Numerical control machine tool for obliquely machining

A CNC machine tool and tilting processing technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient observation, tool setting, and inconvenient operation and processing, so as to ensure stability and efficiency, and facilitate operation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

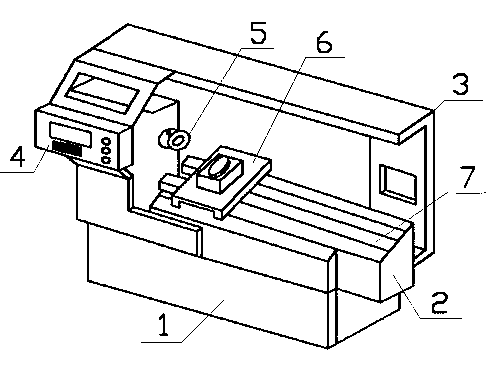

[0010] Such as figure 1 As shown, a CNC machine tool for inclined machining of the present invention includes a machine tool body 3 composed of a machine bed 1 and a guide rail workbench 2, a control panel 4 arranged in front of the machine tool body 3, and a control panel 4 arranged on the left side of the machine tool body 3 The main shaft 5, and the tool post feed pallet 6 arranged on the guide rail table 2, the guide rail table 2 is arranged on the machine bed 1, the upper surface of the guide rail table 2 is an inclined surface 7, The tool holder feeding pallet 6 is obliquely installed on the inclined surface 7 of the guide rail workbench 2 .

[0011] Wherein, the angle between the inclined surface 7 and the horizontal ground is 30 degrees; the highest point of the tool rest feeding pallet 6 is lower than the horizontal position of the axis of the main shaft 5, and the tool rest feeding pallet 6 and the main shaft 5 are mutually independent. Interference is beneficial to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com