Laser shock strengthening method for small-pitch gear surface

A laser shock strengthening and gear technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of peeling, weakening the surface performance of the workpiece, and easy warping of the absorbing layer, so as to solve the problems of easy warping, easy cleaning, and improvement effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the examples.

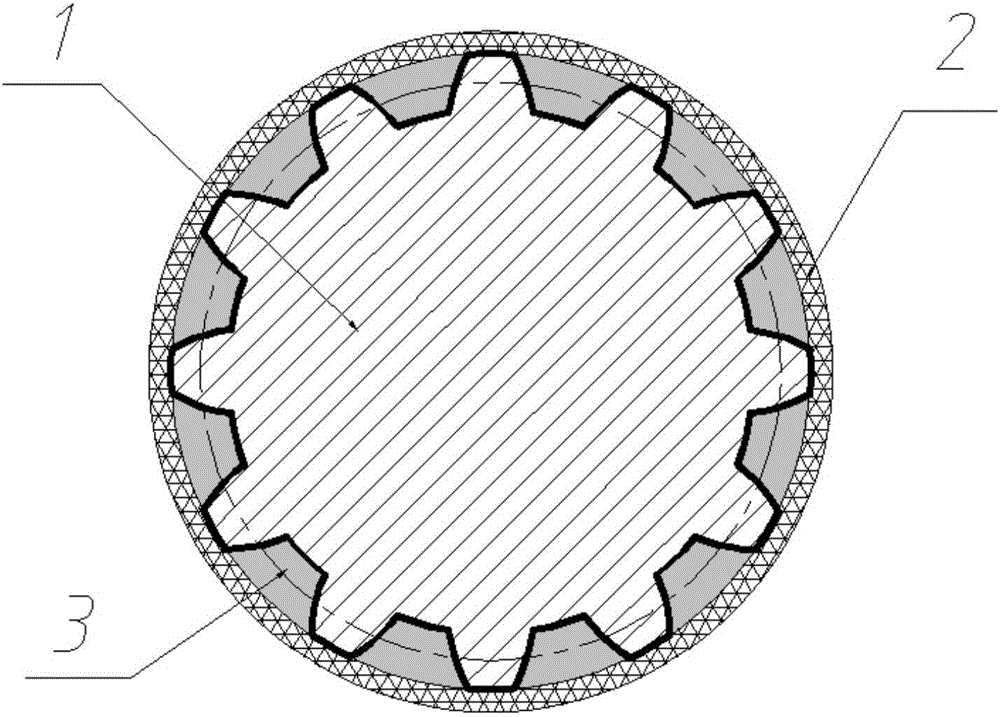

[0028] This embodiment adopts a small-pitch standard gear made of 304 stainless steel used at the engine end of an automobile, and its geometric dimensions are as follows: the number of teeth is 50, the modulus is 1 mm, and the pitch is 3 mm.

[0029] An example of using the above-mentioned workpiece for laser shock strengthening, the specific steps are:

[0030] (1) Mix PVC organic sol, acrylic synthetic resin and organic solvent thickener aluminum hydroxide in a certain proportion, and stir fully to form a uniform viscous transparent filling, and the components of the transparent filling The ratio by weight is: 70g of PVC organosol, 28g of acrylic synthetic resin, and 2g of organic solvent thickener.

[0031] (2) Put the above-mentioned transparent filler into a vacuum to discharge the air bub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com