Fireproof door production and assembling method

A technology for producing and assembling fire doors, which is applied in the directions of devices for coating liquids on surfaces, material gluing, and connecting components. The effect of manpower, improving assembly efficiency and stabilizing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

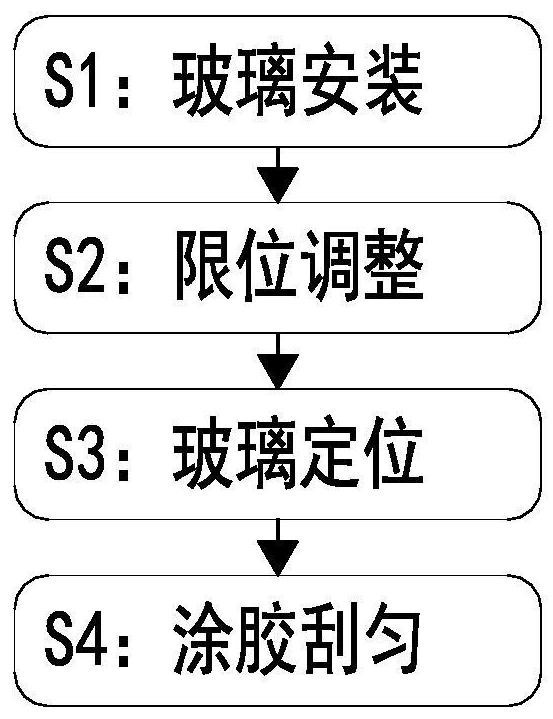

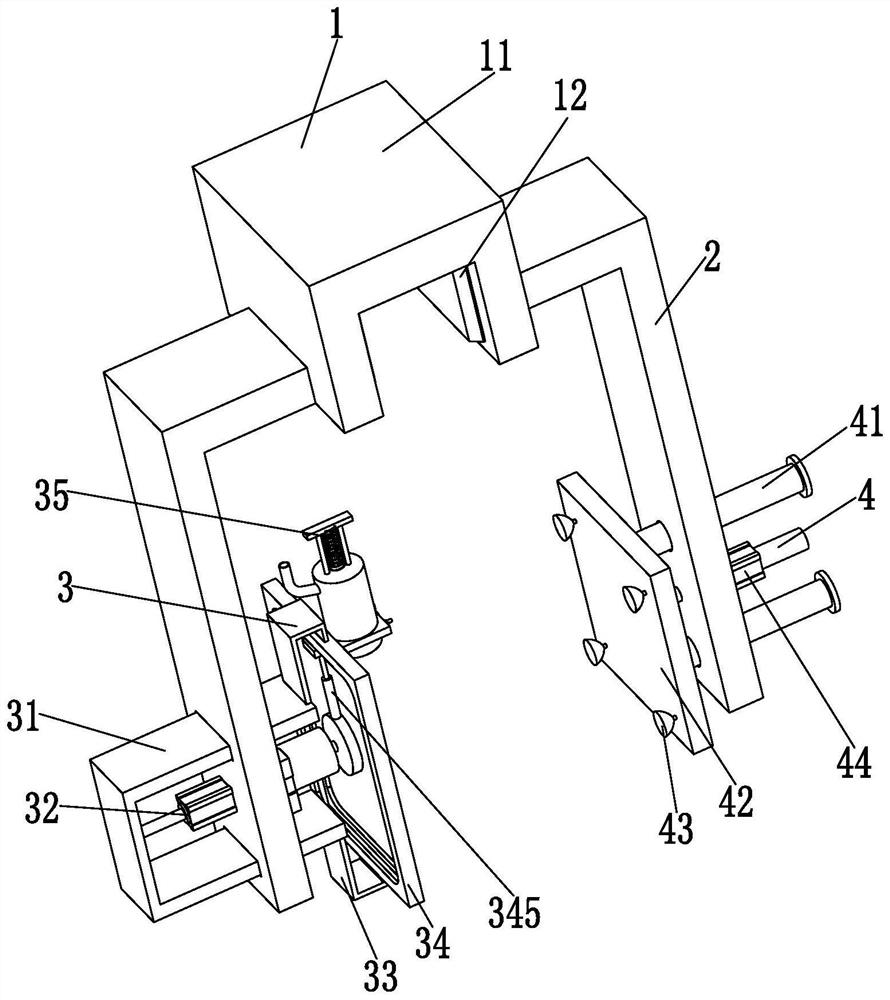

[0038] like Figure 1 to Figure 8 as shown,

[0039] A fire door production and assembly method, which uses a fire door production and assembly machine: the machine includes a limit movement frame 1, an L-shaped installation rod 2, a gluing device 3 and an installation device 4, and the limit movement frame 1 The lower sides of the left and right ends are symmetrically fixed with L-shaped installation rods 2, the lower side of the left L-shaped installation rod 2 is equipped with a glue applicator 3, and the lower side of the right L-shaped installation rod 2 is provided with a mounting device 4.

[0040] The limit moving frame 1 includes a limit frame 11 and a limit mechanism 12, and a limit mechanism 12 is arranged in the limit move frame 1. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com