Automatic edge grinding machine for glass-ceramics

An automatic edging machine and glass-ceramics technology, which is applied in the direction of grinding racks, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of inability to meet higher requirements of consumers, low processing accuracy and automation Vibration affects the processing effect and other issues, to achieve the effect of improving processing accuracy and effect, sensitive response, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

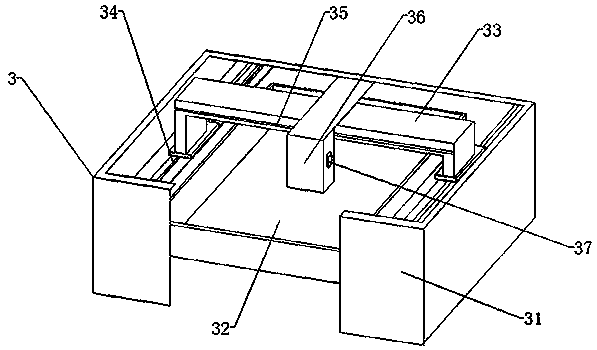

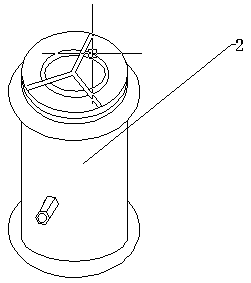

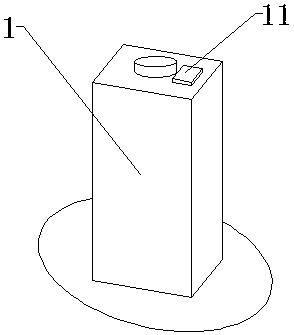

[0017] An automatic edging machine for glass-ceramics, comprising a positioning block 1, a suction cup 2, a vacuum pump and a body 3, the positioning block 1 is provided with an inclination sensor 11, the suction cup 2 and the vacuum pump are connected through a trachea, and the body 3 includes a frame 31, a workbench 32, a gantry 33, a guide rail 34, a slide rail 35 and a spindle assembly 36, the workbench 32 is erected on the frame 31, and the guide rails 34 are arranged on both sides of the frame 31, so The gantry 33 is located above the workbench 32 and erected on the guide rail 34 , the slide rail 35 is arranged on the gantry 33 , and the spindle assembly 36 is installed on the slide rail 35 .

[0018] Further, the spindle assembly 36 includes a laser two-dimensional sensor 37 , and the laser two-dimensional sensor 37 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com