Manufacturing method for laminated electrode, carbon film and manufacturing method for carbon film

An electrode and stacking technology, which is applied in the field of supercapacitor electrode preparation, can solve problems such as difficult to guarantee performance consistency, reduced capacity and cycle performance, and no competitive advantage in products, so as to achieve high active material loading and strengthen fibrosis effect, the effect of low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

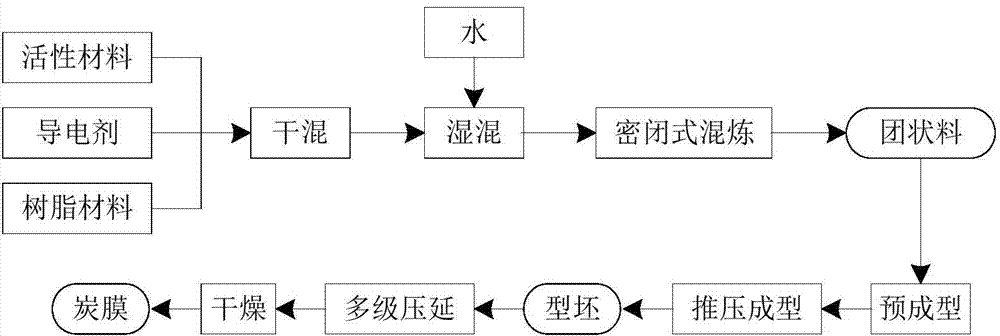

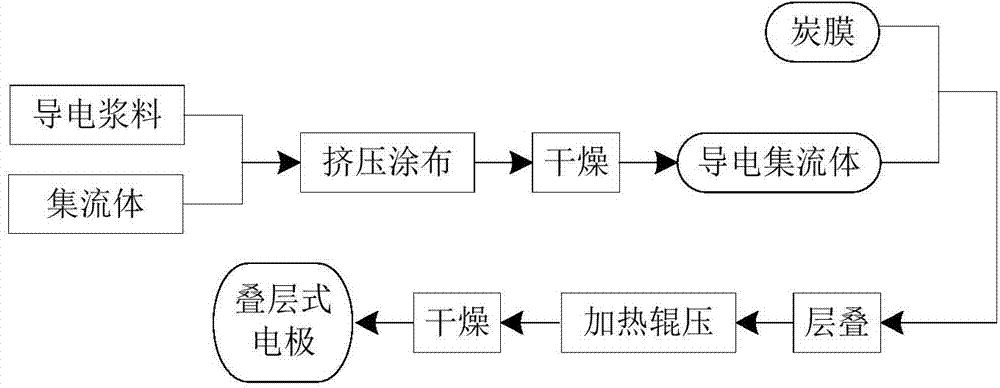

[0043] The present invention is used for the preparation method flow chart of the laminated electrode of supercapacitor as follows figure 2 As shown, it mainly includes the following steps:

[0044] Step 1: Prepare a carbon membrane according to the aforementioned carbon membrane preparation method;

[0045] Step 2: Coating the conductive paste on the current collector by extrusion coating, and then drying to obtain a conductive current collector;

[0046] Step 3: Laminate the carbon film and the conductive current collector, heat and roll, and dry to prepare a laminated electrode for a supercapacitor.

[0047] In a specific embodiment of the present invention, the current collector may be aluminum foil or etched aluminum foil.

Embodiment 1

[0050] In the first step, 94 parts by mass of activated carbon, 4 parts by mass of conductive carbon black, and 2 parts by mass of PTFE (polytetrafluoroethylene) dispersion resin are stirred and mixed according to the proportioning ratio. In the second step, 200 parts by mass of water are added to the mixed materials, and stirring is performed to fully mix the materials. It is also preferable to introduce a high-shear dispersing device and design an improved automatic stirring and dispersing process system, so that the processed materials can have a strong dispersion and crushing effect, and finally achieve the purpose of rapid ultra-fine dispersion. The third step is to add the mixed wet powder into the closed mixer, and in the high-temperature and high-pressure internal mixer, knead, disperse, and mix in a short period of time (2 to 12 minutes), so as to enhance the plasticity of the material , Make the wet powder material subject to strong shearing, extrusion and stirring, ...

Embodiment 2

[0054] The difference with embodiment one is that the proportioning of the mixture of the present embodiment is the activated carbon of 90 parts by mass, the conductive carbon black of 5 parts by mass, the PTFE (polytetrafluoroethylene) dispersion resin of 5 parts by mass; and Add 100 parts by mass of water during wet mixing; add 18 parts by mass of naphtha to the dough before preforming. The carbon film obtained by the preparation method of this example has good mechanical properties such as strength, toughness and bending resistance. It is obtained through experiments and tests that there is still no crease after 20 times of 90° bending, the thickness is ≥ 280 μm, and the bulk density is ≥ 0.6g / cm 3 , specific capacity ≥1.2F / cm 2 .

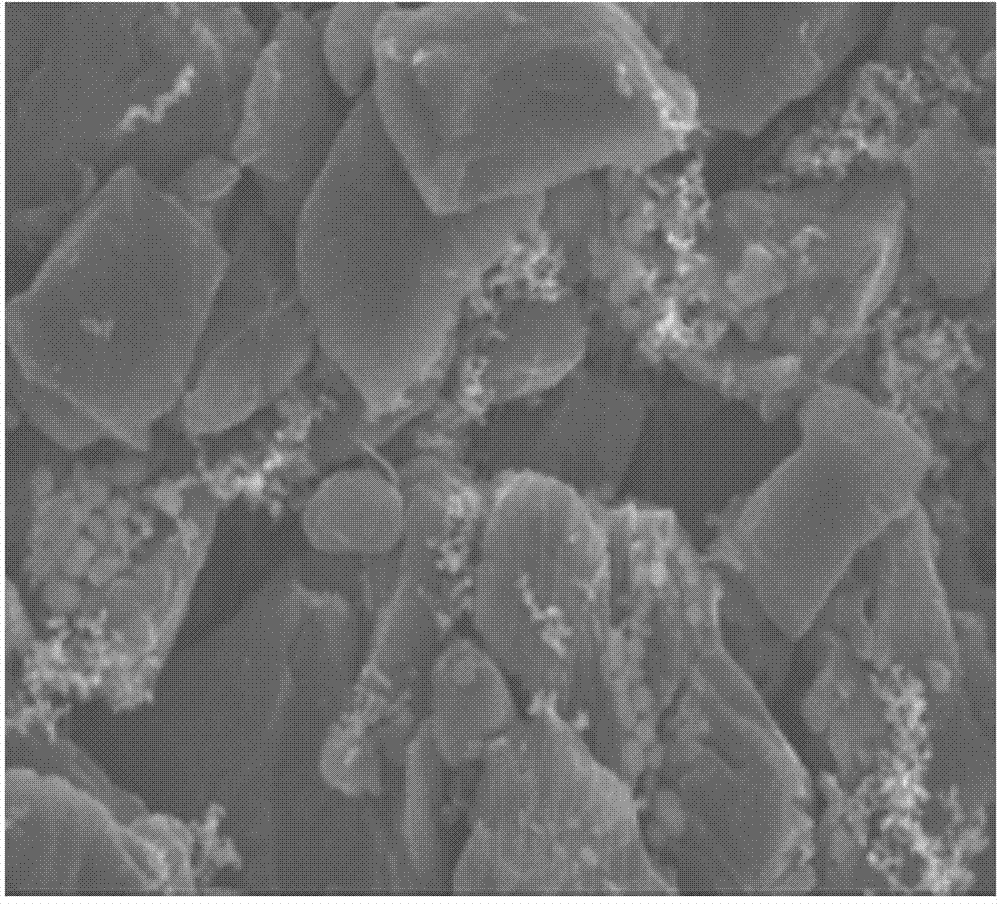

[0055] The scanning electron microscope image of the surface of the laminated electrode prepared after the carbon film prepared in this example and the aluminum foil coated with the conductive intermediate layer on both sides is overlapped an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com