Prepn of polyolefine resin specially for permeating curtain coated film

A technology of polyolefin and high permeability, which is applied in the field of preparation of special resin for polyolefin high air-permeable cast film, can solve the problems of unsatisfactory air-permeable uniformity and mechanical properties, meet the requirements of production and processing and use requirements, and improve dispersion Uniformity, the effect of improving mechanical properties and processing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

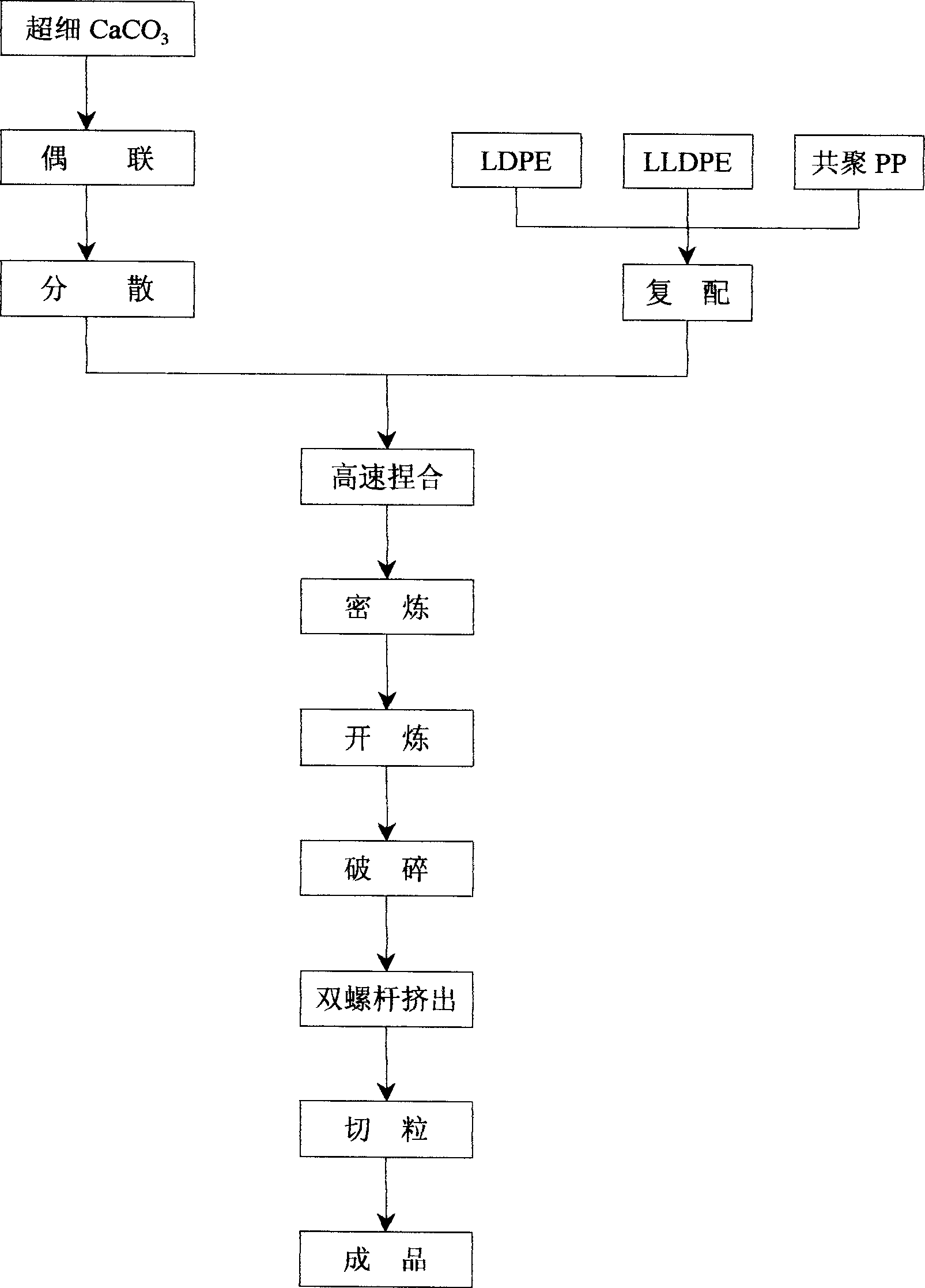

Method used

Image

Examples

Embodiment 1

[0015] Superfine CaCO 3 (Particle size 3 ~ 10um) 25kg placed in a high-speed kneader (speed 1000r p m, temperature 105 ± 2 ℃) kneaded for 20 minutes, added 0.6kgTi-Al composite coupling agent, kneaded for 15 minutes, then added 2kgOPE Dispersant, knead for 10 minutes, then add 5kg of LDPE, 6kg of LLDPE, 2.5kg of copolymerized PP, 2.5kg of POE modifier PP, mix for 5 minutes, put it in a pressurized internal mixer (temperature 135±3°C) and banbury for 10 minutes Then put it in a double-roller rubber mixing machine and roll it into thin slices of about 3mm. After cooling, it will enter the crusher and be crushed into granules of about 3×4mm. ~168℃, Zone II 168~172℃, Zone III 168~172℃, Zone IV 160~165℃, Die 150~153℃) Extruded and pelletized to form a special resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com