A manufacturing method for an ITO auxiliary thin-type multi-junction gallium arsenide solar cell bottom electrode

A solar cell, gallium arsenide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as warping and affect the assembly of solar arrays, and achieve the effect of reducing weight, reducing coverage, and solving warping problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

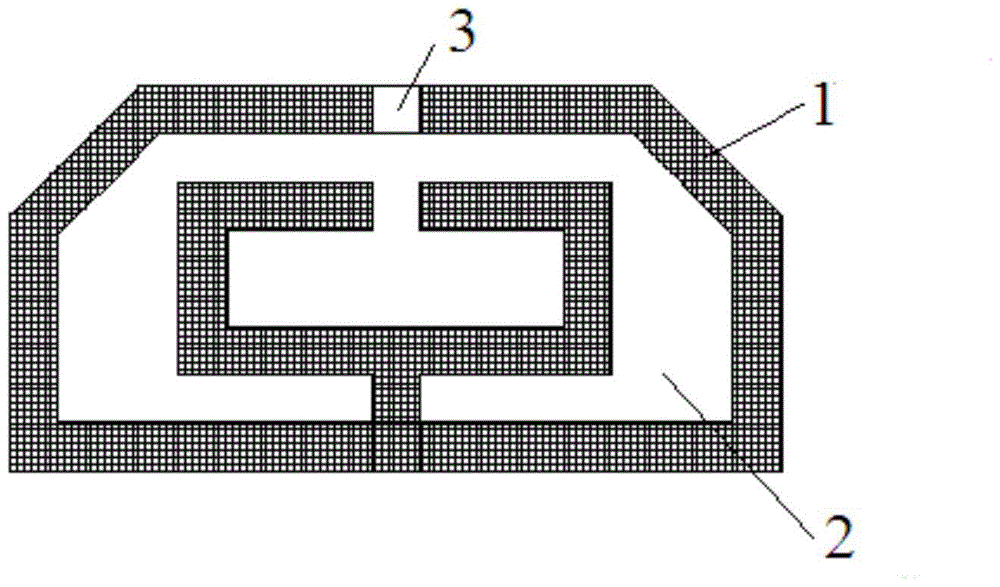

[0030] The following combination Figure 1-Figure 3 , taking an ITO-assisted triple-junction gallium arsenide solar cell as an example, the preparation method of its lower electrode is introduced:

[0031] (1) Evaporation lower electrode:

[0032] Put the epitaxial wafer on which the upper electrode has been vapor-deposited into a glue coating machine, apply glue on the side of the vapor-deposited upper electrode, and bake in an oven at 60°C to 110°C for 40s to 60s after the glue is applied.

[0033] (2) Cleaning:

[0034] After baking, the epitaxial wafer is etched in a hydrofluoric acid solution with a concentration of 10% to 20% for 20 to 40 seconds, and then cleaned with deionized water for 2 to 3 times. Then soak in acetone for 3 to 5 minutes to remove the glue on the upper electrode, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com