Nutritional low-sensitivity wheat flour

A technology of low-sensitivity wheat flour and nutrition, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food drying, etc., can solve the problems of unbalanced intake of nutrient elements, and achieve the effect of high nutrient content and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

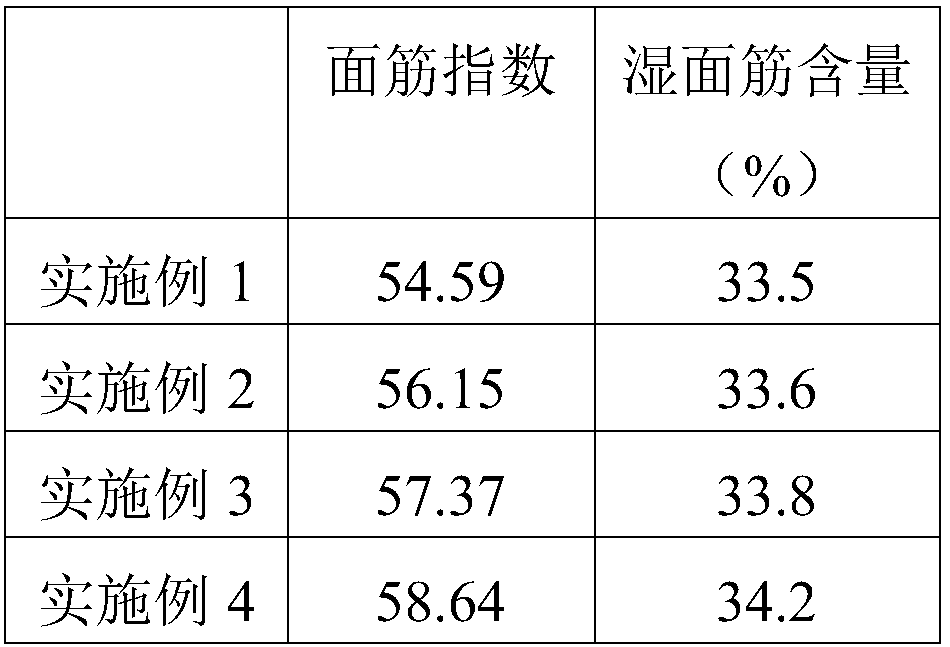

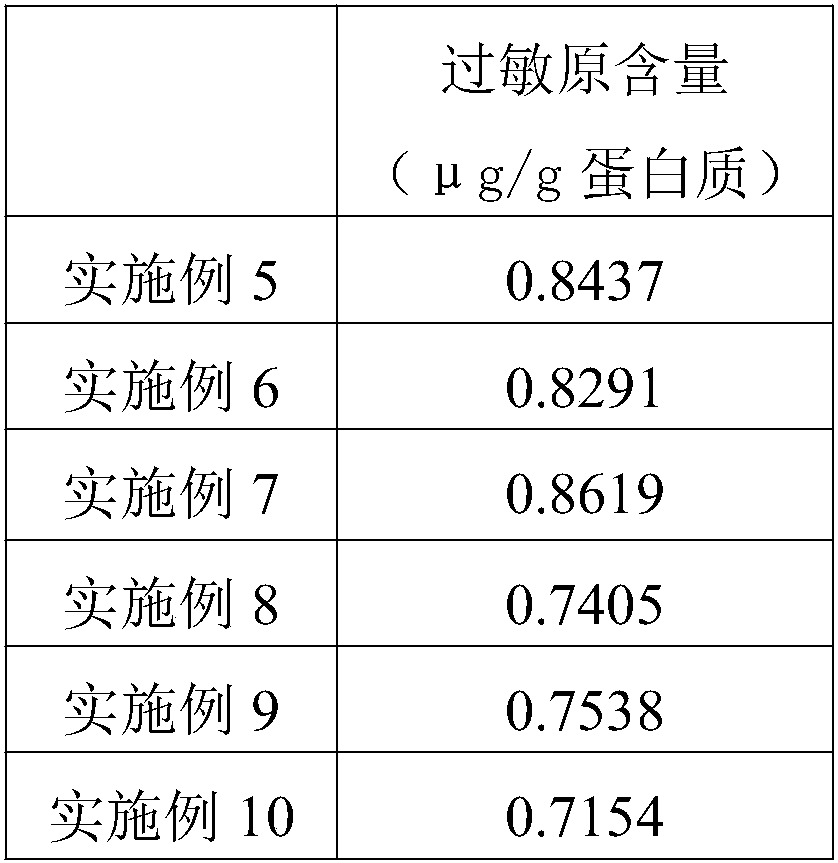

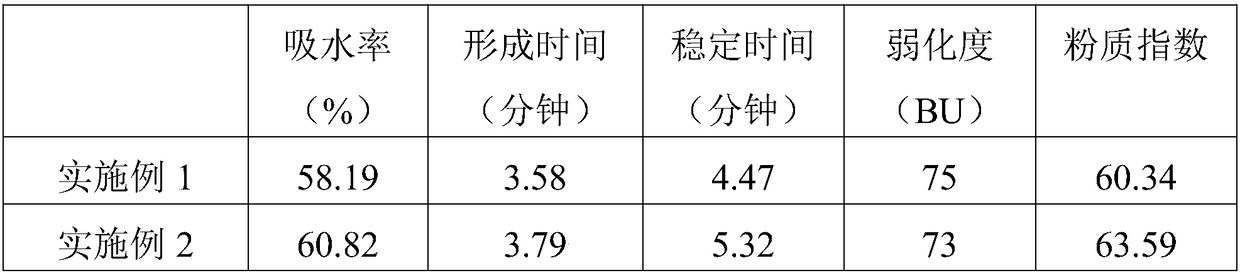

Examples

Embodiment 1

[0044] Nutritional hypoallergenic wheat flour raw material formula: 100 parts by weight of wheat flour and 4 parts by weight of grape seed extract.

[0045] The preparation process of the nutritional hypoallergenic wheat flour comprises the following steps:

[0046] (1) Selecting wheat and removing impurities: first, use a high-efficiency vibrating sieve to remove debris such as wheat straw, broken skin, and hemp rope; then use a specific gravity classifier to remove stones; then use a low-pressure fan to remove dust and chaff Wait for light and small impurities; finally, remove the gravel and non-magnetic metal impurities with a washer, destoner and dryer, and at the same time clean the small hair clusters on the wheat grains and the attached dirt;

[0047] (2) milling the cleaned wheat obtained in step (1) to obtain wheat flour;

[0048](3) Weigh the raw materials according to the formula;

[0049] (4) Mixing the wheat flour and the grape seed extract evenly to obtain the ...

Embodiment 2

[0051] Nutritional hypoallergenic wheat flour raw material formula: 100 parts by weight of wheat flour, 5 parts by weight of wheat germ flour and 4 parts by weight of grape seed extract.

[0052] The preparation process of the wheat germ powder is as follows: the fresh wheat germ is pulverized with a universal grinder at a speed of 3000 rpm for 10 seconds to obtain wheat germ powder with a particle size of 20 mm; The material layer was dried at 140°C for 5 minutes, and then cooled to 25°C under aseptic conditions to obtain the product.

[0053] The preparation process of the nutritional hypoallergenic wheat flour comprises the following steps:

[0054] (1) Selecting wheat and removing impurities: first, use a high-efficiency vibrating sieve to remove debris such as wheat straw, broken skin, and hemp rope; then use a specific gravity classifier to remove stones; then use a low-pressure fan to remove dust and chaff Wait for light and small impurities; finally, remove the gravel...

Embodiment 3

[0059] Nutritional hypoallergenic wheat flour raw material formula: 100 parts by weight of wheat flour, 5 parts by weight of wheat germ flour and 4 parts by weight of grape seed extract.

[0060] The preparation process of the wheat germ powder is as follows: the fresh wheat germ is pulverized with a universal grinder at a speed of 3000 rpm for 10 seconds to obtain wheat germ powder with a particle size of 20 mm; material layer, and then processed under the condition of microwave power 900W for 150 seconds, to obtain.

[0061] The preparation process of the nutritional hypoallergenic wheat flour comprises the following steps:

[0062] (1) Selecting wheat and removing impurities: first, use a high-efficiency vibrating sieve to remove debris such as wheat straw, broken skin, and hemp rope; then use a specific gravity classifier to remove stones; then use a low-pressure fan to remove dust and chaff Wait for light and small impurities; finally, remove the gravel and non-magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com