Ceramic tile cutting process and device

A technology of cutting equipment and cutting process, applied in the field of ceramic tile processing, can solve the problems of large cutting allowance, easily damaged tile plates, and large loss of tile plates, and achieves the effect of small cutting allowance, wide adaptability and loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

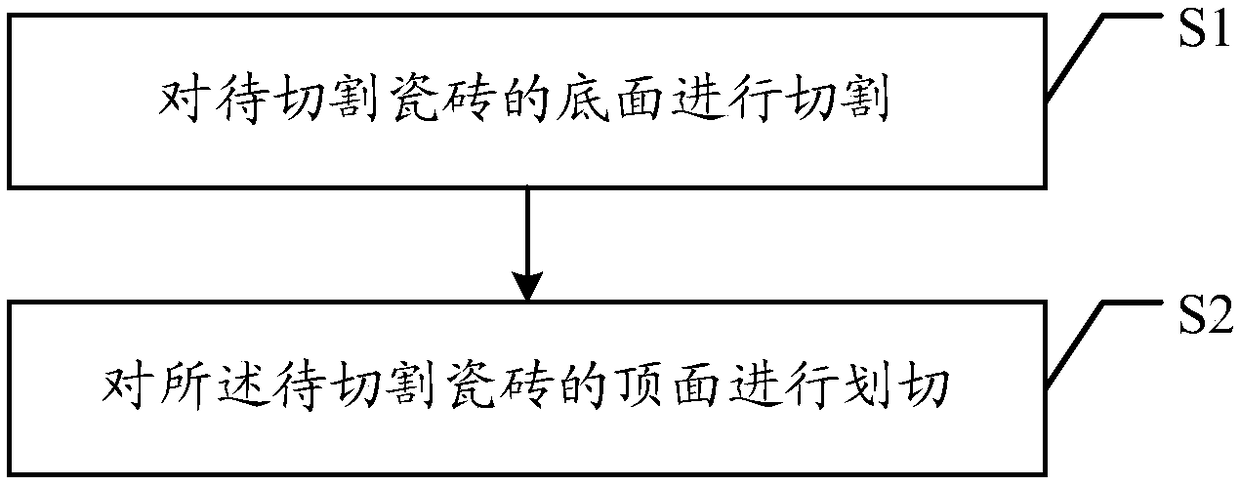

[0061] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention. see figure 1 , is the first embodiment of the ceramic tile cutting process of the present invention, including:

[0062] S1: Cut the bottom surface of the tile to be cut;

[0063] After the tiles to be cut are transported manually or by a conveying mechanism, the bottom surface of the tiles to be cut can be cut first, that is, the bottom cutting operation, and a relatively deep cut mark is formed on the bottom of the tiles to be cut.

[0064] S2: Sc...

no. 2 example

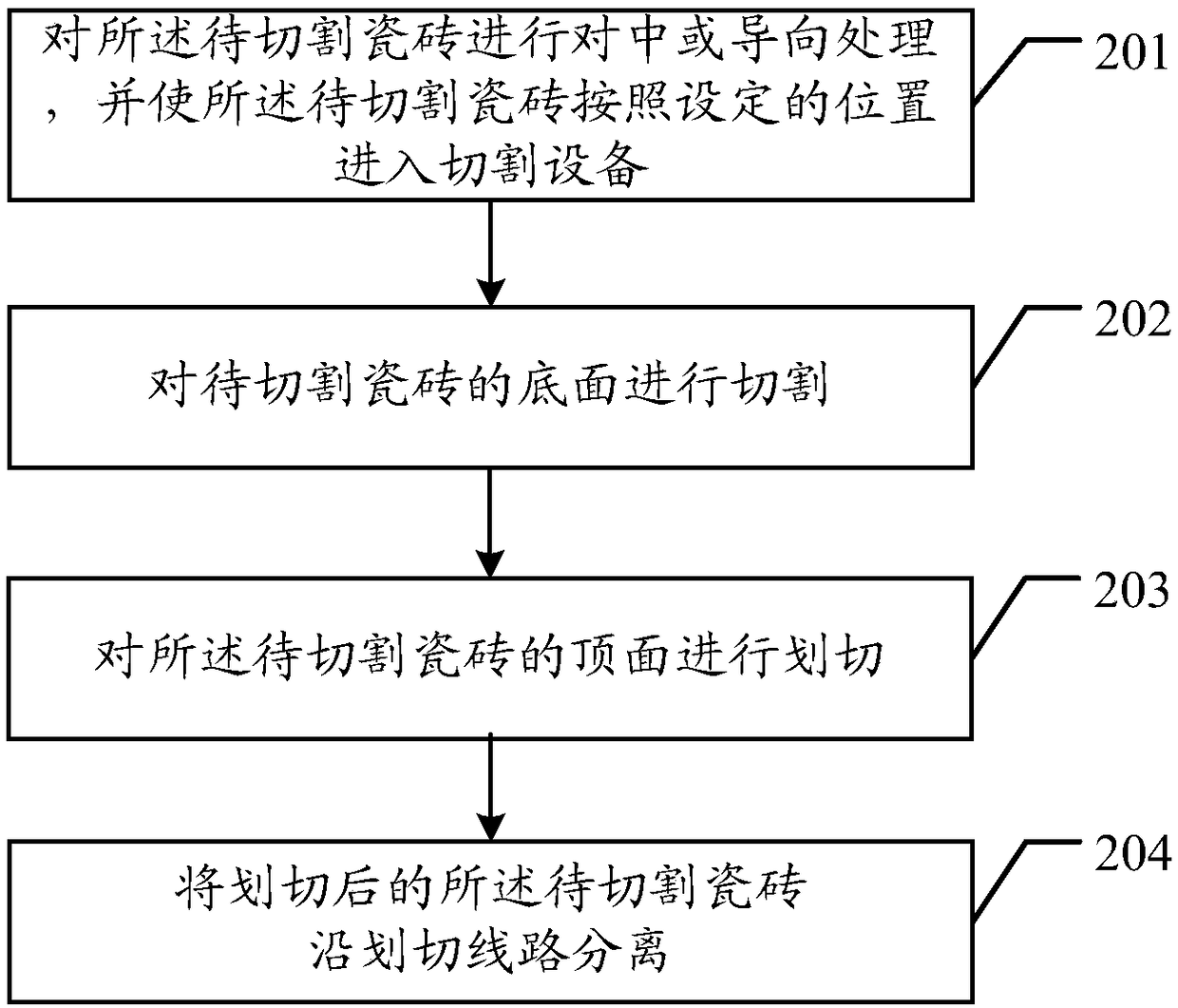

[0068] The first embodiment of the ceramic tile cutting process of the present invention has been introduced above, and the second embodiment of the ceramic tile cutting process of the present invention will be described in detail below, please refer to figure 2 , the second embodiment of the ceramic tile cutting process of the present invention, comprising:

[0069] 201: Perform centering or guiding processing on the tiles to be cut, and make the tiles to be cut enter the cutting device according to the set position;

[0070] After the tiles to be cut are loaded, the tiles to be cut can be centered or guided first, so that the tiles to be cut can enter the cutting equipment according to the set position. It should be noted that the tiles to be cut can also be directly fed to the set cutting position by the robot without adding a centering process, which is not limited here.

[0071] 202: cutting the bottom surface of the tile to be cut;

[0072] Then the bottom surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com