Connecting piece and reinforced light steel keel wall integrated with prestressed flat steel strip

A light steel keel and connecting piece technology, applied in walls, building components, buildings, etc., can solve problems such as difficult waterproofing, easy deformation and warping, and difficult installation of flat steel strips, achieving good integrity, increasing support points, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

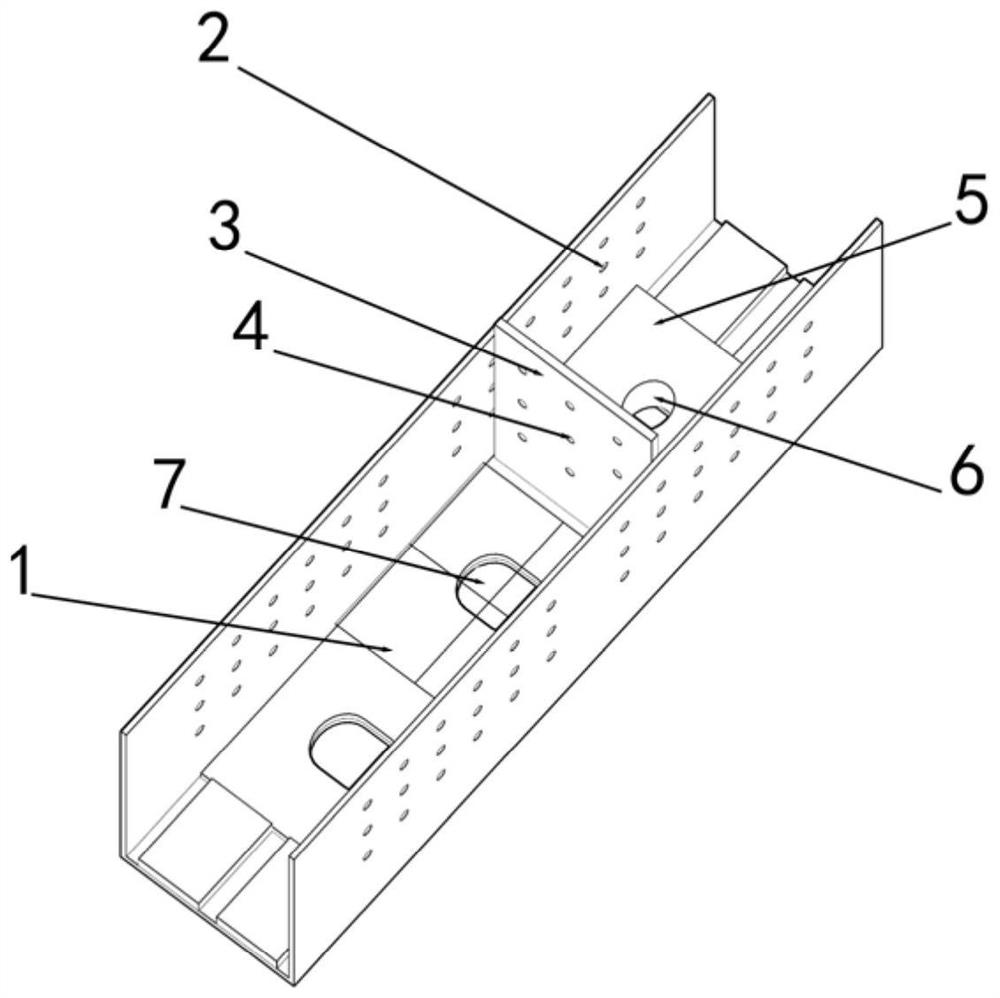

[0033] combine figure 1 As shown, the embodiment of the present invention provides a connector, including: U-shaped mounting frame 1, which includes a belly in the middle and two wings on both sides, the belly is suitable for fixed connection with the main structure of the light steel keel wall , the wings are provided with mounting holes 2 suitable for fixing flat steel strips 9 by bolts. In this embodiment, the U-shaped mounting frame 1 is a one-piece structure; in other embodiments, the U-shaped mounting frame 1 may also be a structure in which two parts or even multiple parts are spliced by welding, buckling and other fixing means. In this embodiment, the outer surface of the abdomen of the U-shaped mounting frame 1 is fixed on the light steel keel wall by welding, which is more secure and easy to operate; in other embodiments, the abdomen of the U-shaped mounting frame 1 can also be fixed by bolts. , buckle and other common means for fixing.

[0034] refer to figure ...

Embodiment 2

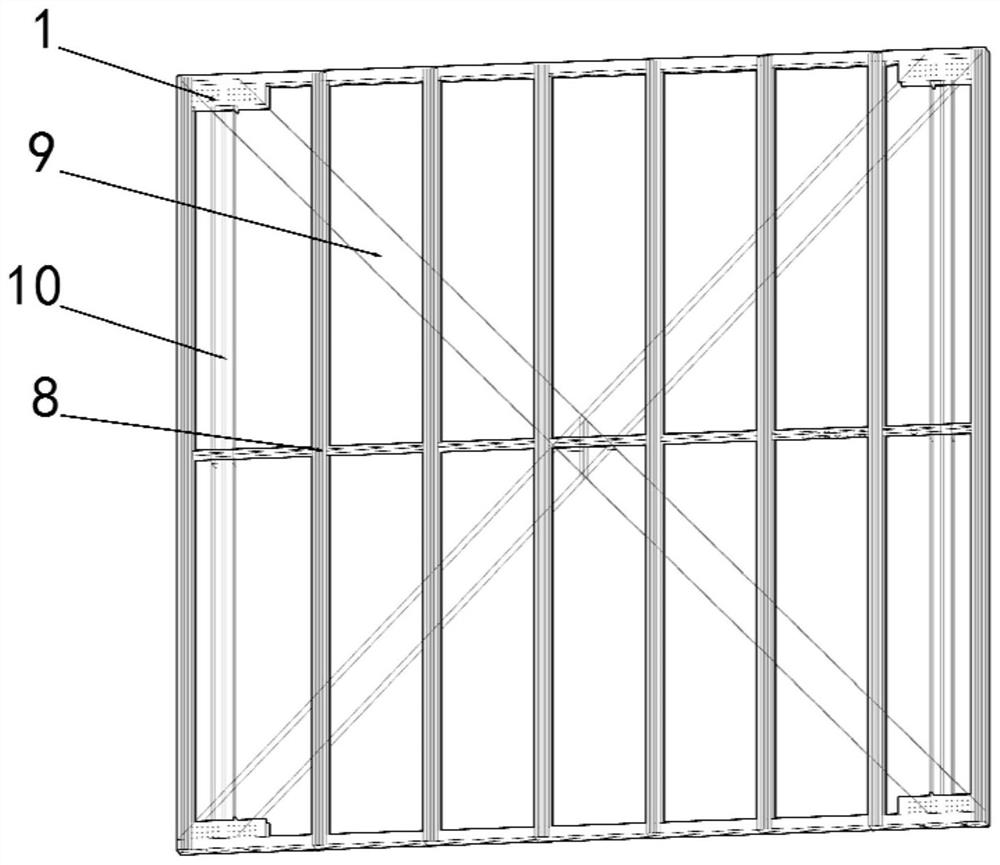

[0041] combine Figure 1-Figure 2 As shown, the embodiment of the present invention also provides a reinforced light steel keel wall integrated with prestressed flat steel strips 9 , including a light steel keel wall body 8 , four connectors and two sets of flat steel strips 9 .

[0042]In this embodiment, the four connectors are respectively fixed on the inside of the four corners of the light steel keel wall 8; two sets of flat steel strips 9 are respectively fixed on the two walls of the light steel keel wall 8, The flat steel strip 9 includes two cross-arranged ones, and the two ends of each flat steel strip 9 are respectively fixed on two diagonally distributed connectors.

[0043] In the light steel keel wall of this embodiment, the flat steel strip 9 is indirectly fixed on the main structure through the connector, without destroying the main structure of the wall, the waterproof performance of the end can be strengthened, and the light steel keel wall 8 can be prevented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com