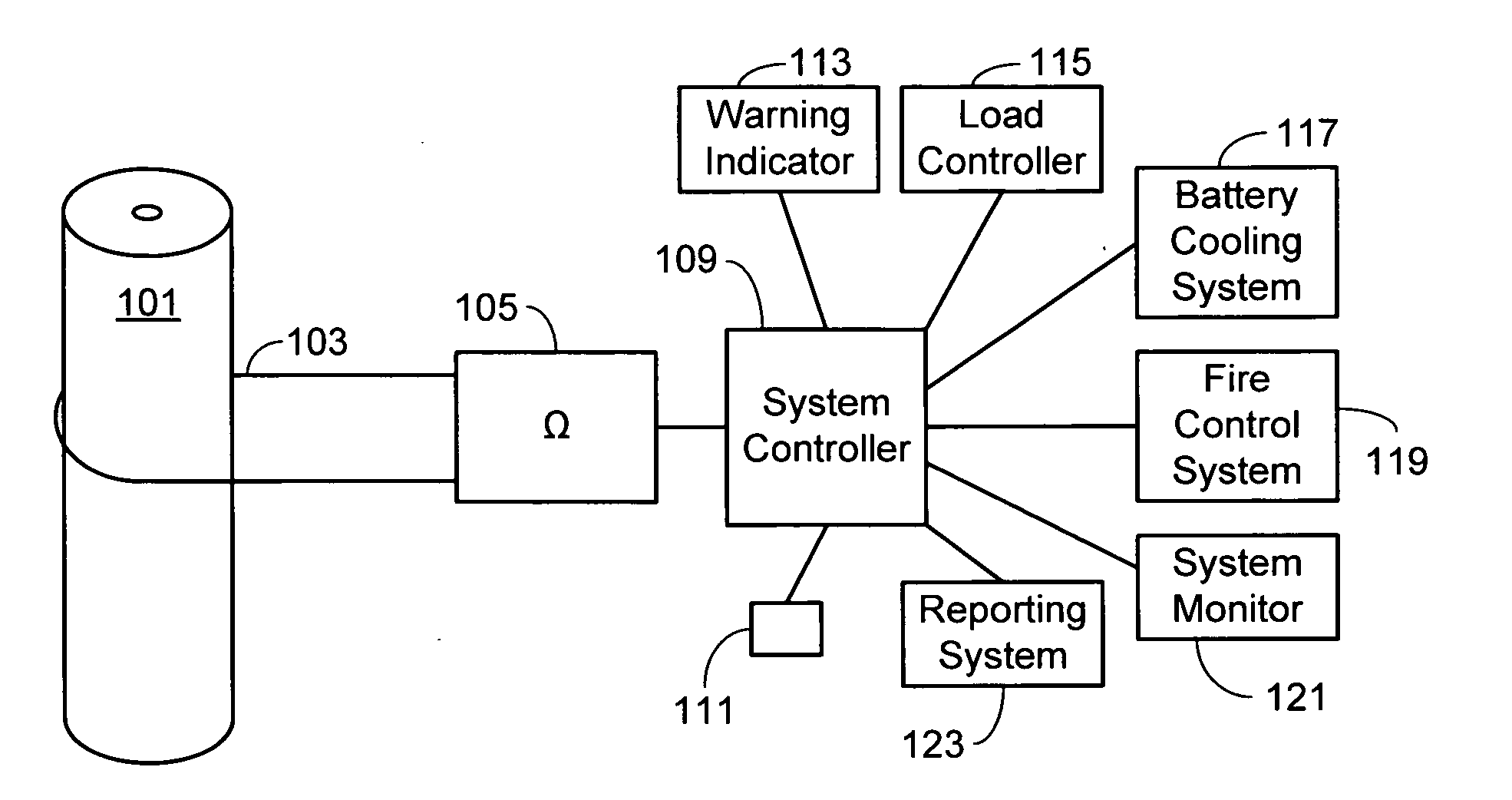

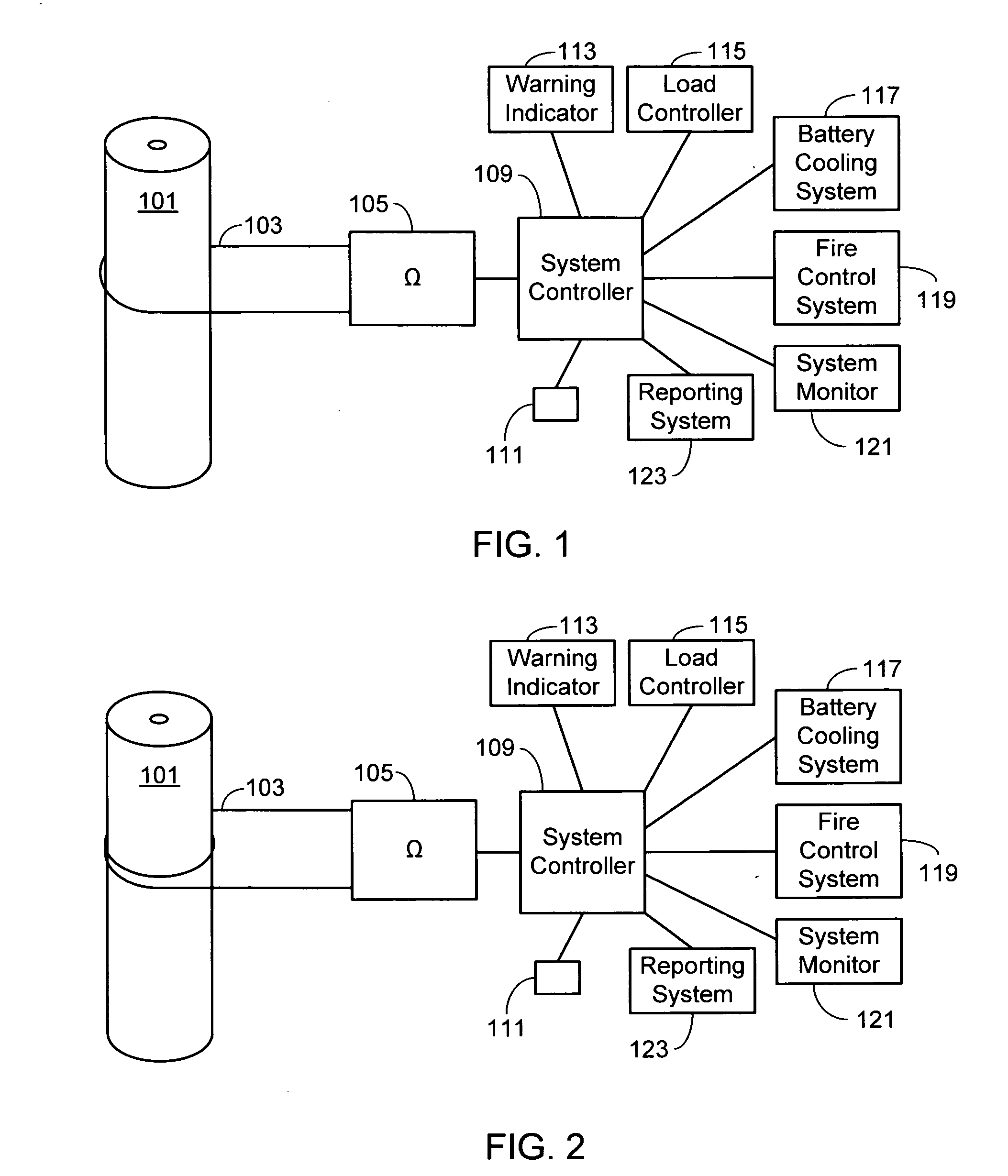

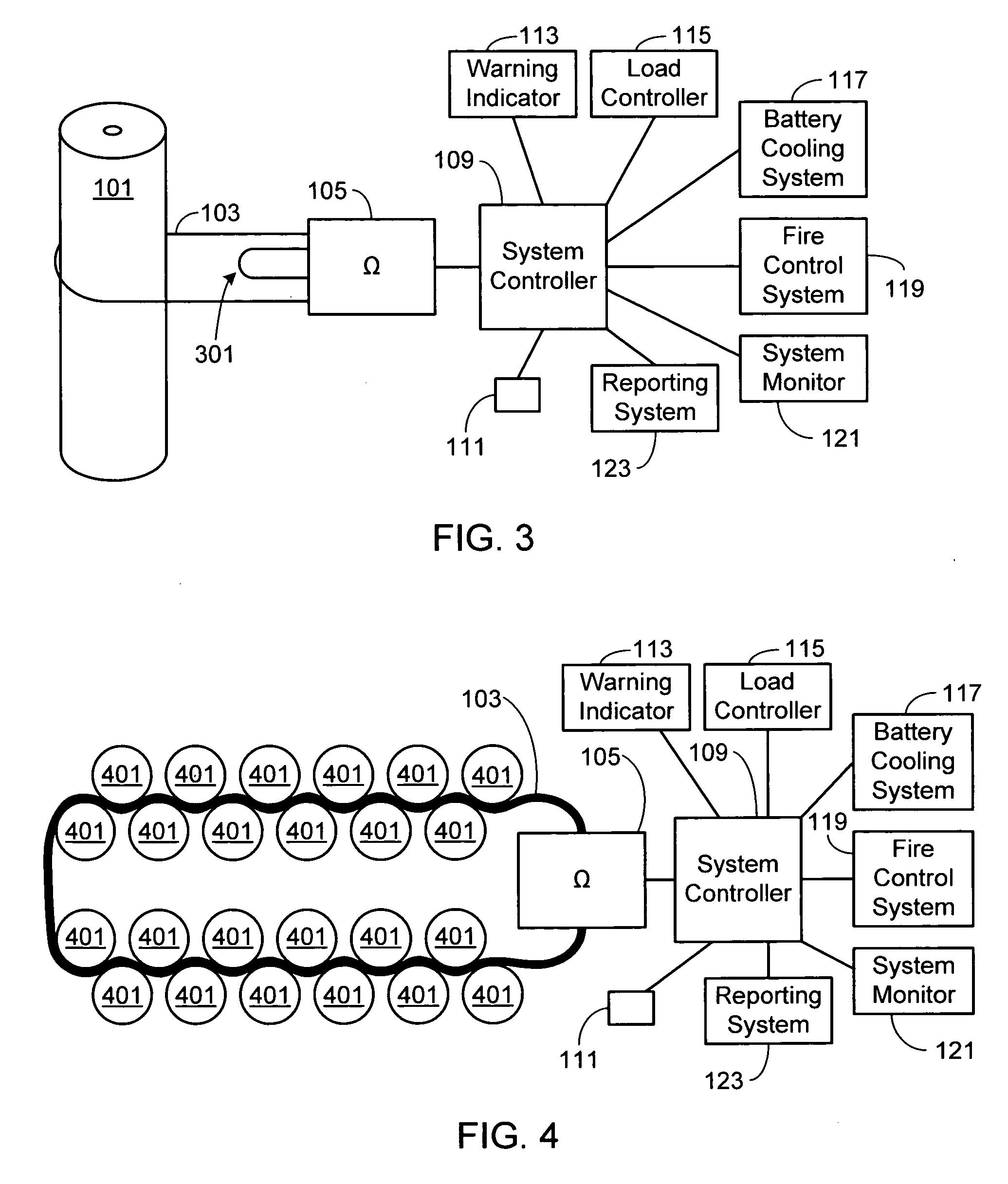

Battery thermal event detection system using a thermally interruptible electrical conductor

ActiveUS20100302051A1Programme controlBatteries circuit arrangementsElectrical resistance and conductanceElectrical conductor

A method and apparatus is provided for determining when a battery, or one or more batteries within a battery pack, undergoes an undesired thermal event such as thermal runaway. The system uses a conductive member mounted in close proximity to, or in contact with, an external surface of the battery or batteries to be monitored. A resistance measuring system such as a continuity-tester or an ohmmeter is coupled to the conductive member, the resistance measuring system outputting a first signal when the temperature corresponding to the battery or batteries is within a prescribed temperature range and a second signal when the temperature exceeds a predetermined temperature that falls outside of the prescribed temperature range.

Owner:TESLA INC

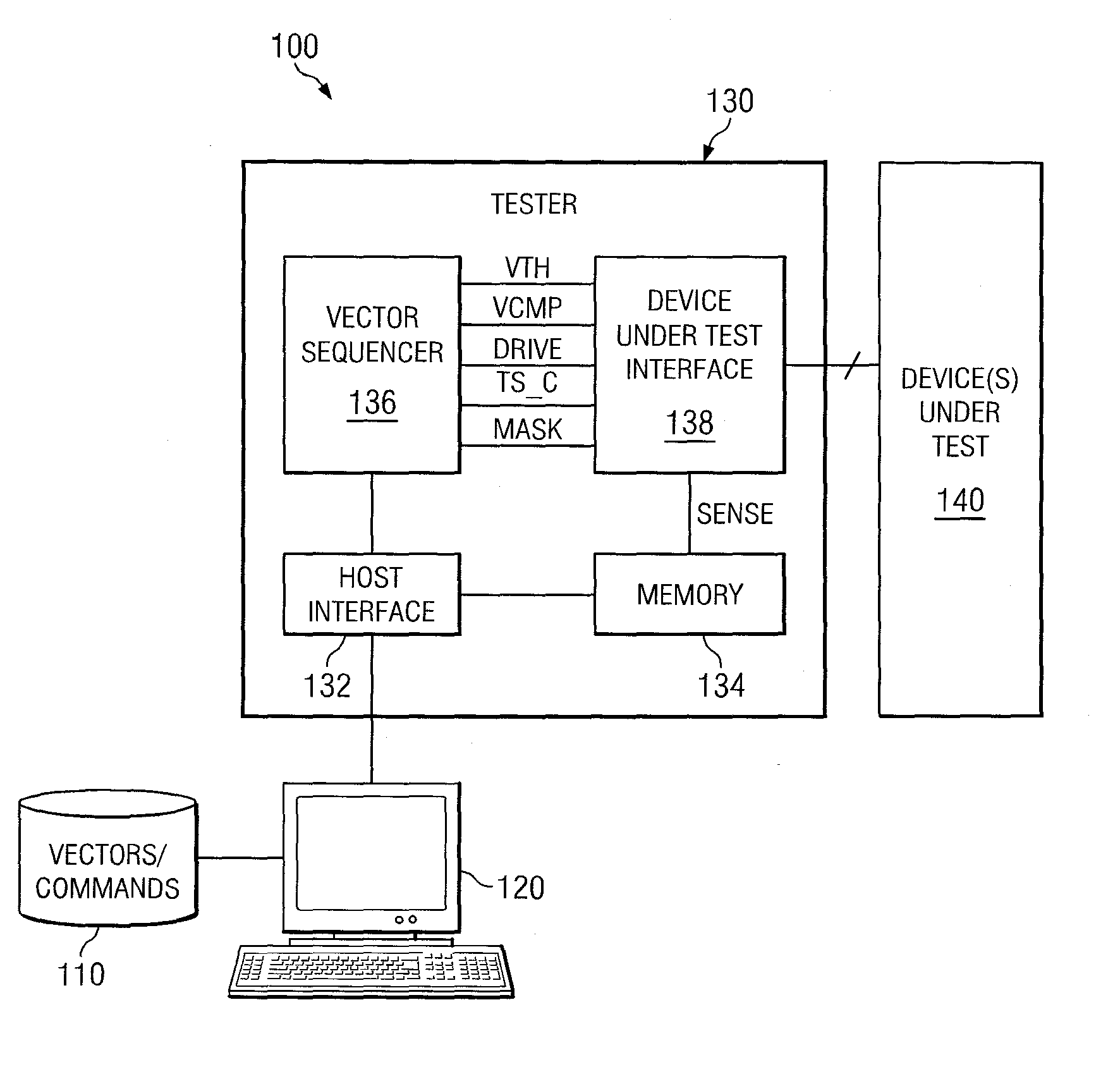

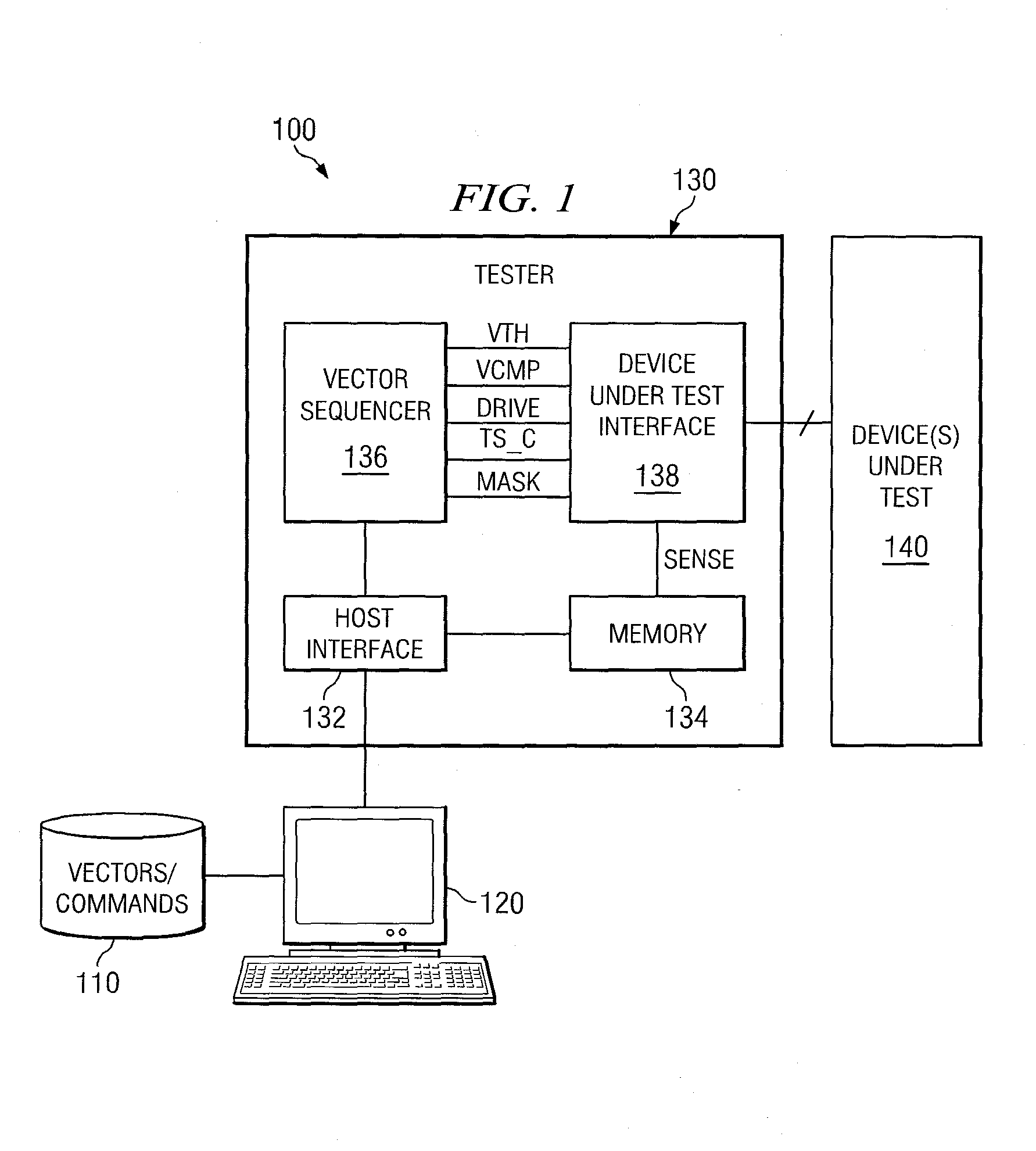

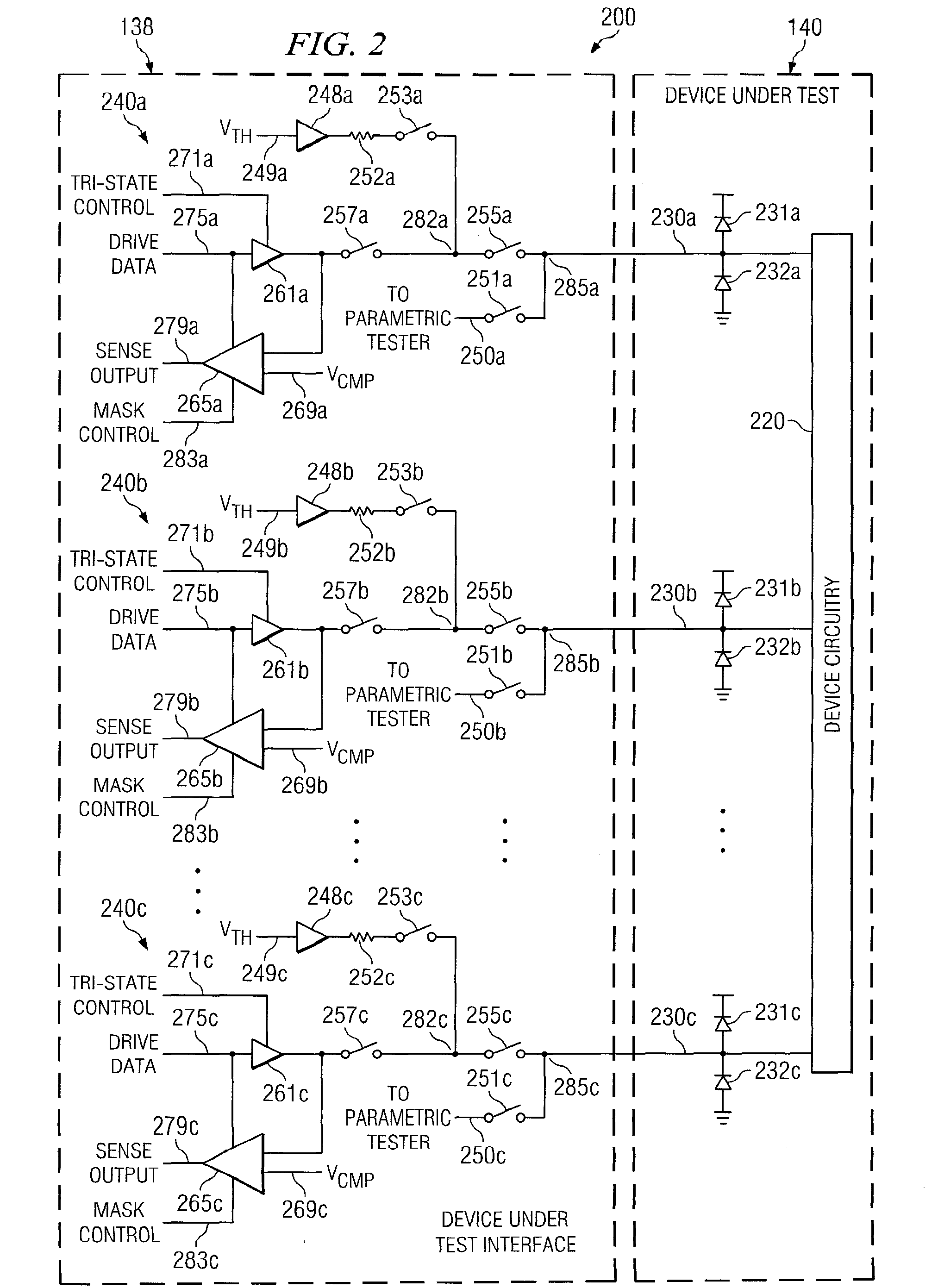

Systems and Methods for Continuity Testing Using a Functional Pattern

ActiveUS20080030217A1Increase speedIndividual semiconductor device testingShort-circuit testElectricity

Various systems and methods for device configuration are disclosed herein. For example, some embodiments of the present invention provide high speed pin continuity and pin-to-pin short tester circuits. Such circuits include a threshold driver, a test driver, and a comparator. An input of the threshold driver is electrically coupled to a voltage threshold, and an output of the threshold driver is electrically coupled to a test pin node via a current limiting resistor. An input of the test driver is electrically coupled to a drive data input, and an output of the test driver is electrically coupled to the test pin node. One input of the comparator is electrically coupled to the test pin node, and the other input of the comparator is electrically coupled to a threshold comparator input.

Owner:TEXAS INSTR INC

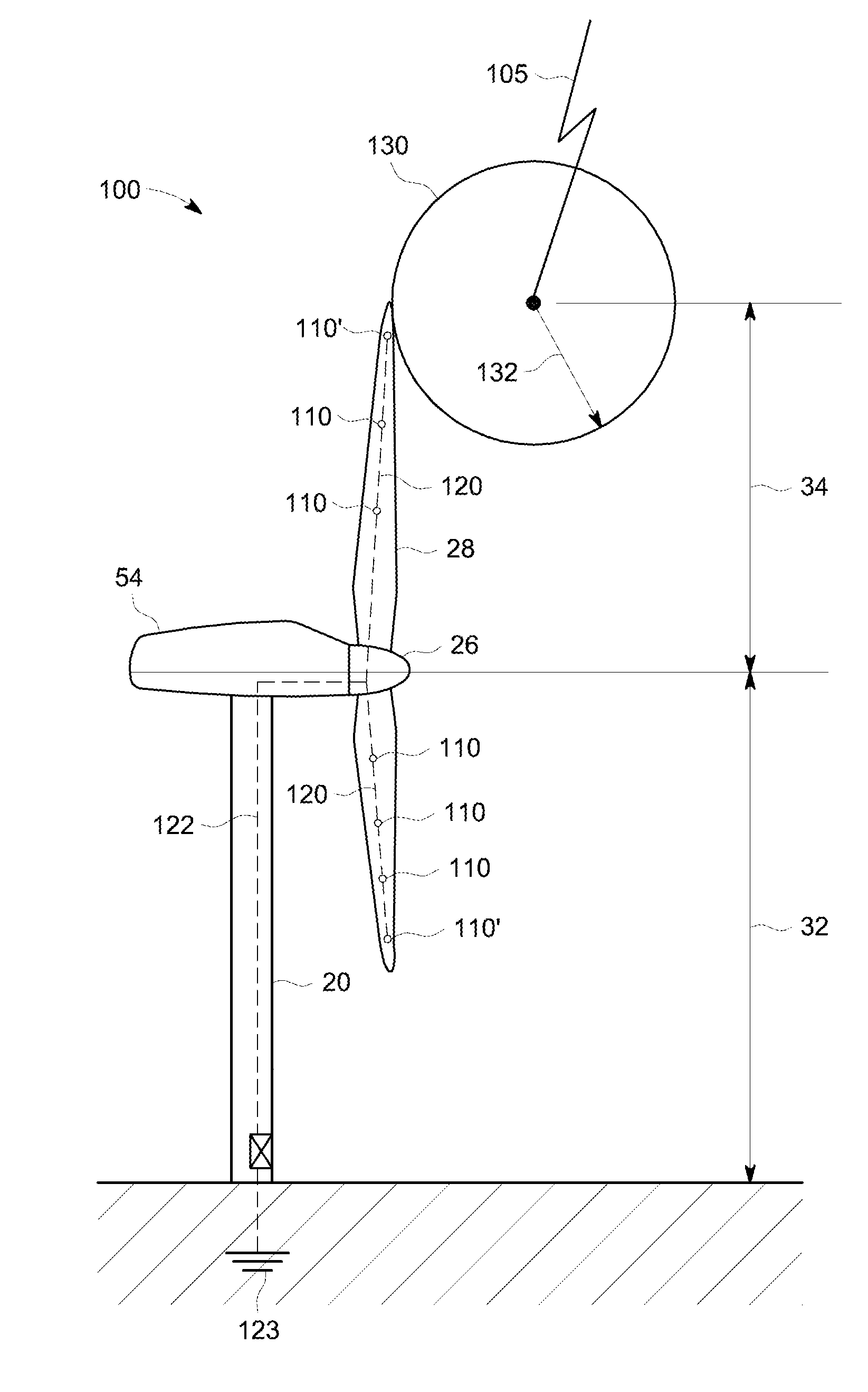

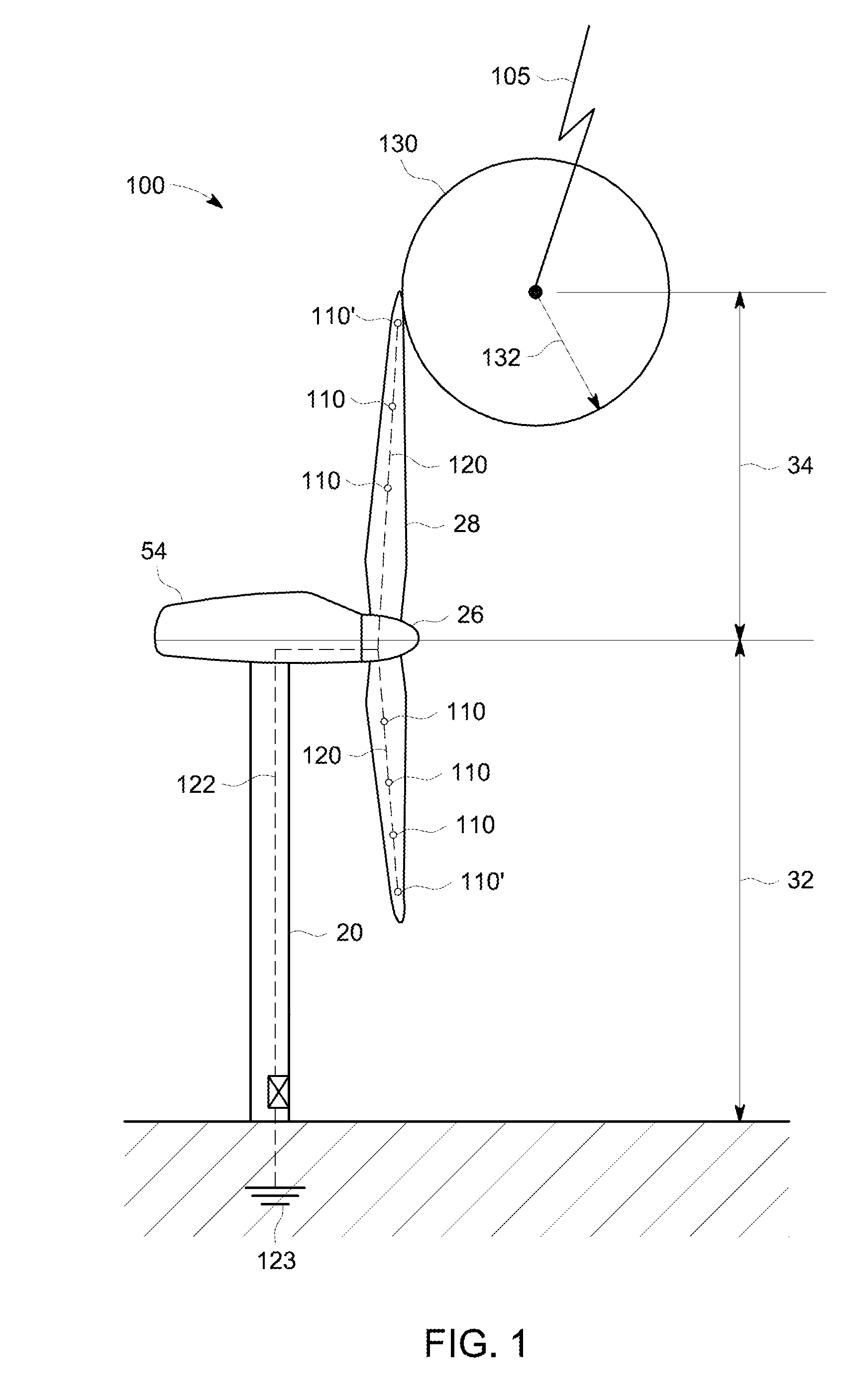

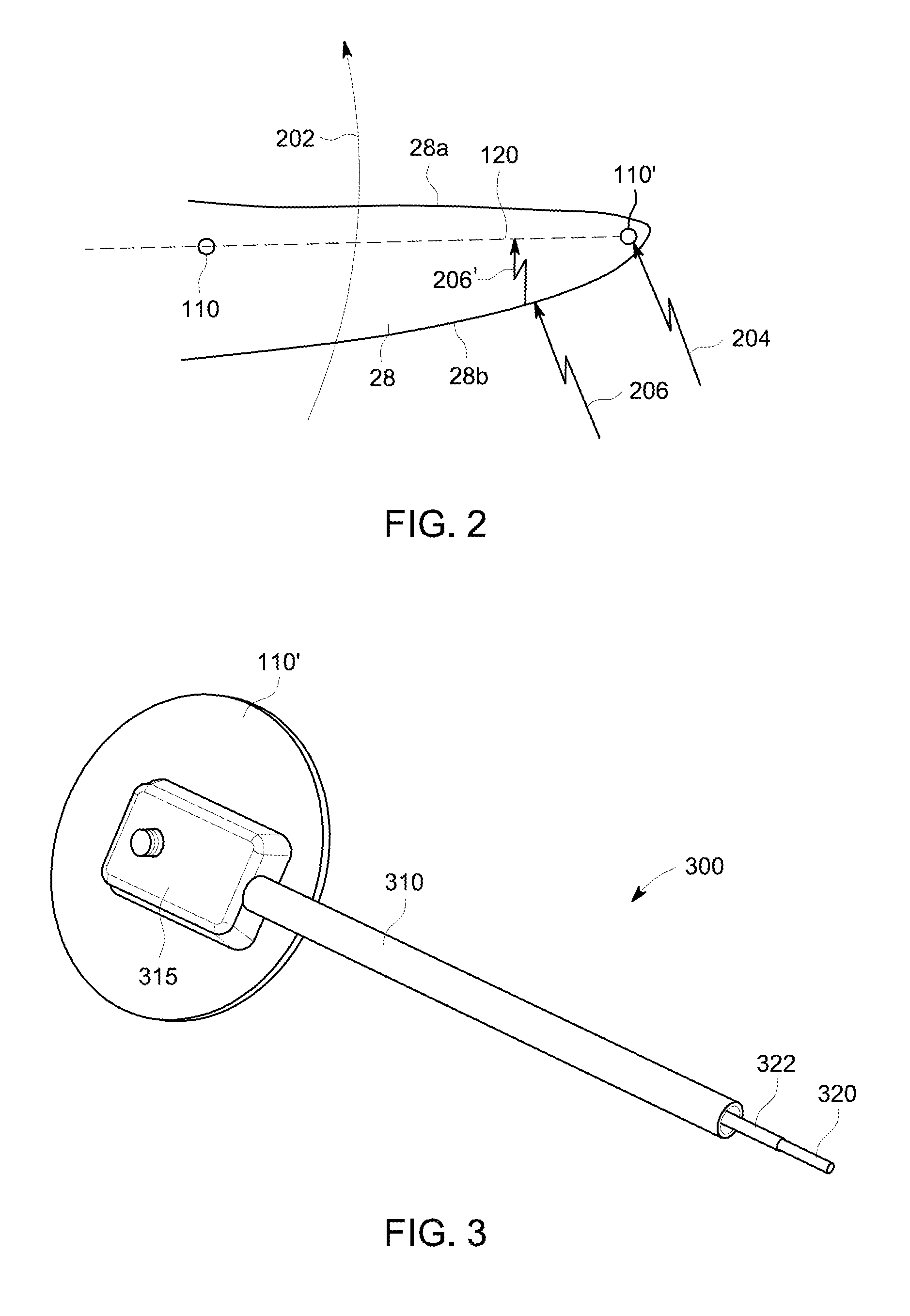

Lightning protection for wind turbines

ActiveUS20110142643A1PropellersDischarge by conduction/dissipationElectrical conductorContinuity test

A rotor blade for a wind turbine is provided. The rotor blade includes a rotor blade body, at least one receptor adapted to be a location for lightning impact, and at least one down conductor connected to the receptor and located within the rotor blade body. The down conductor includes a first conductor connected to the receptor and a ground connection of the wind turbine, and a second insulated conductor connected to the receptor and a non-grounded location of the wind turbine. A path is formed from the ground connection of the first conductor to the non-grounded location of the second insulated conductor. This path facilitates a continuity test used to evaluate a condition of the lightning protection system.

Owner:GENERAL ELECTRIC CO

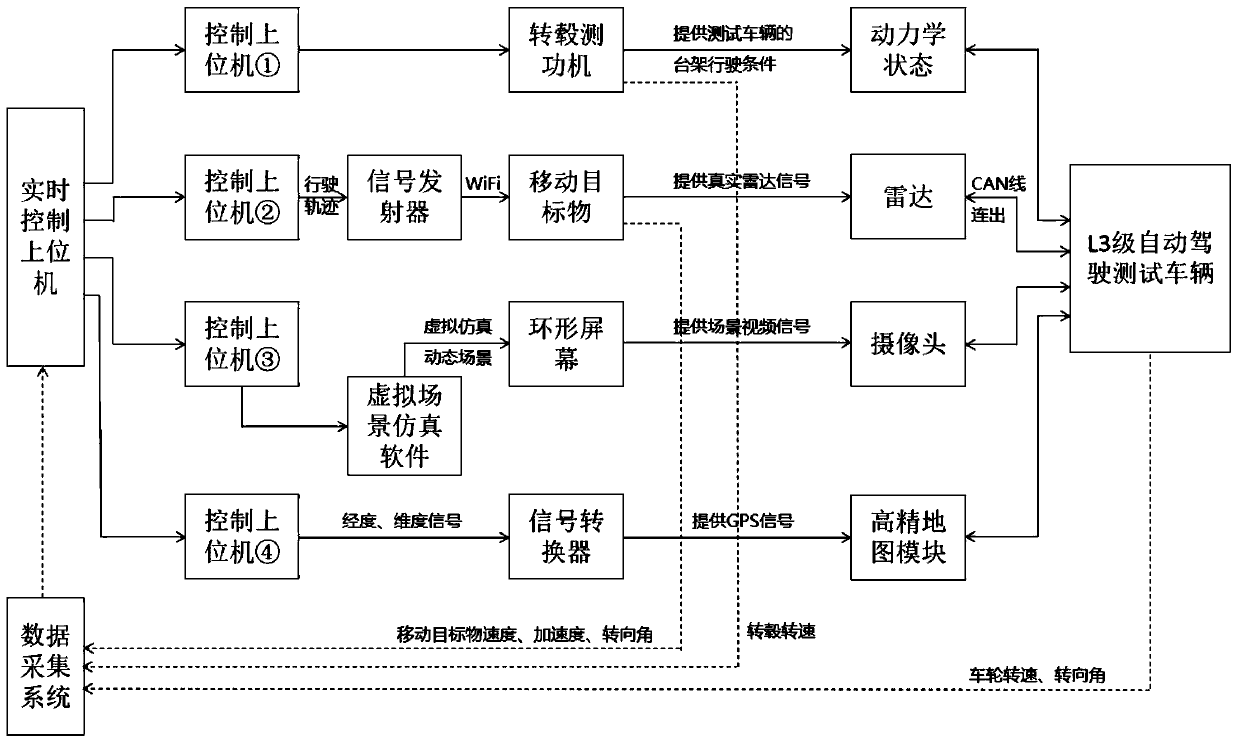

Whole-vehicle in-loop test bench system of L3-level automobile driving automobile

The invention provides a whole-vehicle in-loop test bench system of an L3-level automobile driving automobile. The system comprises a chassis dynamometer located at the central position of an annularscreen, wherein a first vehicle is placed on the chassis dynamometer, the first vehicle comprises a first vehicle body and a first vehicle controller, at least one vehicle-mounted camera is installedon the first vehicle body, an image data signal output end of each vehicle-mounted camera is connected with an image data signal input end of the first vehicle controller, and the vehicle-mounted cameras are used for acquiring continuous test scenes displayed on the annular screen. Through the system, changing of the lane line sate in the testing process can be realized; and through real-time synchronous changing of a moving target (e.g., another vehicle, a bicycle and a pedestrian), lane lines and surroundings, whole-vehicle continuous in-loop testing of the L3-level automobile driving automobile is realized.

Owner:CHINA AUTOMOTIVE ENG RES INST

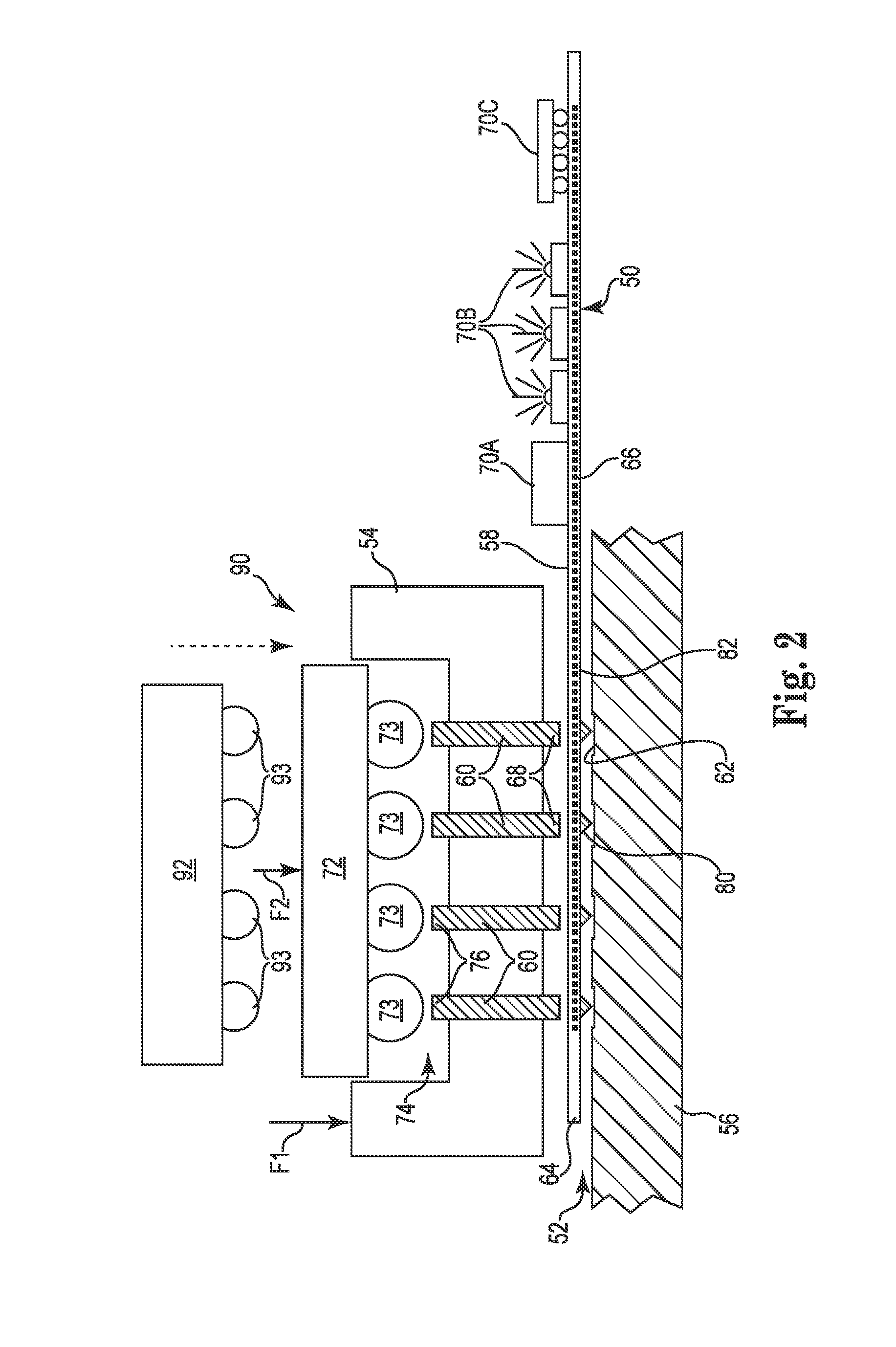

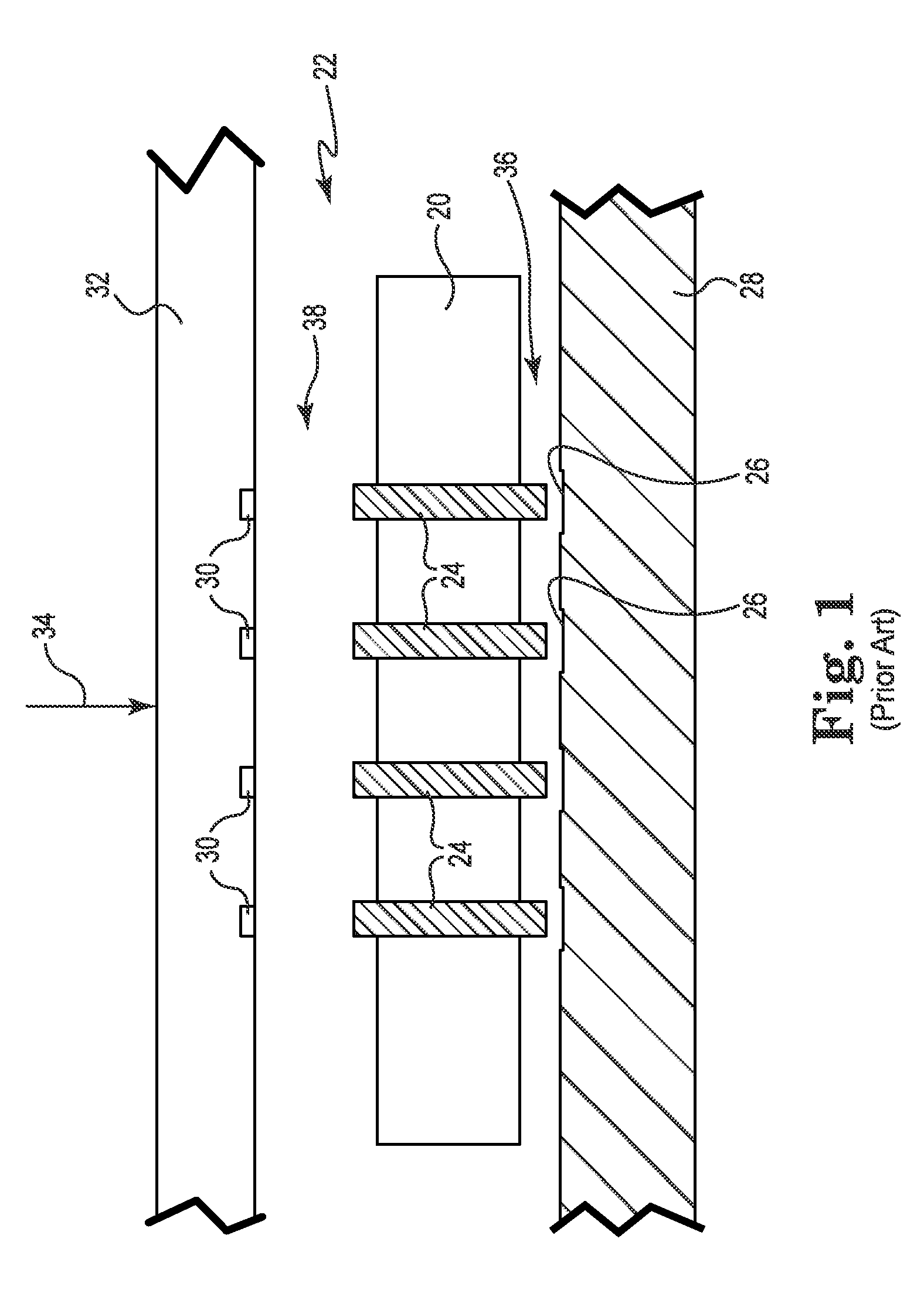

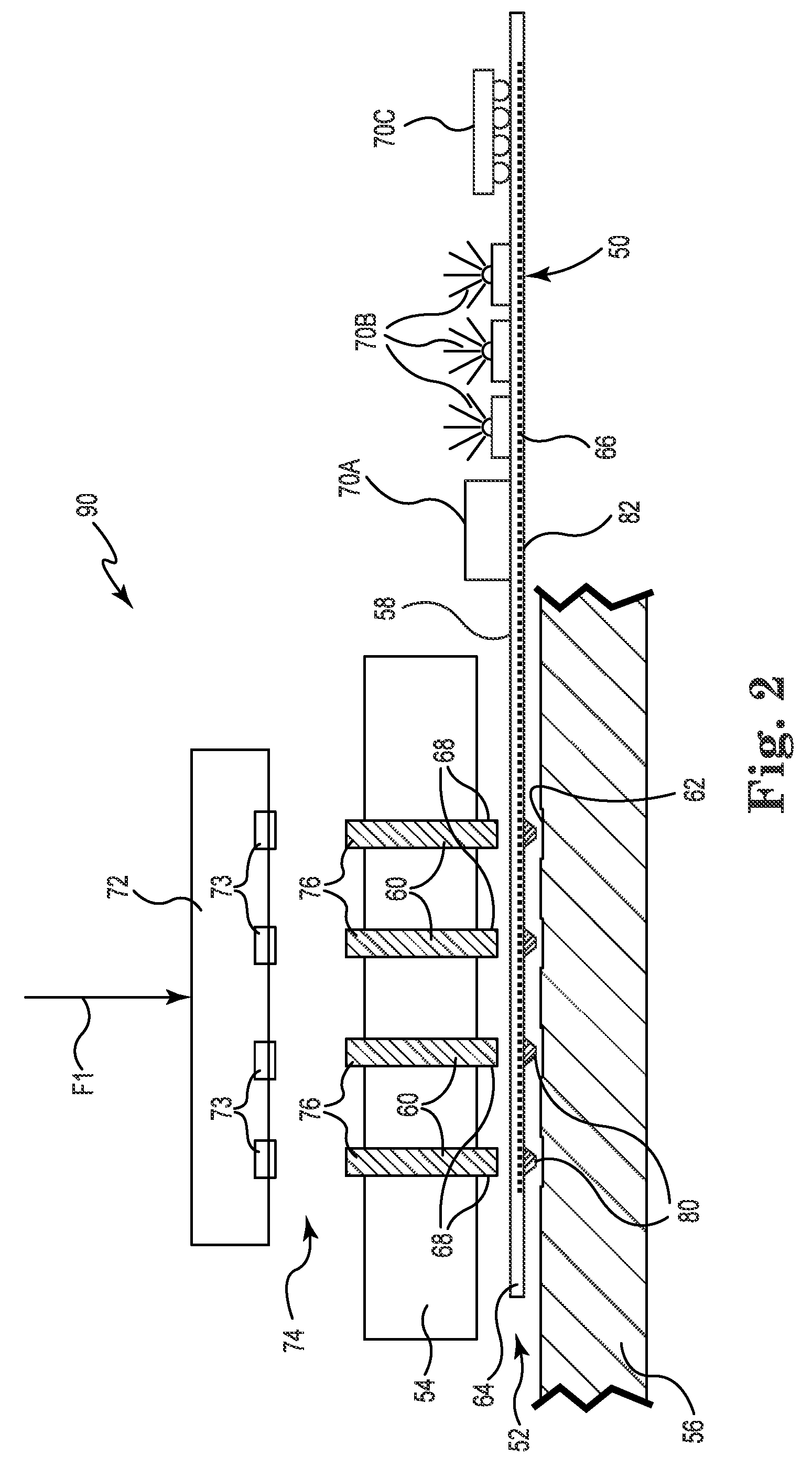

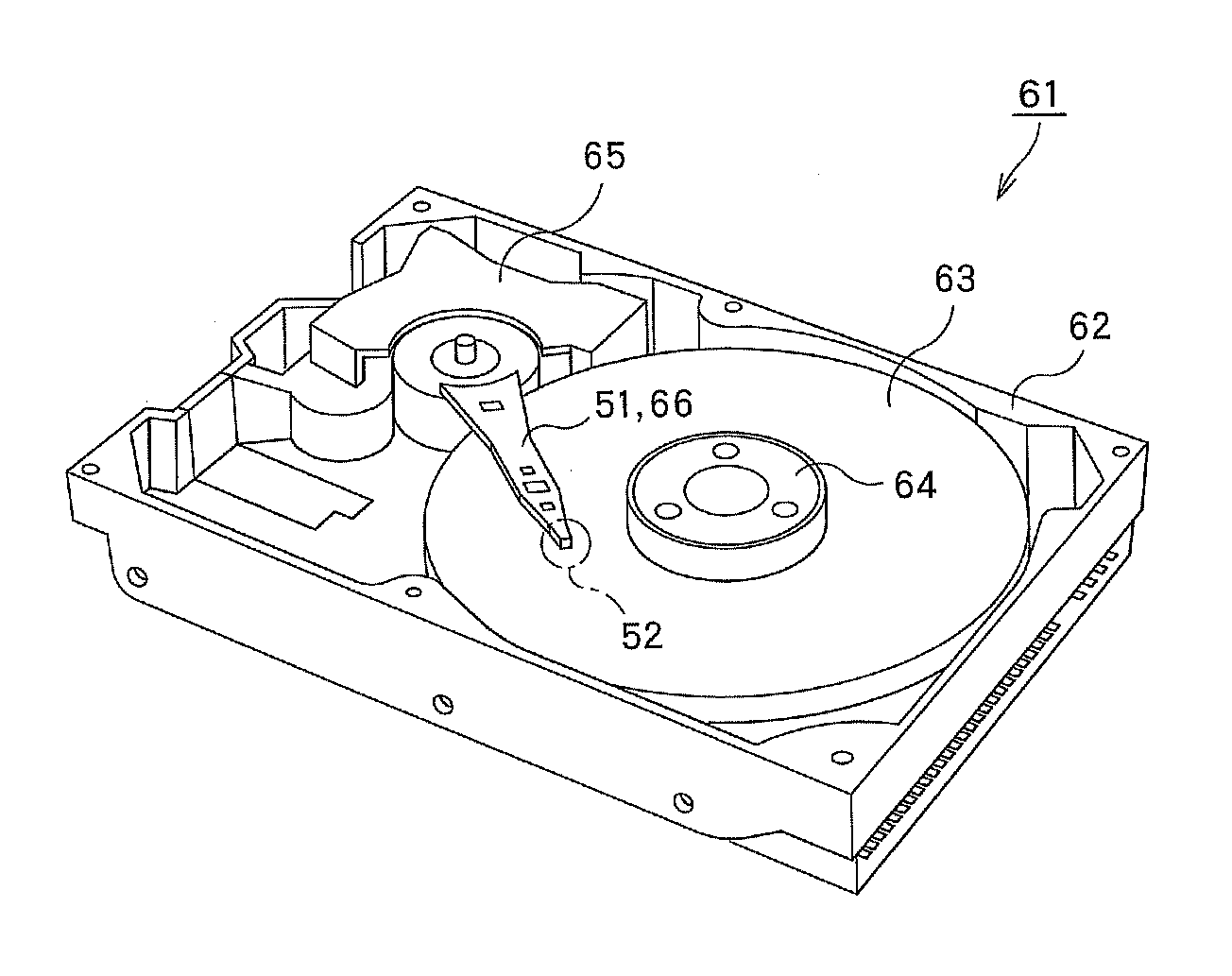

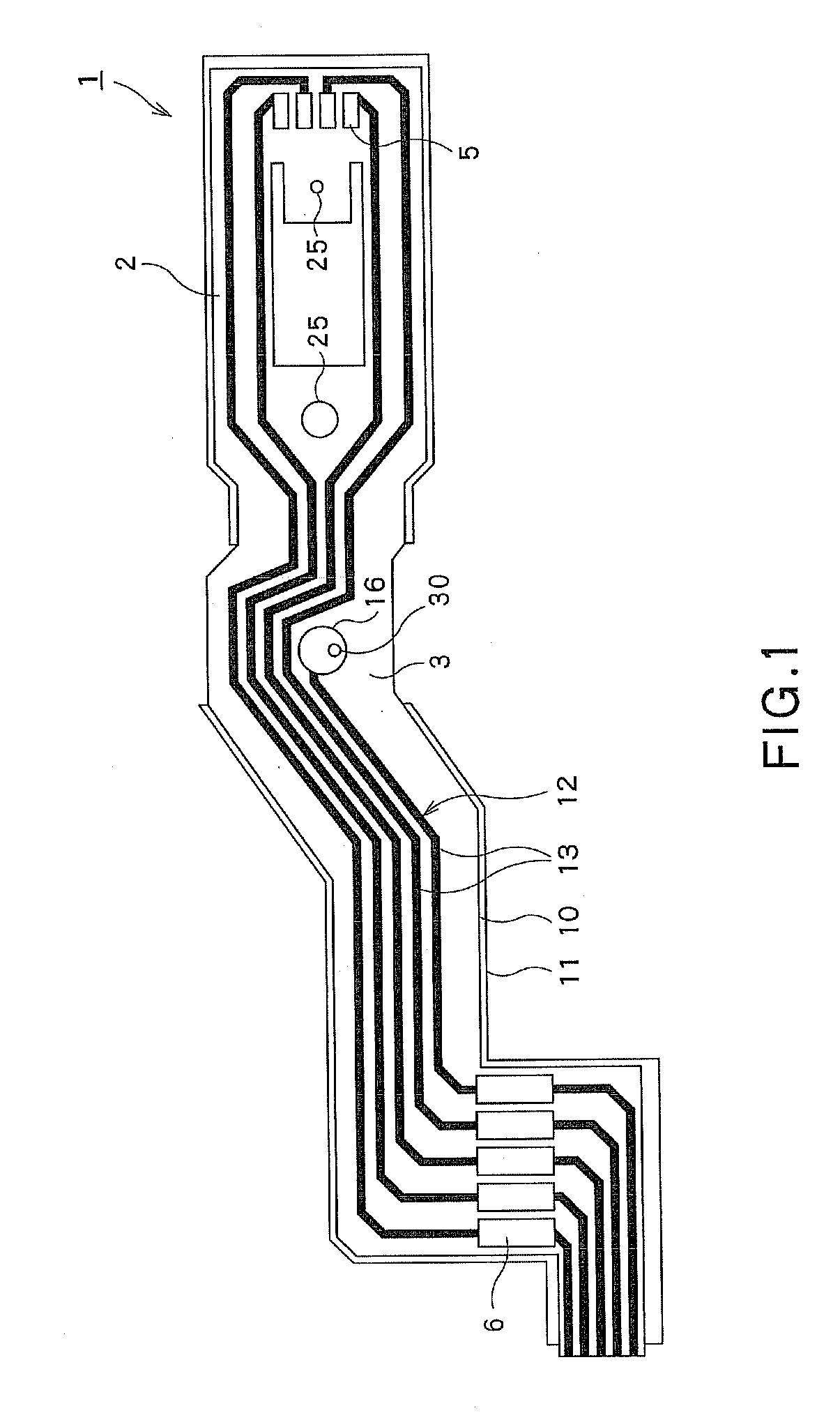

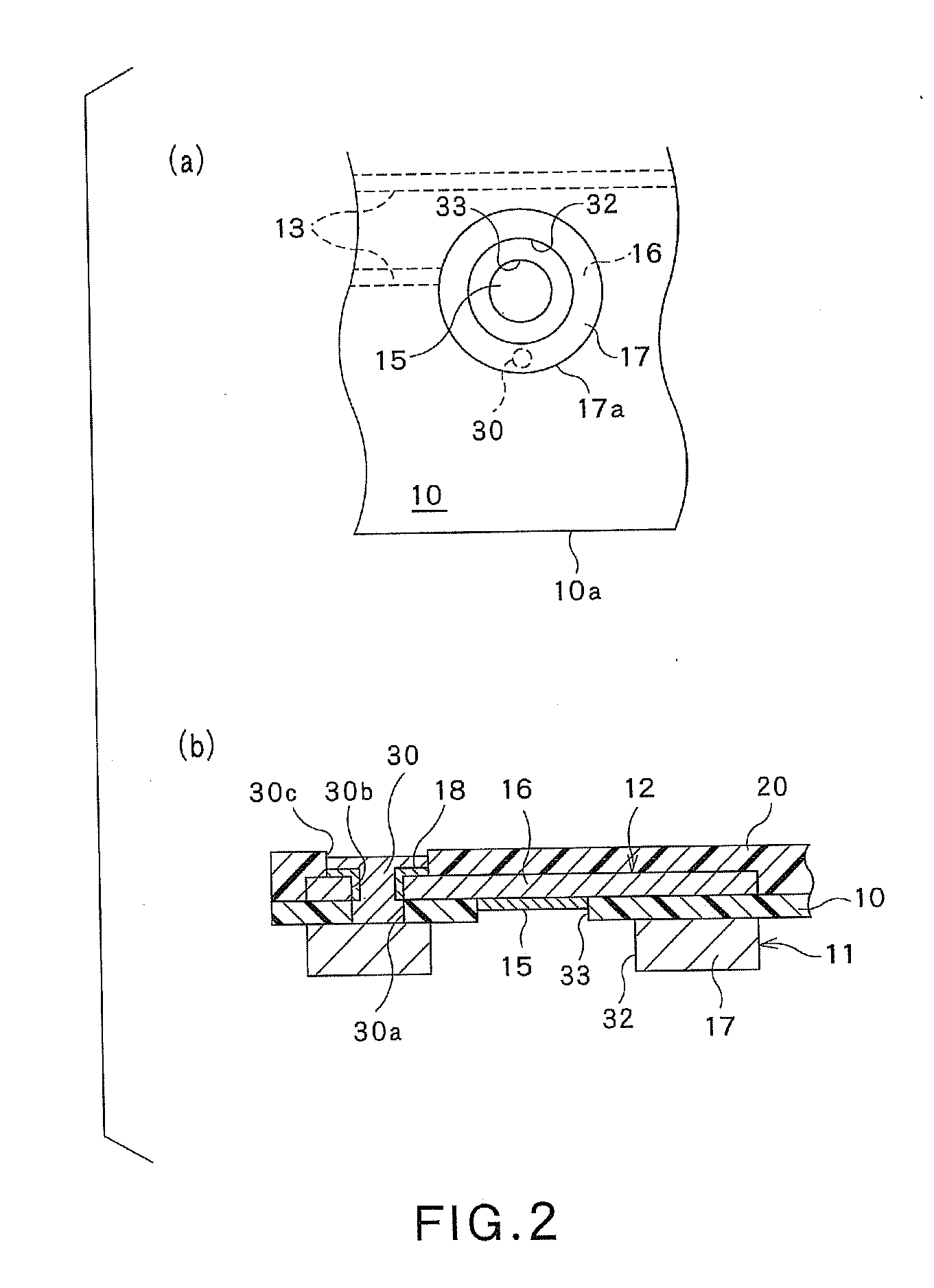

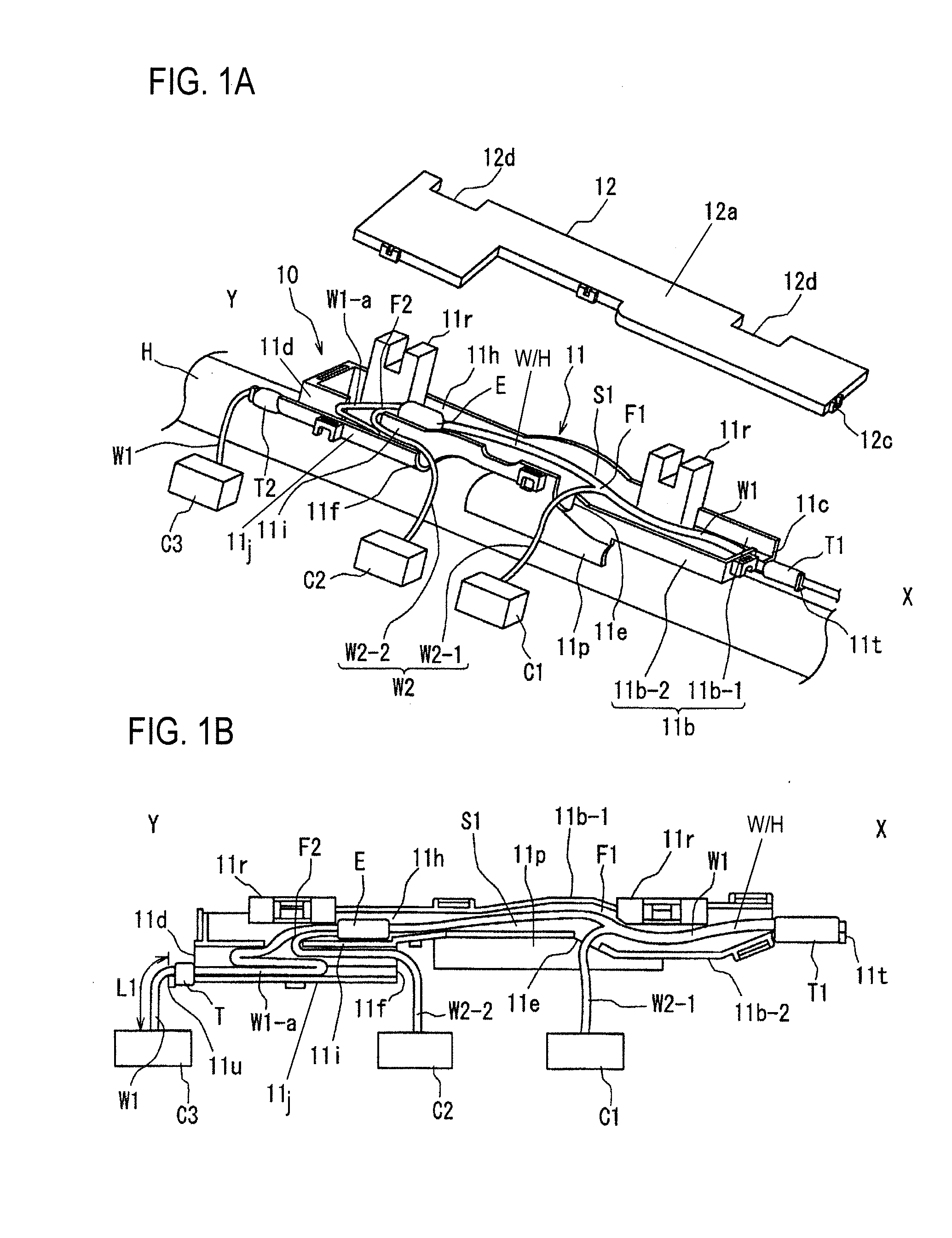

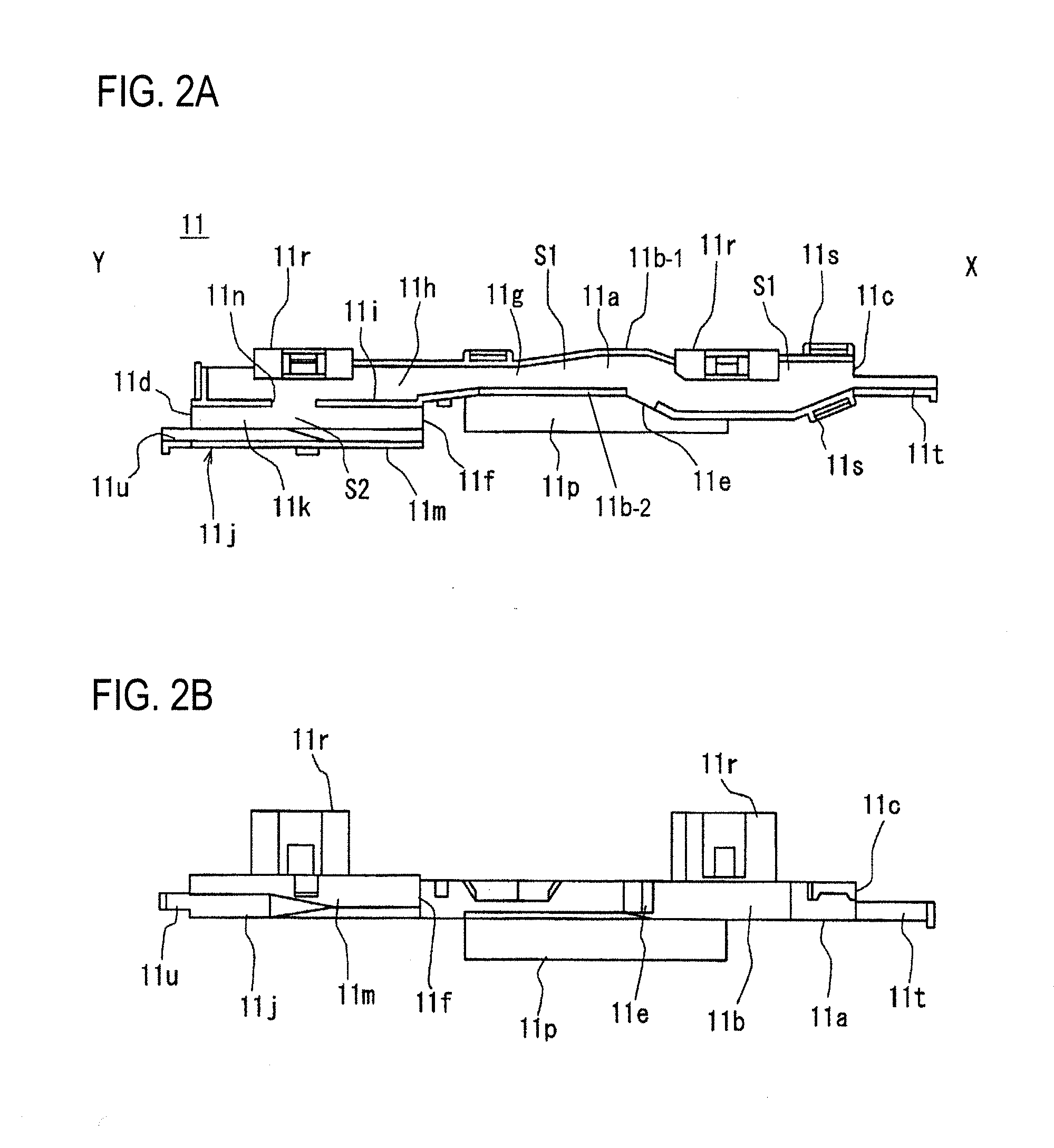

Suspension substrate, suspension, head suspension, hard disk drive, method for manufacturing suspension substrate, and method for testing continuity of suspension

InactiveUS20120014017A1Ensure electrical connection reliabilityImprove reliabilityElectronic circuit testingRecord information storageAdhesiveContinuity test

A suspension substrate according the present invention includes: an insulating layer; a metallic support layer provided on the actuator element's side of the insulating layer. A wiring layer is provided on the other side of the insulating layer. This wiring layer includes a plurality of wirings and a wiring connection section that can be electrically connected with the actuator element via a conductive adhesive. A conductive connection section extending through the insulating layer and configured to connecting the metallic support layer with the wiring connection section of the wiring layer is provided in the connection structure region.

Owner:DAI NIPPON PRINTING CO LTD

Connection verification technique

ActiveUS20070152692A1Easy to testEfficient verificationFinal product manufacturePrinted circuit aspectsElectricityContinuity test

Embodiments of the present invention are generally directed to testing connections of a memory device to a circuit board or other device. In one embodiment, a memory device that is configured to facilitate continuity testing between the device and a printed circuit board or other device is disclosed. The memory device includes a substrate and two connection pads that are electrically coupled to one another via a test path. A system and method for testing the connections between a memory device and a circuit board or other device are also disclosed.

Owner:MICRON TECH INC

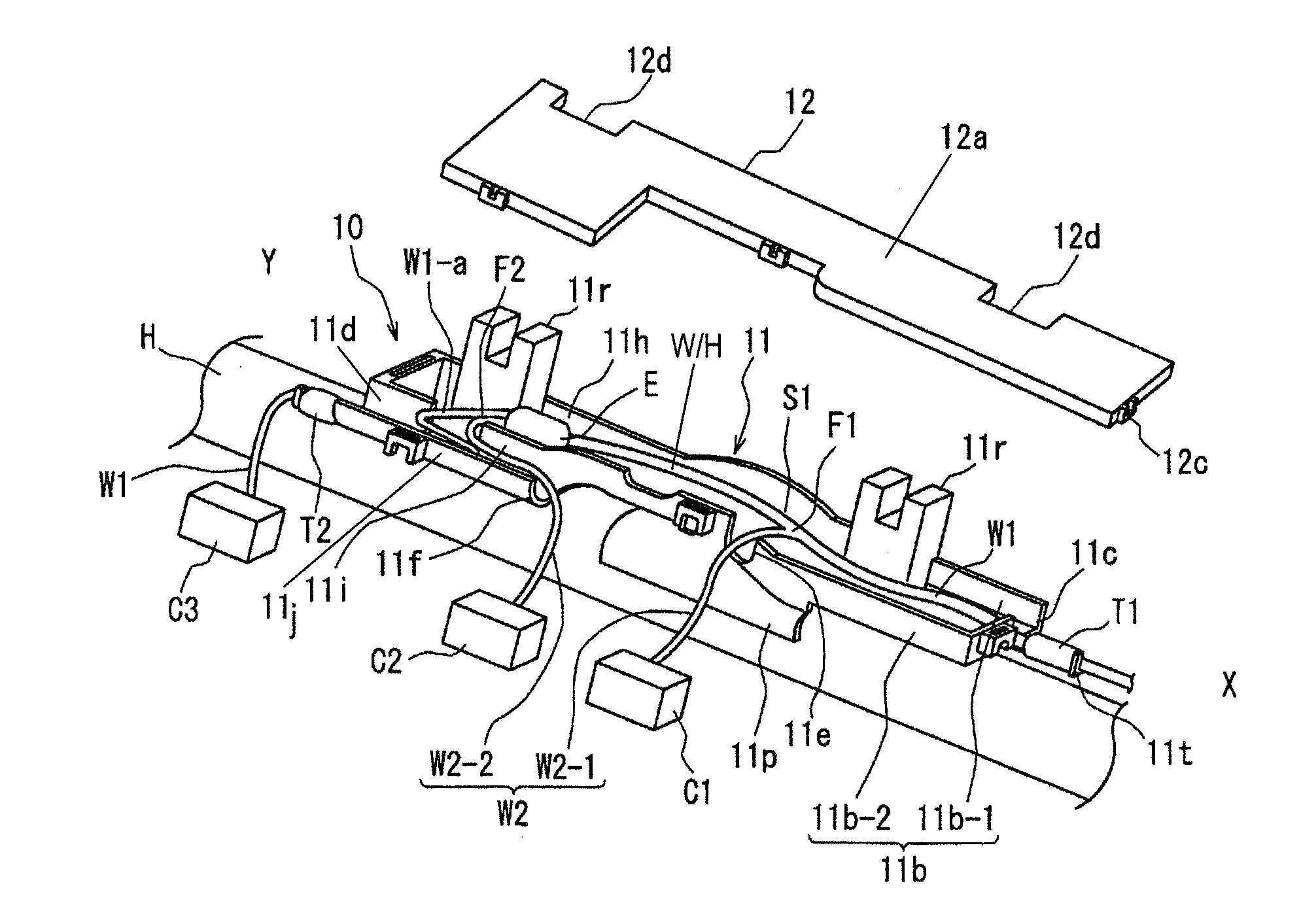

Protector for wire harness and method for fixing protector to wire harness

InactiveUS20100218976A1Increase the lengthAvoid insufficient lengthPipe supportsMeasurement/indication equipmentsContinuity testCable harness

A wire harness includes a main line and branch lines. A protector has longitudinal ends with main line inlet and outlet ports and branch line ports between the ends. Branch line connectors are connected to the branch lines drawn out of the branch line ports. A main line connector is connected to the main line drawn out of the main line outlet port. The branch line connectors and the main line connector are connected to test connectors for a continuity test. Lengths of the branch lines and / or the main line are greater than required in the motor vehicle so that the main line and branch line connectors are connected to the test connectors. A wire additional length containing space is provided in the protector and communicates with the branch line ports and / or with the line outlet port for the lines having the additional lengths.

Owner:SUMITOMO WIRING SYST LTD

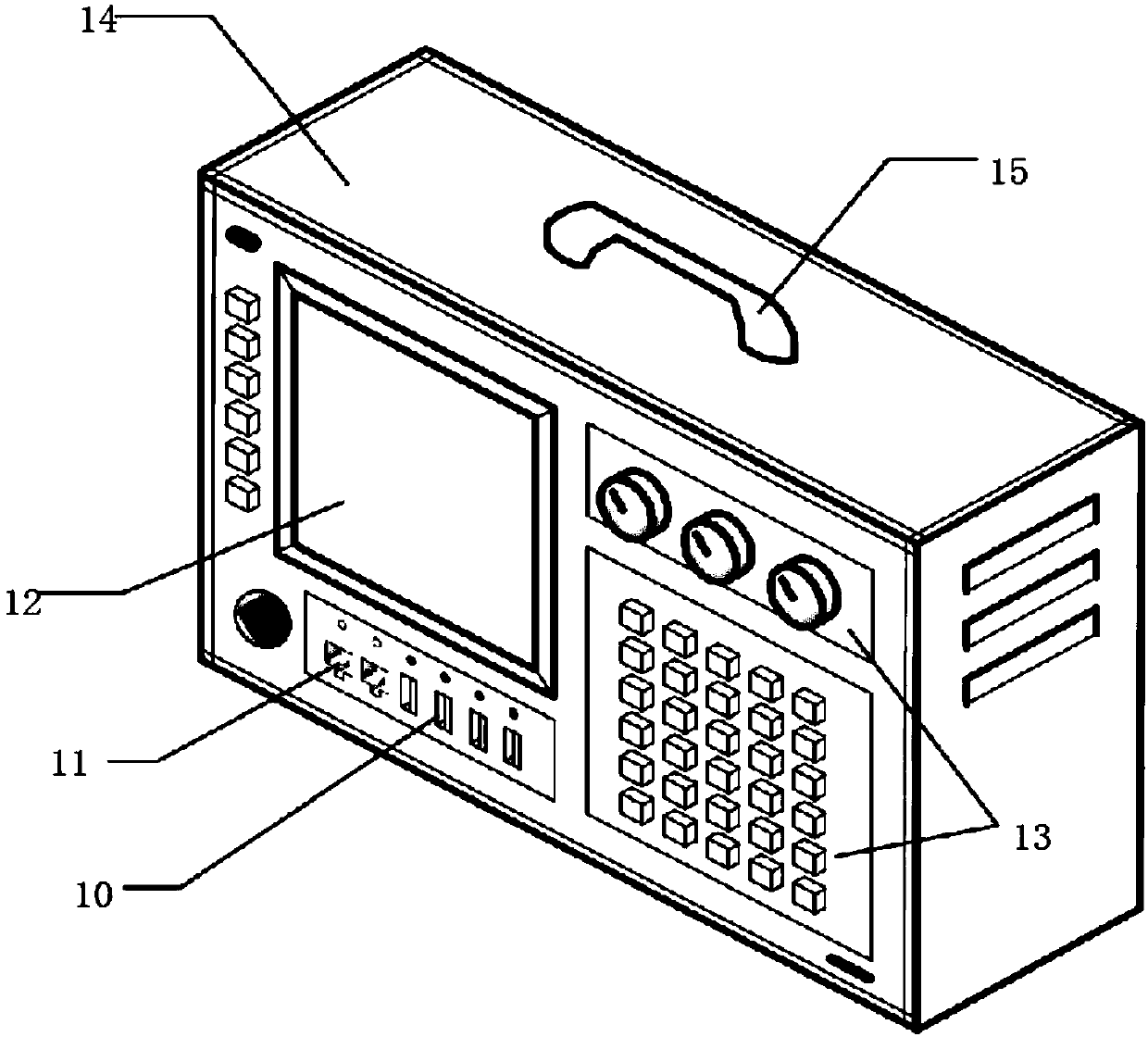

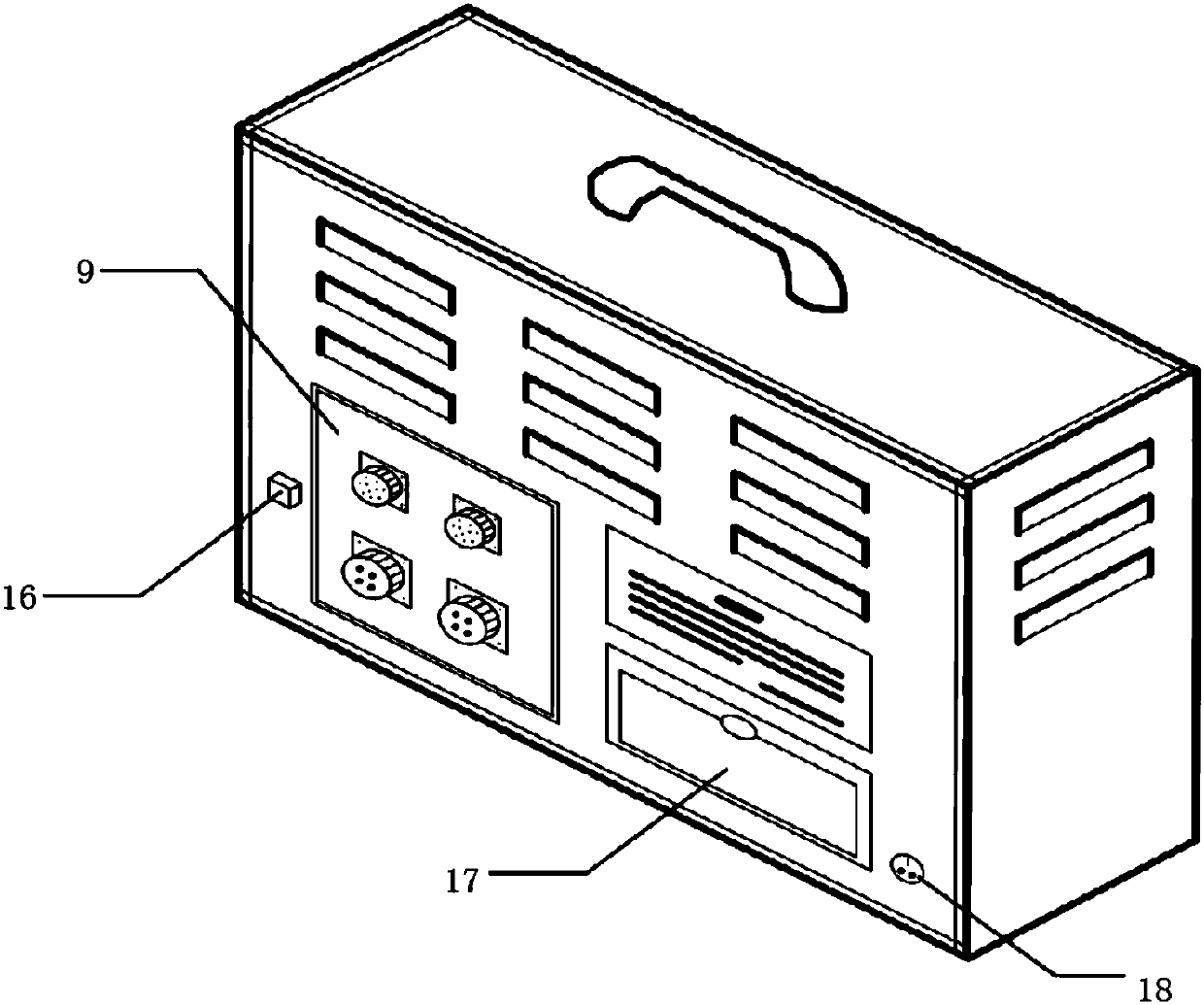

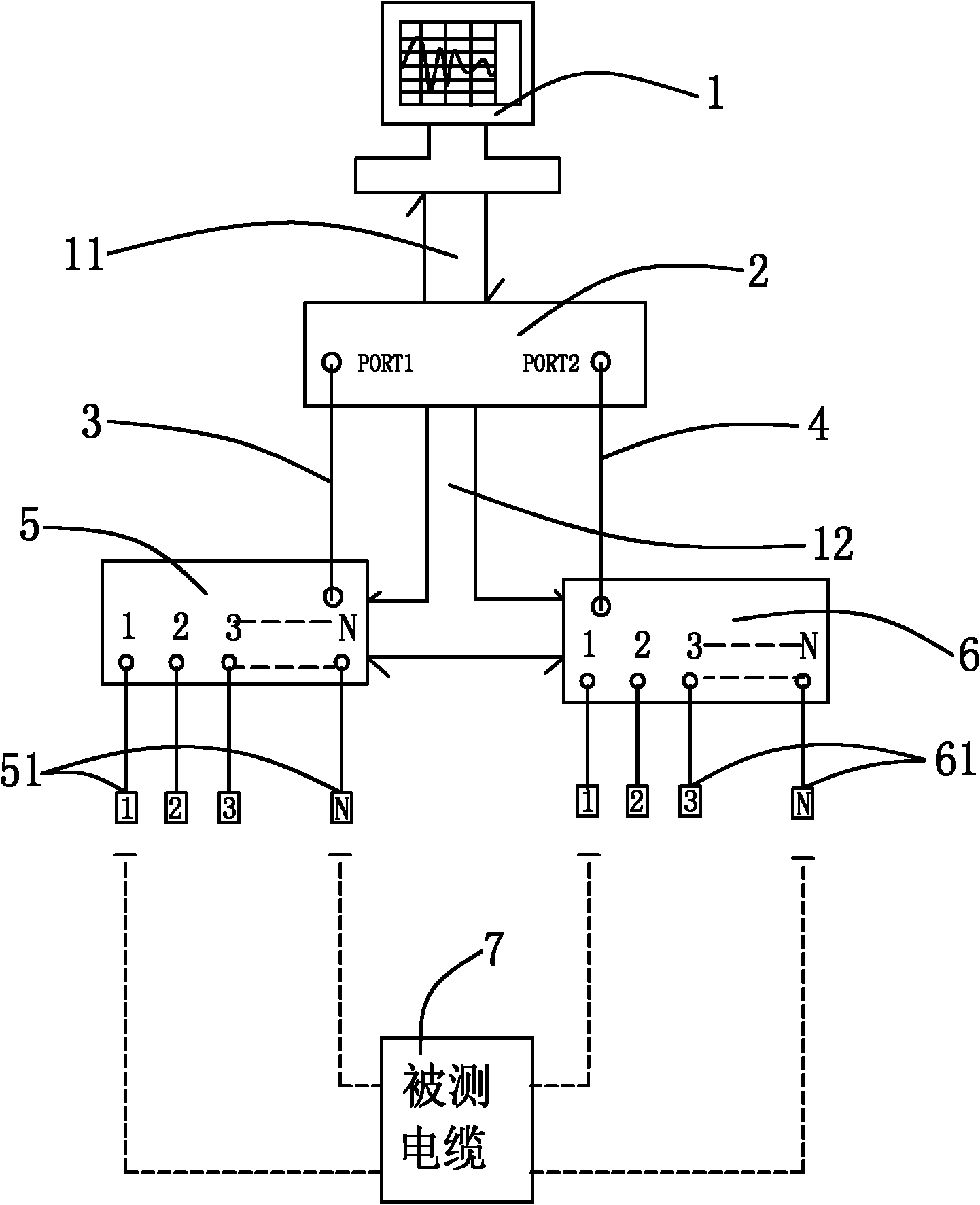

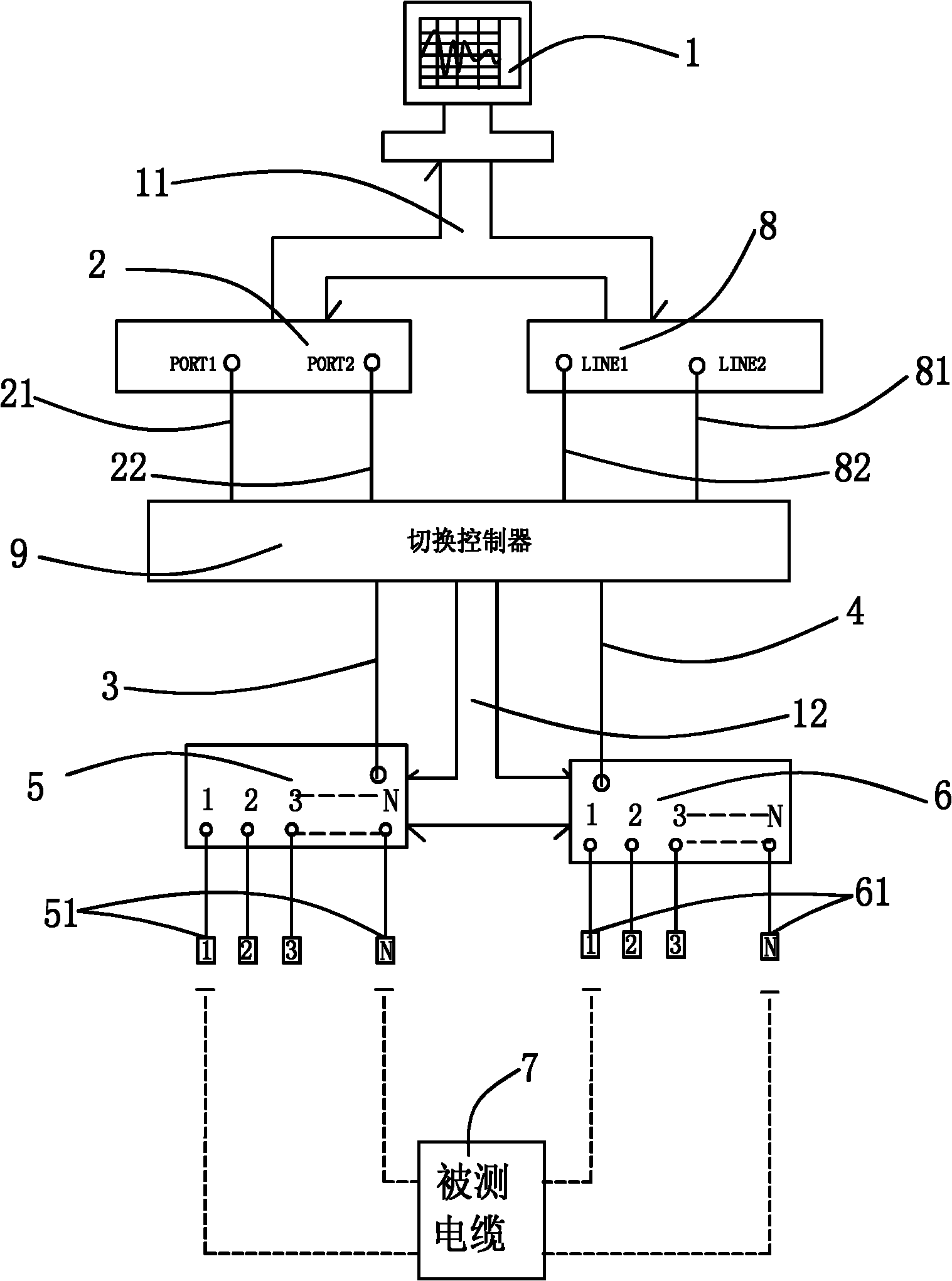

Portable multifunctional aerospace cable detection instrument and method

PendingCN107728007AImprove test efficiencyReduce labor intensityFault location by conductor typesDisplay deviceContinuity test

The invention provides a portable multifunctional aerospace cable detection instrument and method, and belongs to the field of automated instruments. The detection instrument includes external USB interfaces, an Ethernet interface, and a liquid crystal display linked computer; the computer is connected with a digital input / output module, an insulation resistance detection module, a continuity testmodule, a four-wired resistor detection module, a dielectric strength test module and an input equipment through USB interfaces; the digital input / output module, the insulation resistance detection module, the continuity test module, the four-wired resistor detection module and the dielectric strength test module are connected with a test unit adapter through a relay matrix module. The method includes the steps of obtaining the cable test state, the electrical element test state and the calibration state. The automated test process is achieved through computer control, integration of varioustest functions is achieved, the test efficiency is improved, and the labor intensity is reduced. A shell case is designed to be miniaturized, lightweight and portable, a handle is arranged, and the detection instrument is easy to carry.

Owner:航天科工哈尔滨风华有限公司

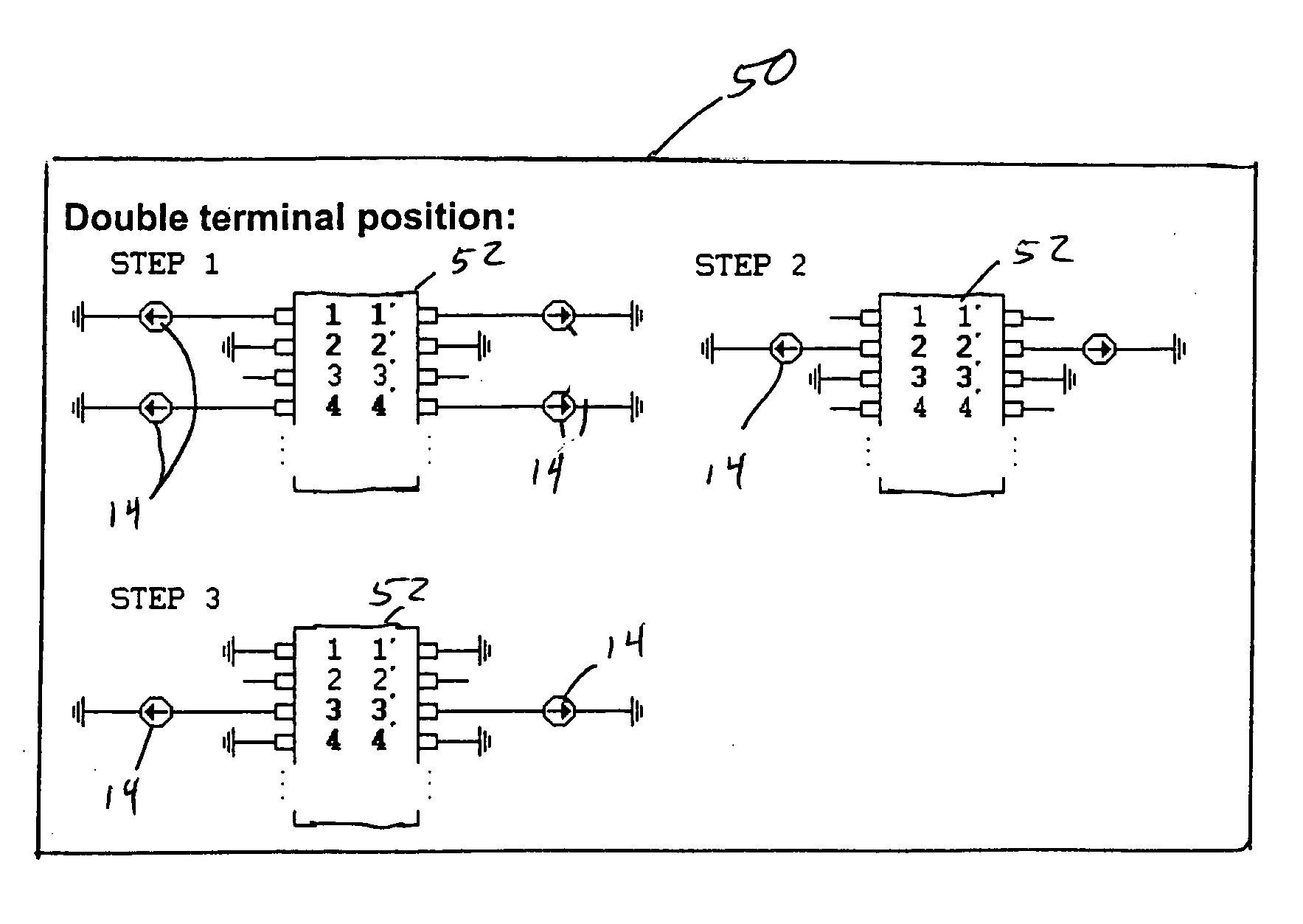

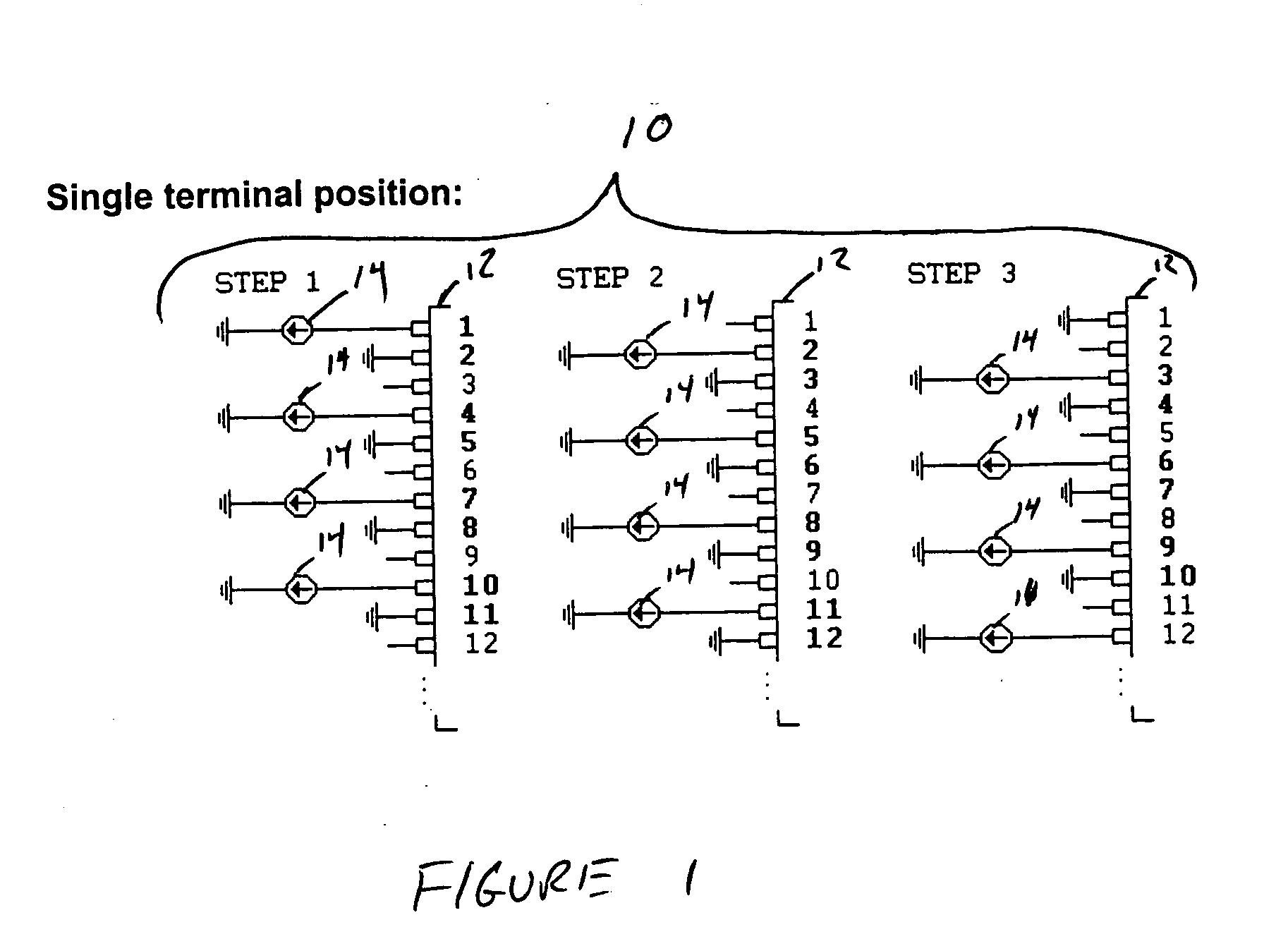

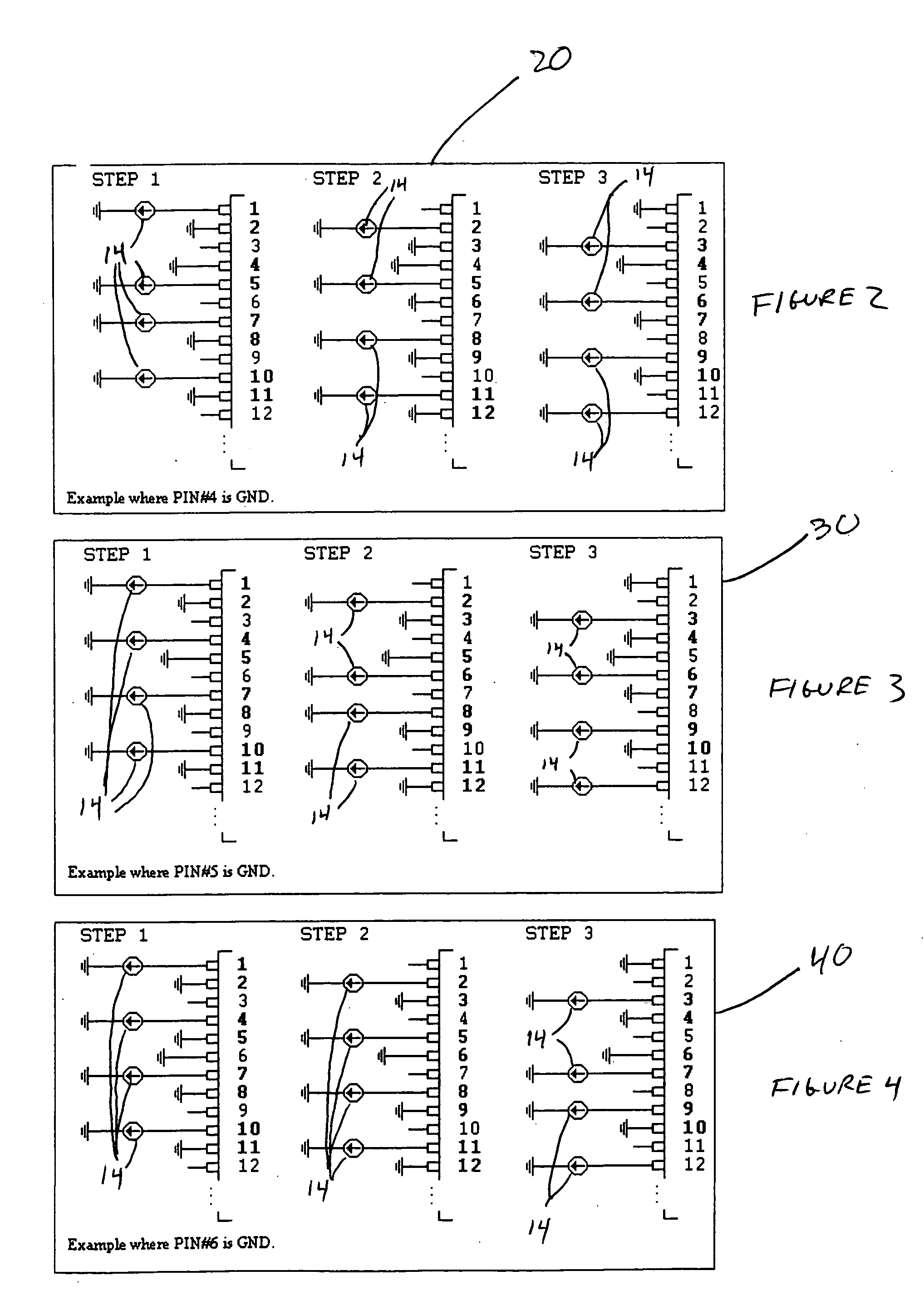

Simultaneous pin short and continuity test on IC packages

ActiveUS20050134301A1Reduce processElectronic circuit testingIndividual semiconductor device testingEngineeringContinuity test

An integrated circuit functionality test determining shorts between adjacent pins of all the IC pins while simultaneously determining pin continuity in only three steps. The process includes categorizing all pins of the IC into three sets of pins. One set of pins is connected to digital instruments, a second set of pins is connected to 0 volts, and a third set of pins is left open. The digital instruments sink current in parallel from the first set of pins to identify any shorts of the first set of pins. The process is repeated for each of the other two sets of pins. For IC packages having double and quad terminal positions, each terminal position is treated like a single terminal position, and the measurements of the respective sets of pins of each terminal position is measured in parallel.

Owner:TEXAS INSTR INC

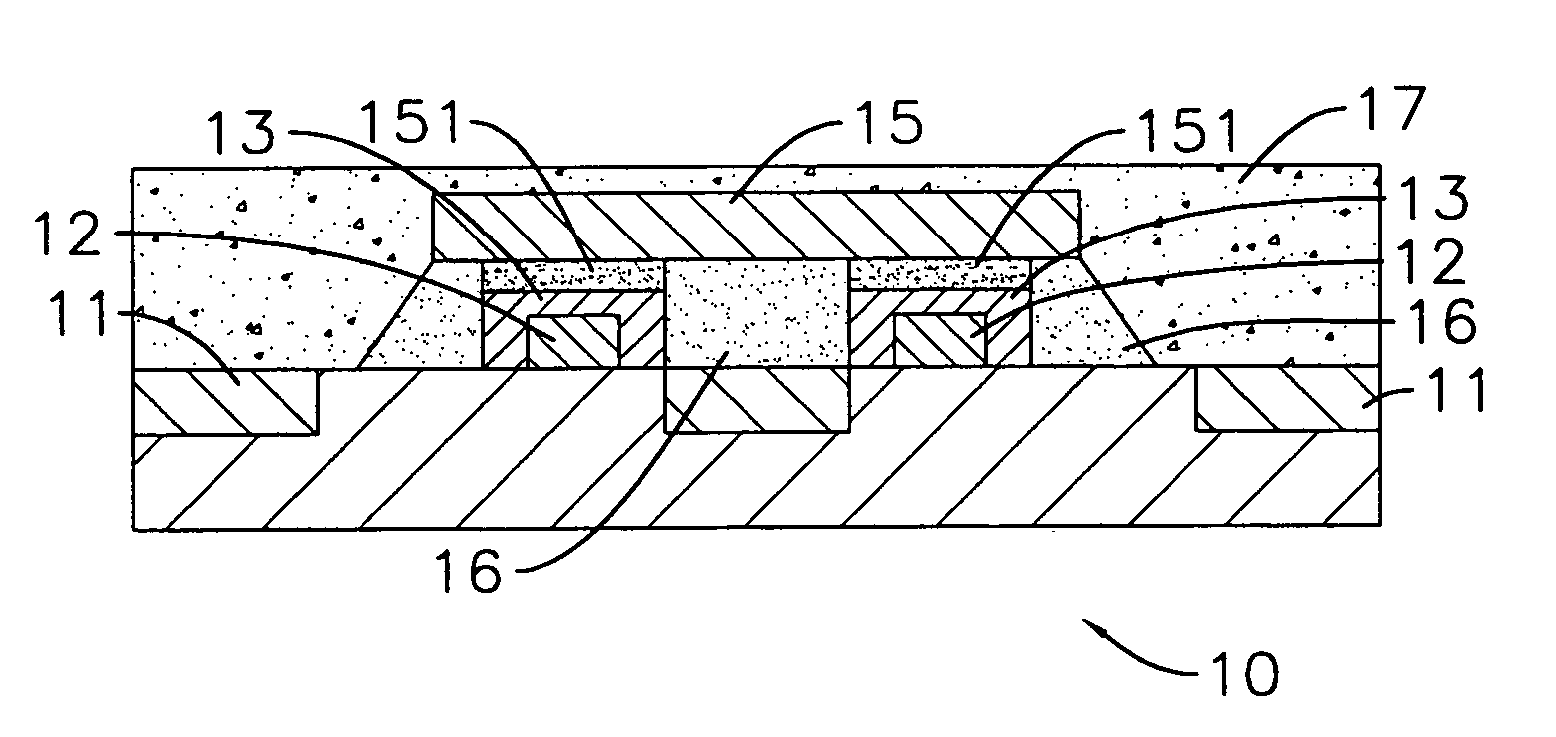

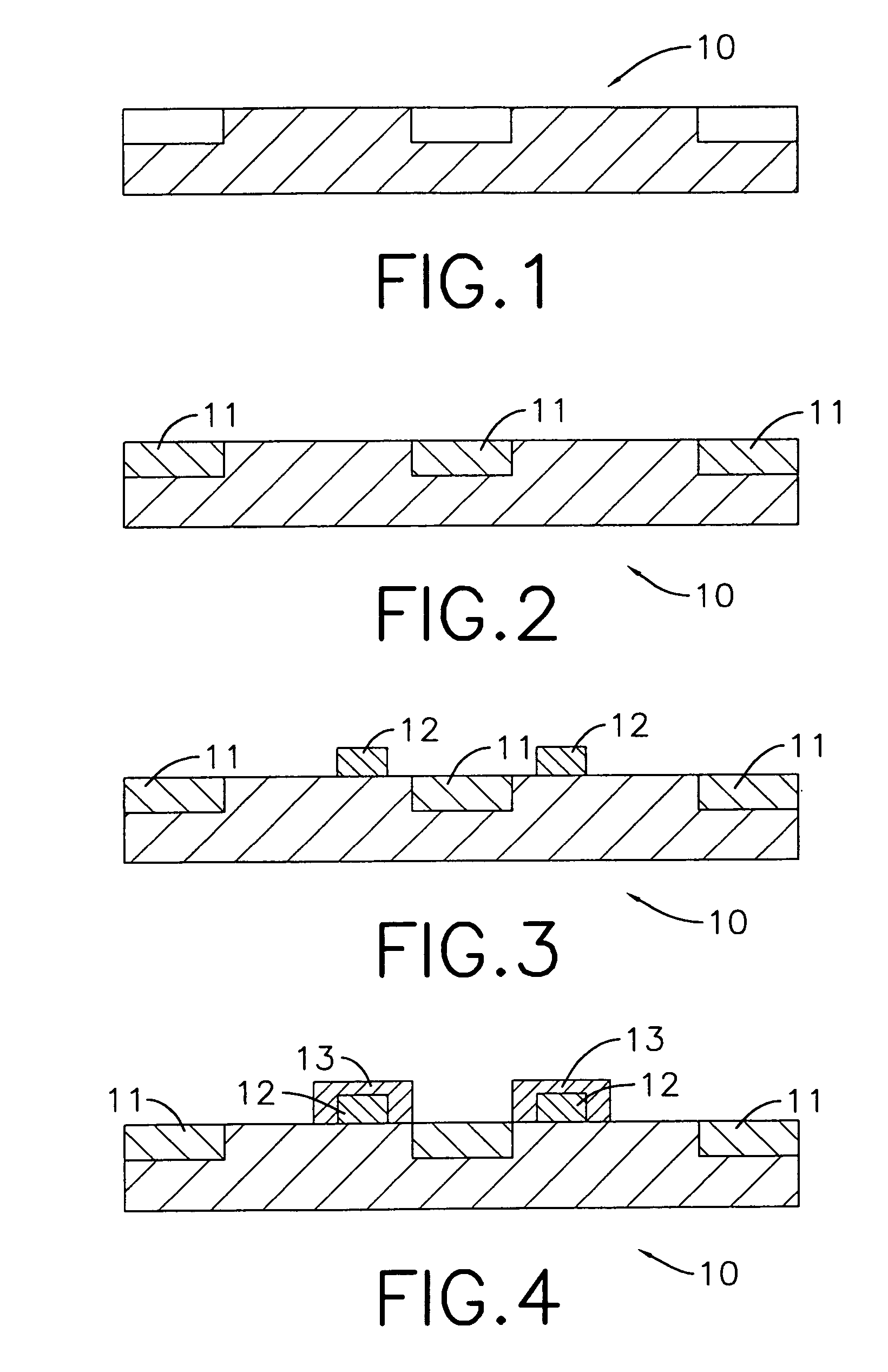

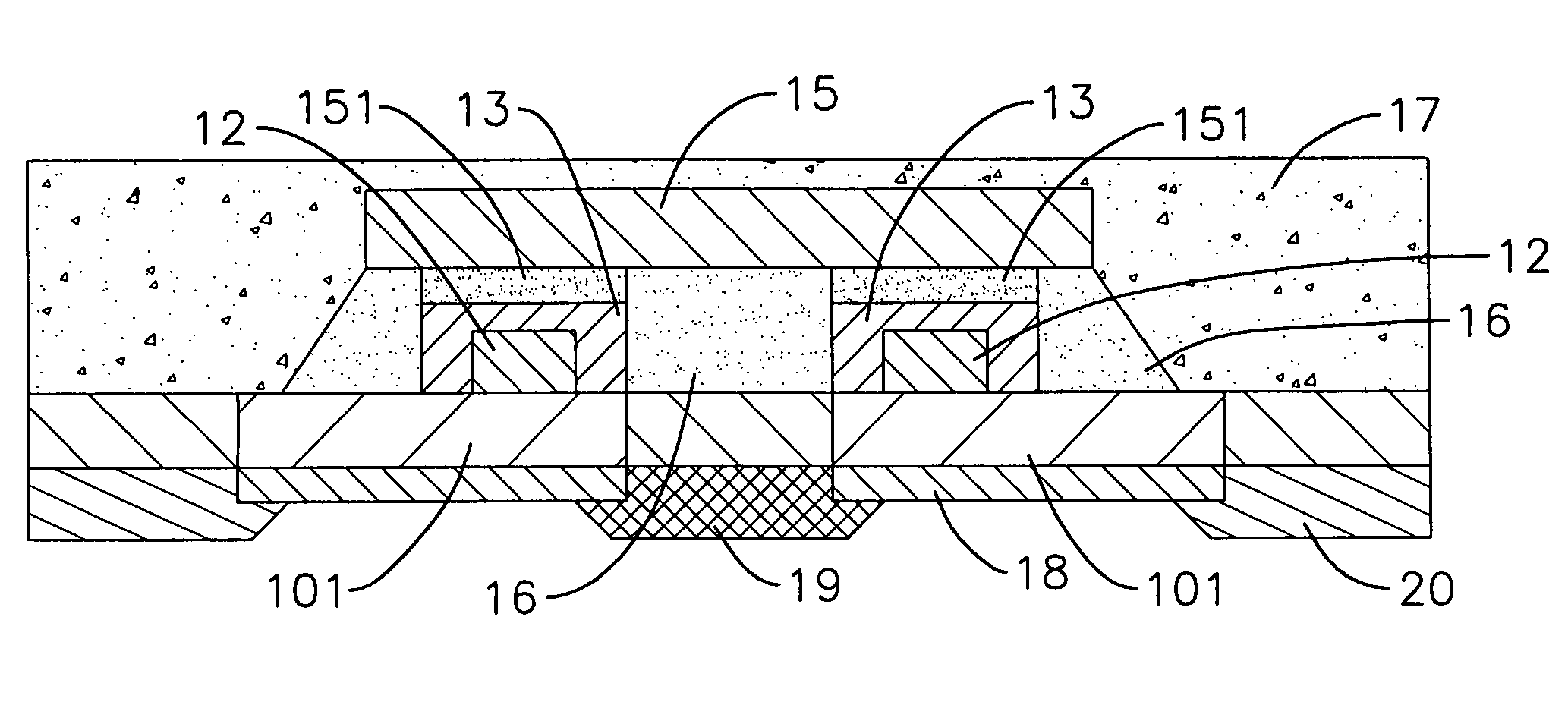

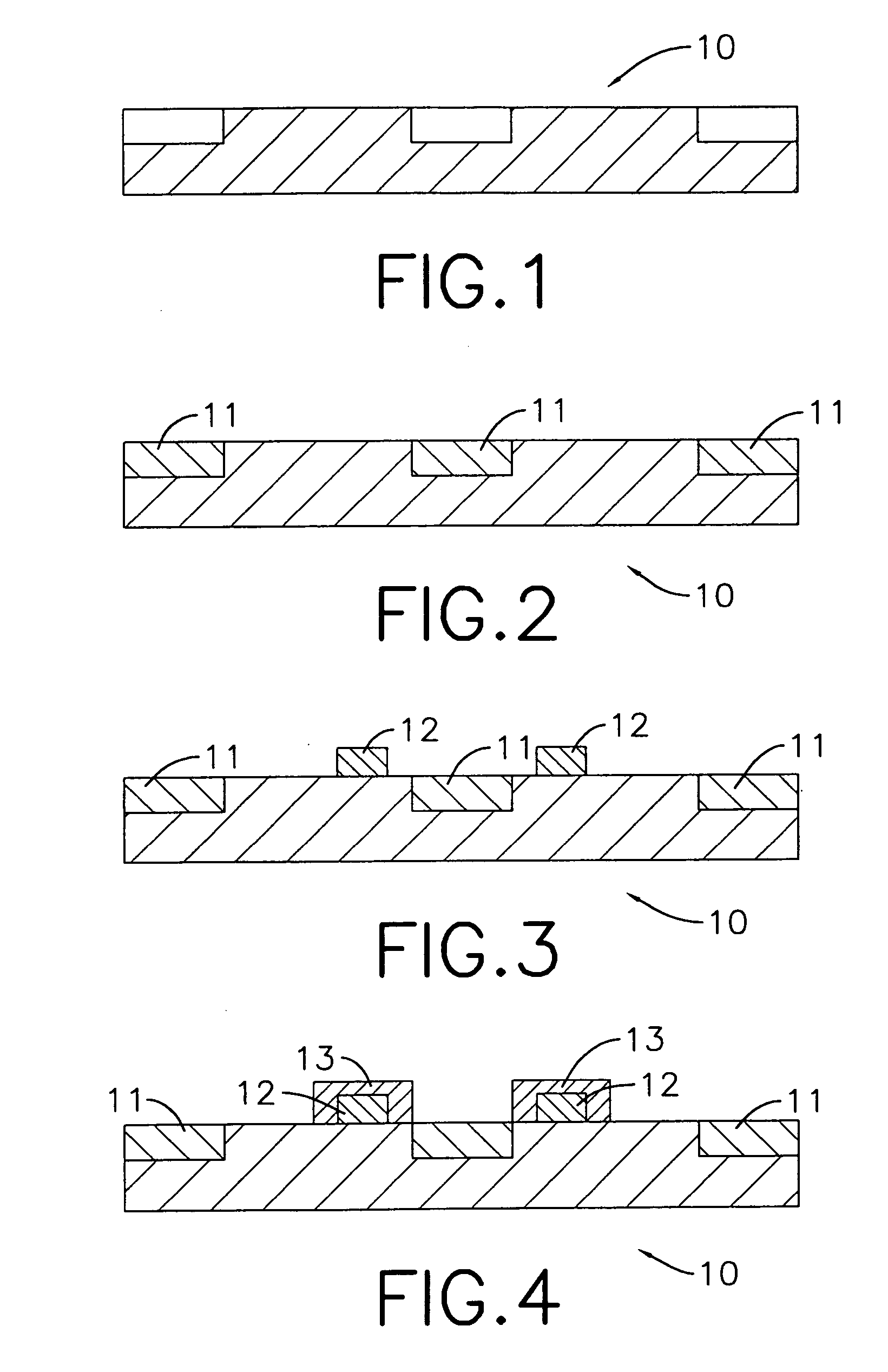

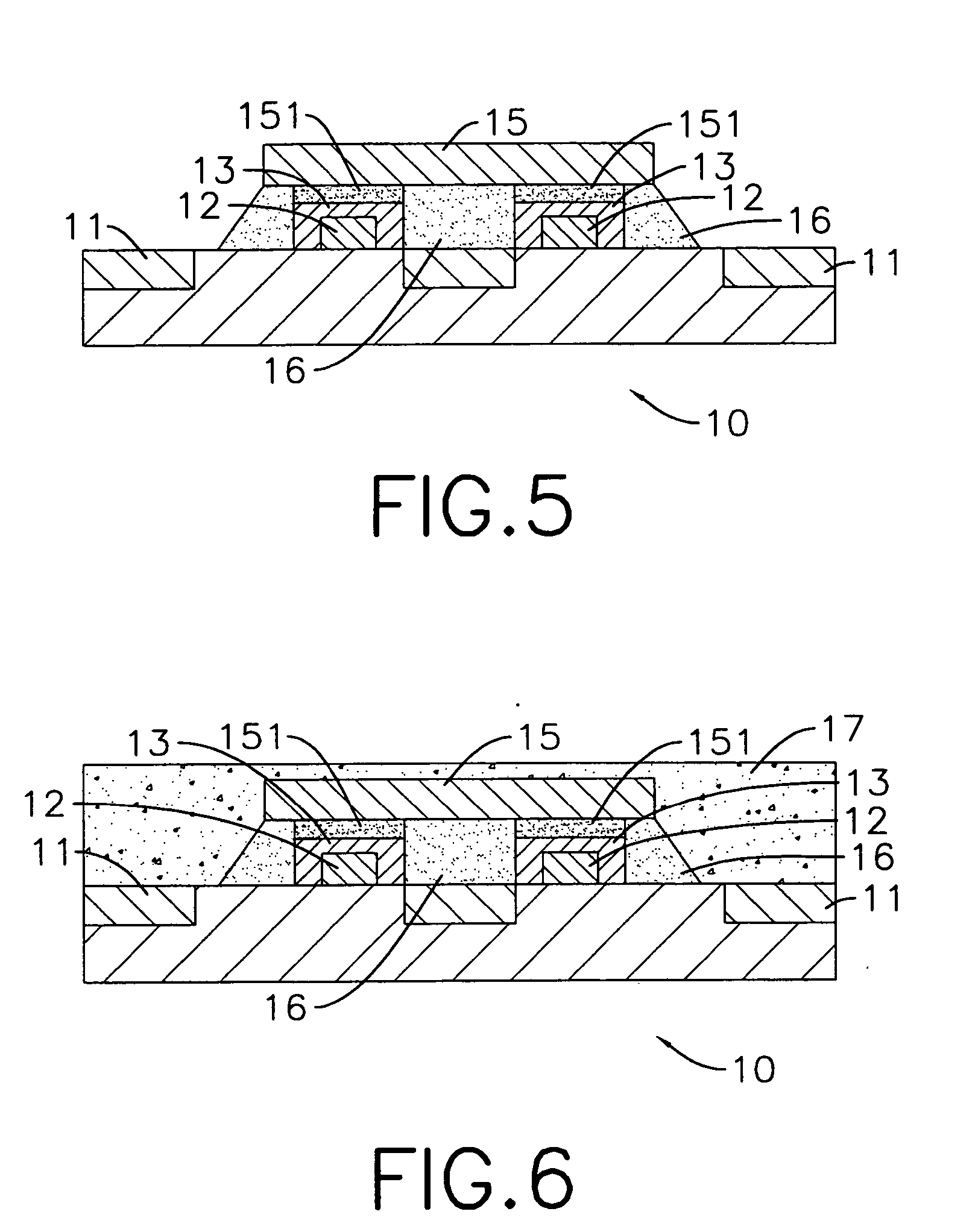

Packaging method for an electronic element

InactiveUS20060084191A1Improve productivityLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsResistHigh density

A packaging method for an electronic element has: etching portions of a top surface of a metal board to form recesses between raised unetched segments and filling the recesses with a dielectric material of high density polymer; forming multiple solder balls respectively on the raised unetched segments; coating the solder balls with a thin flux layer; bonding contacts on a die respectively to the solder balls with the thin flux layer; injecting an encapsulant between the die and the metal board; sealing the die with an outer encapsulant; etching a bottom surface of the metal board to form multiple metal leads; coating the bottom surface of the metal board other than the metal leads with a solder resist; and conducting a continuity test. The solder balls are not formed directly on the fragile die so the packaging method can be used with any types of dies and has a good applicability.

Owner:MUTUAL PAK TECH

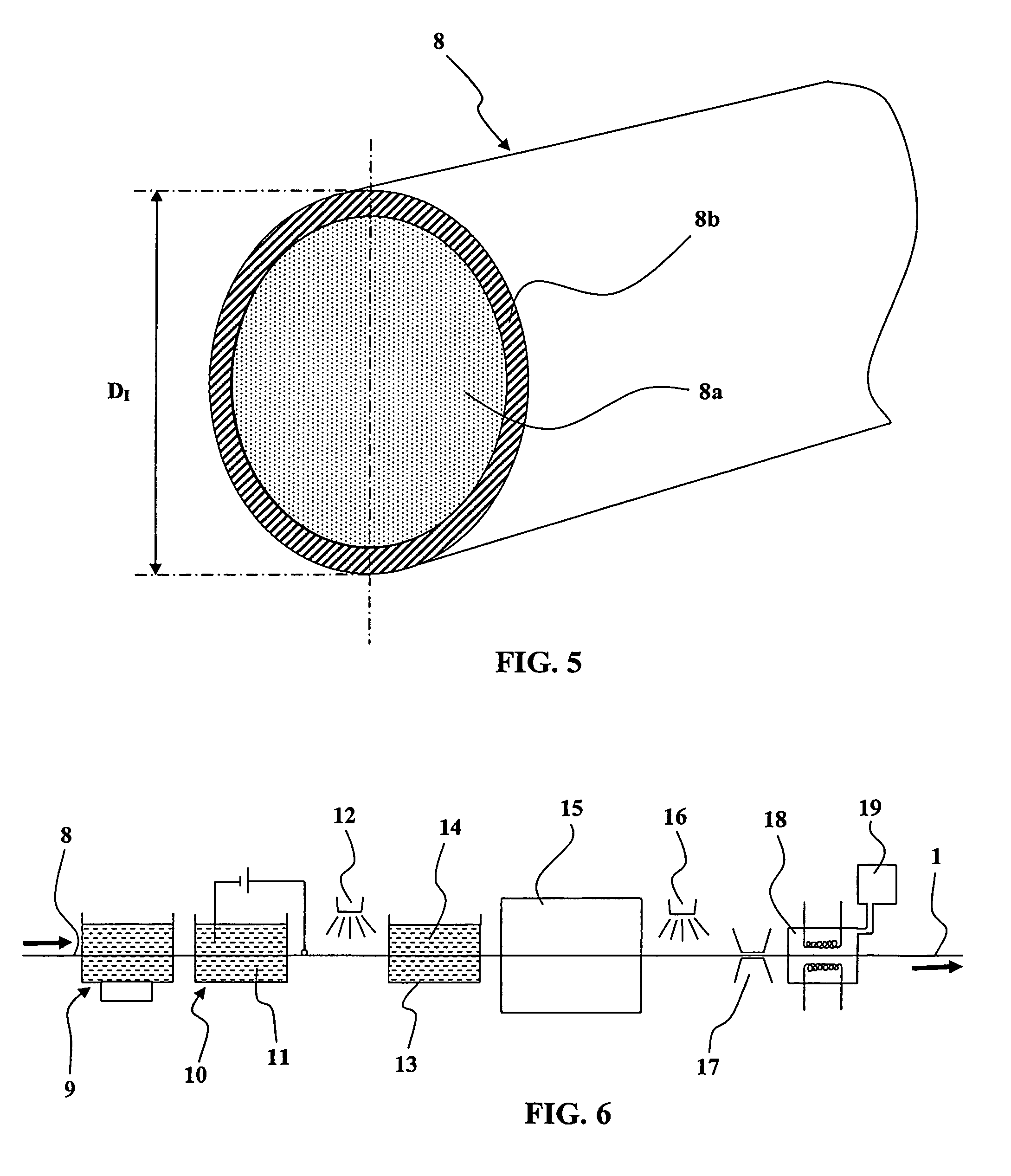

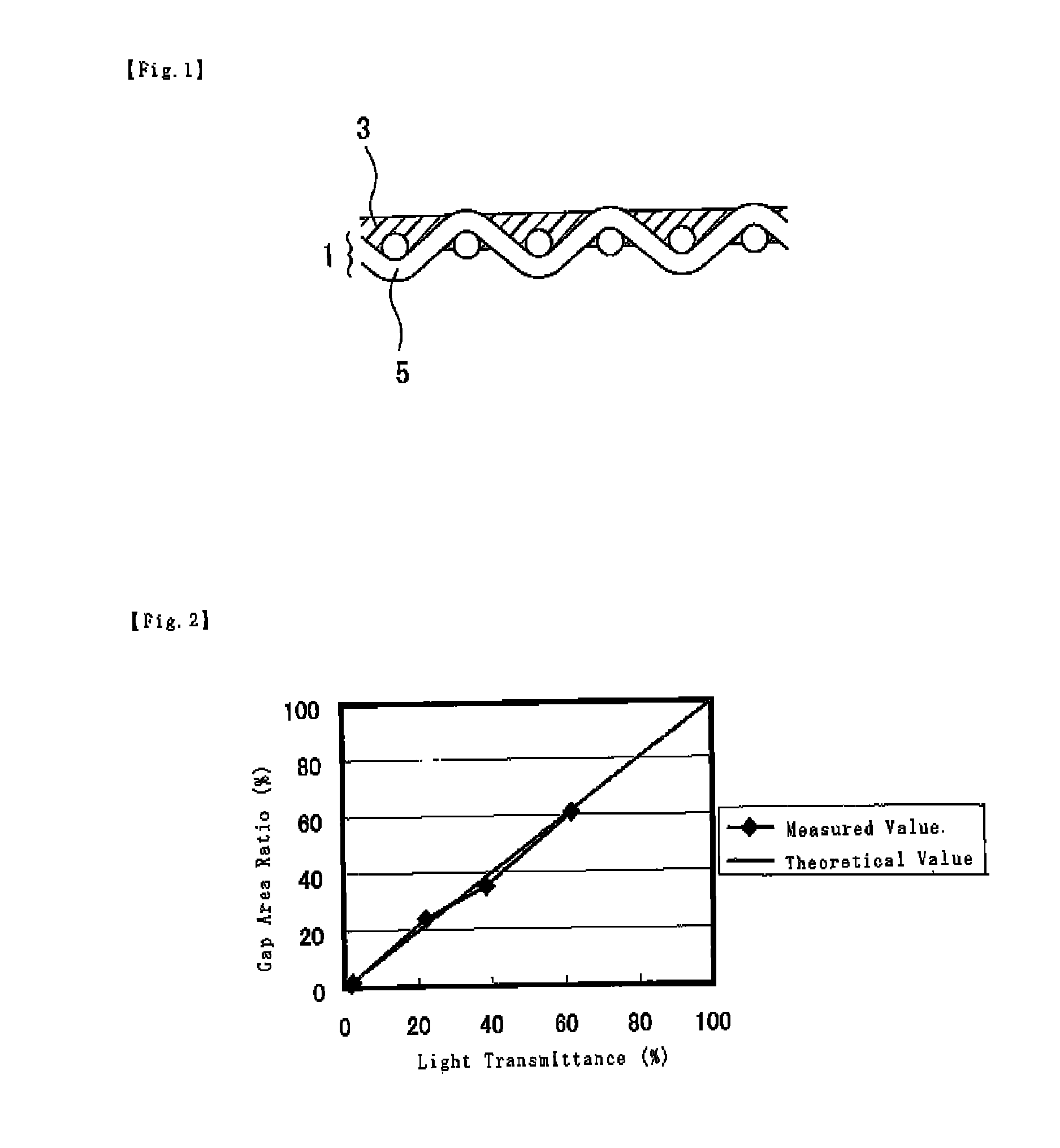

Stranded copper-plated aluminum cable, and method for its fabrication

ActiveUS7105740B2Low resistivityGood flexibilityConductive materialPower cables for overhead applicationElectricityCopper plating

Aluminum cable type electrical conductor having at least one stranded conductor based on conductive wires with an aluminum core coated with an intermediate layer of copper itself coated by a surface layer of nickel. The surface layer of nickel has a thickness from about 1.3 μm to about 3 μm, it has sufficient continuity to resist a polysulfide bath continuity test for at least 30 seconds without visible traces of attack of the copper appearing at ×1O magnification. This kind of conductor is particularly suitable in small diameters for conducting electricity in aircraft and motor vehicles.

Owner:F S P.-1

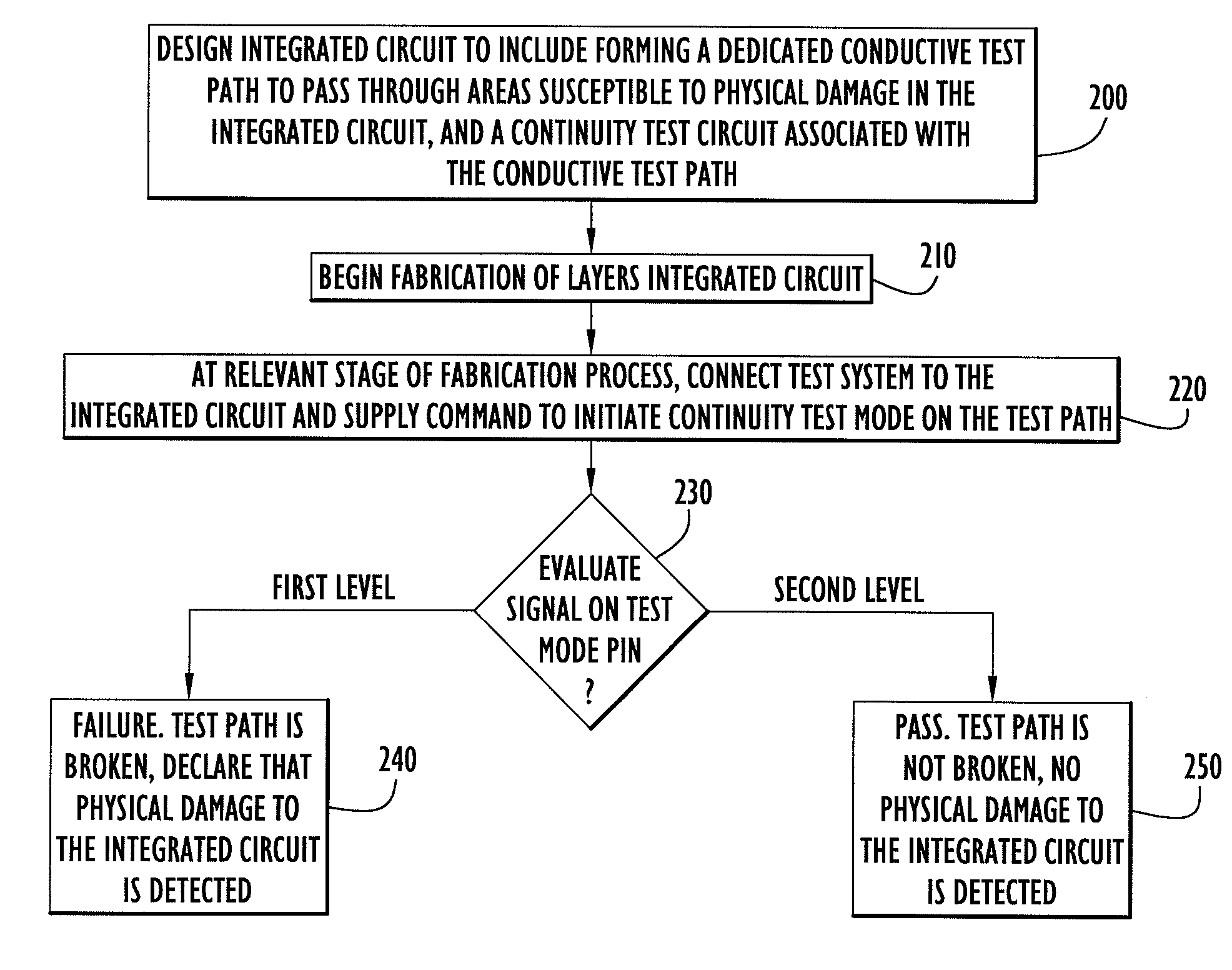

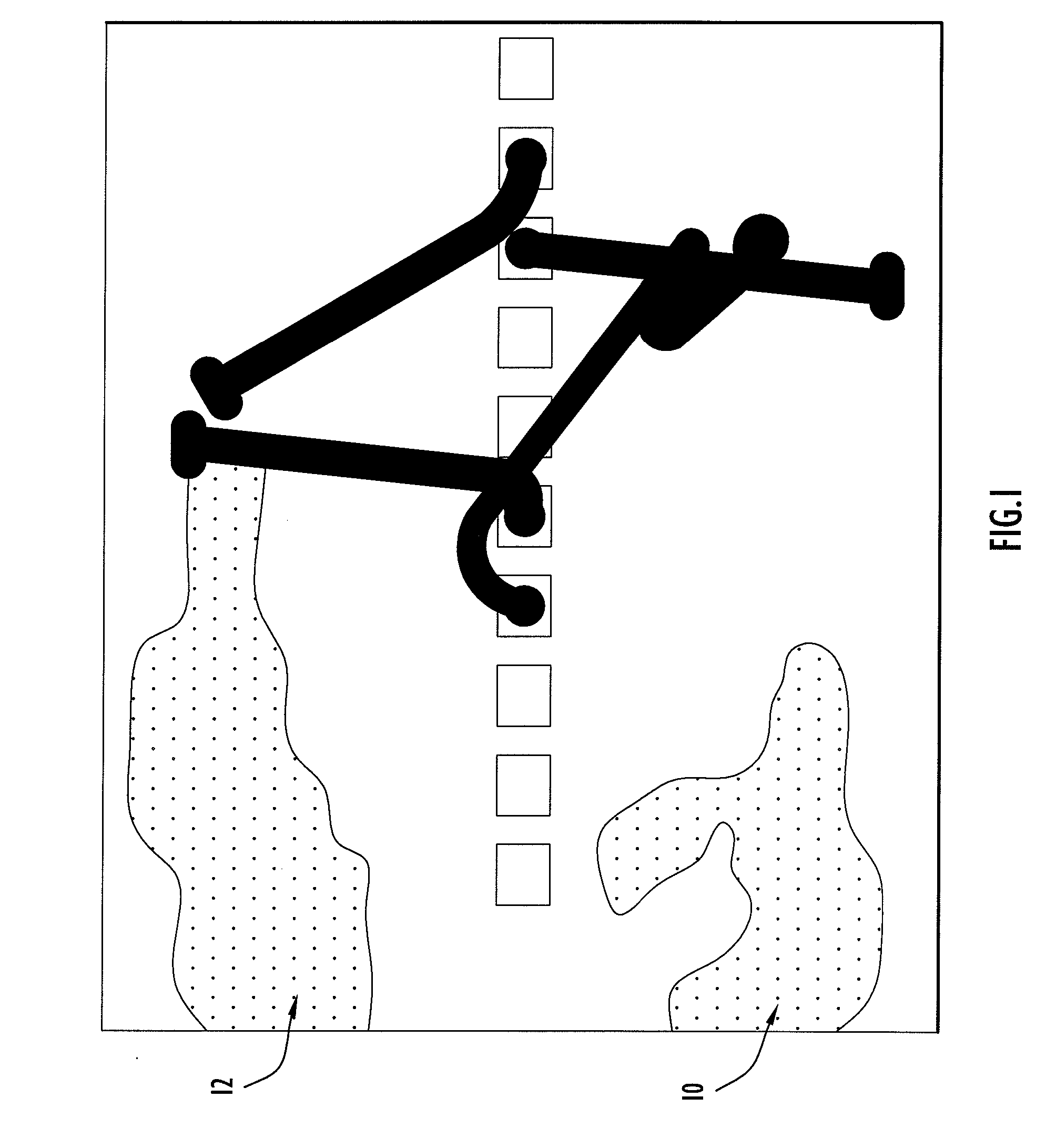

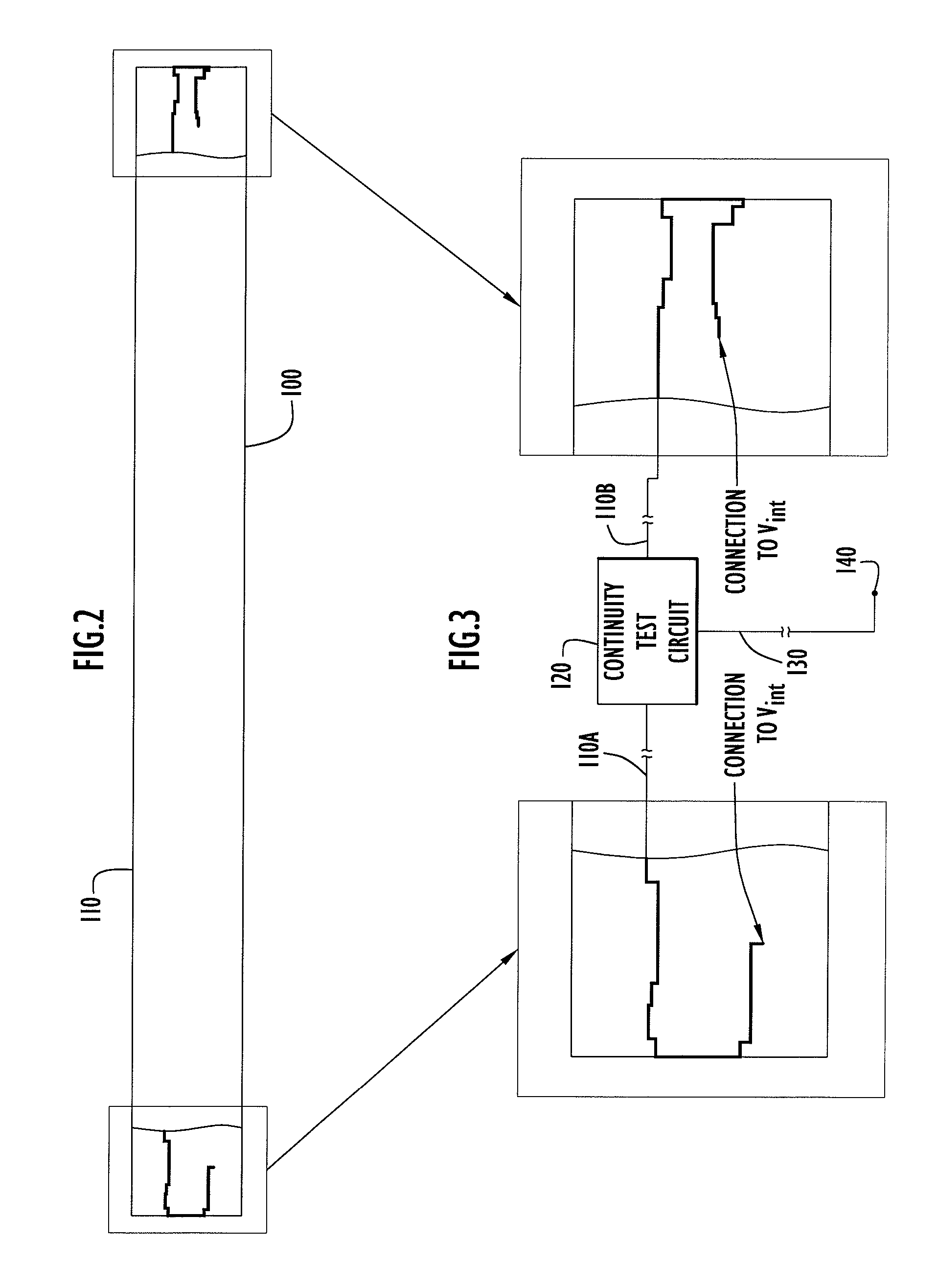

Circuit and Method for Physical Defect Detection of an Integrated Circuit

InactiveUS20080184083A1Low signal levelElectronic circuit testingFunctional testingContinuity testEngineering

A semiconductor integrated circuit device having a physical damage testing capability and a method for testing for physical damage caused during fabrication, assembly or test of the semiconductor integrated circuit are provided. A dedicated conductive test path is formed during fabrication of the integrated circuit device. The test path is routed to pass through areas of the integrated circuit which are susceptible to physical damage. A test circuit is included in the integrated circuit and is connected to the dedicated conductive test path. The test circuit tests the dedicated conductive test path for a characteristic indicative of physical damage. In one embodiment, the test circuit is a continuity circuit that measures whether there is continuity on the conductive test path. The continuity test circuit is activated in response to an externally supplied test command, such as from a test system, and to supply an output signal to a pad that is externally readable by the test system.

Owner:QIMONDA

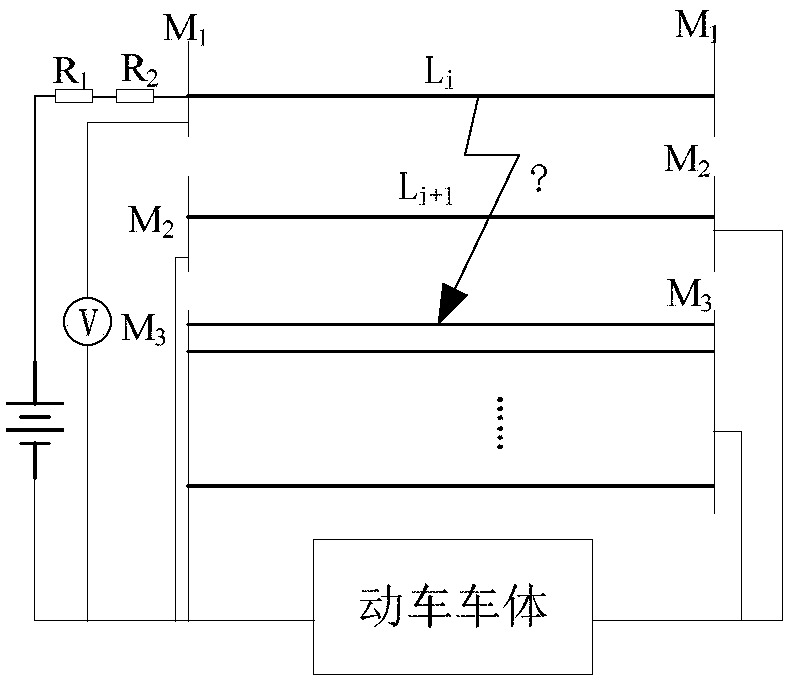

Hand-held cable continuity test device and system and test method for rail vehicle

ActiveCN107907779AReduce the number of movementsReduce in quantityElectrical testingReverse orderHand held

The invention provides a hand-held cable continuity test device for a rail vehicle. The bus switch module (A) of the device is provided with a cable end. The contacts of A are connected with an idle bus and a test bus respectively. Each bus is connected with a grounding end through the contacts of grounding switch modules (B). Drive and grounding ports are arranged. Each switch module is providedwith an enable end and contacts. The slave device of the system comprises the hand-held cable continuity test device, control and communication modules, a power supply, a power supply switch module (C) and a voltage measurement circuit. The power supply is connected with the test bus through the contacts of C. The control module is connected with the drive. The enable end is connected with contacts and the drive. Short circuit and continuity test is carried out on a connected first cable. A master device determines a corresponding test result. Next cables on the same A are tested in reverse order until the last one. The test comprises the steps that the master device sends a test signal to the slave device; and the slave device controls the contact action of the slave device, and notifiesthe master device to control the contact action after switching. The test result is determined according to voltage. The volume is small, and the speed is fast.

Owner:CRRC QINGDAO SIFANG CO LTD

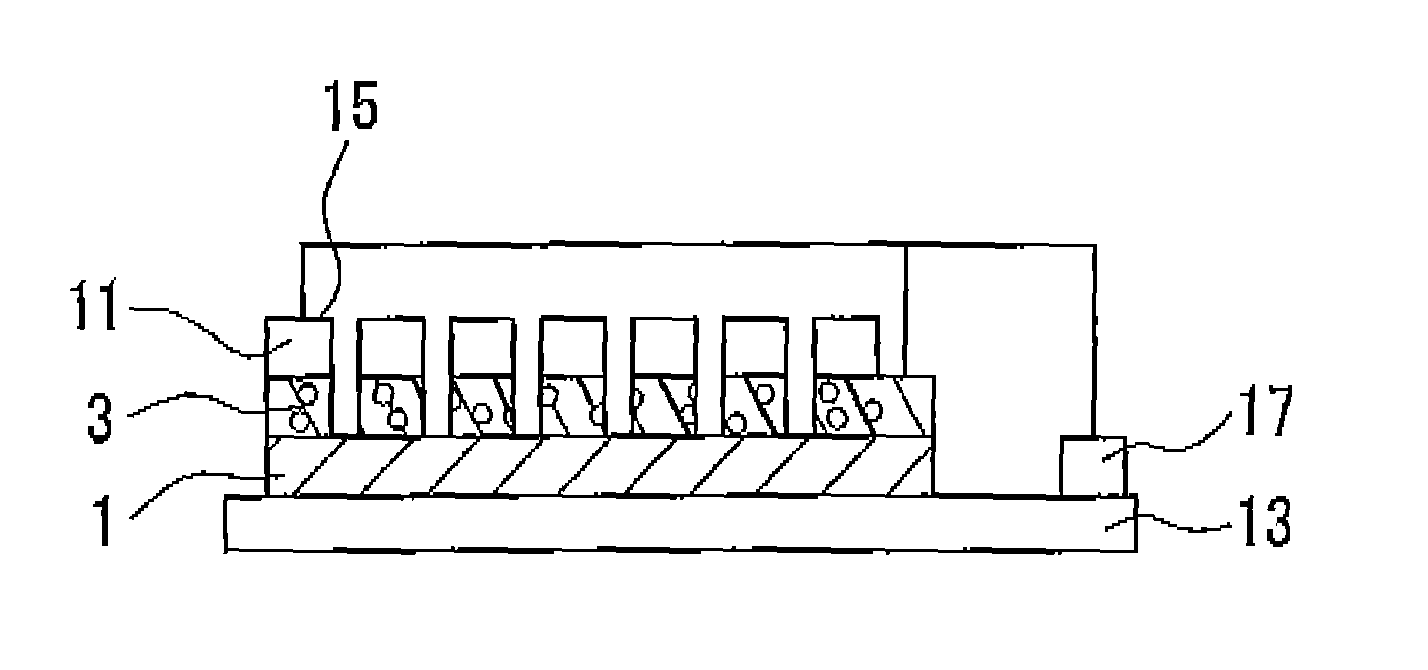

Pressure-sensitive adhesive sheet and process for producing semiconductor device having same

InactiveUS20110065217A1Improve throughputGood flexibilitySemiconductor/solid-state device testing/measurementFilm/foil adhesivesFiberSemiconductor chip

A pressure-sensitive adhesive sheet according to the present invention is a pressure-sensitive adhesive sheet in which a pressure-sensitive adhesive layer is provided on a base film, in which the base film contains conductive fibers, and in which an electrically conductive path is formed between the pressure-sensitive adhesive layer and the base film. With this structure, an electrical continuity test can be performed even in a condition where a semiconductor wafer or a semiconductor chip formed by dicing the semiconductor wafer is applied, and deformation (warping) and damage of the semiconductor wafer and generation of flaws and scratches on the backside can be prevented in the test.

Owner:NITTO DENKO CORP

Method and system for testing swinging cross or breaking of multi-core cable

InactiveCN102854430AImprove test efficiencyReduce the number of testsElectrical testingTest channelMulticore cable

The invention discloses a method and a system for testing swinging cross or breaking of a multi-core cable. The method includes the steps of A, selecting a one cable core of a tested cable and performing a continuity test by respectively connecting two ends of the cable core on a testing channel of a continuity tester; B, selecting another cable core and repeating the step A until continuity tests for all cable cores are finished; C, selecting one pair of cable cores of the tested cable and respectively connecting one ends thereof on a test channel of a capacitance unbalance tester to test capacitance difference of the pair of the cable cores relative to other cable cores and a metal sheath; D, selecting another pair of cable cores and repeating the step C until all capacitance unbalance tests for the cable cores are finished; E, selecting cable core pairs with abnormal test results obtained in the step C and the step D, combining the cable cores two by two, respectively connecting one ends on the continuity tester to finish the continuity test between two random cable cores, obtaining result of the swinging cross, and then recording the result.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

Pressure-sensitive adhesive sheet and process for producing semiconductor device having same

InactiveUS8048690B2Improve throughputGood flexibilitySemiconductor/solid-state device testing/measurementFilm/foil adhesivesFiberSemiconductor chip

A pressure-sensitive adhesive sheet according to the present invention is a pressure-sensitive adhesive sheet in which a pressure-sensitive adhesive layer is provided on a base film, in which the base film contains conductive fibers, and in which an electrically conductive path is formed between the pressure-sensitive adhesive layer and the base film. With this structure, an electrical continuity test can be performed even in a condition where a semiconductor wafer or a semiconductor chip formed by dicing the semiconductor wafer is applied, and deformation (warping) and damage of the semiconductor wafer and generation of flaws and scratches on the backside can be prevented in the test.

Owner:NITTO DENKO CORP

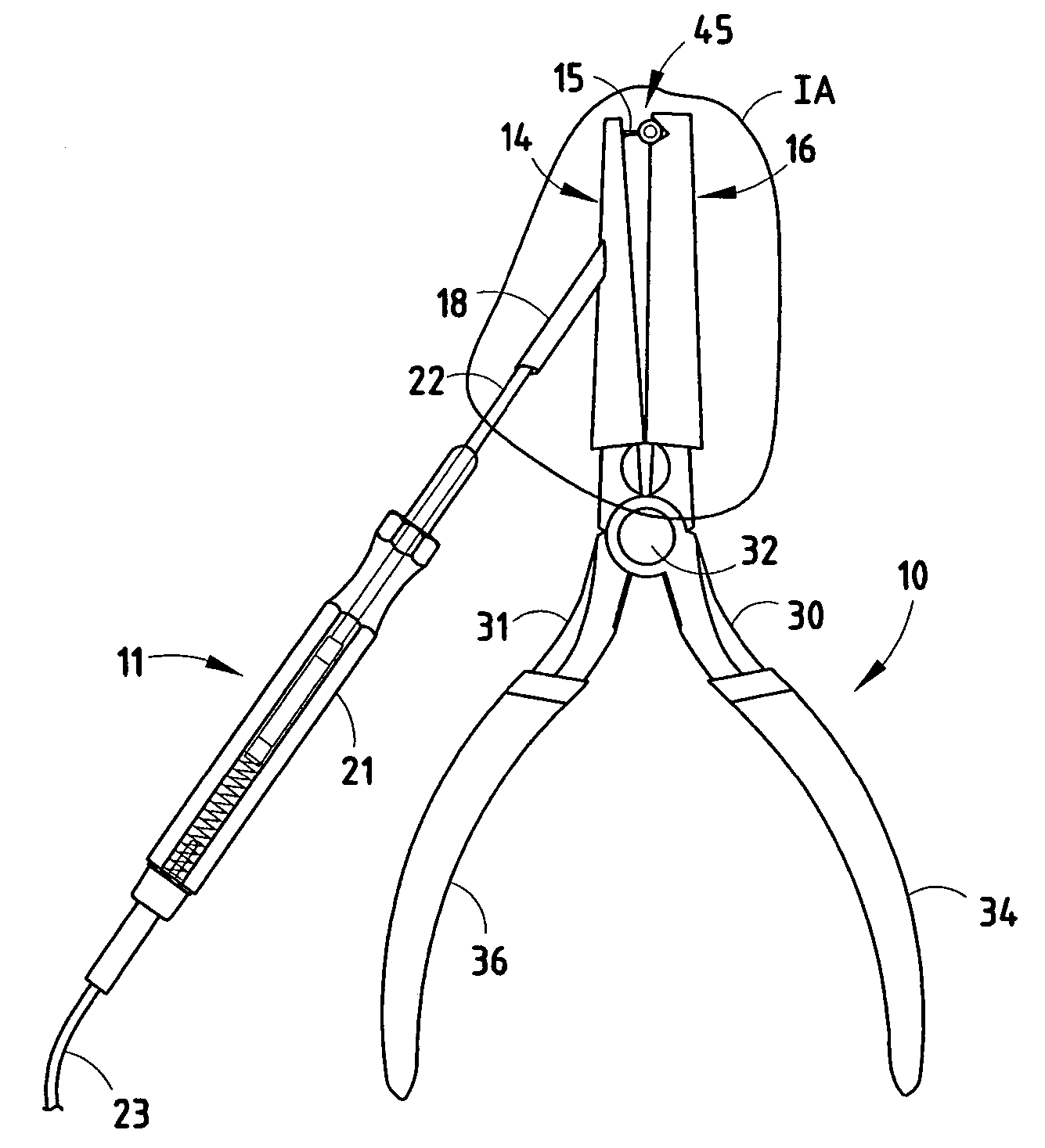

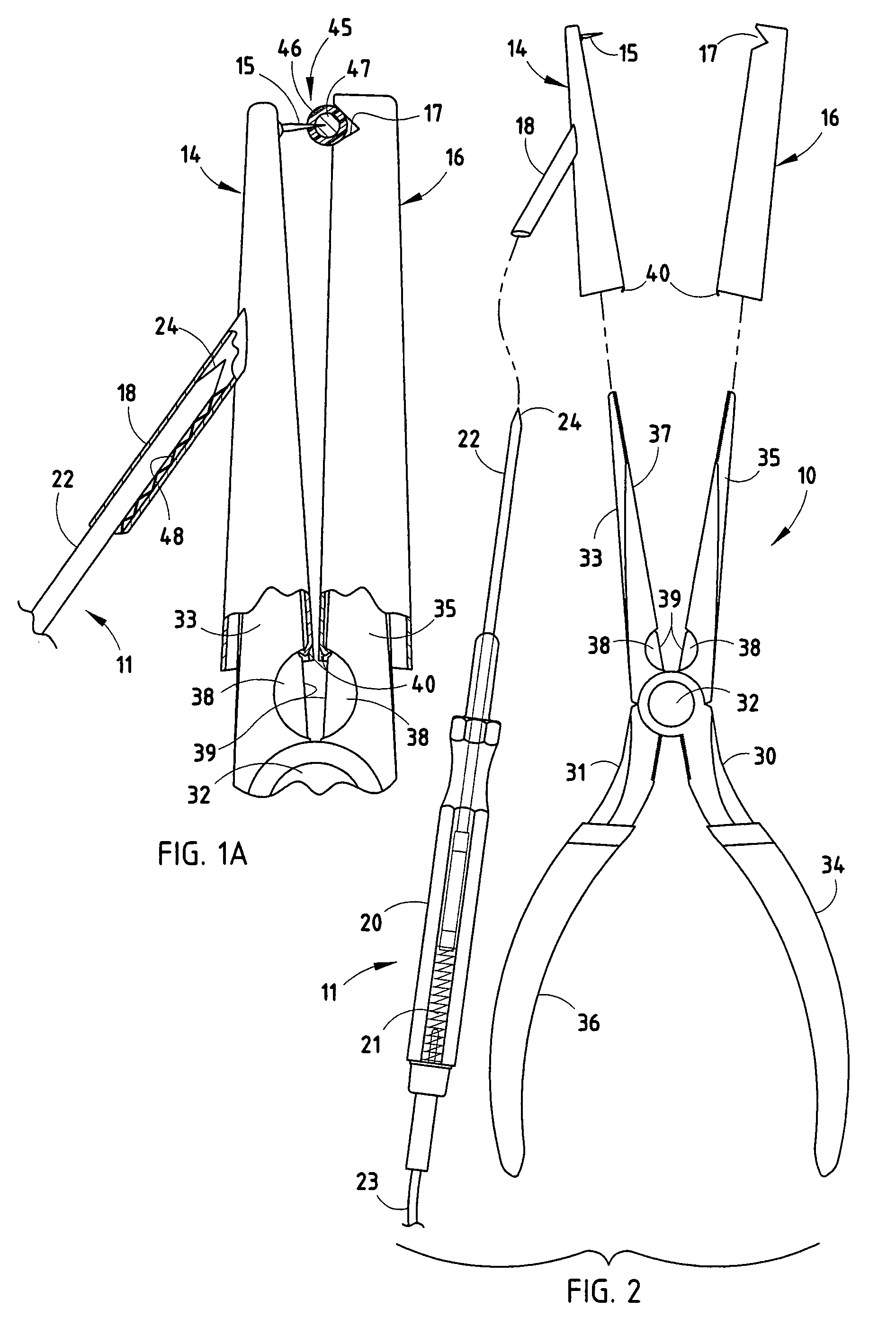

Continuity tester apparatus for wiring

A kit is provided for making a continuity tester from an existing pliers tool and an existing continuity checker to check electrical continuity of a wire. The kit includes a first sleeve adapted to slip onto a free end of a first jaw of the pliers tool and which includes a protrusion that faces laterally, and a second sleeve adapted to slip onto a second jaw and which includes a pocket for holding the wire while the protrusion is piercing the wire. The first and second sleeves are tubular, and are held on by resilient tabs that frictionally engage the jaws. A connector adapted to frictionally engage the probe of the continuity checker is provided either on the first sleeve or on a third sleeve engagable with the first handle of the pliers tool. In one form, the kit is factory-installed as a permanent part of the pliers tool.

Owner:FESSENDEN FRED

Optical transmission apparatus, continuity testing method therein, and optical transmission system

InactiveUS7627244B2Short timeLow costRing-type electromagnetic networksWavelength-division multiplex systemsOptical propagationTransport system

An optical transmission apparatus comprises a preamplifier controlling unit for controlling a preamplifier so that amplified spontaneous emission including all wavelength bands of a wavelength-multiplexed signal beam is outputted toward a wavelength demultiplexing unit, with the wavelength-multiplexed signal beam not inputted, power monitors for monitoring optical powers of the amplified spontaneous emission fed from the preamplifier and wavelength-demultiplexed by the wavelength demultiplexing unit, and a determining unit for determining the continuity state of an optical propagation path of each wavelength component on the basis of a result of monitoring by the power monitors. The optical transmission apparatus allows the continuity test on optical propagation paths of channels including a channel not used at the time of a start of the operation to be made easier than the known techniques.

Owner:FUJITSU LTD

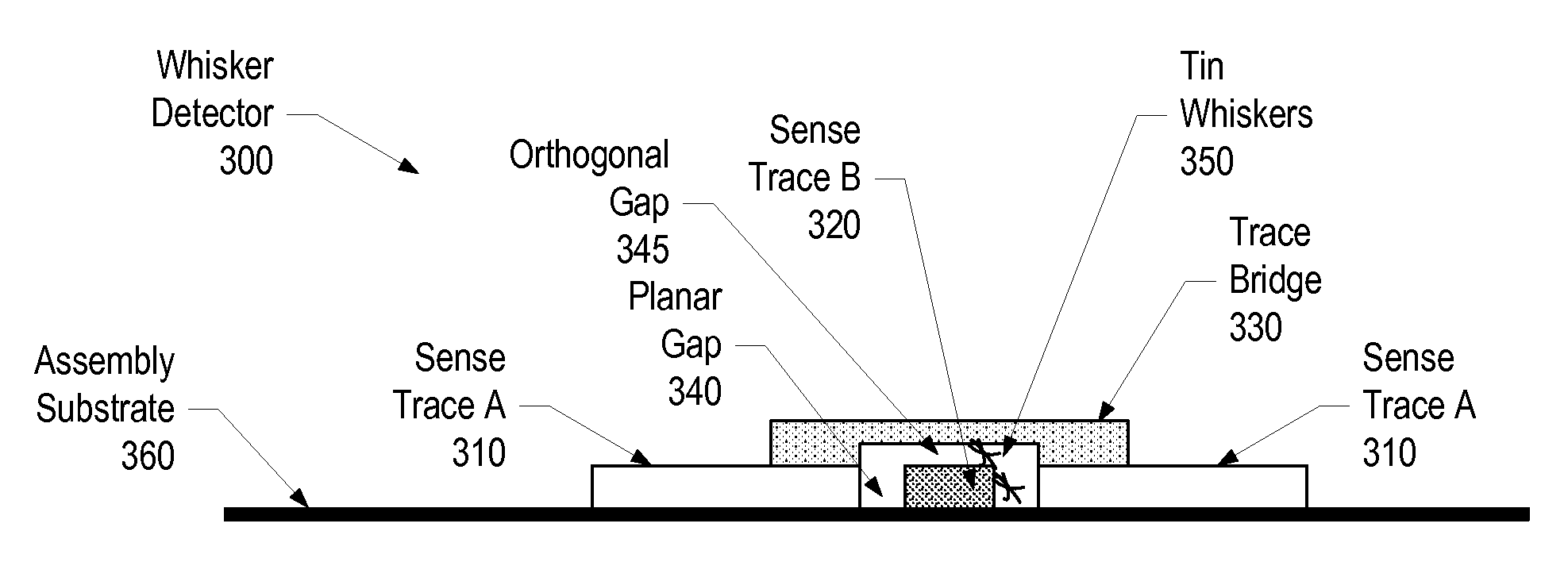

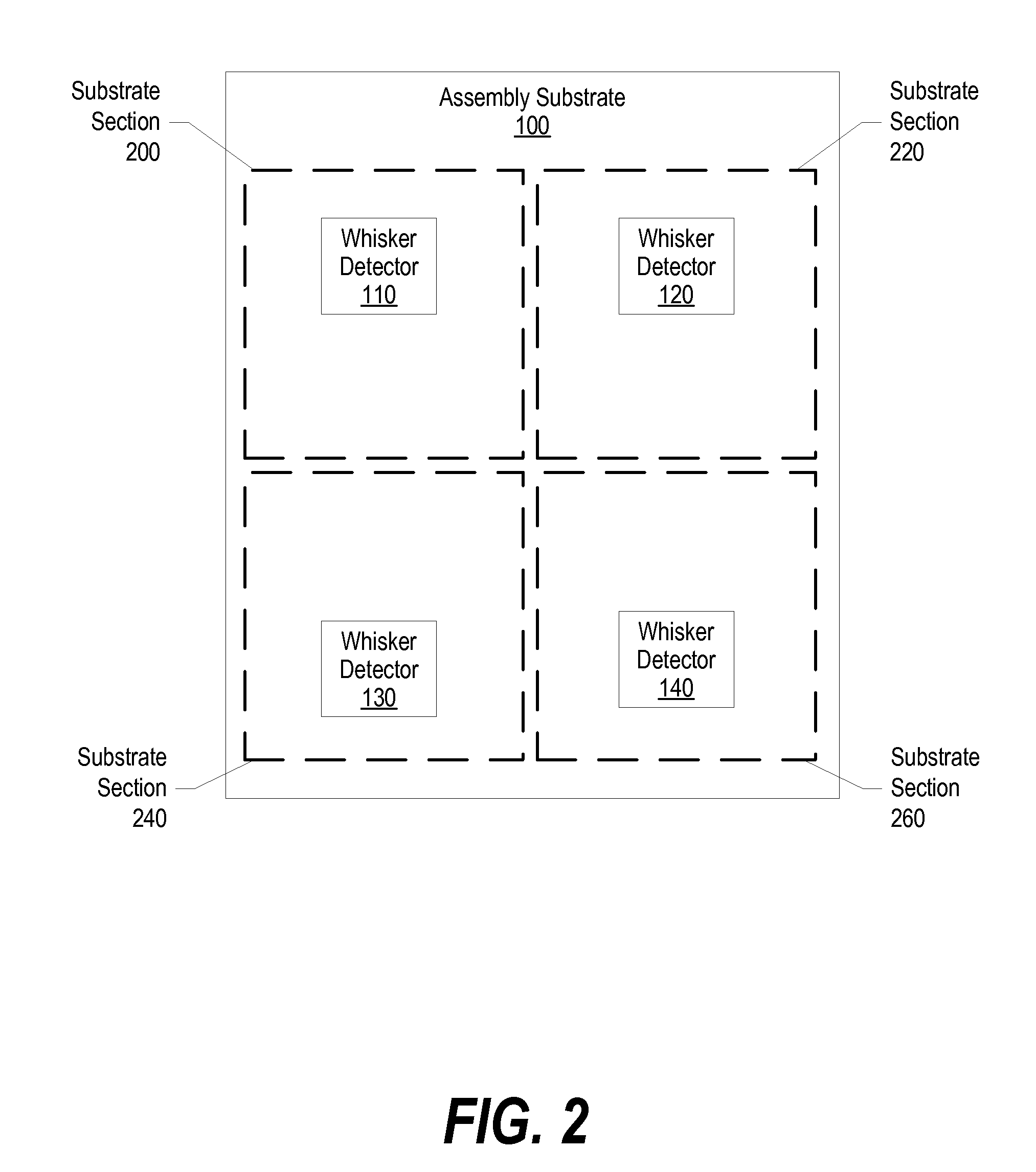

System and method for sensing the formation of tin whiskers

A system and method for sensing the formation of tin whiskers is presented. An assembly substrate includes whisker detectors at various locations for detecting tin whiskers in an X direction, a Y direction, and a Z direction relative to the assembly substrate. Each whisker detector includes sense traces and a trace bridge that produce “planar gaps” and “orthogonal gaps” that are smaller than trace gaps produced by other traces on the assembly substrate. As such, tin whiskers short across the planar gaps and orthogonal gaps before they short across trace gaps. When the assembly substrate is finished with processing steps, a system tester performs a continuity test on the whisker detectors. When the continuity test fails, an operator is notified to check for tin whiskers on the assembly substrate. Once shipped, a processor monitors the whisker detectors for shorts throughout the product's lifecycle.

Owner:LENOVO (SINGAPORE) PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com