Automobile cleaning and polishing agent capable of avoiding scratches as well as preparation and application of automobile cleaning and polishing agent

A car scratch technology, applied in the field of chemical detergents, can solve the problems of accelerated oxidation of rubber parts such as car tires, parts that do not play a protective role, and scratches on the surface of car paint, etc., to achieve low surface tension, significant effect, and penetration strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

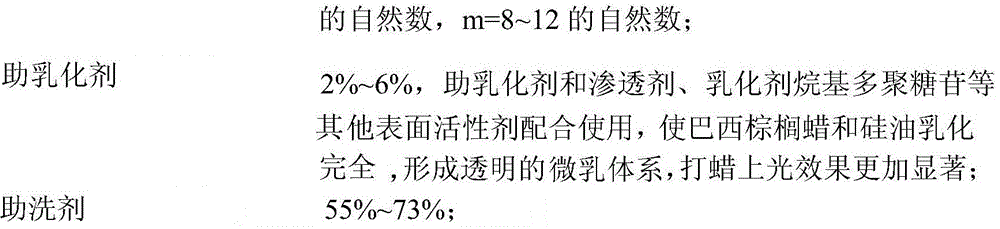

[0028] Embodiment 1: each component and its mass fraction are shown in Table 1:

[0029] Table 1:

[0030] component name

[0031] Specific preparation method: put 4g co-emulsifier glycerin in a container, then weigh 5g carnauba wax No. 3 tablets and 3g simethicone oil, slowly raise the temperature to 70°C, and add 4g penetrant JFC- 2C 8 Fatty alcohol polyoxyethylene ether, 8g emulsifier fatty acid methyl ester ethoxylate, 3g AEO, 7g alkyl polyglycoside, mix well; when the temperature drops to room temperature, add 30g sodium citrate, 8g sodium silicate, 28g sulfuric acid Sodium, after stirring and mixing evenly, stand for 1h to obtain a powdery product.

Embodiment 2

[0032] Embodiment 2: each component and its mass fraction are shown in Table 2:

[0033] Table 2:

[0034] component name

[0035] Specific preparation method: Put 7g of co-emulsifier ethylene glycol in a container, then weigh 2g of carnauba wax and 7g of amino silicone oil, slowly heat up to 50°C, and add 3g of penetrant lauryl ether phosphate while stirring AEP, 4g emulsifier sodium secondary alkyl sulfonate, 6g lauryl dimethyl amine oxide and 5g C 9 Fatty alcohol polyoxyethylene ether (AEO-9), 12g alkyl polyglycoside, mix well; when the temperature drops to room temperature, add 40g sodium pyrophosphate, 15g sodium sulfate, stir and mix well, place for 1.5h to get powder product.

Embodiment 3

[0036] Embodiment 3: each component and its mass fraction Table 3:

[0037] table 3:

[0038] component name

[0039] Specific preparation method: put co-emulsifier 1g ethylene glycol and 1g glycerin in a container, then weigh 3g carnauba wax and 1g amino silicone oil, slowly heat up to 80°C, and add penetrant 1g fast penetrant while stirring T and 2g C 8 Fatty alcohol polyoxyethylene ether (JFC-2), emulsifier 4g sodium lauryl sulfate and 2g cocamidopropyl betaine, 7g alkyl polyglycoside, mix well; when the temperature drops to room temperature, add 6g silicon Sodium tripolyphosphate, 30g of sodium tripolyphosphate and 37g of sodium sulfate, stirred and mixed evenly, and left for 2 hours to obtain a powdery product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com