Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205 results about "Scratch marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What Are Causes of Scratch Marks on the Skin? Some common causes for a scratch on the skin are a self-inflicted scratch, a light skin injury or an animal's claws. Another cause may be a skin condition called dermatographia, notes Mayo Clinic. Most scratches to the skin occur through events such as a ...

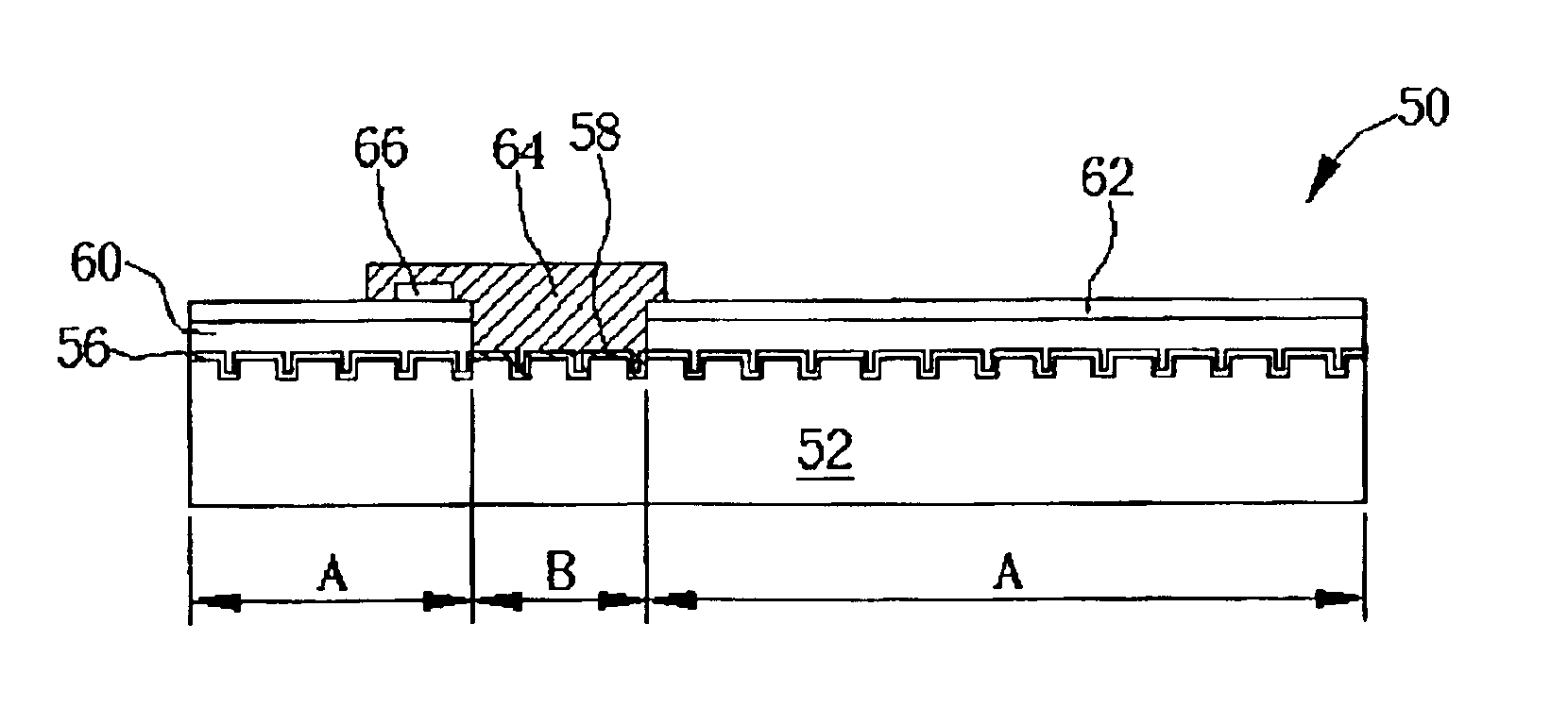

Scratch pad block

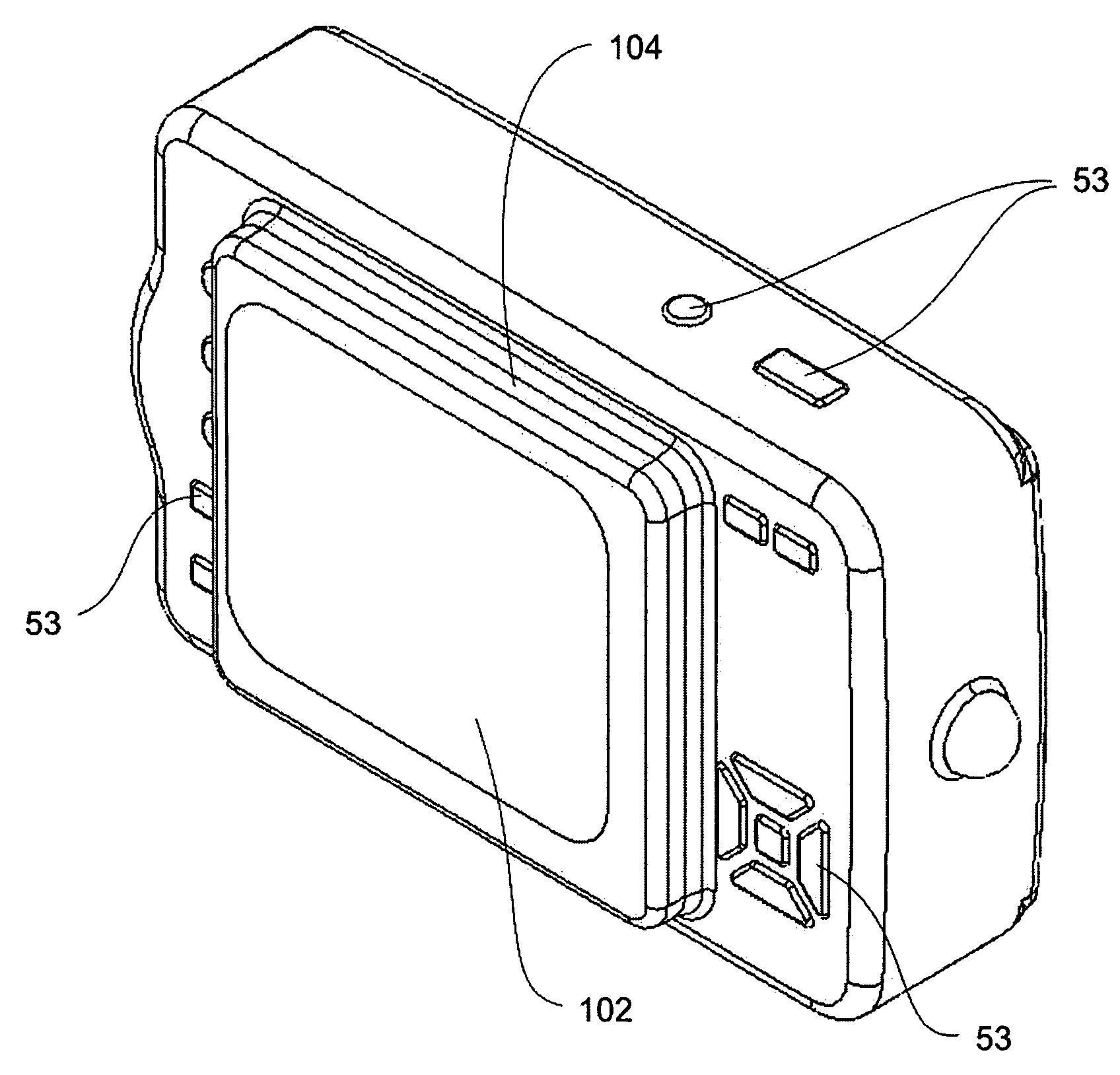

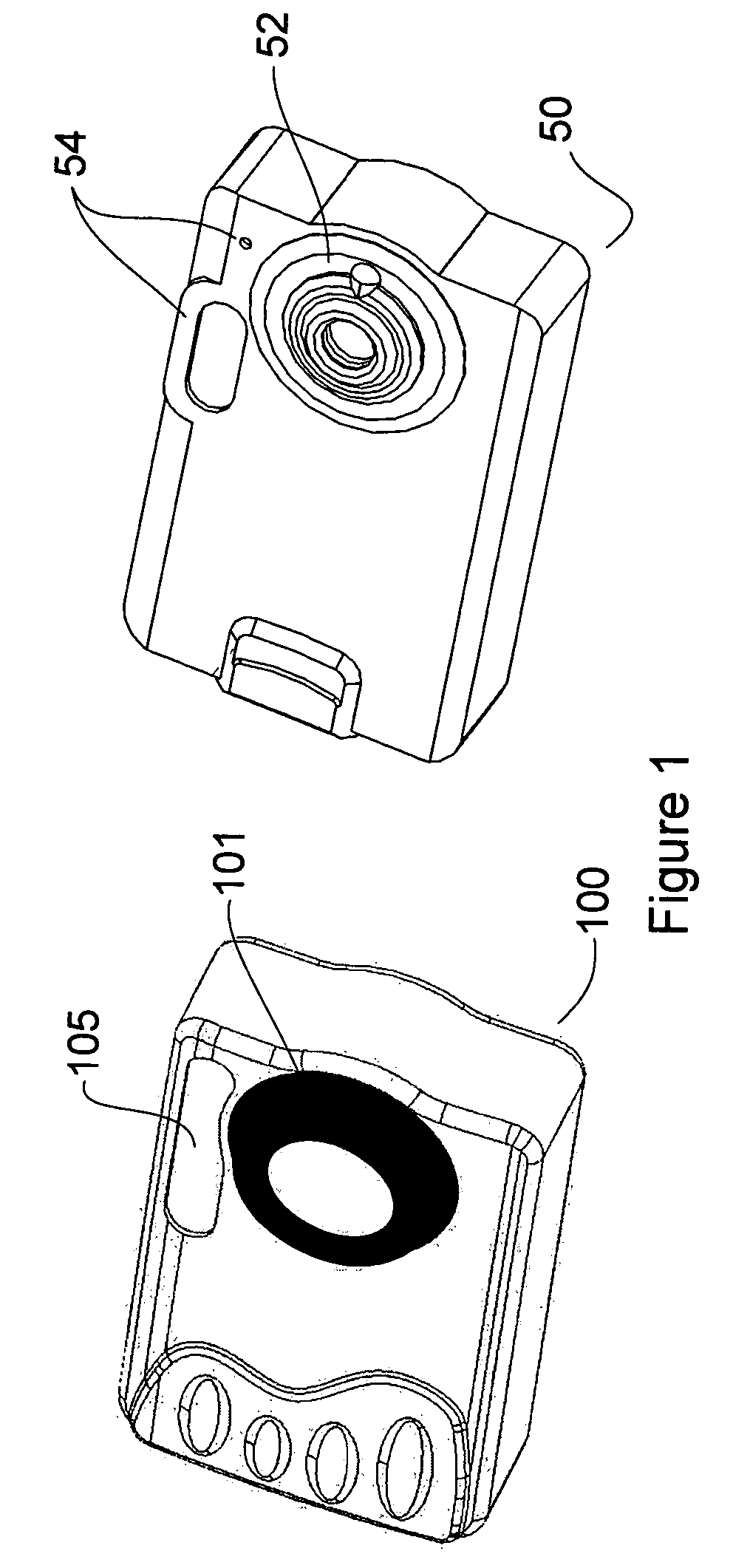

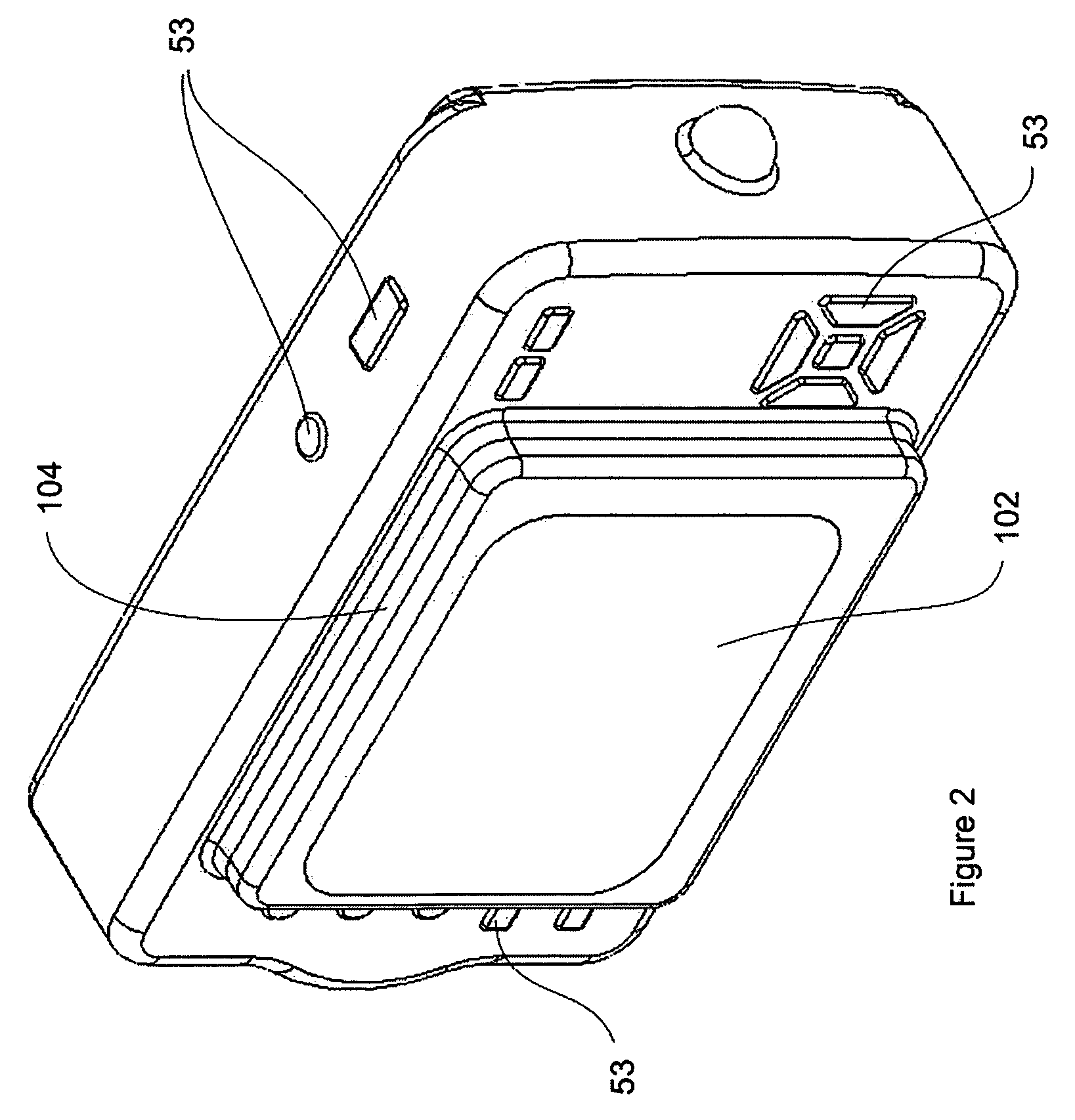

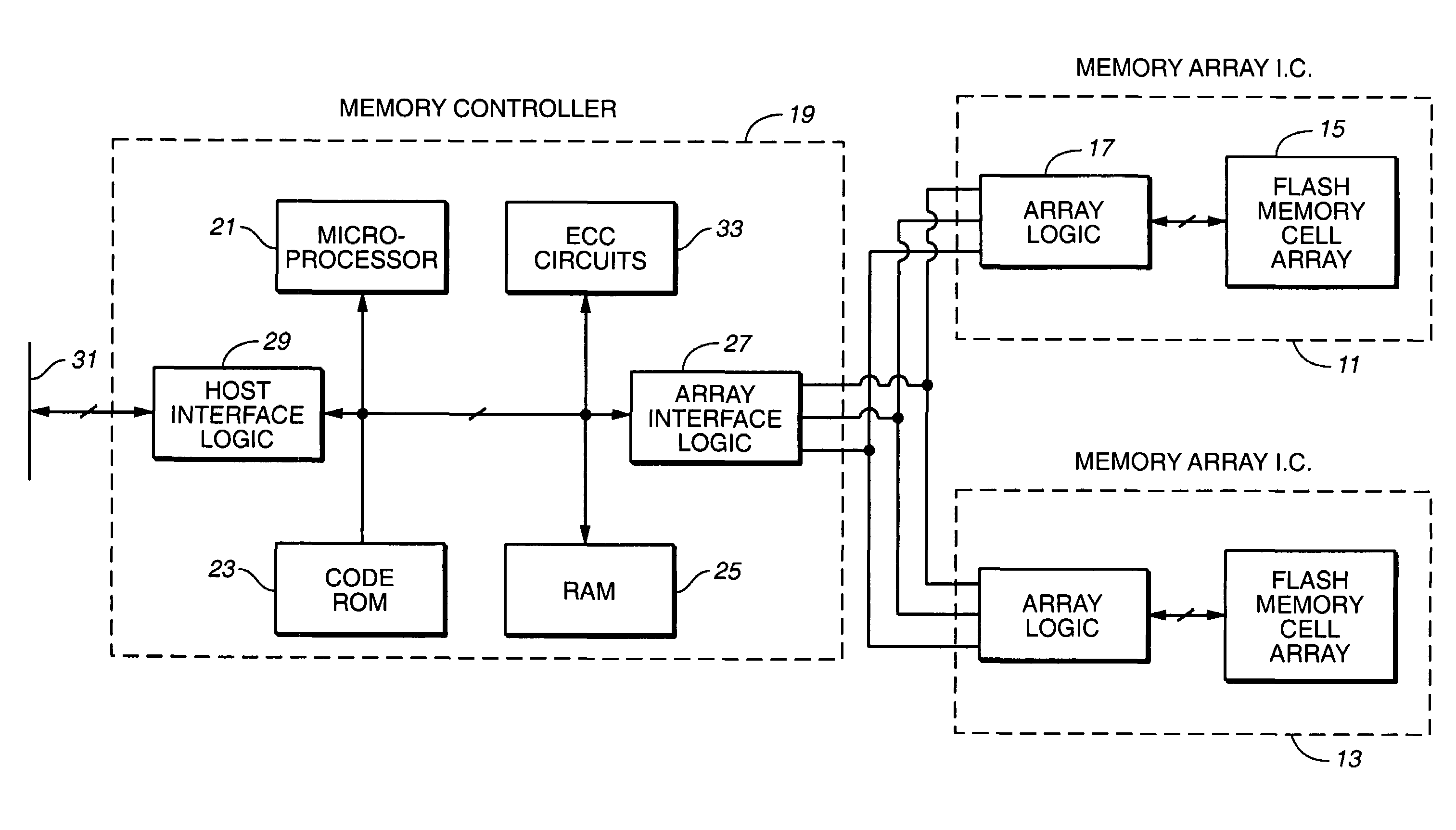

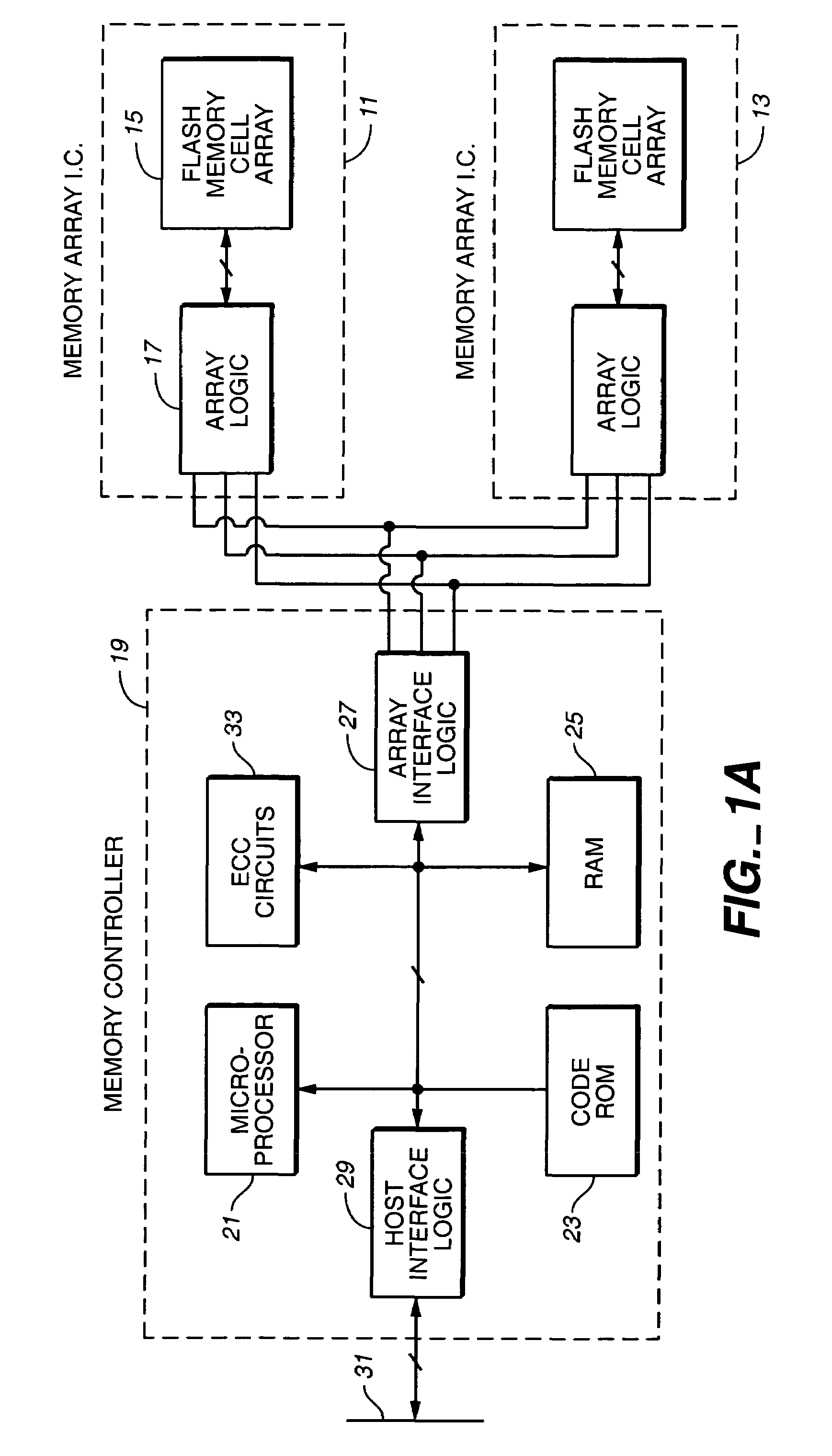

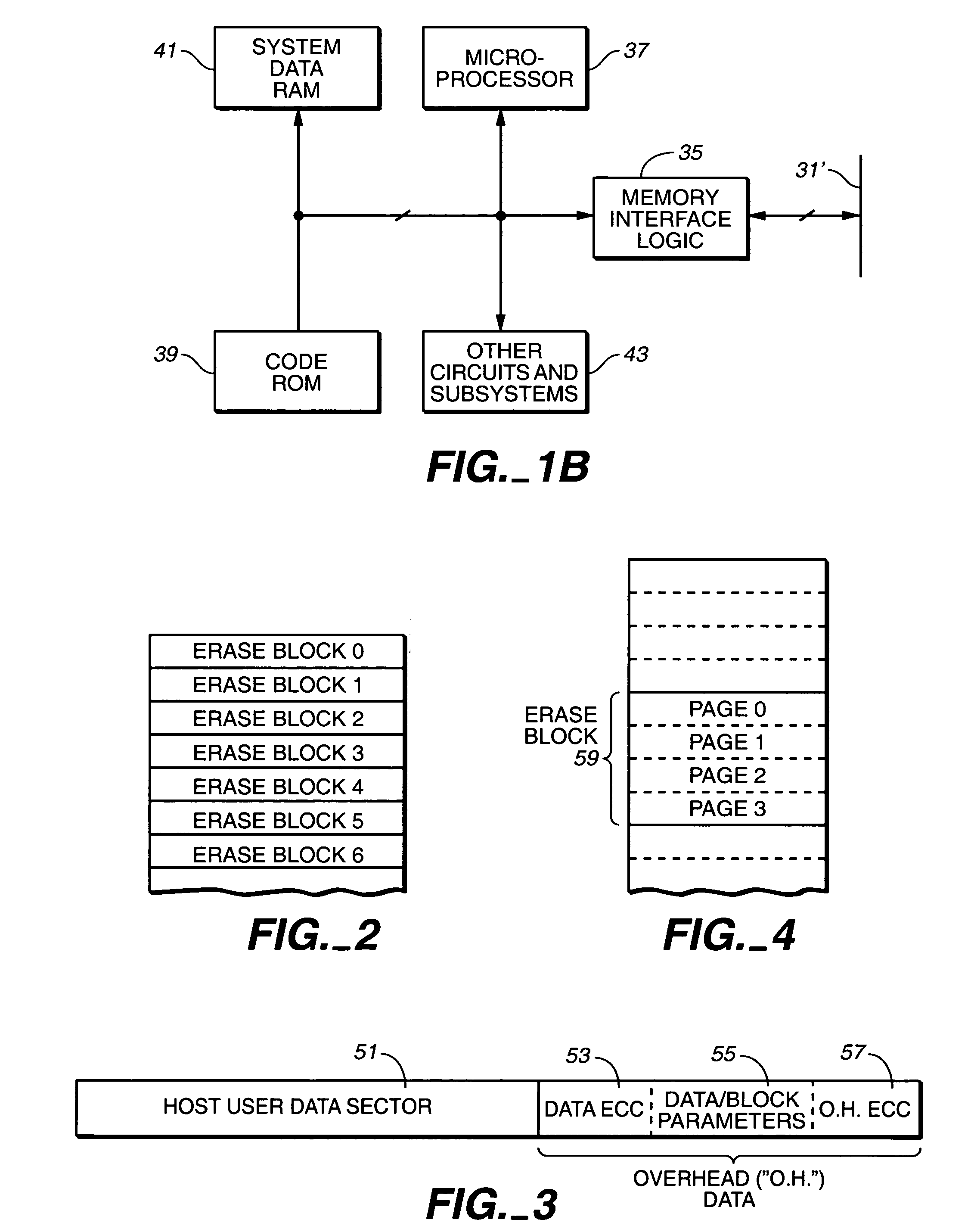

ActiveUS7315916B2Improve performanceWrite efficientlyMemory architecture accessing/allocationRead-only memoriesHigh densityHigh velocity

In a memory array having a minimum unit of erase of a block, a scratch pad block is used to store data that is later written to another block. The data may be written to the scratch pad block with a low degree of parallelism and later written to another location with a high degree of parallelism so that it is stored with high density. Data may be temporarily stored in the scratch pad block until it can be more efficiently stored elsewhere. This may be when some other data is received. Unrelated data may be stored in the same page of a scratch pad block.

Owner:SANDISK TECH LLC

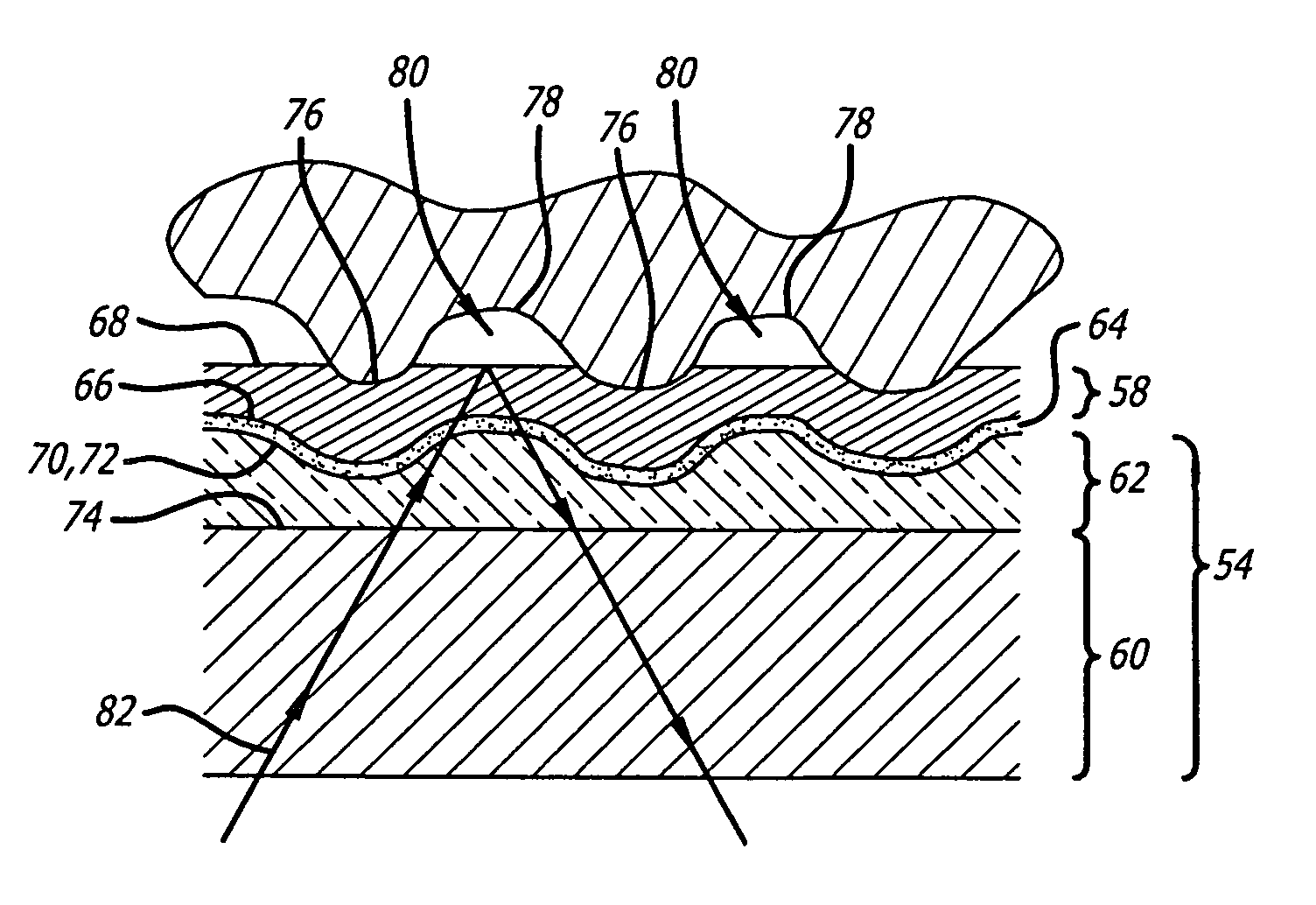

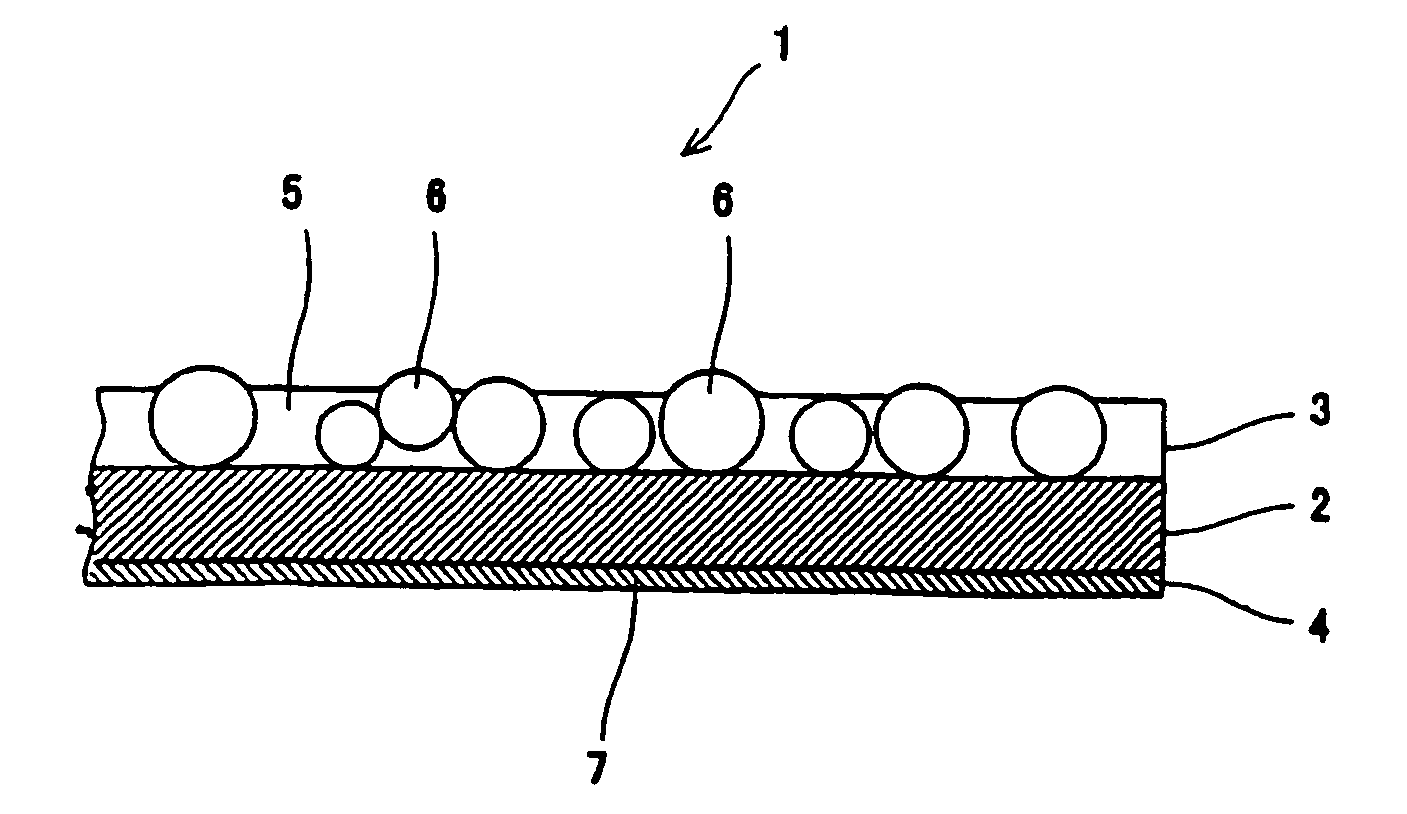

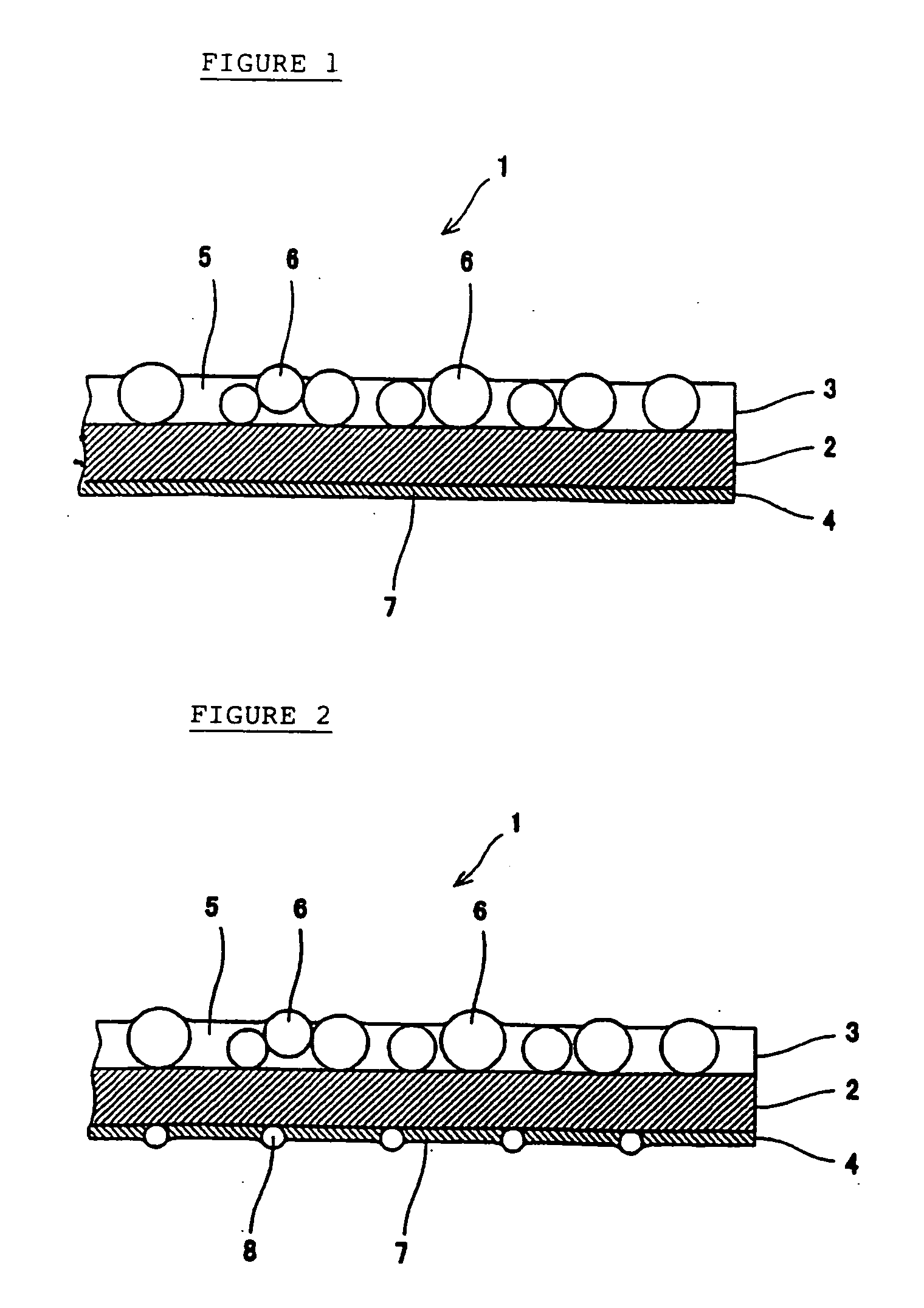

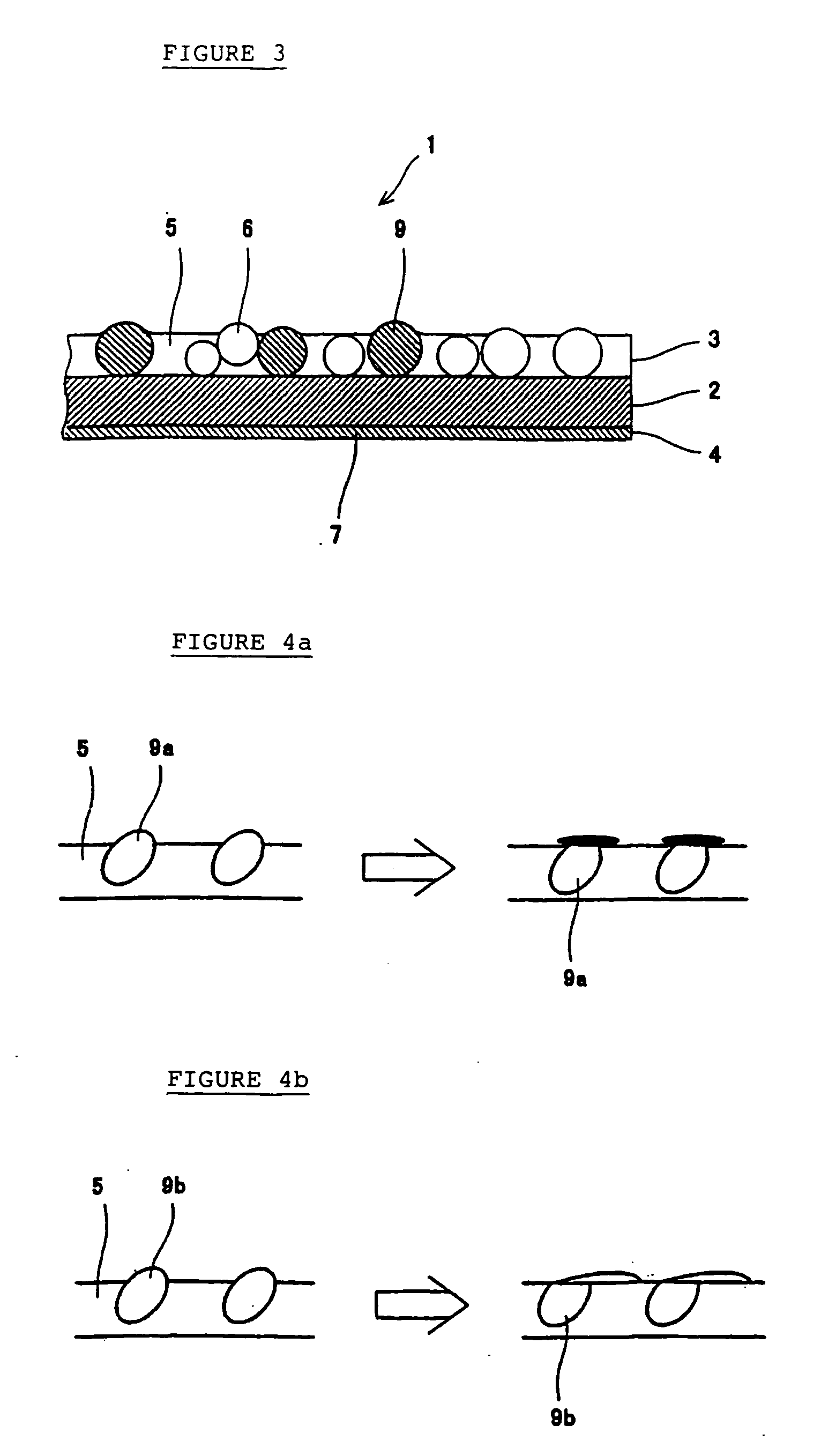

Light diffusion sheet and backlight unit using the same

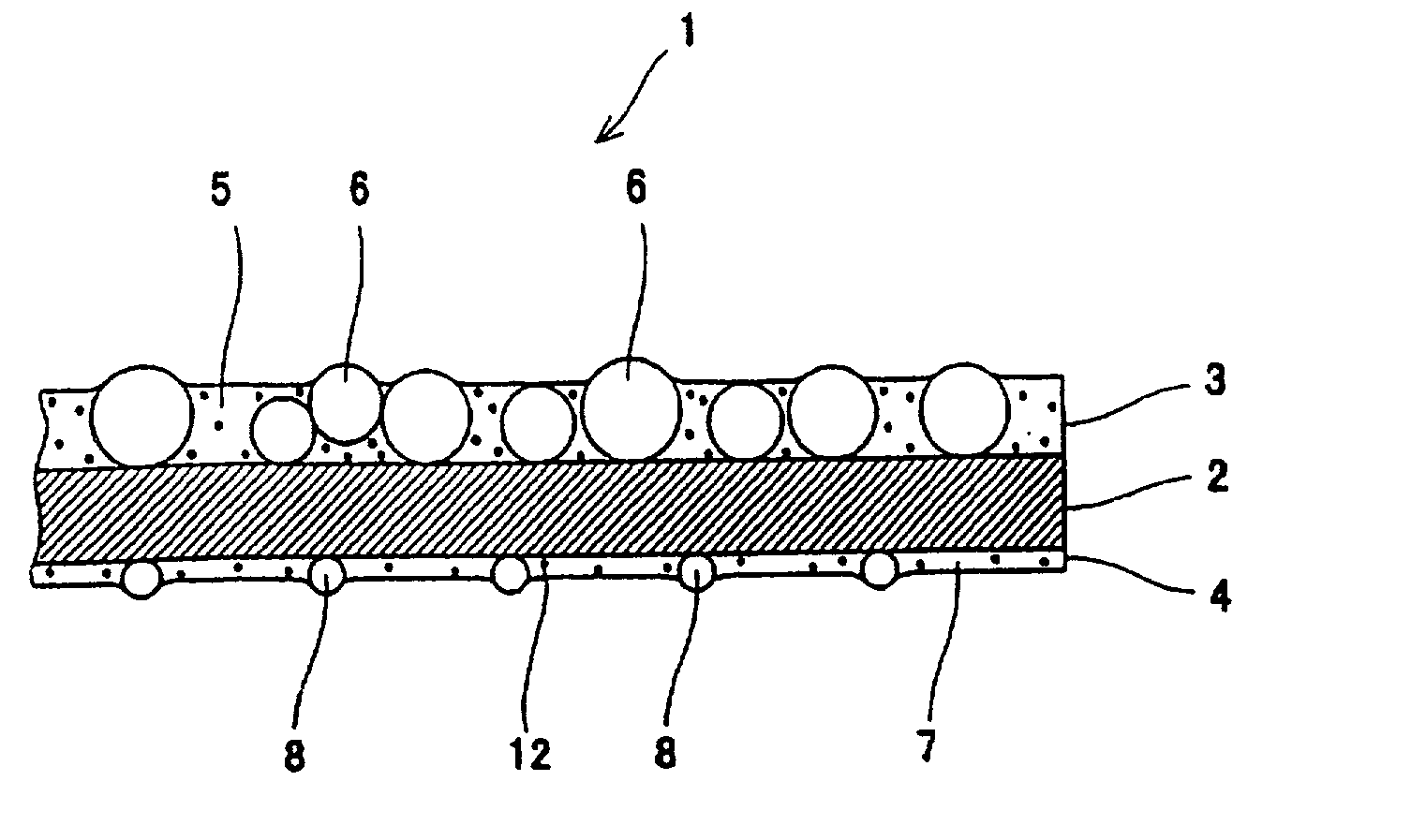

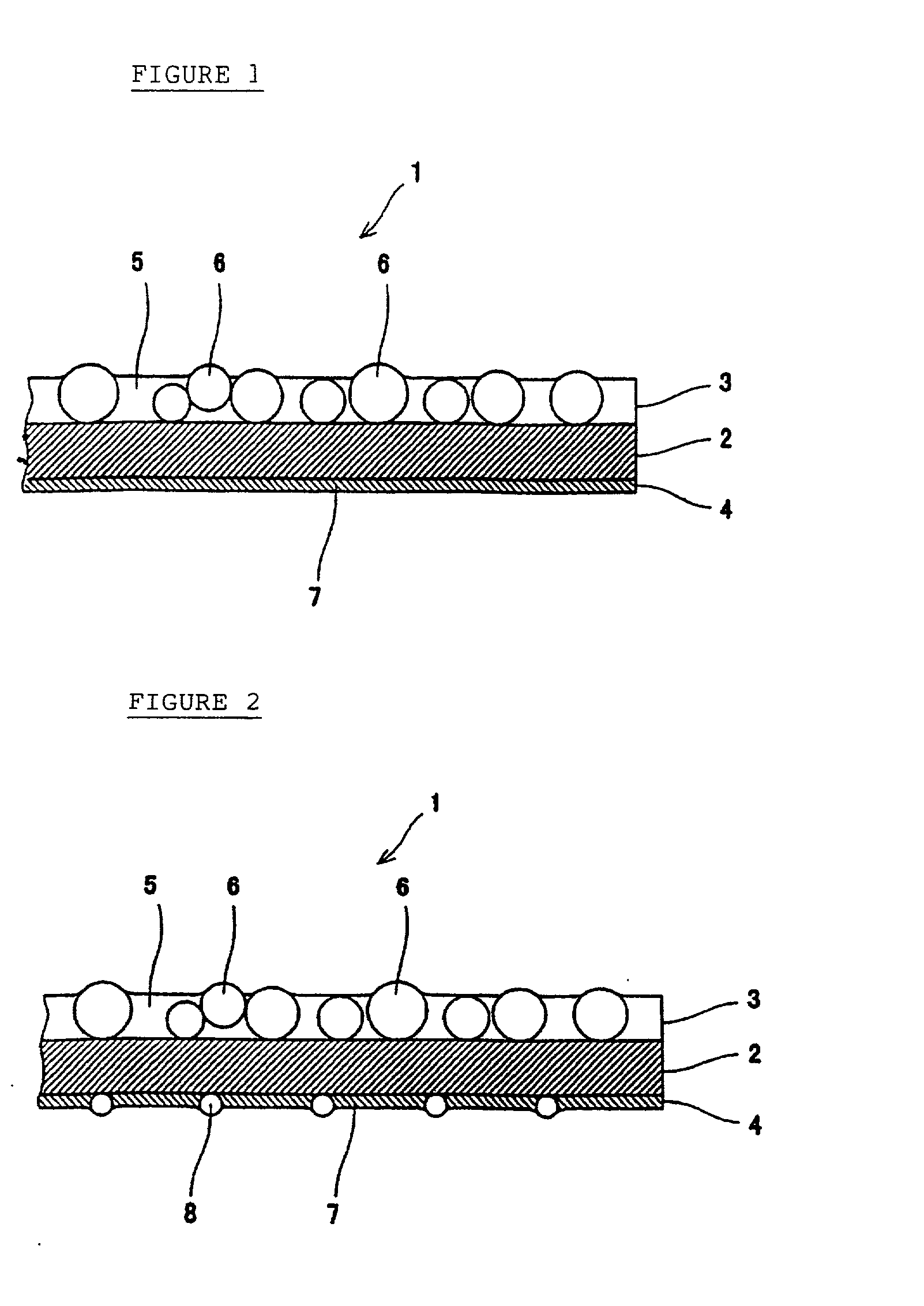

InactiveUS20020114169A1Resists deflectionEasy to handleMechanical apparatusElectric discharge tubesCross-linkDiffusion

A light diffusion sheet comprising a transparent base material sheet; a light diffusion layer laminated on a surface of the base material sheet and containing beads dispersed within a binder; and a sticking-inhibiting layer laminated on a rear face of the base material sheet, wherein the binder of the light diffusion layer contains a thermosetting resin and the sticking-inhibiting layer is a resin layer containing an ionizing radiation curable resin. In the light diffusion sheet of the invention, which employs an ionizing radiation curable resin for the binder of the sticking-inhibiting layer, the cross-linking density of the binder can be increased, whereby the wear resistance of the sticking-inhibiting layer as well as the wear resistance of the rear face of the light diffusion sheet can be increased. Further, possible occurrence of scratches in the sticking-inhibiting layer, which is attributable to the contact between the sticking-inhibiting layer and the beads of the light diffusion layer, can be effectively avoided.

Owner:KEIWA INCORPORATED

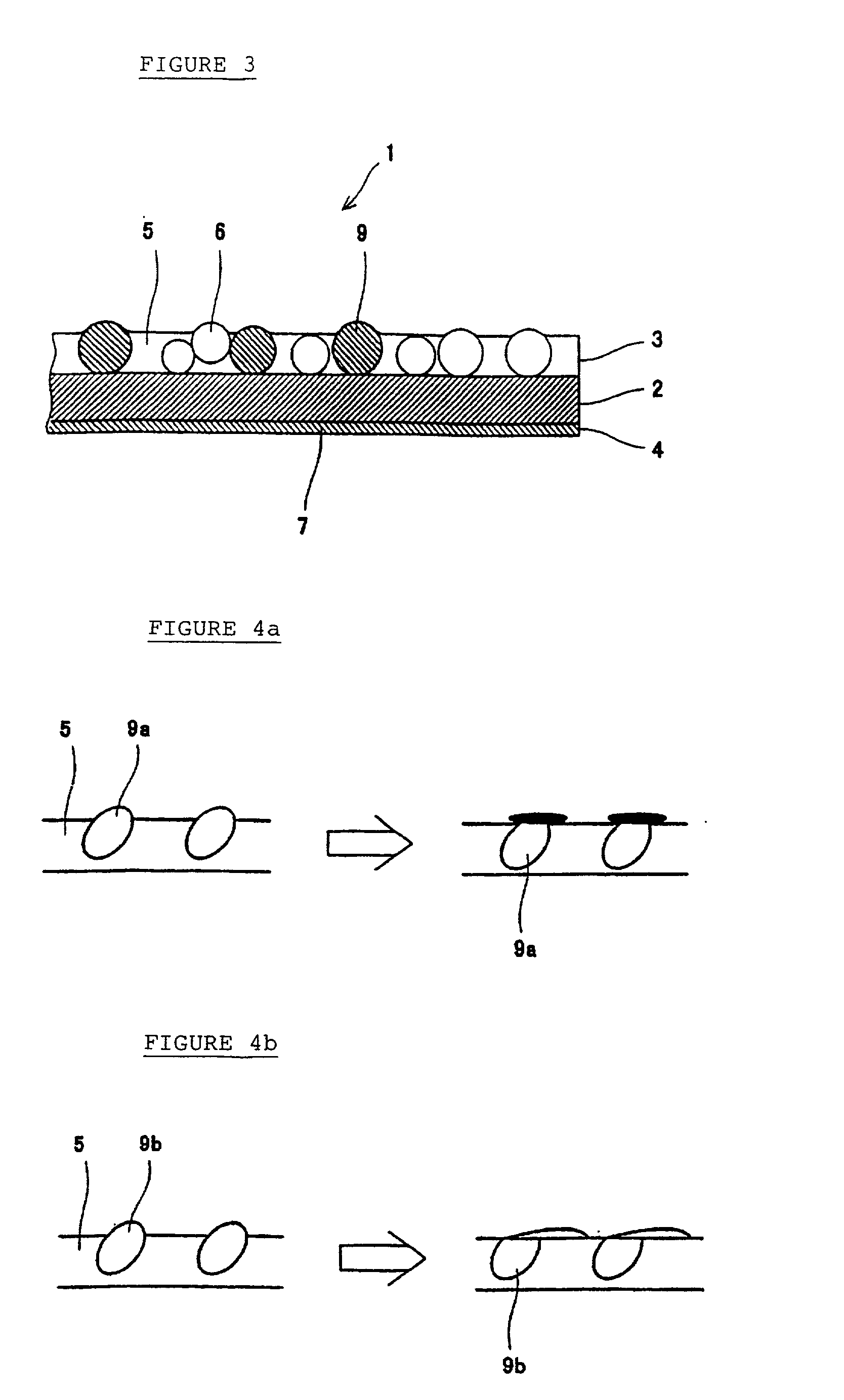

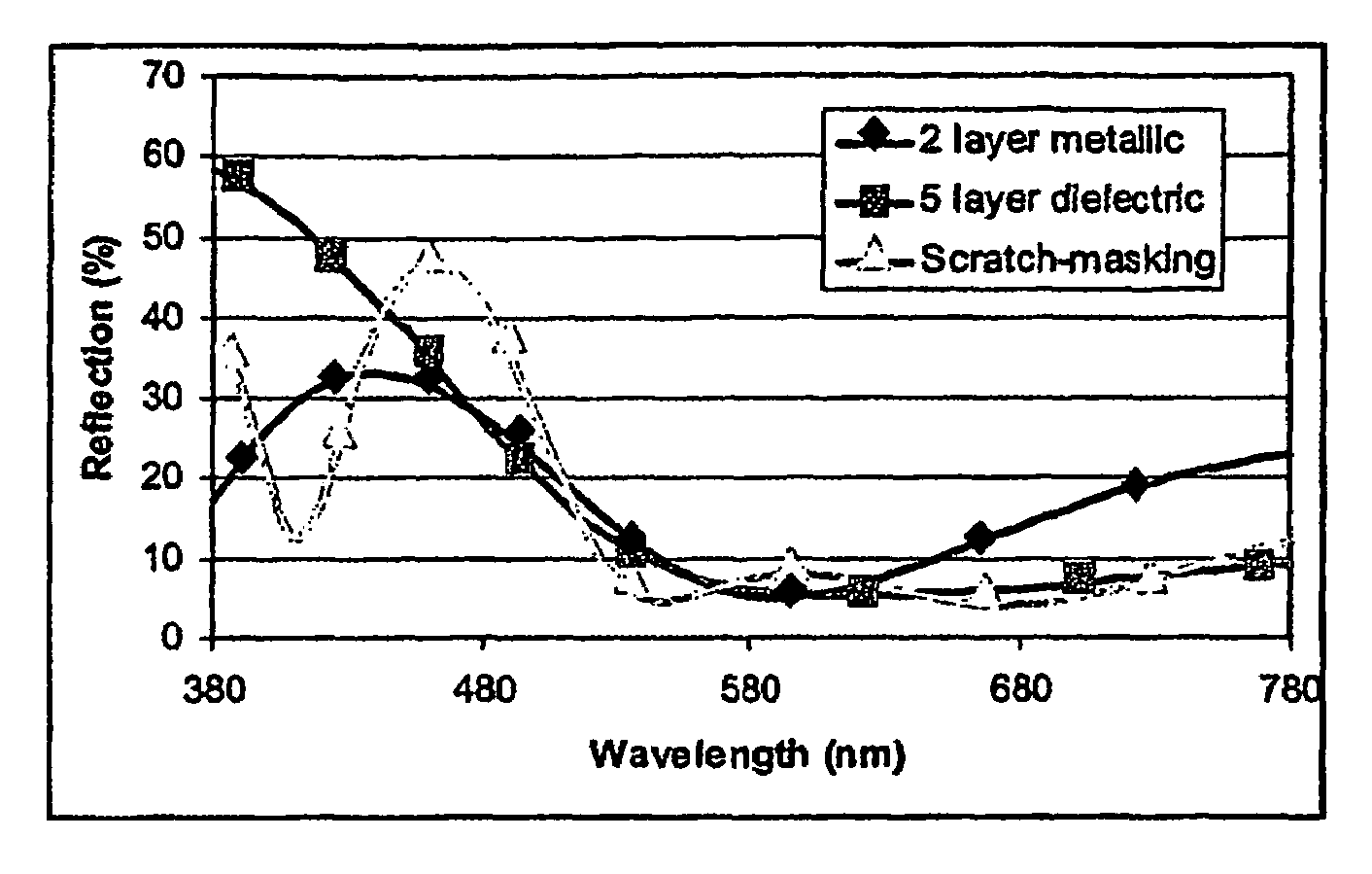

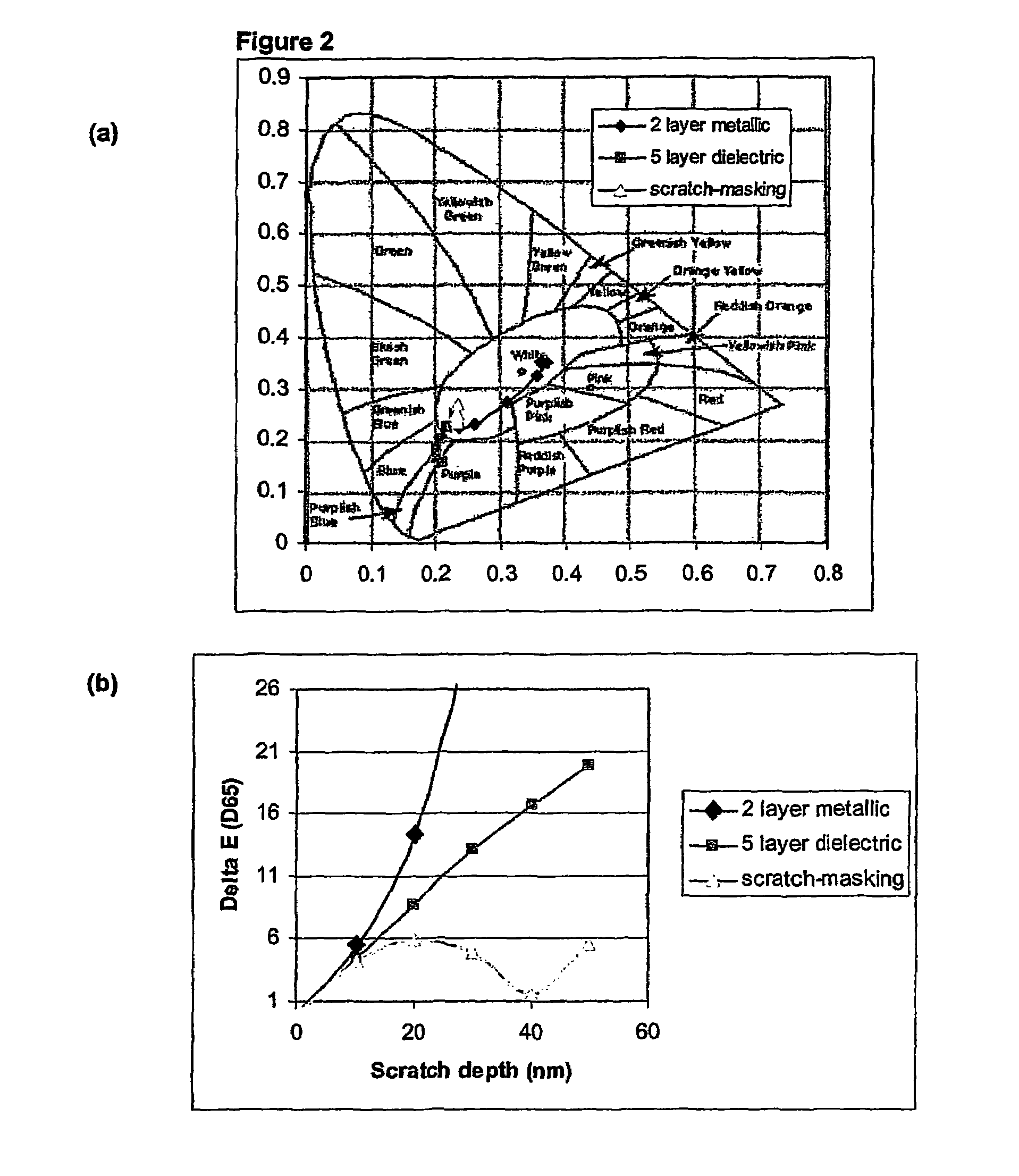

Scratch masking coating for glass containers

InactiveUS20090208657A1Flexible handlingMinimizes problemPretreated surfacesCoatingsBottleScratch marks

The present invention provides a scratch masking coating system for glass containers such as bottles that is adaptable to a variety of bottle surface and application conditions. The scratch masking coating is applied as an oil in water emulsion which provides flexibility in handling and application techniques while minimizing handling problems. In the present invention, the oil in water emulsion is treated with an emulsion breaker or destabilizer so that the emulsion is destabilized or broken after application to the surface to be treated. The destabilization or breaking is instigated by the addition of an emulsion breaker or heat to the emulsion in sufficient quantity to provide the desired break time.

Owner:ARKEMA INC

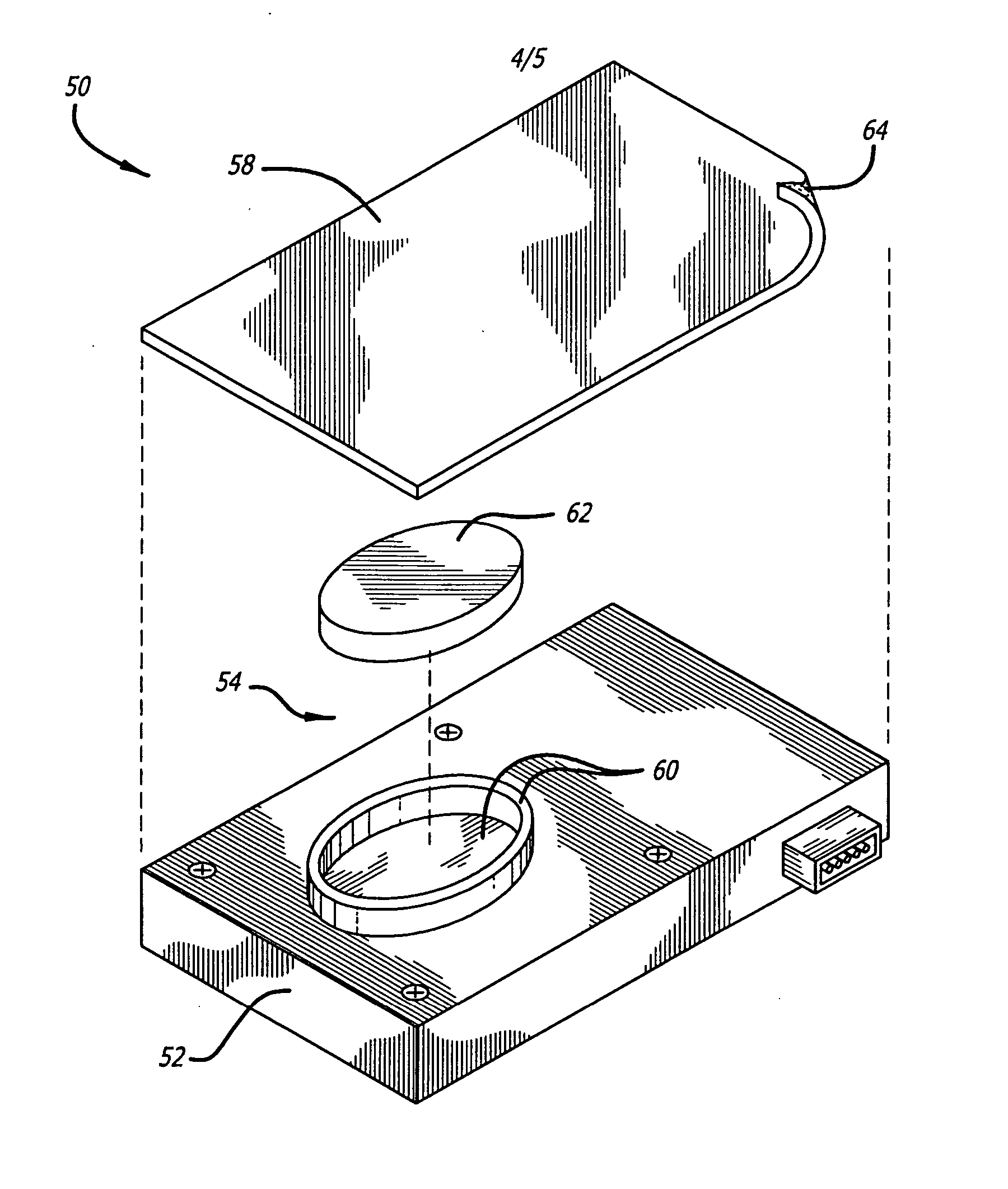

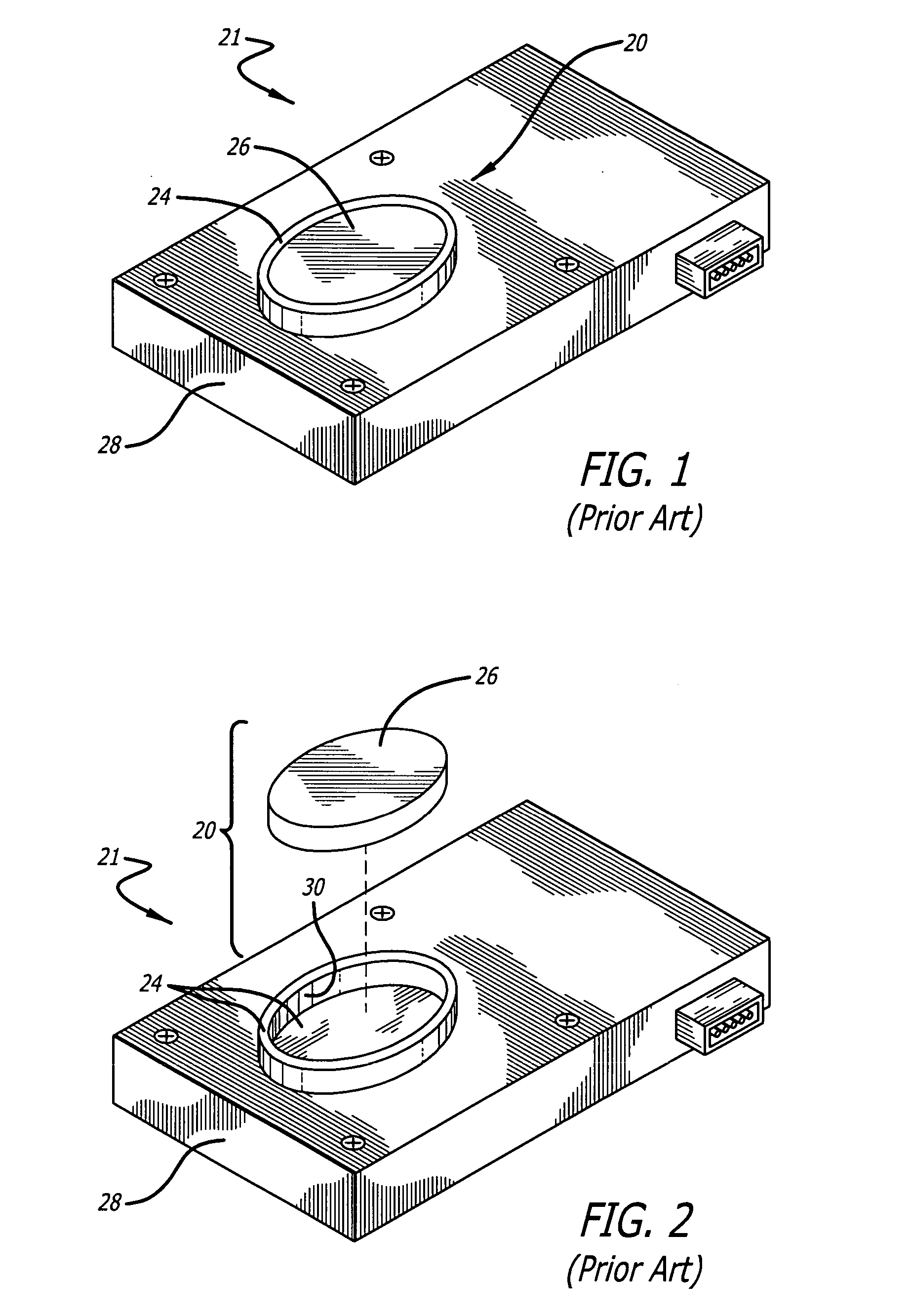

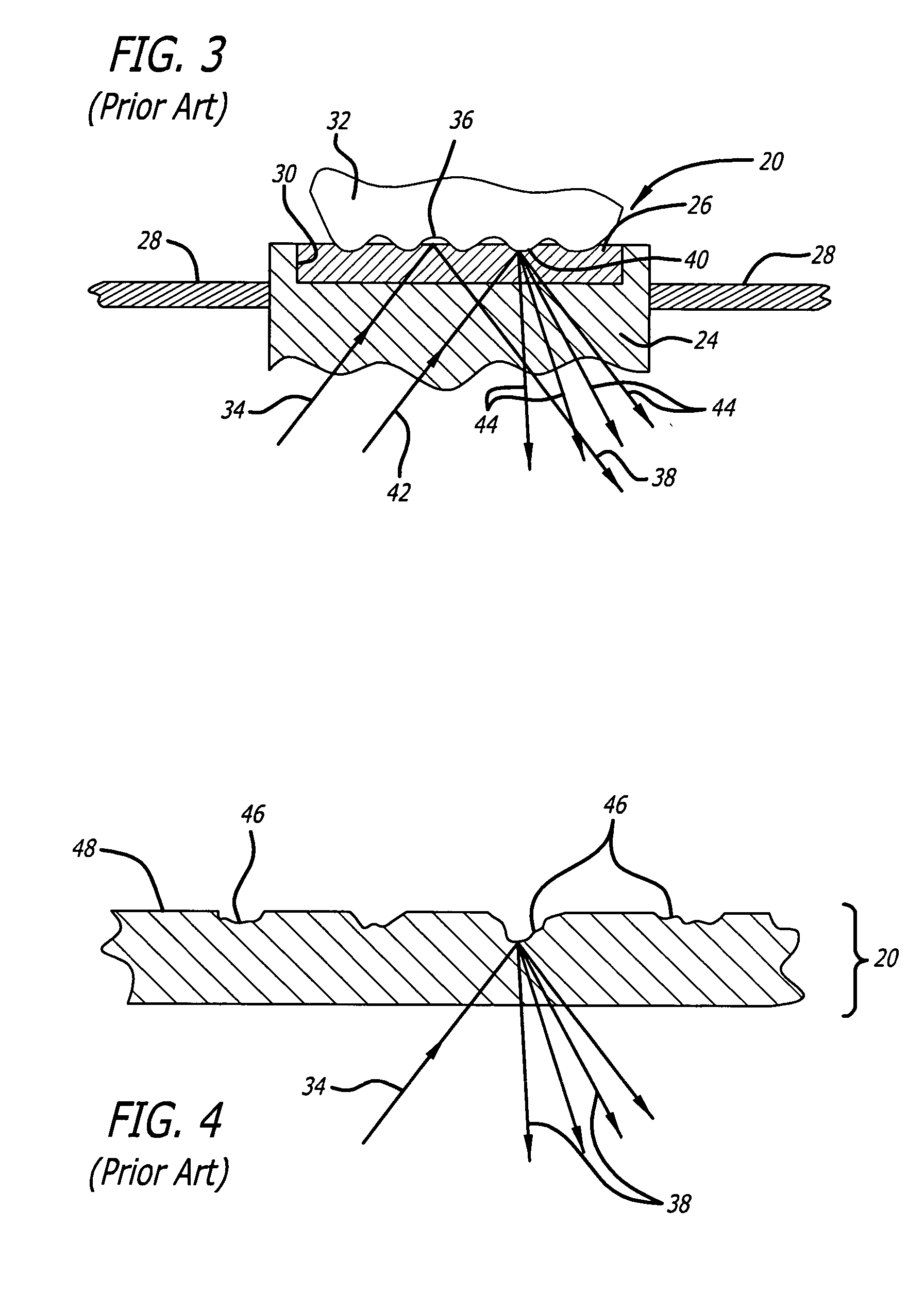

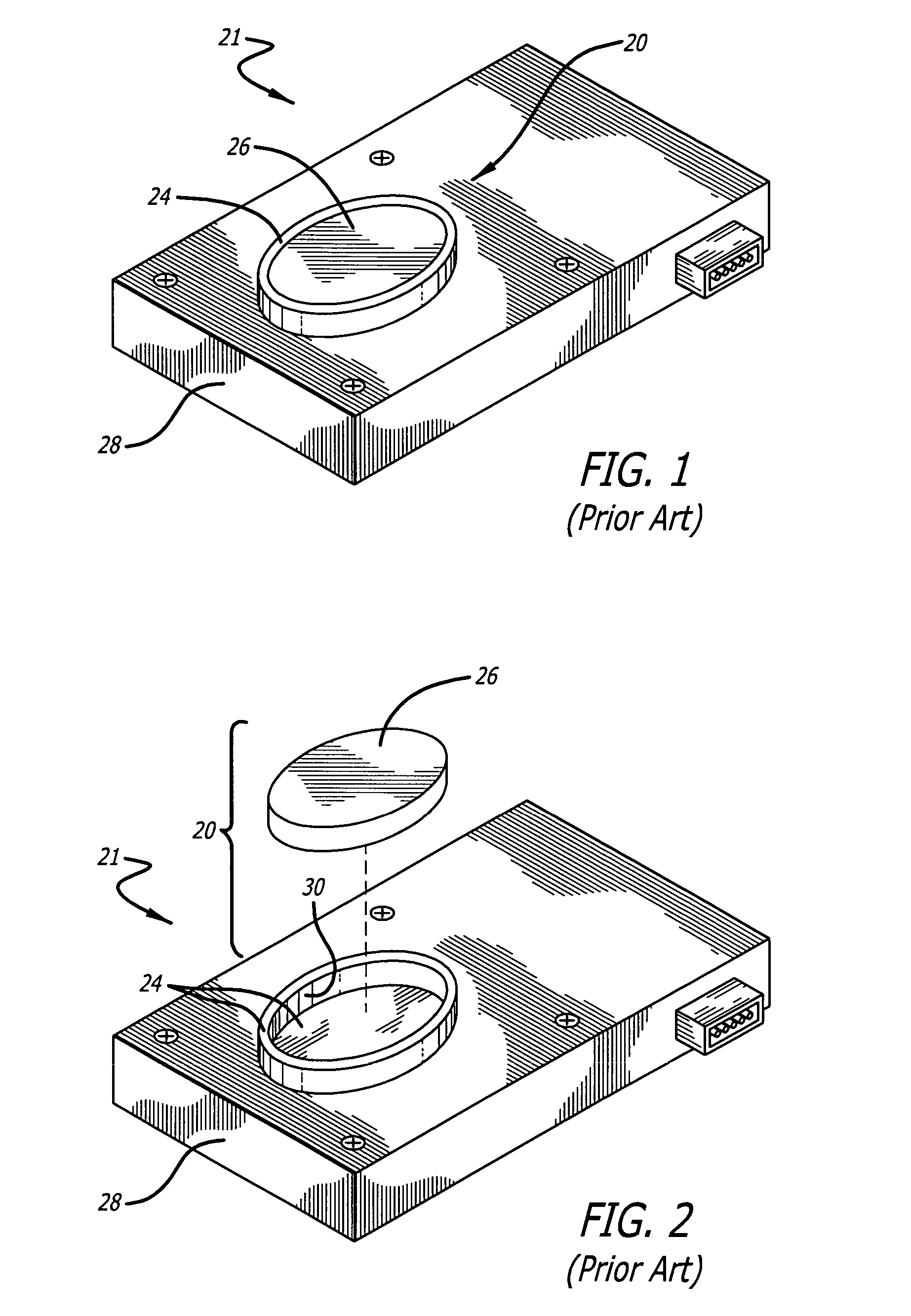

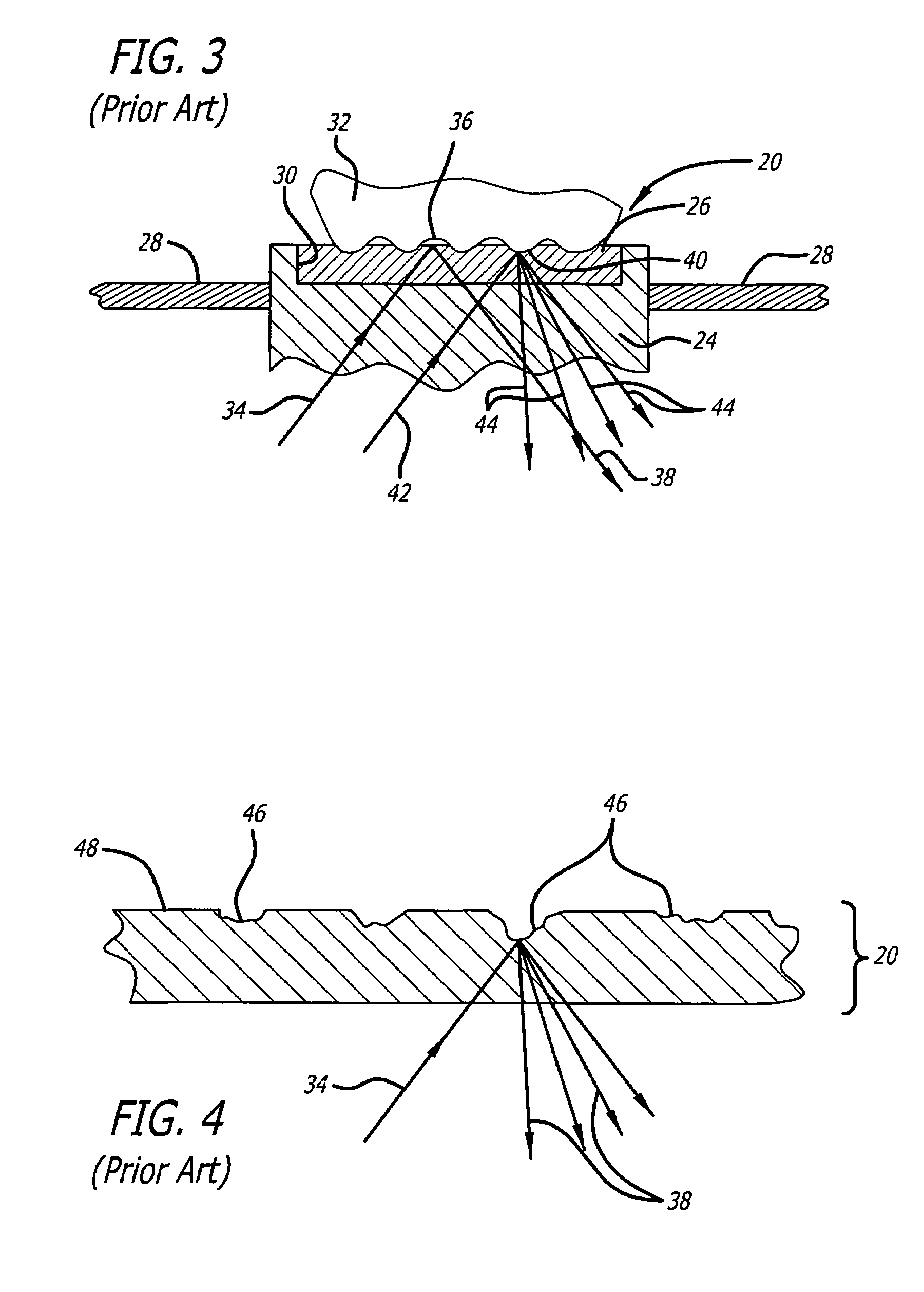

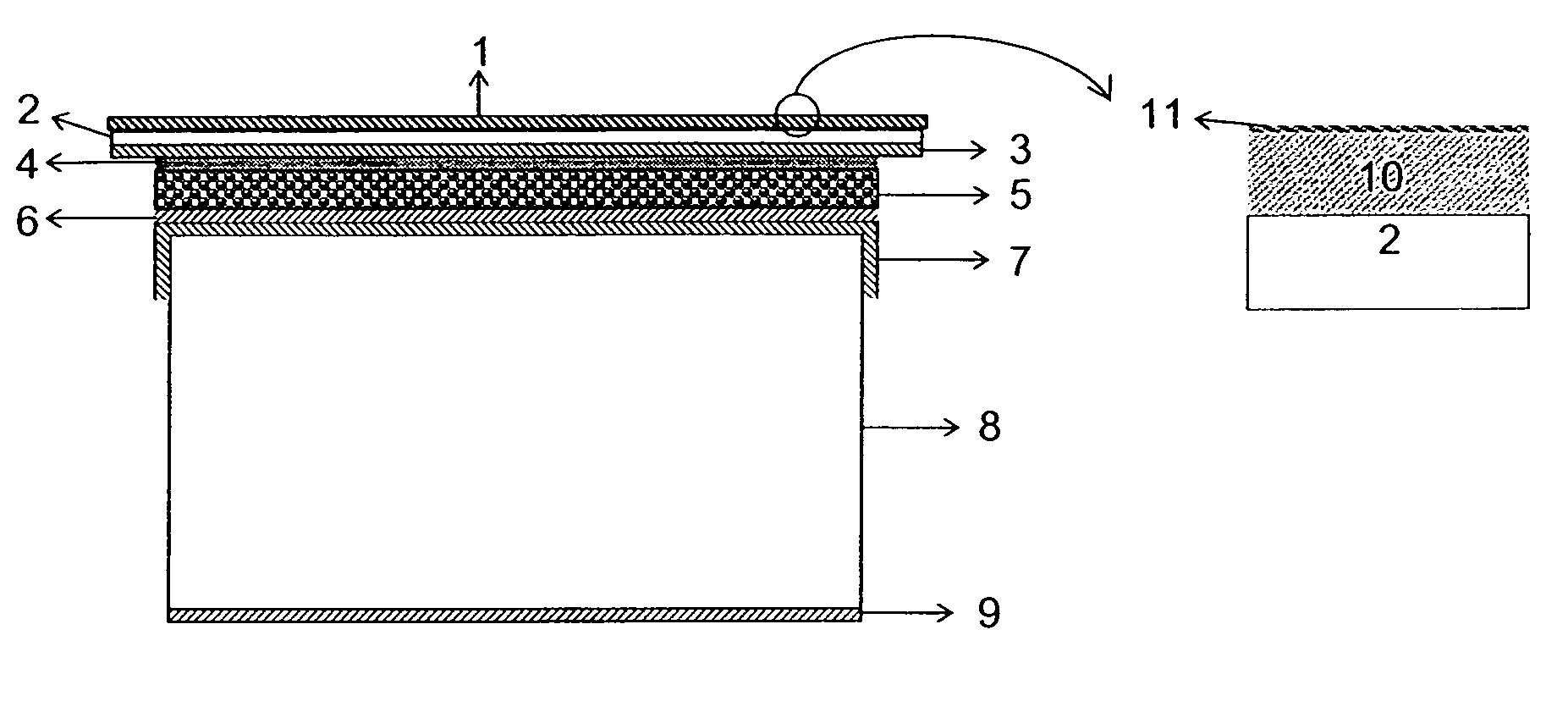

Optical fingerprint imaging system and method with protective film

ActiveUS20070153258A1Spread the wordPerson identificationPattern printingTectorial membraneEngineering

An optical fingerprint imaging system comprises an optically transparent platen and a protective film removably attached to the platen with an adhesive. The protective film protects the platen from scratches, pits, and other surface damage and is substantially chemically inert to petroleum-based substances which may come into contact when receiving a finger pressed to take a fingerprint image. The adhesive has a selected cohesive strength that allows the protective film and adhesive to be removed from the platen without leaving behind an adhesive residue. The protective film can be replaced periodically as part of maintenance of the platen to allow continued acquisition of accurate fingerprint images. A method for protecting a platen is also disclosed.

Owner:CAREFUSION 303 INC

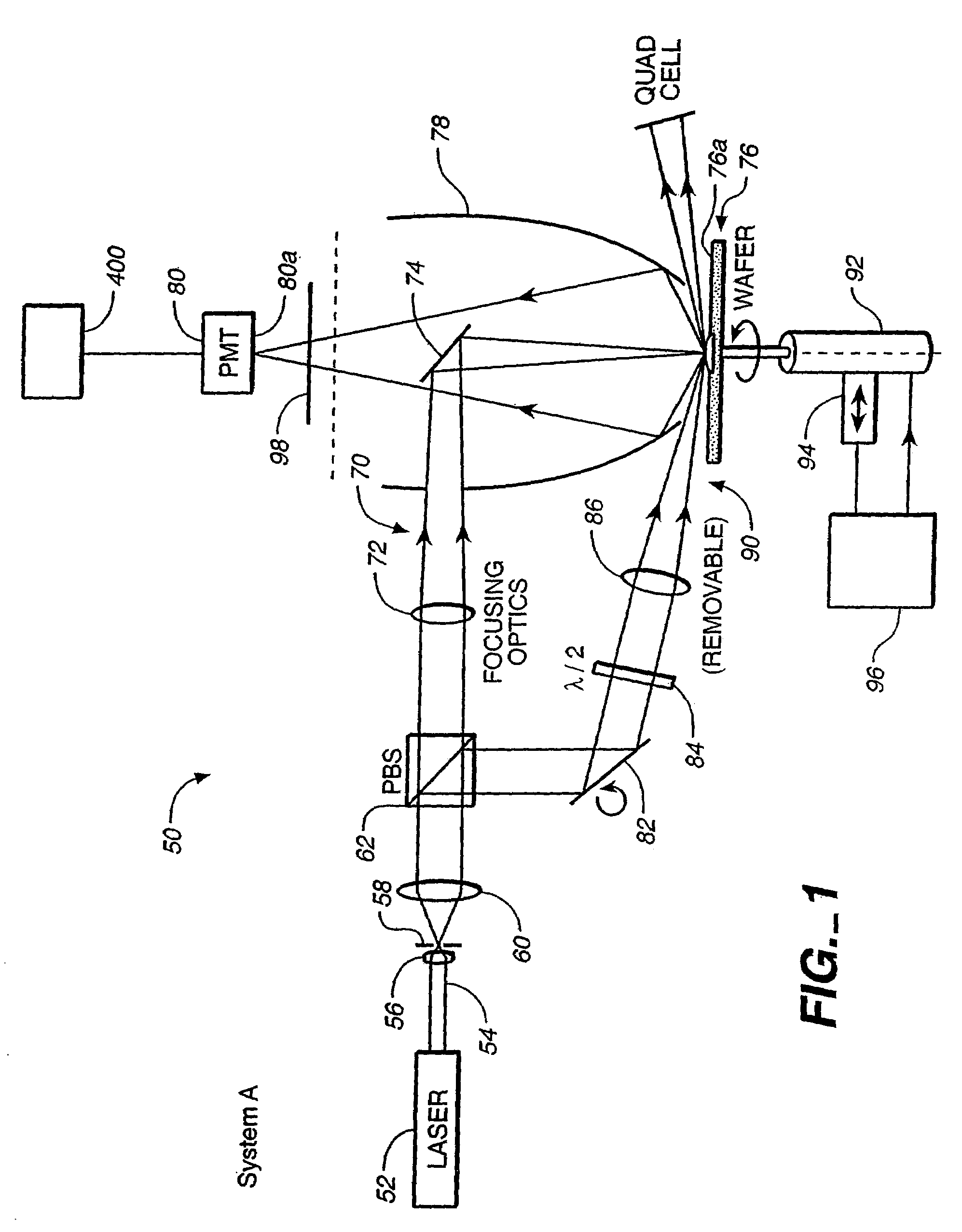

Surface inspection apparatus and method thereof

InactiveUS6894302B2Easy to findEfficient preparationSemiconductor/solid-state device testing/measurementInvestigating moving sheetsForeign matterEpi illumination

The invention provides a surface inspection apparatus and a method for inspecting the surface of a sample that are capable of inspecting discriminatingly between the scratch of various configuration and the adhered foreign object that occur on the surface of a work target when the work target (for example, an insulating film on a semiconductor substrate) is subjected to polishing process such as CMP or grinding process in semiconductor manufacturing process or magnetic head manufacturing process. In the invention, the scratch and foreign object that occur on the polished or ground surface of the sample is epi-illuminated and slant-illuminated by use of approximately same light flux, the difference between the scattered light intensity emitted from the shallow scratch and that from the foreign object when epi-illumination is applied and slant illumination is applied to thereby discriminate between the shallow scratch and the foreign object, and the directionality of the scattered light when the epi-illumination is applied and the slant illumination is applied is detected to thereby discriminate between the linear scratch and the foreign object.

Owner:HITACHI LTD +1

Apparatus for inspecting wafer surface, method for inspecting wafer surface, apparatus for judging defective wafer, method for judging defective wafer, and apparatus for processing information on wafer surface

InactiveUS7383156B2Accurate defect detectionEasy to detectSemiconductor/solid-state device testing/measurementNuclear monitoringPhysicsScratch marks

It is possible to inspect scratches and staining on a wafer surface on the basis of an LPD map obtained from a particle counter 11, by providing a means 21 for detecting aggregation of clustered point defects (LPD) from two-dimensional distribution information 30 for such fine LPD on the surface of a silicon wafer, and an improvement in the inspection efficiency and the precision of judgements of “defective” status can be achieved. Furthermore, the system is devised so that the trend of generation of scratches and staining in a specified process can easily be detected by accumulating wafer surface information such as scratch information, staining information and the like for the wafer surface detected by a wafer surface inspection device 11 (especially as image information or numerical information), and superposing sets of information thus accumulated. Plans for improving processes can be made by both the wafer supplier and wafer consumer by sharing such information with both parties.

Owner:SUMCO TECHXIV

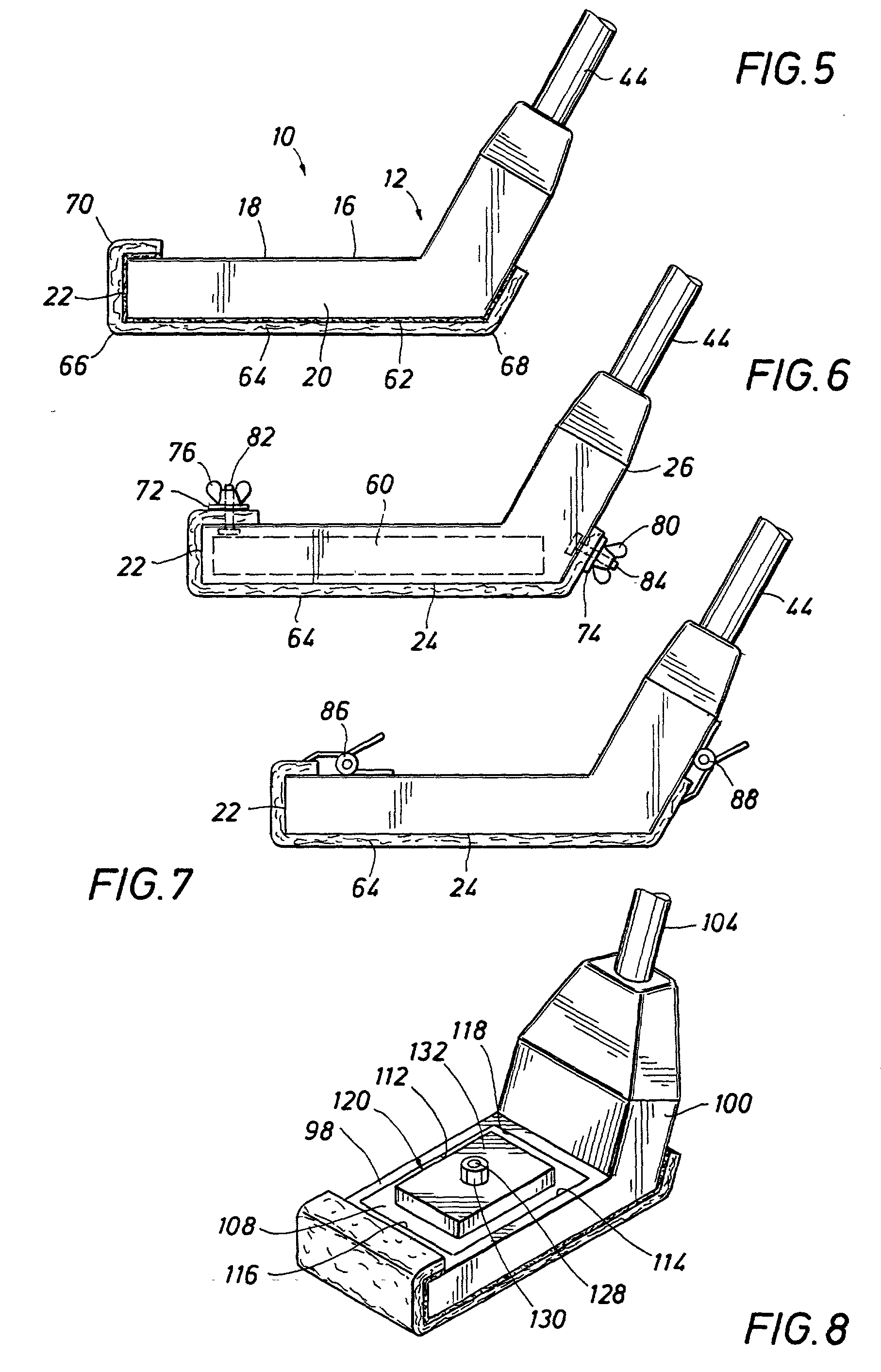

Scuff mark removal tool for floors

InactiveUS20040019995A1Reduce the amount requiredSimply and efficiently removedBoard cleaning devicesCarpet cleanersEdge surfaceEngineering

A manual scuff mark removal tool for removing random scuff marks from floor surfaces has an angulated head with a pad support block which has a bottom surface and a front edge surface and defines toe and heel corners and edges. A handle projection is defined by the head and is oriented in obtuse angular relation with the pad support block and defines a handle receptacle receiving a handle with a hand grip. A weight is preferably encapsulated within the head for continuously applying a weight induced downward force to a floor during scuff mark removal. A replaceable pad is secured to and covers the bottom surface, front edge surface and the toe and heel corners of the pad support block and by selectively positioning the head of the tool, selected portions of the pad engages the floor surface being cleaned.

Owner:BLUEBONNET INDAL BRUSH

Optical fingerprint imaging system and method with protective film

An optical fingerprint imaging system comprises an optically transparent platen and a protective film removably attached to the platen with an adhesive. The protective film protects the platen from scratches, pits, and other surface damage and is substantially chemically inert to petroleum-based substances which may come into contact when receiving a finger pressed to take a fingerprint image. The adhesive has a selected cohesive strength that allows the protective film and adhesive to be removed from the platen without leaving behind an adhesive residue. The protective film can be replaced periodically as part of maintenance of the platen to allow continued acquisition of accurate fingerprint images. A method for protecting a platen is also disclosed.

Owner:CAREFUSION 303 INC

Surface inspection apparatus and method thereof

InactiveUS20050185172A1Efficient preparationImprove reliabilitySemiconductor/solid-state device testing/measurementInvestigating moving sheetsForeign matterEngineering

A surface inspection apparatus and a method for inspecting the surface of a sample are capable of inspecting discriminatingly between scratches of various configuration and adhered foreign objects that occur on the surface of a work target when the work target (for example, an insulating film on a semiconductor substrate) is subjected to a polishing process such as CMP or a grinding process, in semiconductor manufacturing process or magnetic head manufacturing process. In the invention, the scratch and foreign object that occur on the polished or ground surface of the sample is epi-illuminated and slant-illuminated by use of approximately same light flux, the difference between the scattered light intensity from the shallow scratch and from the foreign object is applied to thereby discriminate between the shallow scratch and the foreign object, and the directionality of the scattered light is detected to discriminate between the linear scratch and the foreign object.

Owner:HITACHI LTD +1

Composition curable with actinic energy ray and use thereof

InactiveUS20050148739A1Improve scratch resistancePolyurea/polyurethane coatingsOptical elementsScratch marksMaterials science

In a cured product having a thickness of 60 μm obtained from an actinic energy ray-curable composition of the present invention, when a scratch mark is made at a vertical load of 235 mN using a diamond indenter with a tip diameter of 15 μm, the scratch mark is repaired by a self-repairing ability under an atmosphere at 25° C. and at a relative humidity of 50%. Therefore, the actinic energy ray-curable composition is useful as coating agents or paints for products where scratch resistance is required.

Owner:NATOCO

Apparatus and method for inspecting defects

InactiveUS7187438B2Improve reliabilityImprove efficiencyImage analysisSemiconductor/solid-state device testing/measurementLuminous fluxUltimate tensile strength

The present invention is characterized by the following: incident illumination and oblique illumination are performed on a scratch and a foreign material, which have been made on a surface of a polished or a ground insulating layer, with substantially the same luminous flux; and on the basis of a correlation such as a ratio of intensity of scattered light generated by the shallow scratch and the foreign material between the incident illumination and the oblique illumination, the shallow scratch is discriminated from the foreign material.

Owner:HITACHI HIGH-TECH CORP +1

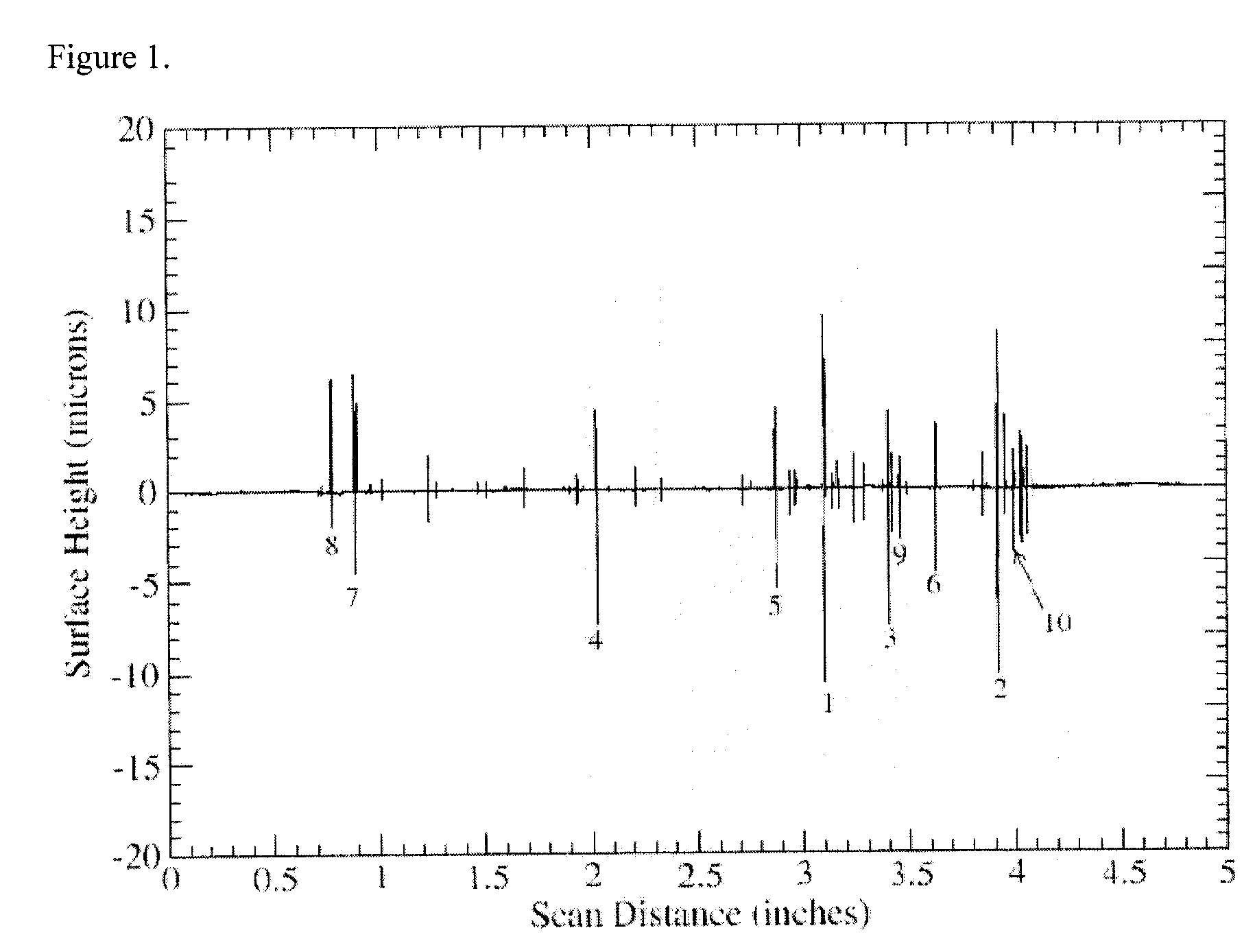

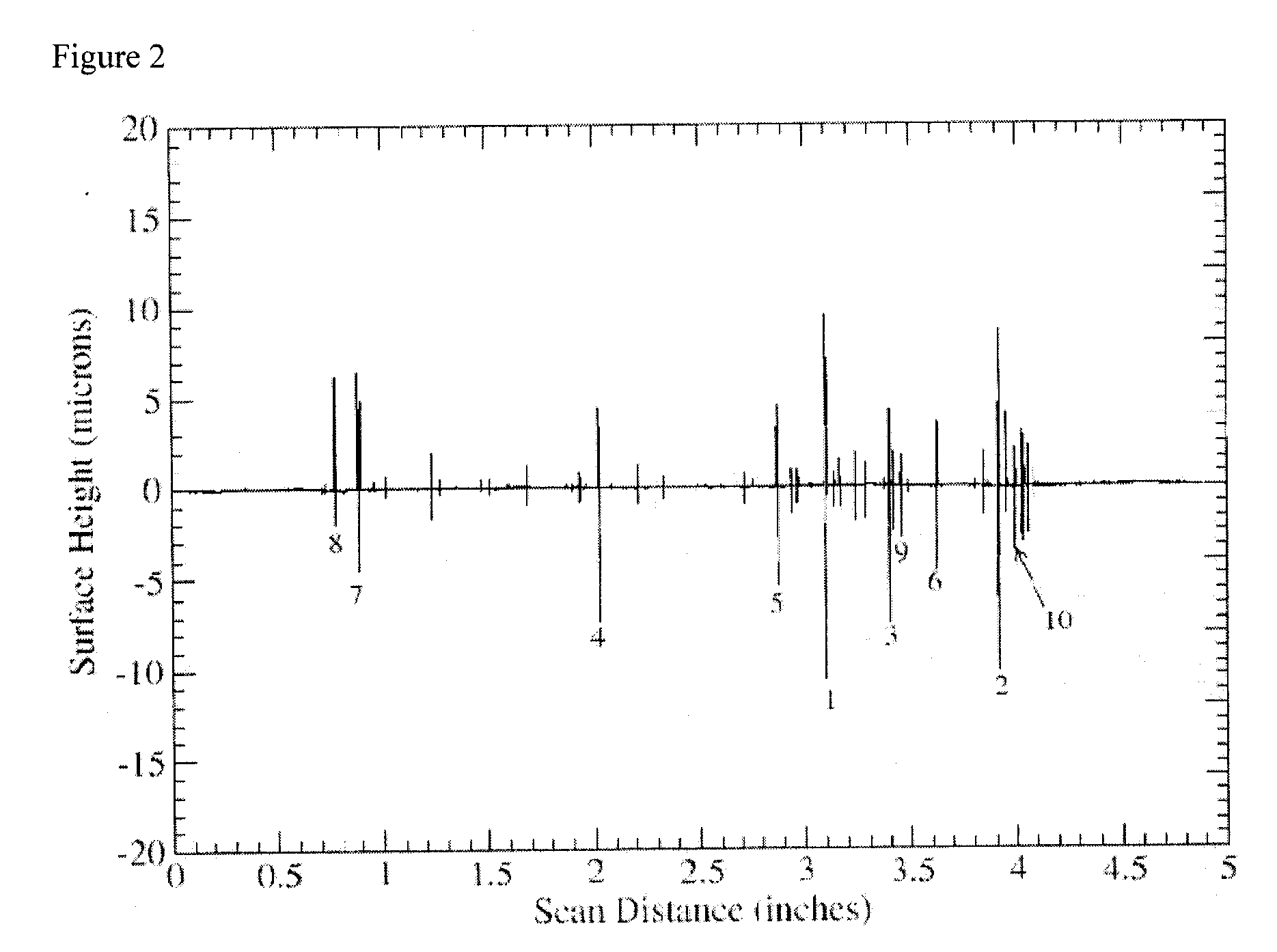

Method for counting and characterizing aggressive diamonds in cmp diamond conditioner discs

InactiveUS20100186479A1Using mechanical meansInvestigating abrasion/wear resistanceCircular discMicroscopic exam

The present invention is a method for determining the location of and distinguishing aggressive diamonds from active diamonds on a diamond conditioner disc, comprising: (a) contacting a diamond conditioner disc with a hard surface, wherein the diamond-containing side of the diamond conditioning disc is facing the hard surface, (b) pushing the conditioner disc a sufficient distance that all diamonds could possibly be scratching the surface at the same time and at least a distance corresponding to the length of the said diamond conditioner disc (c) observing number and position of the scratches left by diamonds on the hard surface to determine the number and position of active diamonds on the diamond conditioner disc, and (d) selecting the diamonds, the marks for which are the most pronounced and which comprise 50% or more of the total furrow area observed for all of the active diamonds in descending order of furrow are plus any diamonds in excess of the number needed to achieve said 50% or more whose individual furrow area is 2% or more, which diamonds are determined to be aggressive diamonds, or impressing the diamond conditioner disc under a load onto a hard surface and the impression of the most aggressive diamonds in the hard surface being confirmed by microscopic examination to in turn confirm the position and aggressiveness of the aggressive diamonds observed or (e) contacting a diamond conditioner disc with a hard surface, wherein the diamond-containing side of the diamond conditioning disc is facing the hard surface, (f) pushing the conditioner disc a sufficient distance that all diamonds could possibly be scratching the surface at the same time and at least a distance corresponding to the length of the said diamond conditioner disc (g) observing number and position of the scratches left by diamonds on the hard surface to determine the number and position of active diamonds on the diamond conditioner disc, (h) the hard surface further comprises a layer of contrasting material such that when the diamond conditioner disc moves across the hard surface, the said diamond conditioner disc crosses the limits of the layer entirely from one end to the other and scratches the layer of contrasting material on the hard surface thereby leaving a visible mark, (i) the said layer is between 8 and 15 microns thick and (j) selecting the diamonds which cut entirely through the said layer allowing backlighting to be easily viewed.

Owner:ARACA

Defect detection system

InactiveUS6862096B2Easy to detectReduce crosstalkPhotometry using reference valuePolarisation-affecting propertiesScanning probe microscopyOptical polarization

Scattered radiation from a sample surface is collected by means of a collector that collects radiation substantially symmetrically about a line normal to the surface. The collected radiation is directed to channels at different azimuthal angles so that information related to relative azimuthal positions of the collected scattered radiation about the line is preserved. The collected radiation is converted into respective signals representative of radiation scattered at different azimuthal angles about the line. The presence and / or characteristics of anomalies are determined from the signals. Alternatively, the radiation collected by the collector may be filtered by means of a spatial filter having an annular gap of an angle related to the angular separation of expected pattern scattering. Signals obtained from the narrow and wide collection channels may be compared to distinguish between micro-scratches and particles. Forward scattered radiation may be collected from other radiation and compared to distinguish between micro-scratches and particles. Intensity of scattering is measured when the surface is illuminated sequentially by S- and P-polarized radiation and compared to distinguish between micro-scratches and particles. Representative films may be measured using profilometers or scanning probe microscopes to determine their roughness and by the above-described instruments to determine haze in order to build a database. Surface roughness of unknown films may then be determined by measuring haze values and from the database.

Owner:KLA CORP

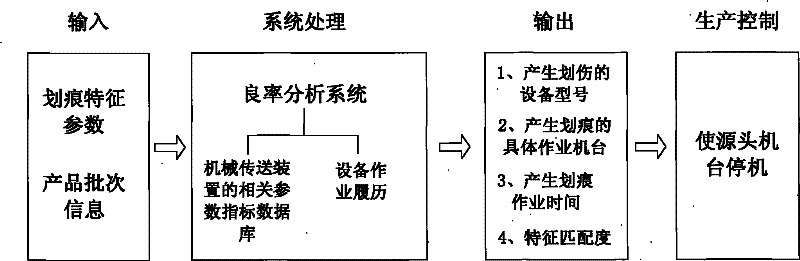

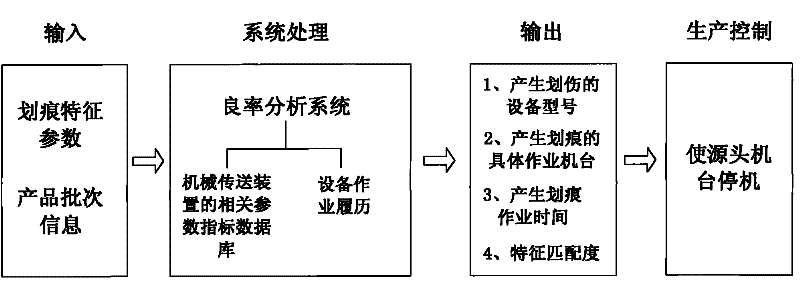

Method for detecting mechanical scratching condition of silicon wafers

InactiveCN102130030AReduce lossesAvoid time consumingSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationProduction lineSilicon

The invention discloses a method for detecting the mechanical scratching condition of silicon wafers. A method for detecting source machines which are subjected to mechanical scratching comprises the following steps of: 1, establishing a characteristic information database of a mechanical transmission device of a silicon wafer carrying device on a silicon wafer production line; 2, when detecting that the silicon wafers are subjected to the mechanical scratching on the production line, collecting characteristic parameters of silicon wafer scratches; 3, comparing the characteristic parameters of the silicon wafer scratches with the characteristic information of the mechanical transmission device in the database to retrieve equipment models matched with the scratches; and 4, analyzing the equipment operating records of the silicon wafers, and screening specific operating machines with the scratches and operating time out. By the method, the source machines with the scratches can be found quickly, and machine halt can be performed as soon as possible when the silicon wafers are scratched to reduce damaged batches and the loss of the wafers and improve the yield.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

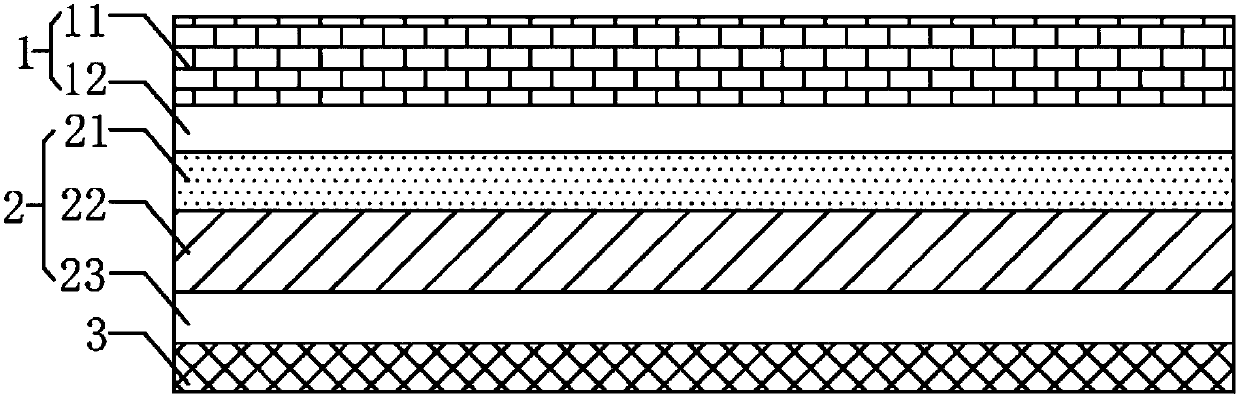

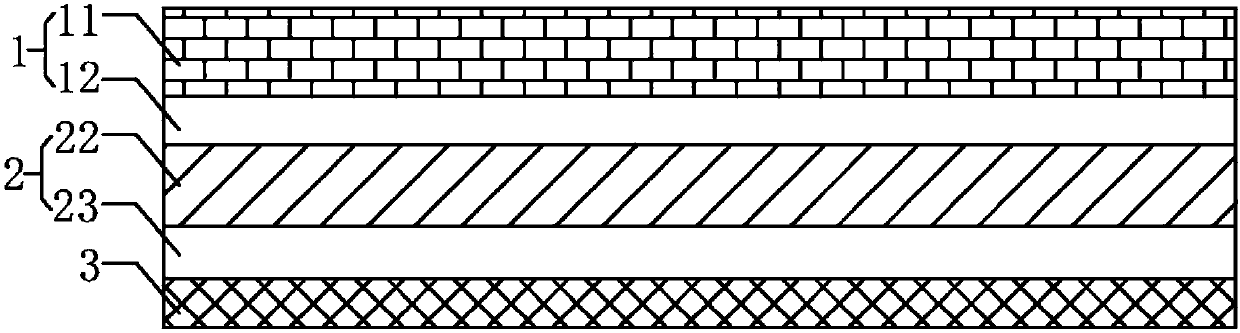

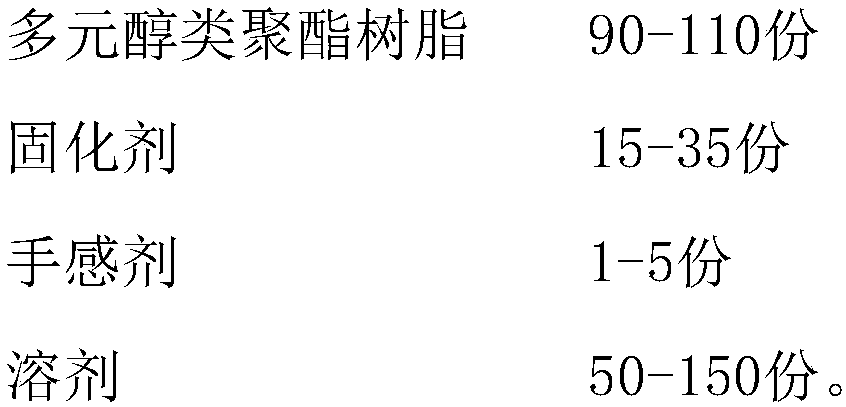

Flexible all-coating soft film and preparation method thereof

ActiveCN107936860AEvenlyGood flexibilityPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesTectorial membraneEngineering

The invention relates to the technical field of protective films, and particularly relates to a flexible all-coating soft film and a preparation method thereof. The flexible all-coating soft film comprises a film protecting layer, a using layer and a stripping layer which are sequentially adhered from top to bottom; the protecting film layer comprises a base material layer and a film protecting glue layer which are sequentially adhered from top to bottom; the using layer comprises a self-repairing layer, a flexible soft film layer and a using glue layer which are sequentially adhered from topto bottom; the lower surface of the film protecting glue layer is adhered to the upper surface of the self-repairing layer; and the lower surface of the using layer is adhered to the upper surface ofthe stripping layer. The flexible all-coating soft film provided by the invention has smooth hand feeling and large stripping force, a curved screen can be all coated, relatively good resilience and self-repairing effect can be achieved, scratch marks can be repaired automatically, and the service life of the flexible all-coating soft film is prolonged. The preparation method provided by the invention is simple, the operation control is convenient, conventional production processes are simplified, the production efficiency is high, the production cost is low, the prepared product is high in yield and stable in quality, and the preparation method is suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Light diffusion sheet and backlight unit using the same

InactiveUS20040047163A1Resists deflectionEasy to handleMechanical apparatusElectric discharge tubesCross-linkDiffusion

A light diffusion sheet comprising a transparent base material sheet; a light diffusion layer laminated on a surface of the base material sheet and containing beads dispersed within a binder; and a sticking-inhibiting layer laminated on a rear face of the base material sheet, wherein the binder of the light diffusion layer contains a thermosetting resin and the sticking-inhibiting layer is a resin layer containing an ionizing radiation curable resin. In the light diffusion sheet of the invention, which employs an ionizing radiation curable resin for the binder of the sticking-inhibiting layer, the cross-linking density of the binder can be increased, whereby the wear resistance of the sticking-inhibiting layer as well as the wear resistance of the rear face of the light diffusion sheet can be increased. Further, possible occurrence of scratches in the sticking-inhibiting layer, which is attributable to the contact between the sticking-inhibiting layer and the beads of the light diffusion layer, can be effectively avoided.

Owner:KEIWA INCORPORATED

Scratch and mar resistant PDLC modulator

A PDLC modulator is fabricated using at least one a selection of specially-formulated UV curable organic hard coatings as a protective layer on the exposed side of polyester (Mylar) film. The hard coatings of various related types show good adhesion on a polyester film substrate, superior hardness and toughness, and have a slippery top surface, which minimizes unnecessary wear. The coating as applied on the modulator surface significantly reduces scratch damage on modulators caused by unexpected particles on the panels under test. In addition, the slip surface will reduce stickiness to particles and therefore also reduce the possibility of panel damage.

Owner:ORBOTECH LTD

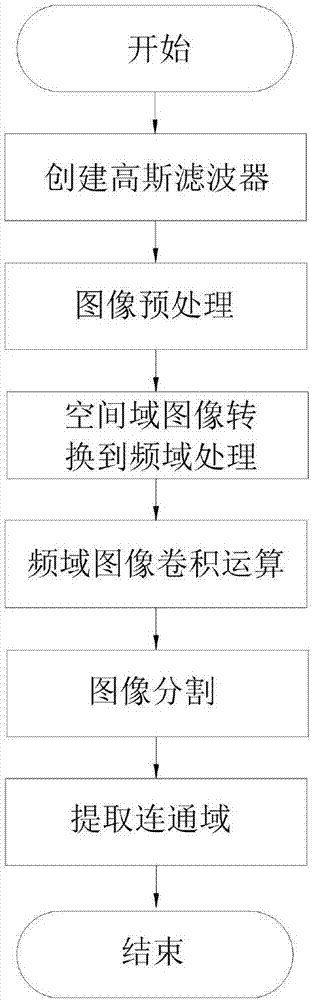

A stainless steel surface defect detection method based on machine vision

InactiveCN107478657AThe test result is accurateImprove detection efficiencyOptically investigating flaws/contaminationMachine visionFourier transform on finite groups

The invention relates to a stainless steel surface defect detection method based on machine vision. The method includes S1) collecting a surface image of stainless steel to be detected by adopting a CCD industrial camera; S2) subjecting the collected surface image of the stainless steel to be detected to two-dimensional defect detection based on Blob analysis; S3) subjecting the collected surface image of the stainless steel to be detected to three-dimensional defect detection according to frequency-domain-based Fourier transform; and S4) separating out the defective stainless steel according to two-dimensional and three-dimensional defect detection results. For two-dimensional defects, a surface detect detection algorithm based on the Blob analysis is provided, and a frequency-domain-based Fourier transform algorithm is provided for three-dimensional defects. Common surface defects, such as scratch, oil stain, rust, air bubbles, cracks, impurities, rolling marks and roll marks, of stainless steel products can be effectively detected. In addition, the detection results of a scheme are accurate and the detection efficiency is high.

Owner:GUANGDONG UNIV OF TECH

System and methods for classifying anomalies of sample surfaces

InactiveUS7038772B2Increase productionSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationClassified informationEngineering

Two or more defect maps may be provided for the same sample surface at different detection sensitivities and / or processing thresholds. The defect maps may then be compared for better characterization of the anomalies as scratches, area anomalies or point anomalies. This can be done without concealing the more significant and larger size defects amongst numerous small and immaterial defects. One or more defect maps can be used to report the anomalies with classified information; the results from this map(s) can be used to monitor the process conditions to obtain better yield.

Owner:KLA CORP

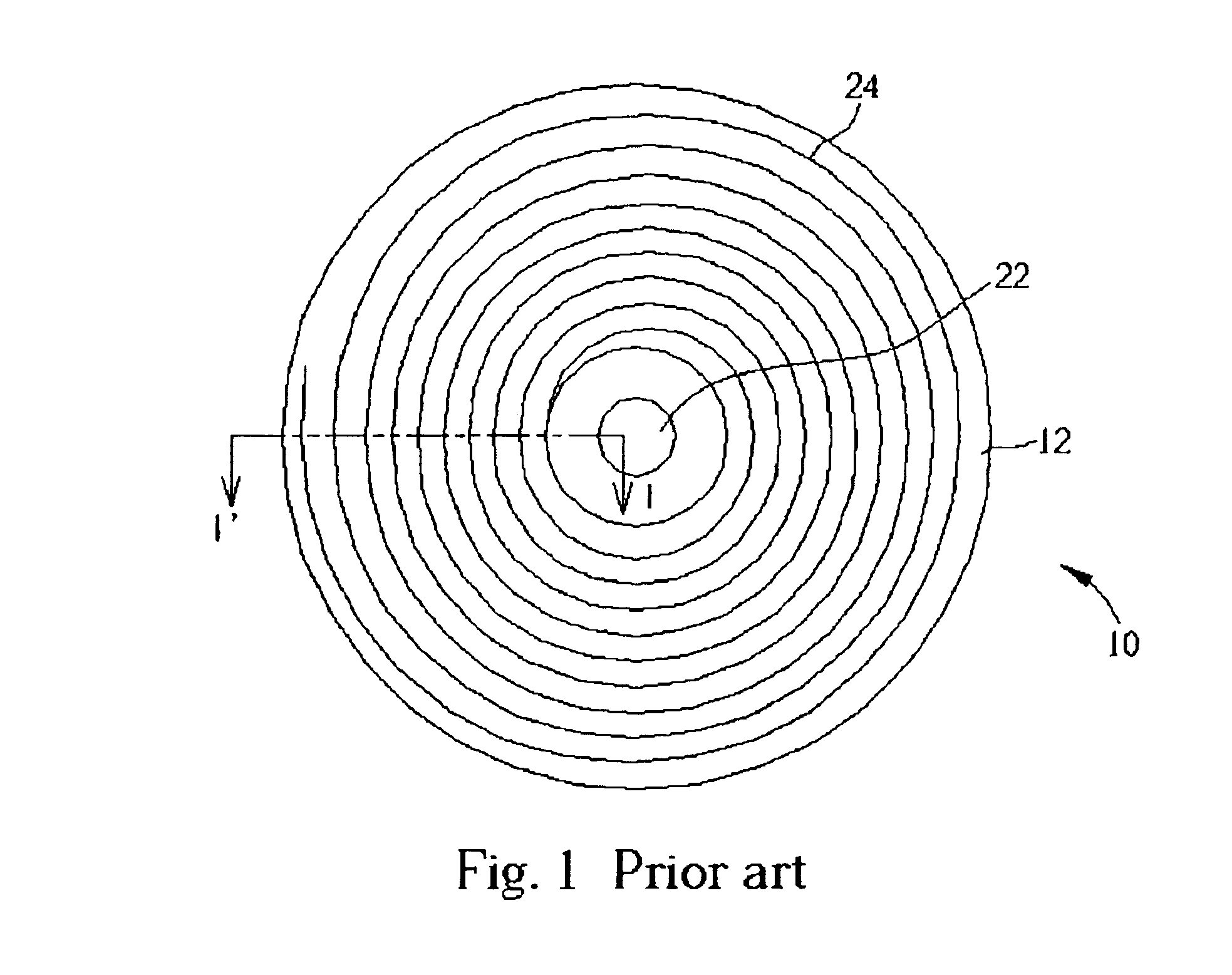

Scratch-off material layer applied on optical recording media

InactiveUS6901043B2Prevent illegal copyingOther printing matterLayered productsOptical recordingReflective layer

An optical recording medium having a scratch-off material layer includes a transparent substrate, a reflective layer formed on the transparent substrate, a protective layer formed on the reflective layer, information formed on a surface of the protective layer, and at least one opaque scratch-off material layer formed on the protective layer for disguising the information.

Owner:U TECH MEDIA

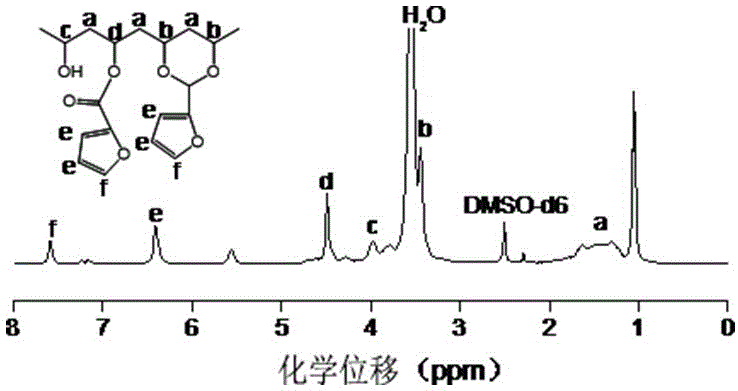

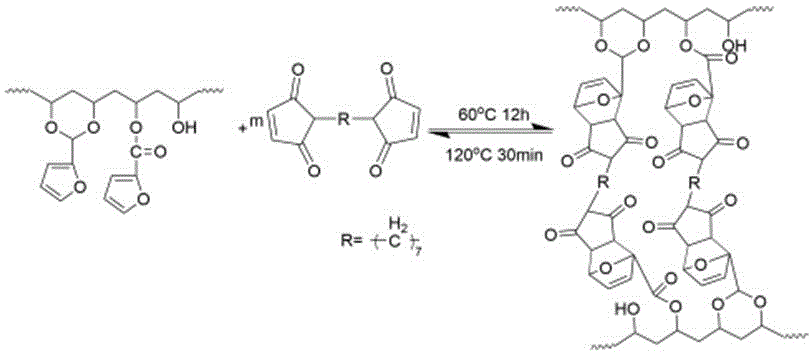

Polyvinyl alcohol membrane with self-repair function implemented by aid of dynamic covalent bonds and method for preparing polyvinyl alcohol membrane

The invention belongs to the technical field of functional materials, and particularly discloses a polyvinyl alcohol membrane with a self-repair function implemented by the aid of dynamic covalent bonds and a method for preparing the polyvinyl alcohol membrane. The dynamic covalent bonds are formed by the aid of Diels-Alder reaction, so that the polyvinyl alcohol membrane can have the self-repair ability. The method includes carrying out graft reaction on polyvinyl alcohol and furan derivatives to obtain furan ring grafted and modified polyvinyl alcohol; adding certain cross-linking agents into the furan ring grafted and modified polyvinyl alcohol and carrying out Diels-Alder reaction to obtain the polyvinyl alcohol membrane with the self-repair function. Diels-Alder reaction can be carried out on the certain cross-linking agents and furan groups. The polyvinyl alcohol membrane and the method have the advantages that the polyvinyl alcohol membrane is excellent in separation performance and hydrophilic performance just like common polyvinyl alcohol membranes, and cross-linked structures of the polyvinyl alcohol membrane are excellent in temperature responsiveness and thermal reversibility; the polyvinyl alcohol membrane is excellent in self-repair ability for drawing and scratching marks under simple conditions, and the gas tightness and the water resistance of the polyvinyl alcohol membrane in wet-state environments can be obviously improved; the polyvinyl alcohol membrane prepared by the aid of the method can be used in broad fields such as the fields of permeation and evaporation membrane separation and the fields of proton exchange membrane fuel cells, catalyst carrying and ion exchange membranes.

Owner:TONGJI UNIV

Method of displaying austenite structure quickly and easily

InactiveCN101587033AKeep abreast of organizational structureMeet the use requirementsPreparing sample for investigationMaterial analysis by optical meansBuretteAustenite

The invention relates to a testing method of metallographic structure, particularly relates to a method of displaying austenite structure quickly and easily. According to the invention provided techniccal scheme, the method includes: first use metallographic abrasive paper to grind the surface to be tested of stainless steel strip until grinding crack on the surface to be tested is uniform and the grinding crack has same direction; then using polishing cloth to polish the grinded surface, and there should be no obvious scratch on the surface when observing under 100X microscope after polishing; then using burette to drop 1-50 drops prepared solution on the polished surface for etching the surface, using soft cloth to wipe etched surface for five to six secondes, at last washing with water and using alcohol to wipe clean, putting clean surface under microscope to observe austenite stainless steel structure. Using the method can checkout matrix structure of materials in short time.

Owner:WUXI HUANSHENG METAL PRODS

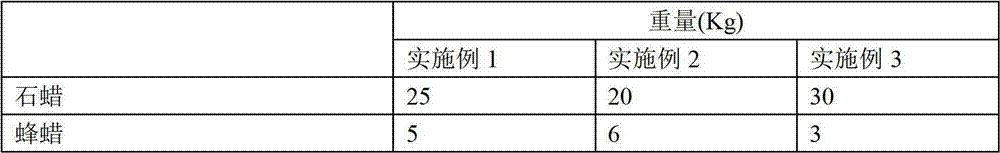

High-durability floor wax

The invention provides high-durability floor wax, and belongs to the technical field of a furniture cleaning agent. The high-durability floor wax comprises the following raw materials by weight: 20 to 30 parts of wax, 3 to 6 parts of beewax, 2 to 3 parts of oxidized polyethlene wax, 5 to 8 parts of Vaseline, 2 to 5 parts of triethanolamine, 5 to 10 parts of stearic acid, 3 to 7 parts of cellulose, 1 to 3 parts of butoxy triethyl phosphate, 2 to 4 parts of diglycol diethyl ether, 1 to 3 parts of dioctyl maleate, 2 to 3 parts of surface active agent, 4 to 6 parts of simethicone, 2 to 4 parts of emulsifying agent, 3 to 6 parts of odorless kerosene, 3 to 5 parts of ammonia water, 1 to 2 parts of benzimidazole methyl carbamate, 2 to 3 parts of silane coupling agent and 200 to 400 parts of water. With the adoption of the floor wax provided by the invention, the glossiness of the surface of a floor can be effectively improved, scratches can be shielded, and the damage of the friction on the floor surface to the floor can be effectively prevented; and after being subjected to a friction test, the floor wax also has high brightness and has no scratch.

Owner:盐城创咏新能源投资有限公司

Surface protective film, method for fabricating the same, pouch thereof and method for fabricating the same

ActiveUS20090104467A1Reduce hardnessSynthetic resin layered productsCeramic shaping apparatusInter layerMedicine

Disclosed is a surface protective film, a method for fabricating the same, and pouch, and a method for fabricating the same. The surface protective film includes a stack of films including a middle layer, and a first skin layer and a second skin layer on opposite sides of the middle layer, wherein at least one of the first skin layer and the second skin layer is formed of a resin having a hardness lower than a hardness of a surface to be protected by the surface protective film, and the middle layer is formed of a resin including high density polyethylene, thereby permitting protection of a display surface without formation of scratch at a very low cost compared to the related art without aging and with slip.

Owner:LG DISPLAY CO LTD +1

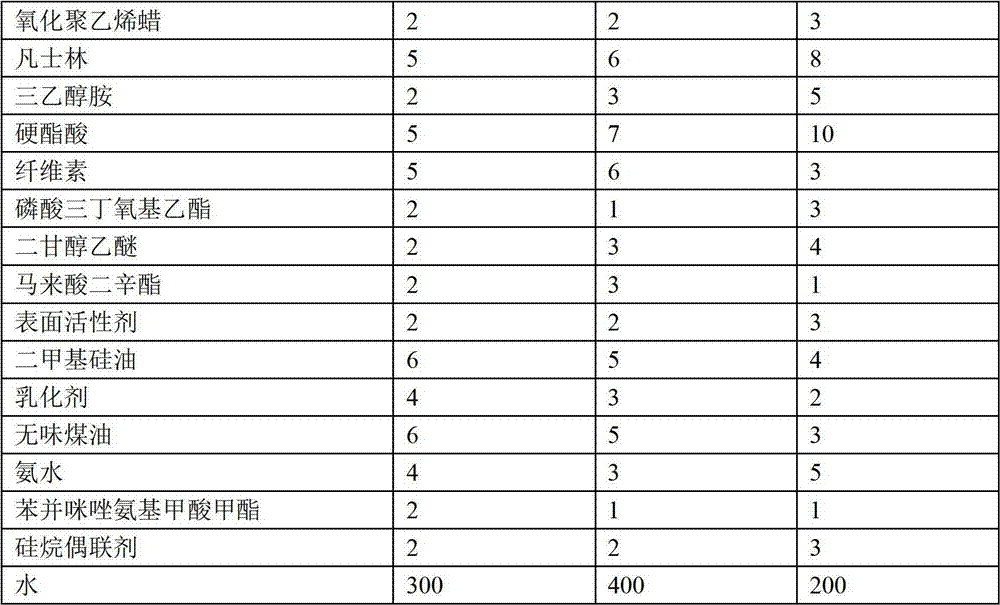

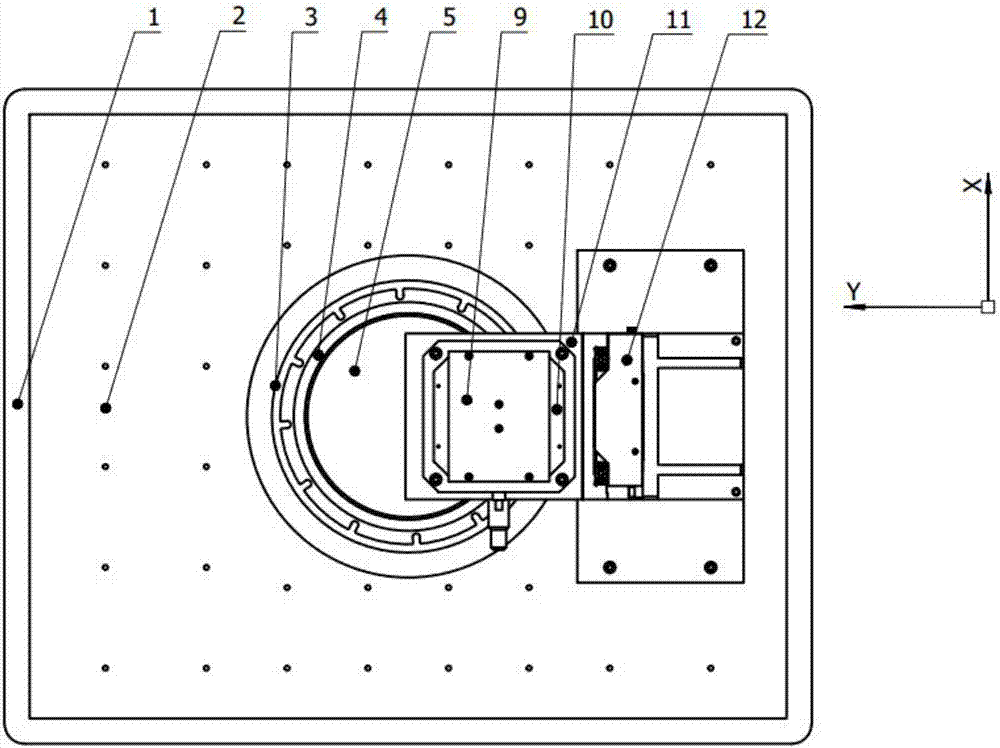

Nano cutting depth high-speed single-point scratch test device and test method thereof

ActiveCN107505248ARestore processing speedScratch at high speedIndividual particle analysisInvestigating material hardnessConvex structureEngineering

The invention discloses a nano cutting depth high-speed single-point scratch test device and a test method thereof. The device comprises a workbench, an air flotation rotary table, a test piece fixture, a test piece, a Z-direction feeding device, a nano motion platform, a force sensor and a scratch tool, wherein a micro convex structure with controllable length and height is machined in the to-be-scratched position of the test piece. The scratch speed is increased from mu m / s to m / s, and the machining speed of abrasive particles in the ultra-precise grinding process is restored really. Scratch force signals under different nano cutting depth conditions are accurately collected under the high-speed scratch condition, and the scratch force-scratch depth correspondence is explicit. The micro convex structure is constructed on the surface of the test piece, the condition that very long scratches are left on the surface of the whole wafer by a diamond needle point is avoided, abundant test data are provided in shorter scratches, the content of effective information in the unit scratch length is greatly increased, following scratch analysis and feature identification of remaining scratches are facilitated, and the integrity of the scratch tool is guaranteed.

Owner:DALIAN UNIV OF TECH

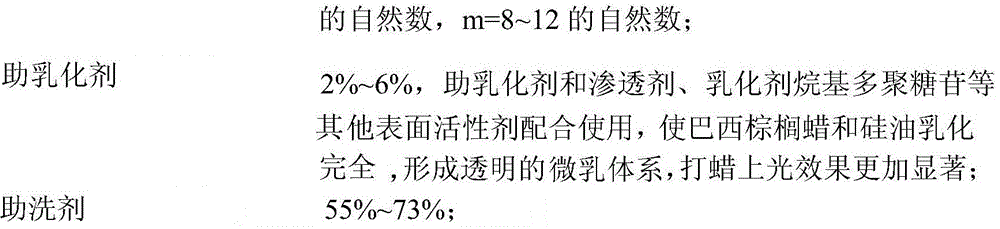

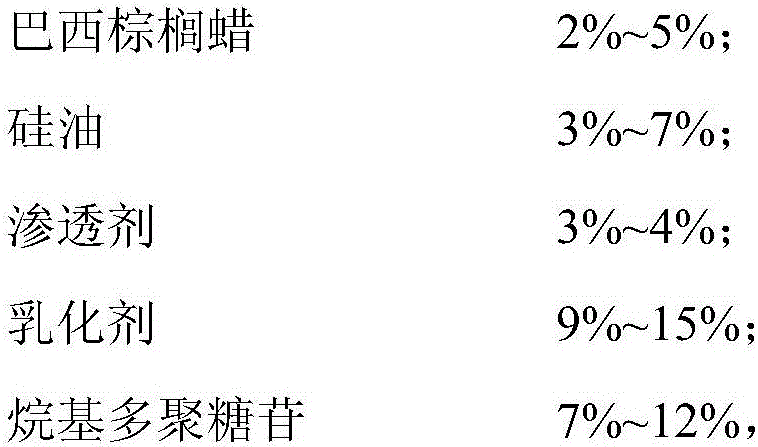

Automobile cleaning and polishing agent capable of avoiding scratches as well as preparation and application of automobile cleaning and polishing agent

InactiveCN105950325ARemove completelyReduce surface tensionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsWater savingCarnuba wax

The invention relates to an automobile cleaning and polishing agent capable of avoiding scratches as well as preparation and application of the automobile cleaning and polishing agent. The automobile cleaning and polishing agent is prepared from components in percentage by mass as follows: 2%-5% of carnauba wax, 3%-7% of silicone oil, 3%-4% of a penetrating agent, 9%-15% of an emulsifier, 7%-12% of alkyl polyglycoside, 2%-6% of a co-emulsifier and 55%-73% of a detergent assistant. The automobile cleaning and polishing agent is prepared from bio-degradable and environment-friendly raw materials, has extremely low surface tension and great permeability and can completely remove traffic films, dust, grease and the like on the surface of the automobile, the automobile does not need to be wiped with sponge in the cleaning process, no scratches are produced, waxing and polishing can be finished in the automobile cleaning process, the secondary waxing process is avoided, the automobile cleaning procedure is greatly simplified, the work efficiency is improved, and the automobile cleaning and polishing agent has the advantages of water saving, energy conservation, time saving and high efficiency.

Owner:浙江金驰环保科技有限公司

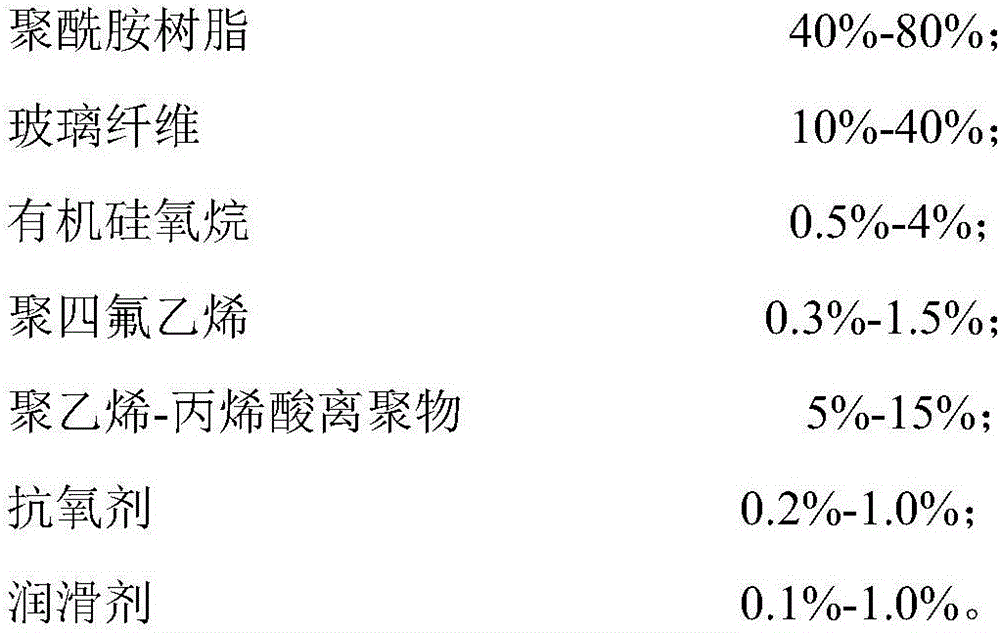

Scratch-resistant polyamide composition and preparation method thereof

The invention discloses a scratch-resistant polyamide composition and a preparation method thereof. The scratch-resistant polyamide composition is prepared from the following raw materials in percentage by mass: 40-80% of a polyamide resin, 10-40% of a glass fiber, 0.5-4% of organo-siloxane, 0.3-1.5% of polytetrafluoroethylene, 5-15% of a polyethylene-crylic acid ionomer, 0.2-1.0% of an antioxidant and 0.1-1.0% of a lubricant. The invention further discloses a preparation method of the scratch-resistant polyamide composition. The scratch-resistant polyamide composition disclosed by the invention is good in scraping resistance, mechanical property and coloring property, no conspicuous scratch marks are caused in five-finger scratch tests, and components and elements made of the composition are not easily scratched in long-term use.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Display Device with Low Scratch Visibility and Manufacturing Method Thereof

ActiveUS20100066944A1Improve visibilityImprove performanceTube/lamp screens manufactureSemiconductor/solid-state device manufacturingVisibilityLight guide

A display device and a manufacturing method thereof are provided. The display device includes a light guide, a light source, and a brightness enhancement film (BEF), and a dual brightness enhancement film (DBEF). The light guide has a first edge along a first direction and a second edge adjacent to the first edge corresponding to the light source. The BEF is disposed on the light guide and has a plurality of prisms along a second direction which rotates from 0 to 90 degrees with respect to the first direction. The DBEF has a transmission axis along a third direction which also rotates from 0 to 90 degrees with respect to the first direction.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com