Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

415results about How to "No oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

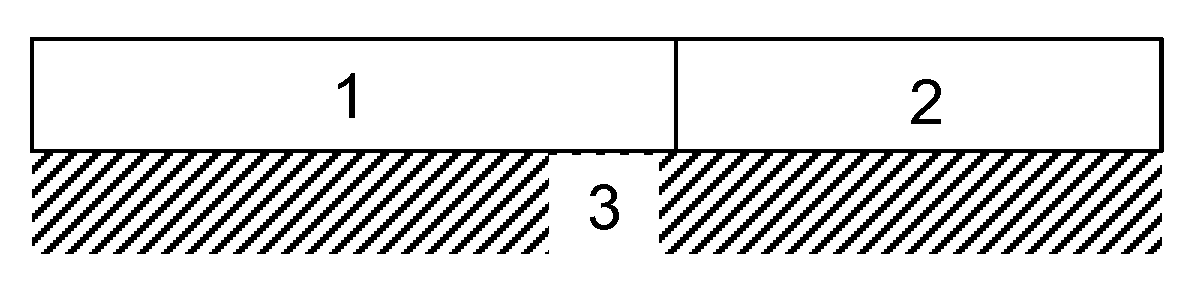

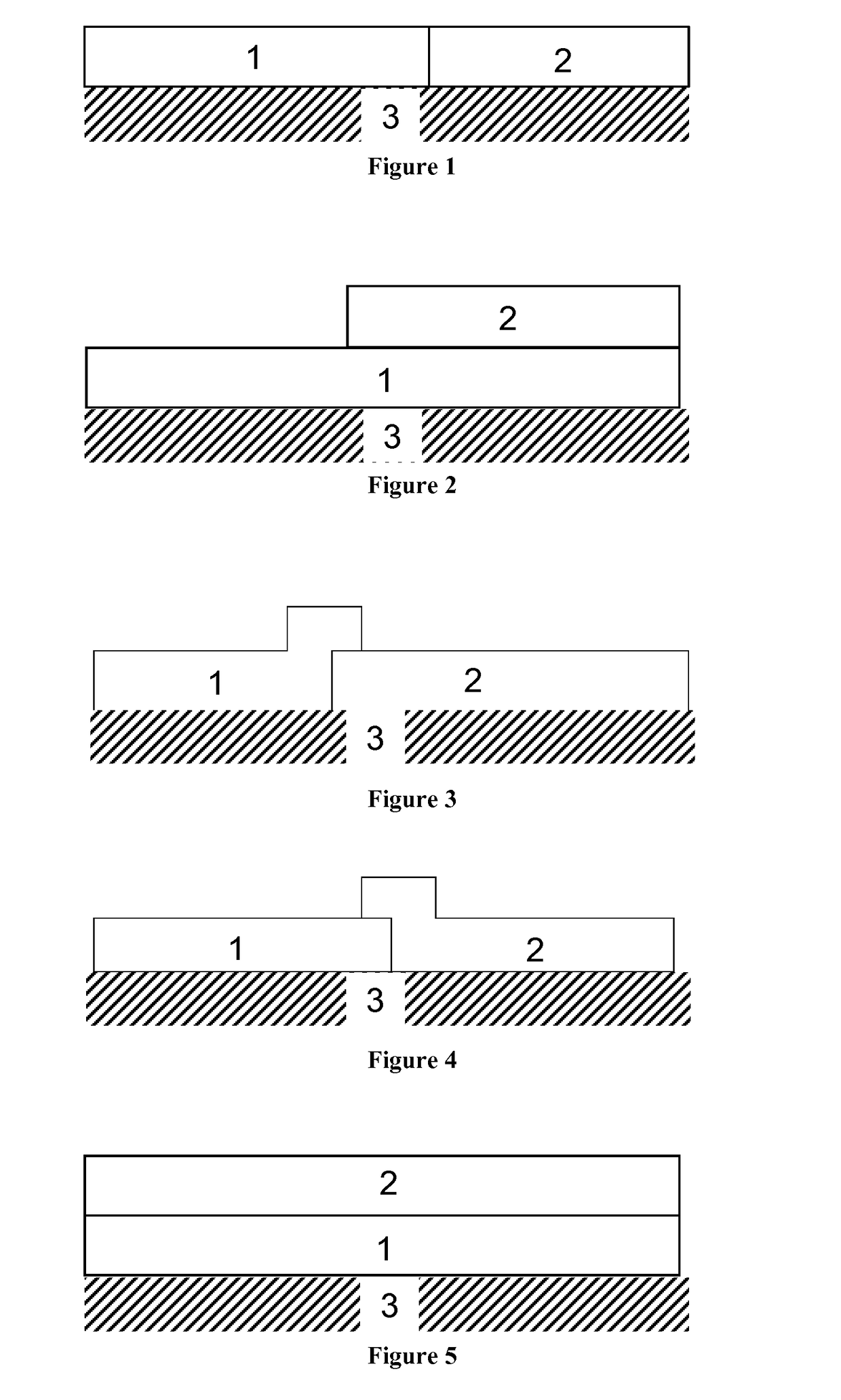

Diesel oxidation catalyst and exhaust system

ActiveUS20150202572A1High activityImprovement in NO oxidation activityNitrous oxide captureCombination devicesManganeseNitric oxide

An oxidation catalyst for treating an exhaust gas from a diesel engine and an exhaust system comprising the oxidation catalyst are described. The oxidation catalyst comprises: a first washcoat region for oxidising carbon monoxide (CO) and hydrocarbons (HCs), wherein the first washcoat region comprises a first platinum group metal (PGM) and a first support material; a second washcoat region for oxidising nitric oxide (NO), wherein the second washcoat region comprises platinum (Pt), manganese (Mn) and a second support material; and a substrate having an inlet end and an outlet end; wherein the second washcoat region is arranged to contact the exhaust gas at the outlet end of the substrate and after contact of the exhaust gas with the first washcoat region.

Owner:JOHNSON MATTHEY PLC

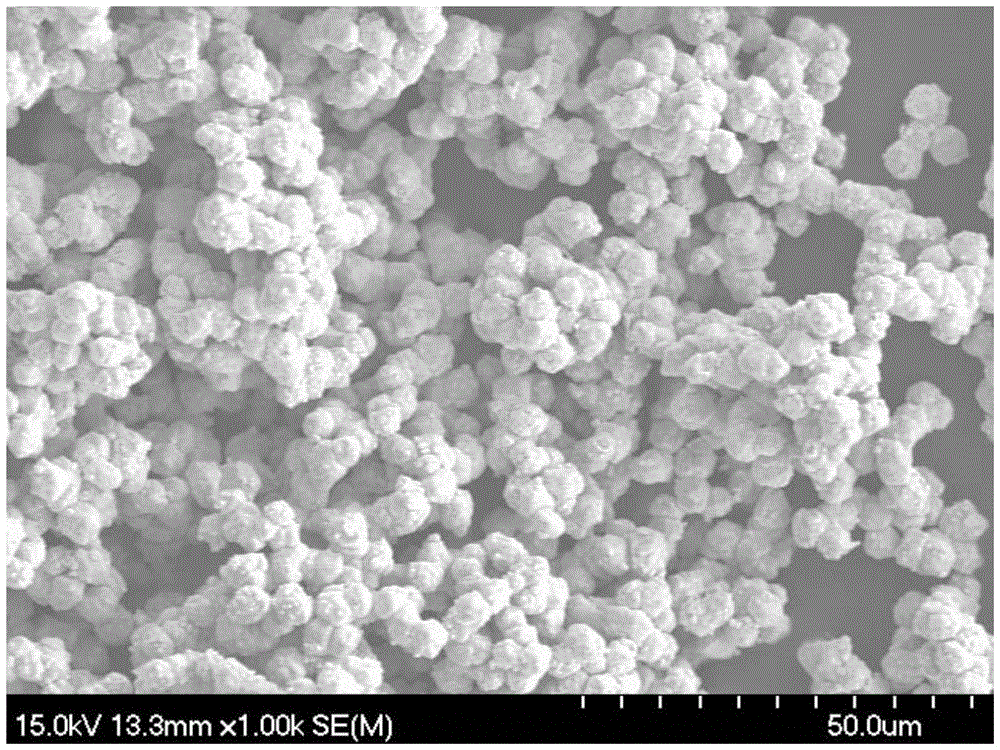

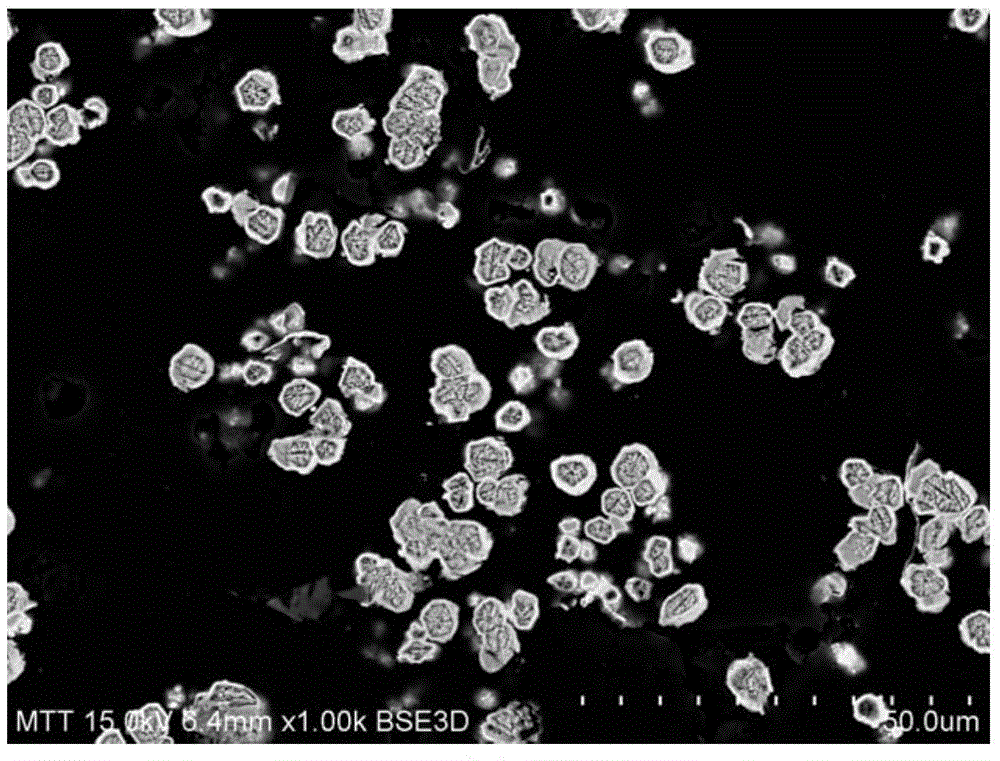

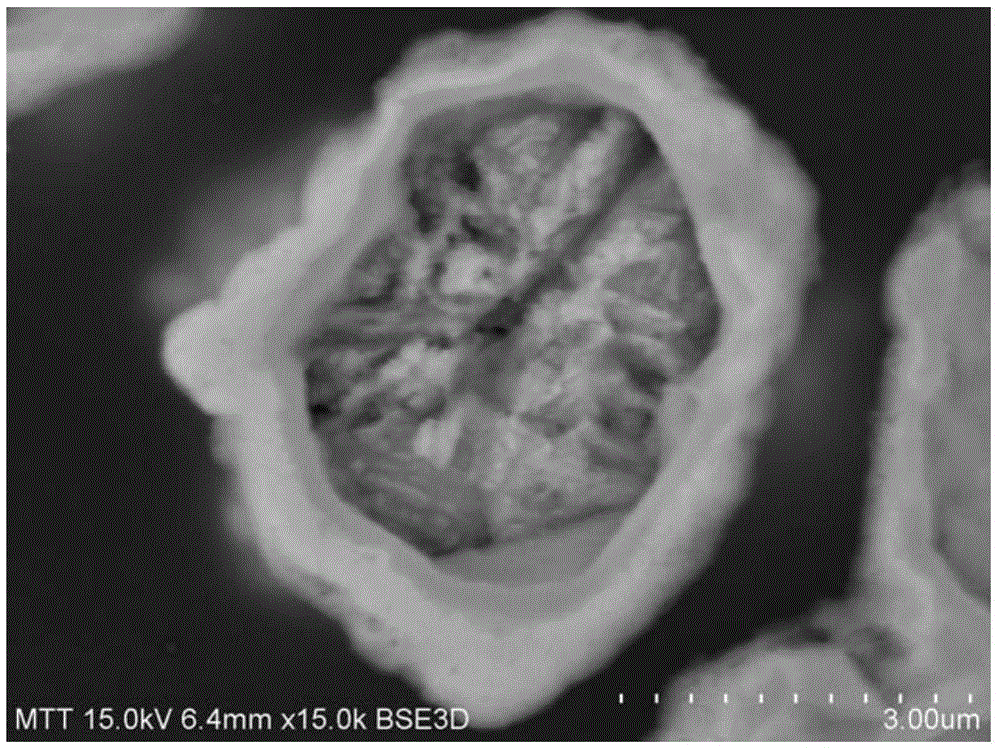

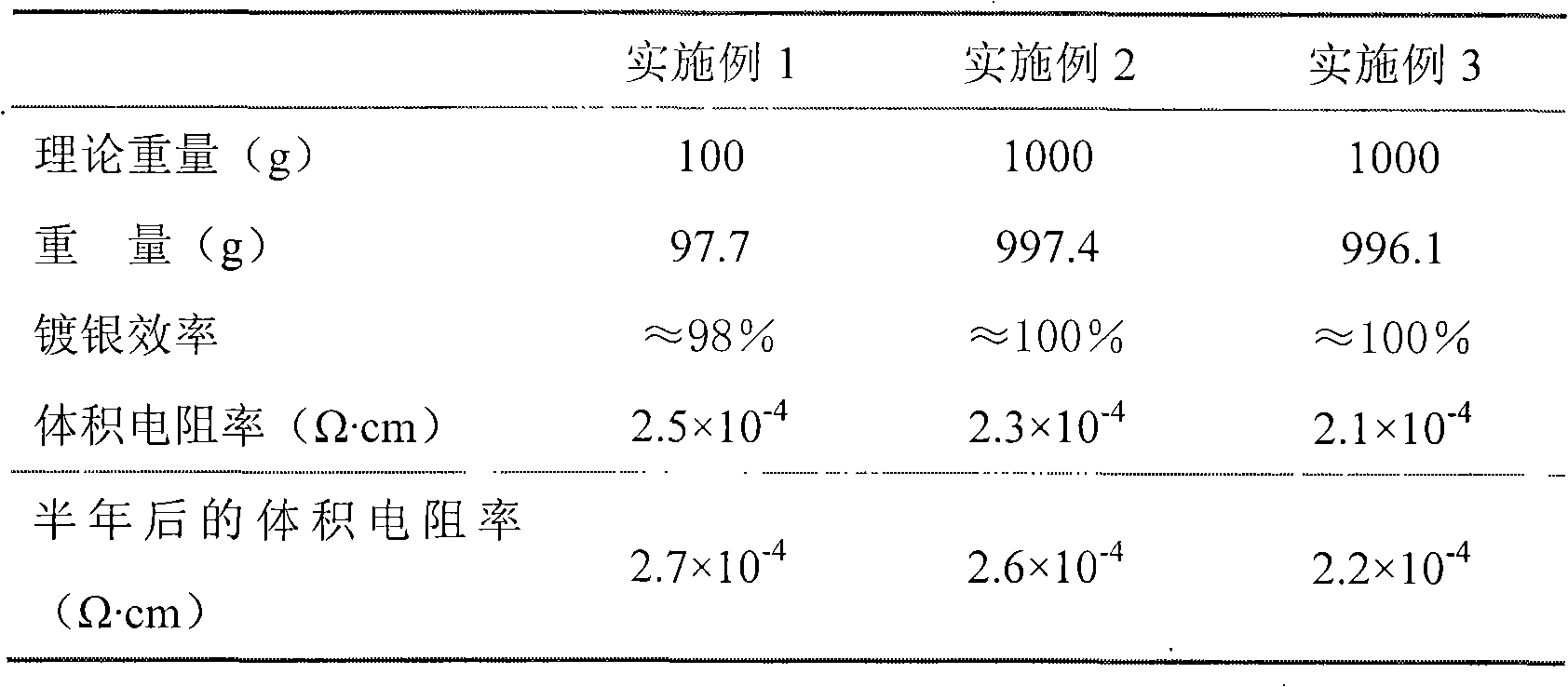

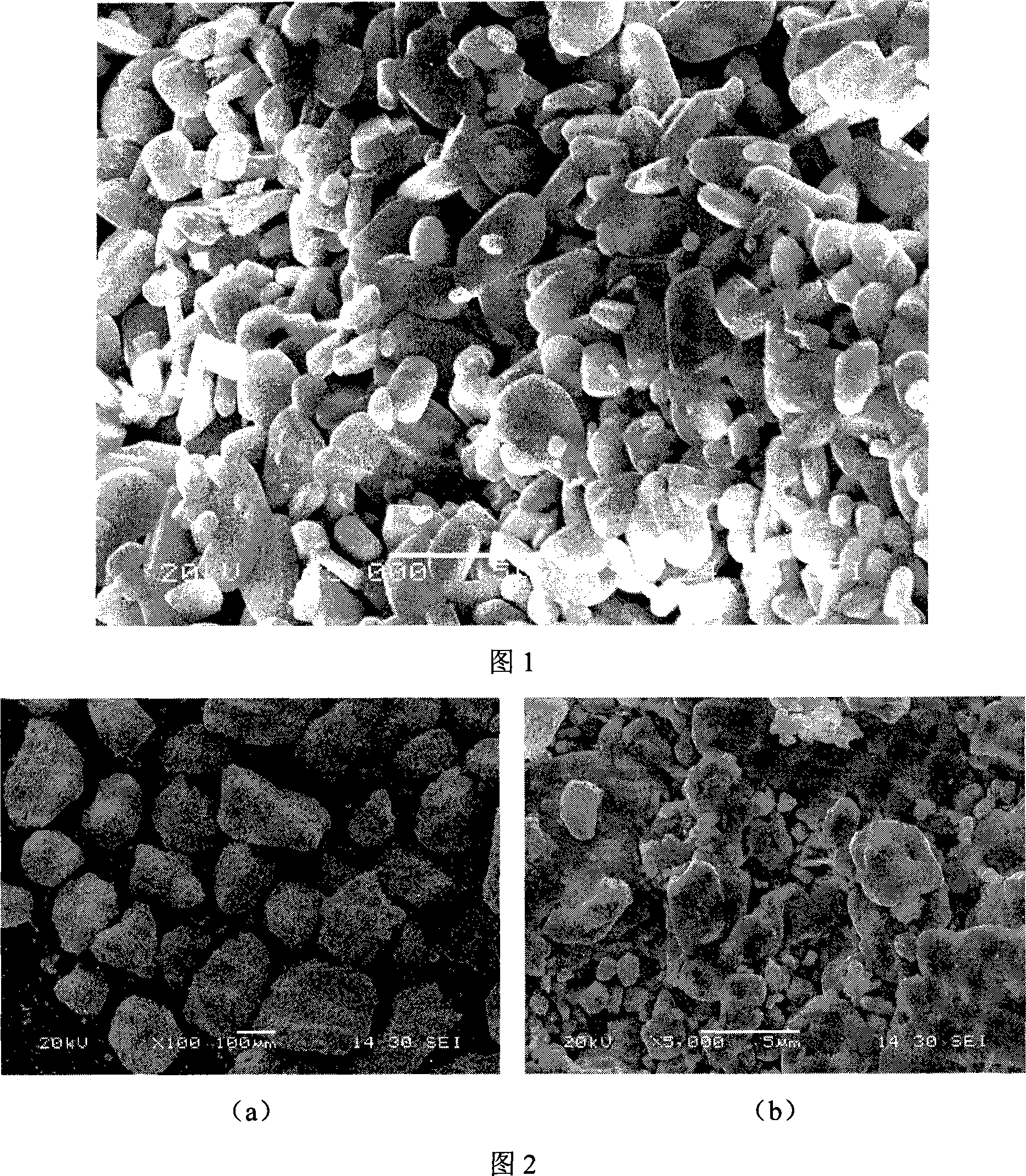

High-temperature-resistant silver-coated and nickel-coated copper conductive powder of core-shell structure and preparation method thereof

ActiveCN105598467AIncrease reaction rateIncrease productivityTransportation and packagingMetal-working apparatusCopperMaterials science

The invention relates to high-temperature-resistant silver-coated and nickel-coated copper conductive powder of a core-shell structure and a preparation method thereof. The structure of silver-coated and nickel-coated copper particles has three layers, namely, the copper core layer, the nickel middle layer and the silver outmost layer. The preparation process includes the four steps of firstly, preprocessing copper powder; secondly, wrapping the surfaces of the copper particles by nickel; thirdly, wrapping the surfaces of the nickel-coated copper particles with silver; fourthly, processing the silver-coated and nickel-coated copper particles. The prepared silver-coated and nickel-coated copper conductive powder of the core-shell structure has excellent high-temperature-resistant oxidation performance and conductivity, can completely or partly replace silver powder, and is wide in application range.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Process for carrying out vacuum cleaning, oil removal and wax removal by modified hydrocarbon cleaner

The invention relates to the technical field of electroplating pretreatment, in particular to a process for carrying out vacuum cleaning, oil removal and wax removal by a modified hydrocarbon cleaner. The process comprises degassing ultrasonic cleaning, vacuum cleaning, vacuum steam flushing, vacuum drying and the like. A plurality of flows are carried out in the vacuum environment with a certain vacuum degree and are matched with a degassing ultrasonic cleaning and vacuum cleaning technology and the modified hydrocarbon cleaner. For the cleaning process, in the whole process, harmful substances of halogen and the like, such as trichloroethylene, methylene chloride, tetrachloroethylene and the like, cannot be used and additional drying equipment is not required. Particularly, the process has excellent cleaning effect on irregular articles with blind holes, joints, gaps, cracks and the like. Meanwhile, the defects of oil removal and wax removal of the conventional process are overcome.

Owner:广东新球清洗科技股份有限公司

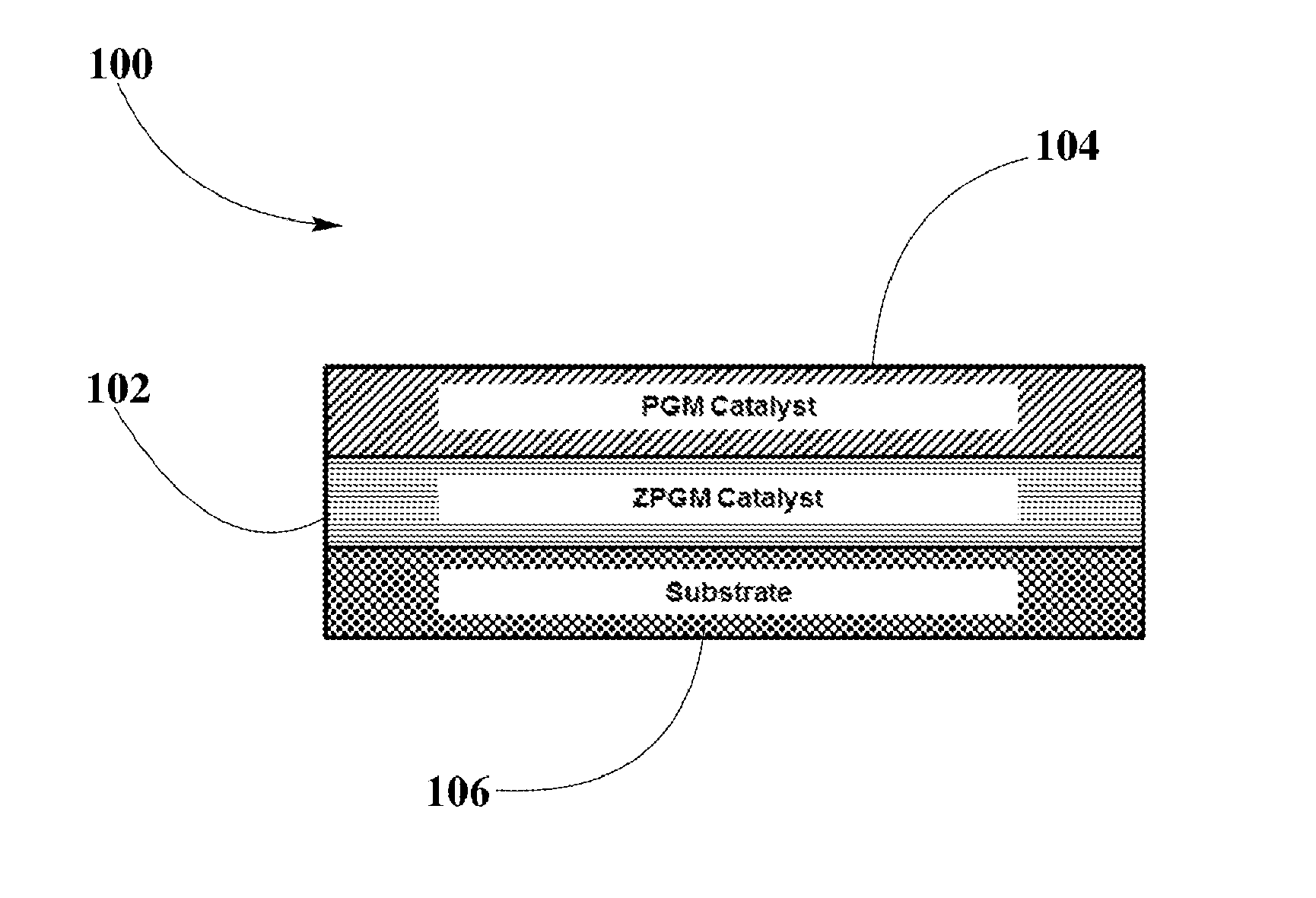

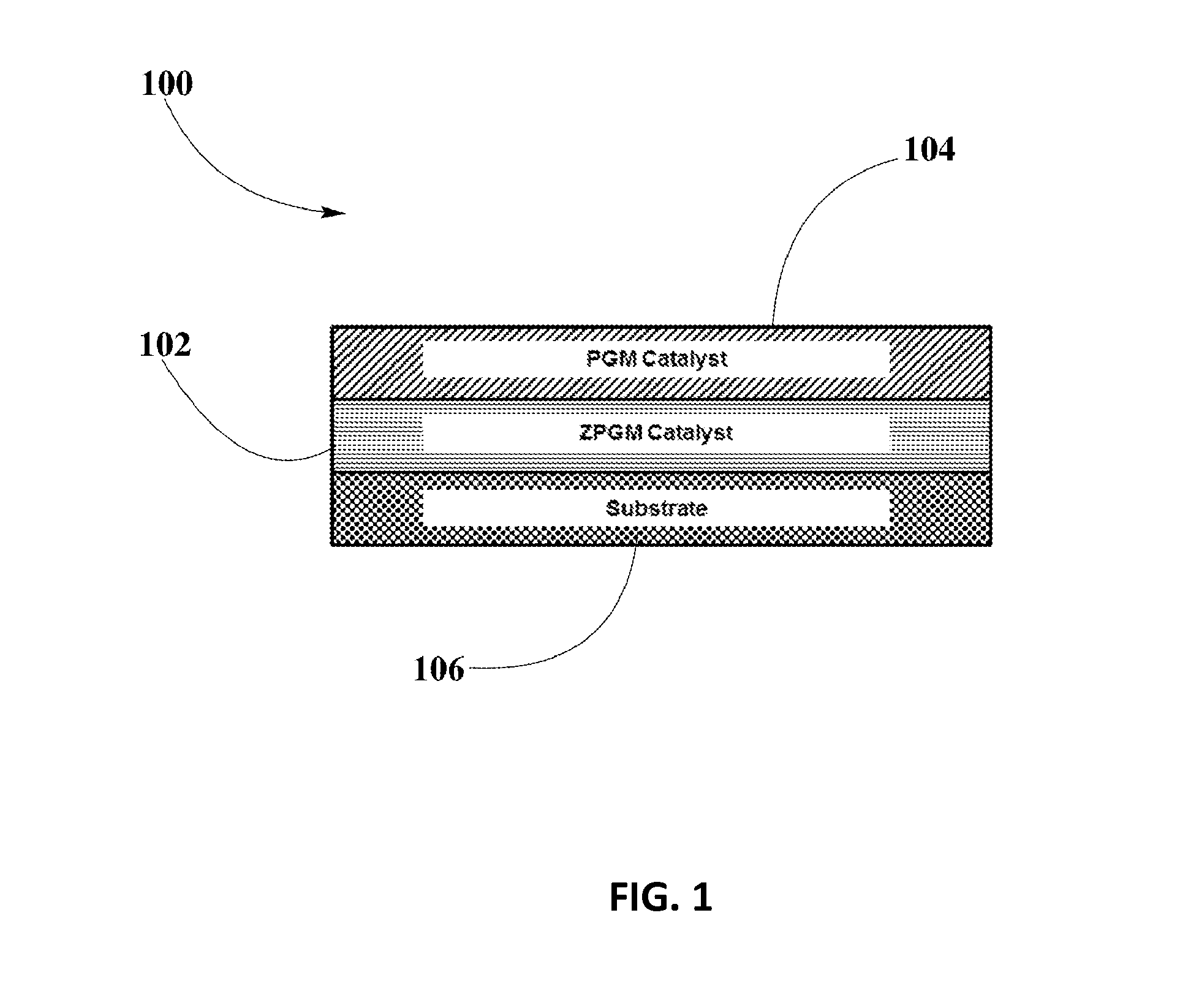

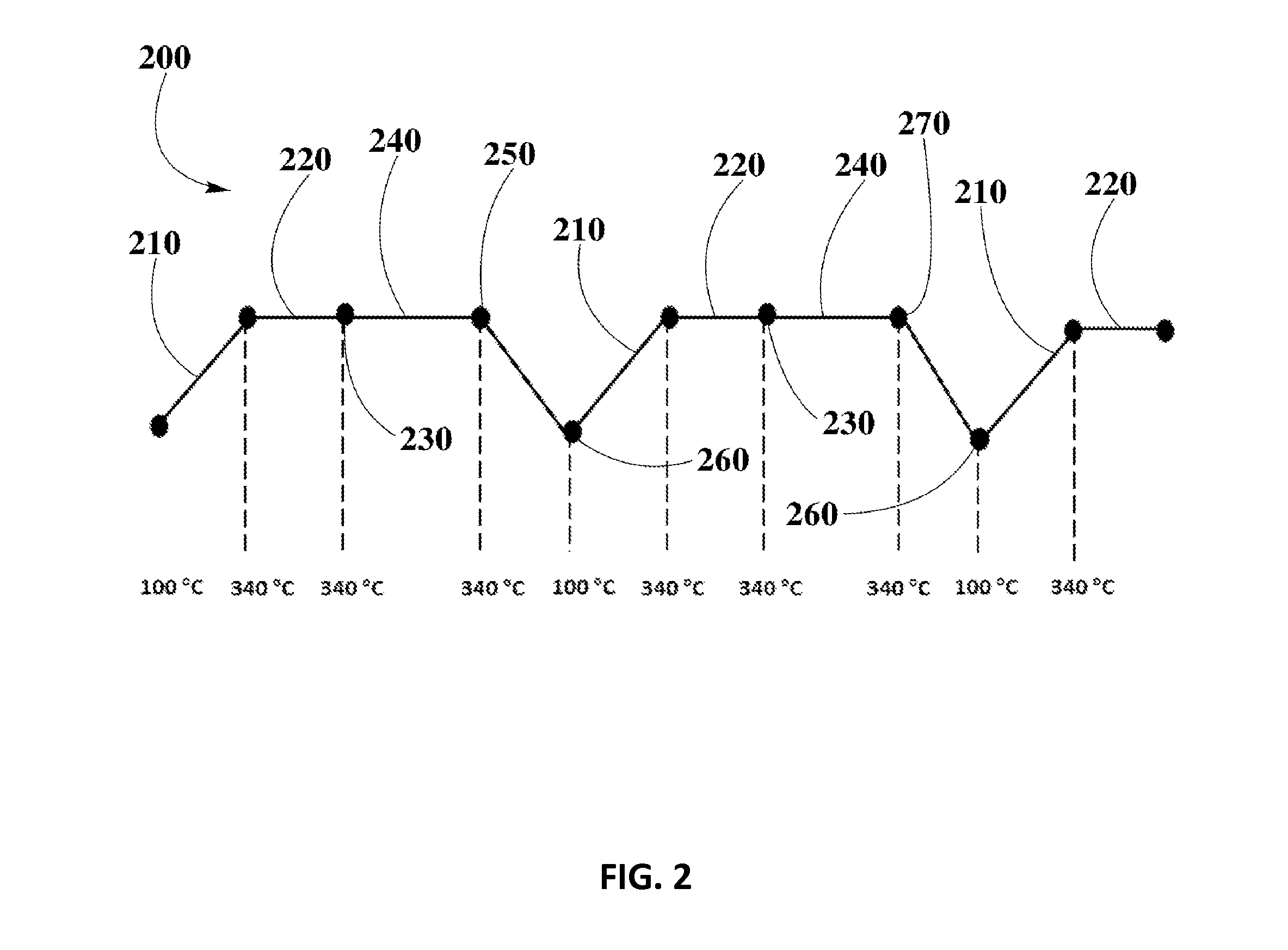

Synergized PGM Catalyst with Low PGM Loading and High Sulfur Resistance for Diesel Oxidation Application

InactiveUS20160136617A1Minimize deactivationMore efficiencyGas treatmentNitrogen compoundsSulfurSilicon dioxide

Sulfur-resistant SPGM catalysts with significant oxidation capabilities are disclosed. Catalytic layers of SPGM samples may be prepared using incipient wetness and metallizing techniques to structure a washcoat layer of ZPGM material of YMnO3 perovskite , and an overcoat layer including Pt / Pd composition on alumina-silica support oxide. Loading of PGM in OC layer is less than 5 g / ft3. A testing methodology for samples may be enabled including of DOC light-off, and soaking under isothermal DOC and sulfated DOC conditions to assess synergistic influence of adding ZPGM to PGM catalyst samples. Resistance to sulfur and catalytic stability may be observed under 5.2 gS / L condition to assess significant improvements in NO oxidation, HC conversion, and CO selectivity. Resistance to sulfur of disclosed SPGM catalyst may be compared with performance of an equivalent PGM control catalyst for DOC applications.

Owner:CLEAN DIESEL TECHNOLOGIES

Diesel oxidation catalyst and exhaust system

ActiveUS9636634B2Reduce the amount requiredHigh activityNitrous oxide captureCombination devicesManganeseDiesel engine

An oxidation catalyst for treating an exhaust gas from a diesel engine, which oxidation catalyst comprises: a first washcoat region comprising a first platinum group metal (PGM), a first support material and a NOx storage component; a second washcoat region comprising platinum (Pt), manganese (Mn) and a second support material; and a substrate having an inlet end and an outlet end.

Owner:JOHNSON MATTHEY PLC

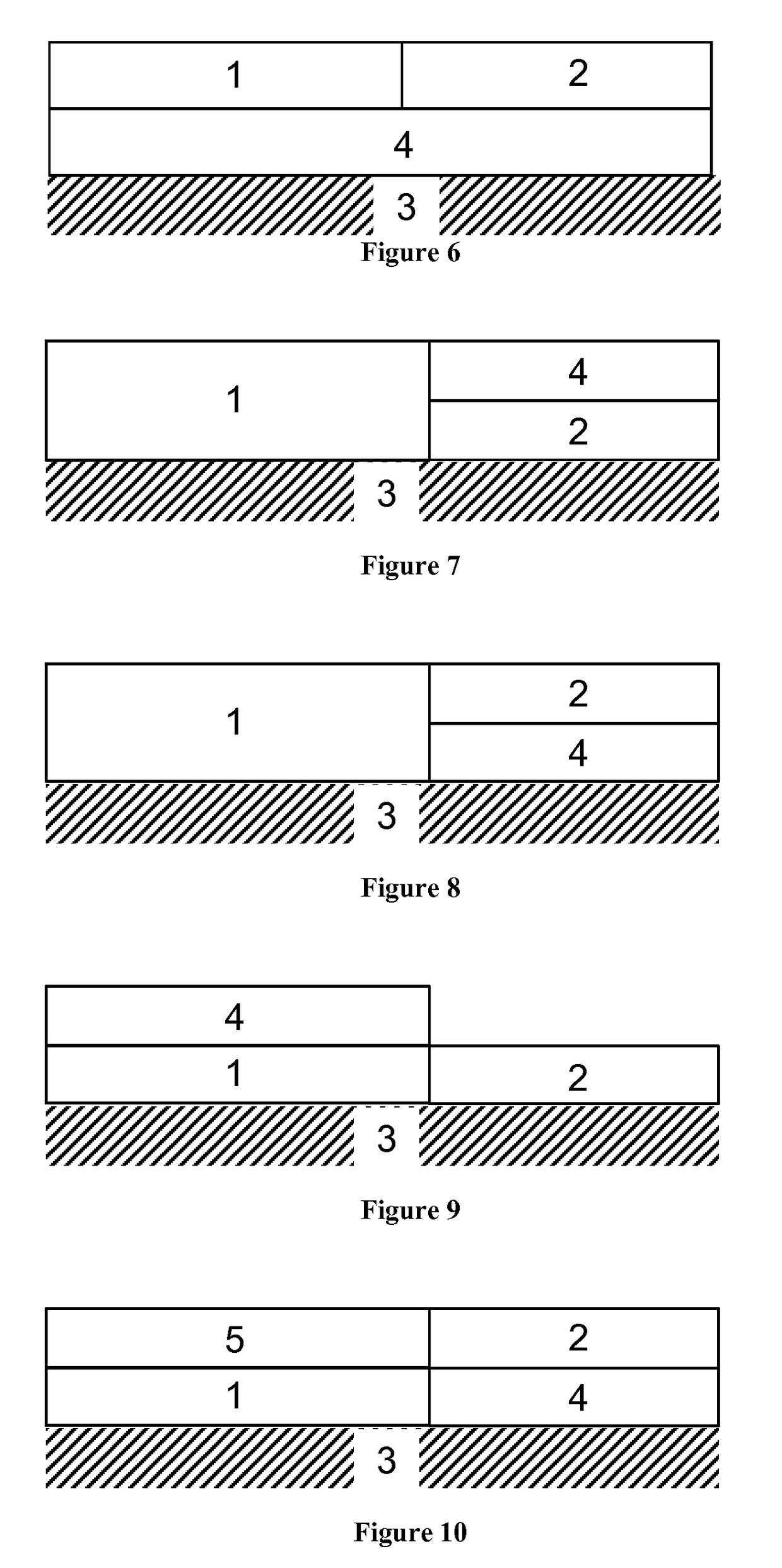

Process for producing silver-plated copper powder for low-temperature slurry

ActiveCN101294281AReduced rate of displacement reactionNo oxidationLiquid/solution decomposition chemical coatingCyanideAcid washing

The invention relates to a method for preparing silver-coated copper powder used for low-temperature paste, which belongs to the technology field of surface treatment. The method comprises the following steps: copper powder balls are ground to D50, namely 10 to 20 micron, oxidizing layers are removed through acid washing, then deionized water is used to ensure the copper powder to be washed to be neutral, water and dispersant are added for even stirring, acidic silver-contained solution is added in the copper powder paste so that cyanide-free chemical silvering reaction is performed, and after the reaction is completed, the silver-coated copper powder product provided with 20 to 45 percent of silver content and used for low-temperature paste can be obtained through cleaning, surface modification, drying and sieving treatment. The method has the advantages of high silvering efficiency, even coating, simple process and low production cost. The electric volume resistivity of the silver-coated copper powder prepared by the method is 2 to 3*10-4 omega cm, and the silver-coated copper powder can be partly or fully replace the pure silver powder in the low-temperature electronic paste field.

Owner:云南铜业科技发展股份有限公司 +1

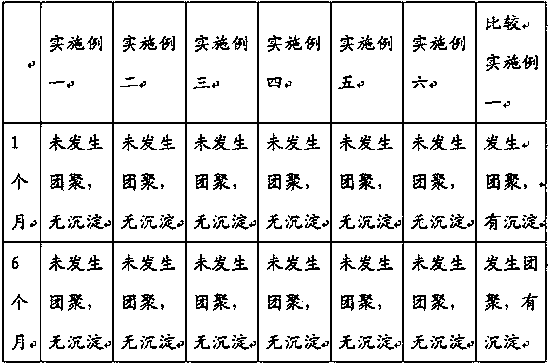

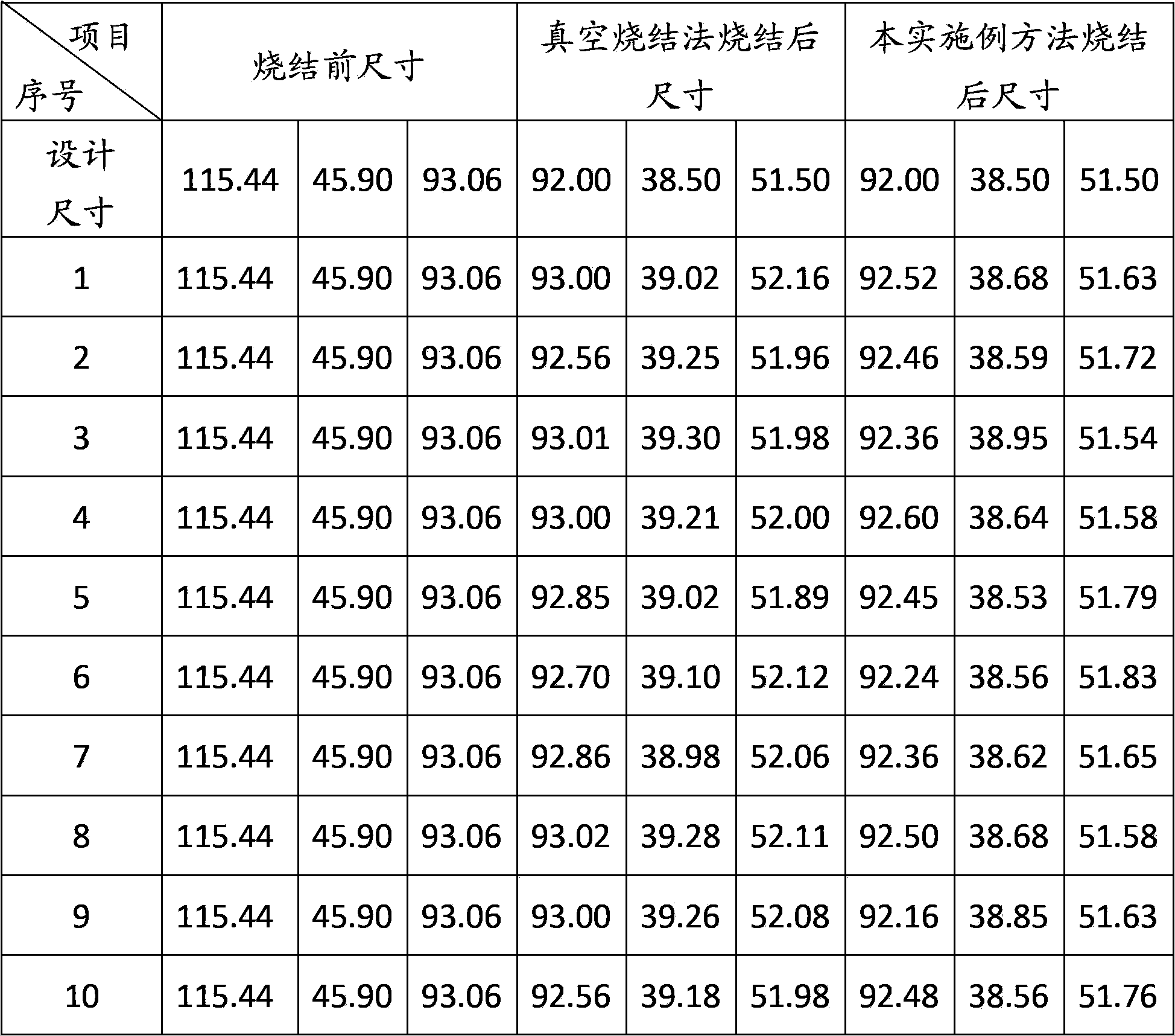

Process method for manufacturing balance weight for compressor by powder metallurgy

InactiveCN102528040AHigh dimensional accuracyNo oxidationTurbinesOther manufacturing equipments/toolsAir compressorMechanical press

The invention discloses a process method for producing a balance weight for a compressor by powder metallurgy, which comprises the steps that: (1), raw materials comprising Mn (17-25%), C (0.5-1.5%) and Fe (the rest) are uniformly blended to produce raw material powder required by production; (2), the raw material powder is put into a mechanical press (or four-column hydraulic press) for compression moulding so as to obtain a pressing compact for the balance weight; (3), the pressing compact for the balance weight is put into a continuous mesh belt furnace (or push rod furnace) for sintering to obtain a sintering compact for the balance weight; and (4), the sintering compact for the balance weight is subjected to shot blasting treatment to obtain a finished product of the high manganese steel weight balance for the air compressor. According to the production method disclosed by the invention, the stability of the sizes of workpieces is good, no impurity is generated, the quality of the surface is excellent, and the components are uniform and stable; the weight variation among products of different batches is small and can be controlled within 1%; no oxidation is generated in the production process, the internal organization of metal is excellent, the crystalline grain is finer, and the bad organizations such as coarse crystal and mixed crystal can be avoided.

Owner:王兴民

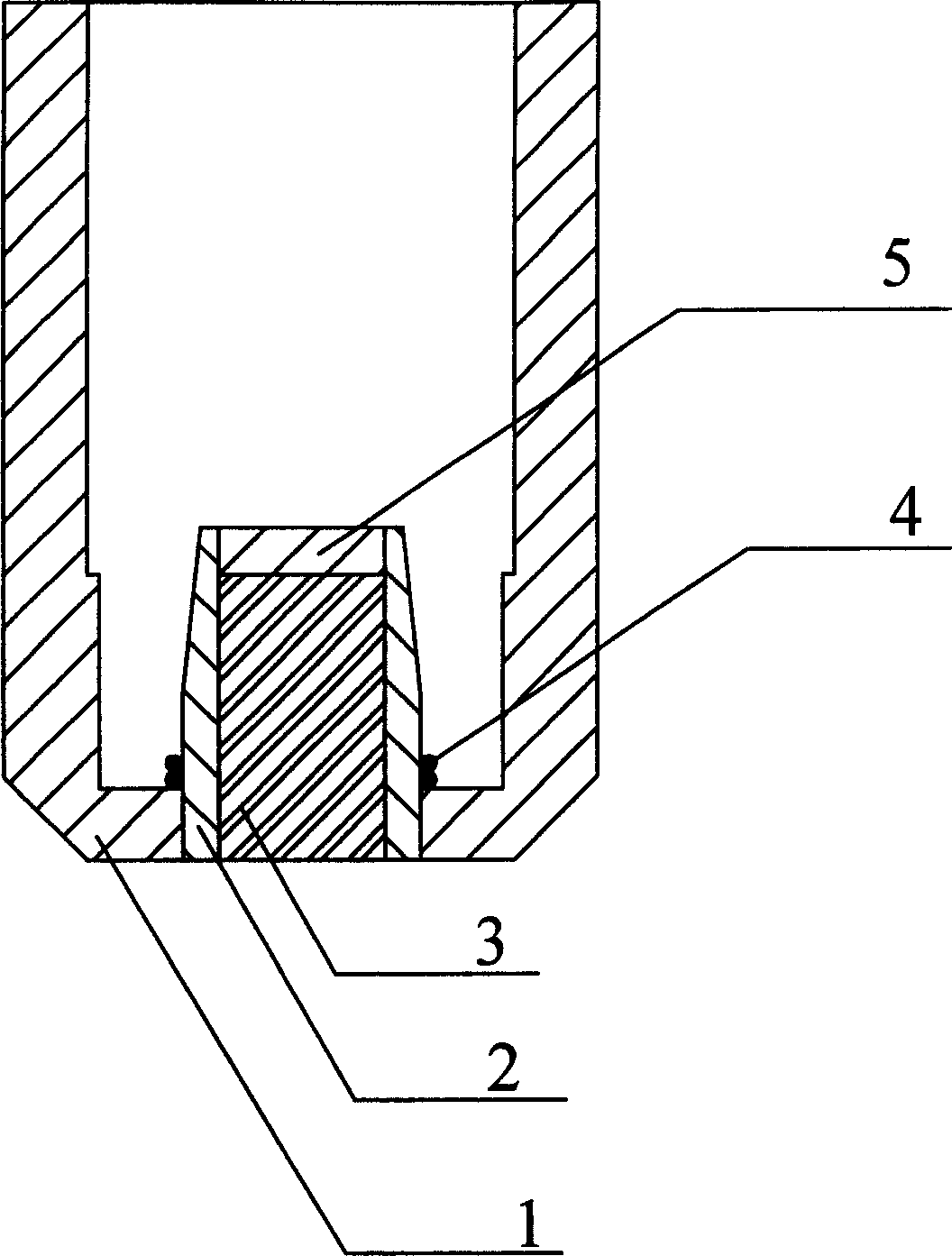

Preparation of nano silicon dioxide lubricating grease

The invention discloses a preparation method of high-performance silicon dioxide grease, which comprises the following components, base oil of 70 to 90 weight percent, silica of 5 to 30 weight percent, modifying agent is in a dose of 5-30 weight percent of the silicon dioxide. The silicon dioxide grease of the invention has a very good storage stability and shear stability, good colloidal stability, water resistant properties of high temperature and low temperature performance. The silicon dioxide grease can be used for electrical insulation, damping system lubrication, vacuum sealed, instruments and cock sealing and lubricating, can also be used for resistant chemical media site lubricating and sealing, and so on. In addition, the silicon dioxide grease can also be used for preparing valves grease, methanol resistance grease, and is applicable in lubrication and interrupter of the metal contact of switch silvering, silver plating, and tinning and other.

Owner:益田润石(北京)化工有限公司

Fence preservation method for prolonging shelf life of cold fresh poultry

InactiveCN101990930AAntibacterialImprove freshnessMeat/fish preservation using chemicalsBiotechnologyCold chain

The invention discloses a fence preservation method for prolonging shelf life of cold fresh poultry. The fence preservation method for prolonging the shelf life of the cold fresh poultry comprises the following steps of: placing fresh poultry which is obtained by slaughtering, washed completely and cut into a refrigeration storage at the temperature of between 2 and 5 DEG C and precooling the poultry for 1 to 2 hours, so that the surface temperature of the poultry is reduced below 5 DEG C and the internal temperature of the poultry is reduced below 10 DEG C; transferring the precooled poultry to a purification room and performing surface sterilization on the poultry through ozone or ozone solution of an ozone generator; immersing the poultry subjected to ozone sterilization into chitosan glutamate solution to retain freshness; taking out and draining the poultry; placing the poultry after corrosion prevention and freshness preservation into a food plastic packaging box; introducing carbon dioxide (CO2) and nitrogen (N2) into the food plastic packaging box and performing sealing package; and storing the packaged poultry into a cold chain at the temperature of between 2 and 5 DEG C. The fence preservation method for prolonging the shelf life of the cold fresh poultry has good effect and is suitable for retaining freshness of the fresh cut poultry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Nano-silver-containing adhesive and using method of adhesive in technical wood

ActiveCN103820056AImprove stabilityGood dispersionNon-macromolecular adhesive additivesAdhesive glueDodecyl sulfate

The invention relates to the field of nanometer materials, and particularly relates to nano-silver-containing adhesive and a using method of the adhesive in technical wood. The nano-silver-containing adhesive is characterized in that nano-silver is uniformly applied to an environmentally friendly glue solution, and flour is used as an additive of glue. A preparation method of the nano-silver comprises the following steps: adding a sodium dodecyl sulfate solution and a hydrazine hydrate solution to a silver nitrate solution so as to obtain mixed liquid, and adding crown ether and an alkali metal-containing reducing agent to the mixed liquid, wherein the molar ratio of the crown ether to the silver nitrate is (1-2): 1, the molar ratio of the alkali metal-containing reducing agent to the silver nitrate is (0.5-1): 1; and controlling a pH value to 8-9, thus obtaining the nano-silver. The using method of the adhesive comprises the following steps: bonding decorative veneer and a base material through the nano-silver-containing adhesive, then feeding into a vacuum tank, and vacuumizing; then carrying out pressurizing treatment; carrying out microwave treatment; and finally taking out, and carrying out cold pressing and hot pressing. The nano-silver-containing adhesive provided by the invention has good stability, dispersity and adhesiveness.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

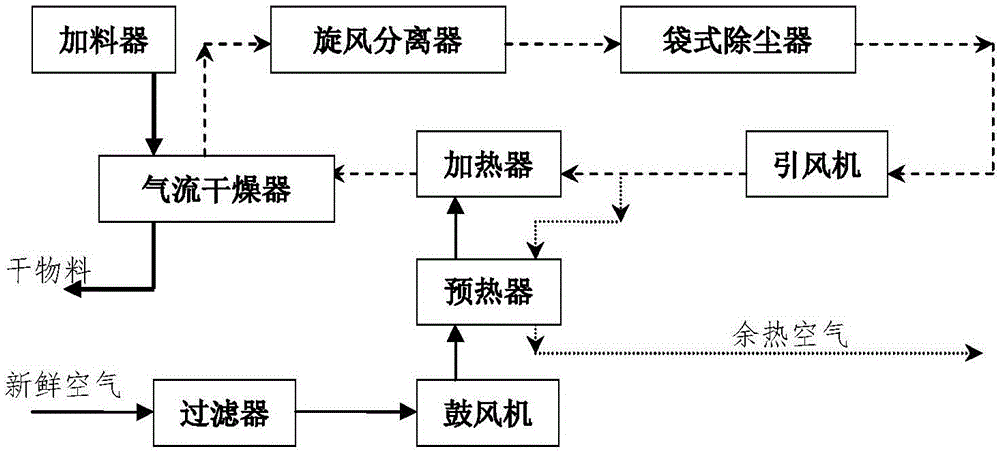

Airflow energy-saving drying device and airflow energy-saving drying method

ActiveCN105115283AReduce consumptionNo oxidationSludge treatment by de-watering/drying/thickeningDrying gas arrangementsBaghouseWaste management

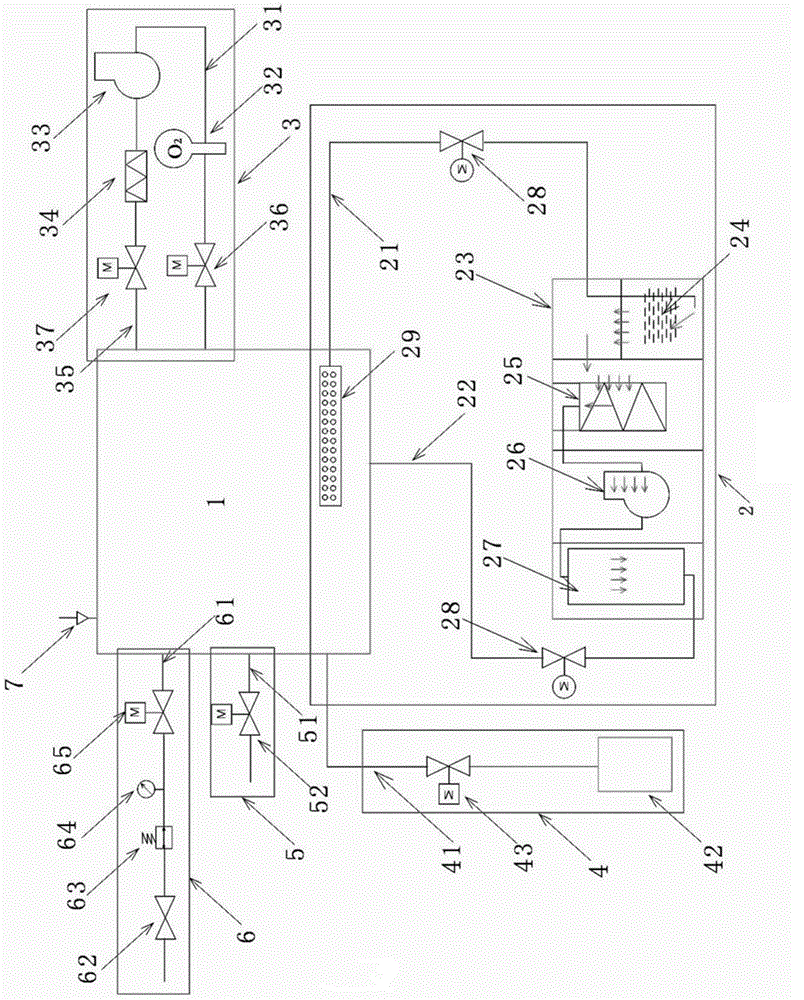

The invention discloses an airflow energy-saving drying device and an airflow energy-saving drying method and belongs to the field of drying and energy saving. The device comprises a filter (1), an air blower (2), a heater (3), a feeder (4), an airflow dryer (5), a cyclone separator (6), a bag dust remover (7), an induced draft fan (8) and a pre-heater (9), wherein the filter (1) is connected to an inlet of the air blower (2); the air blower (2) is connected to an inlet of the pre-heater (9); an outlet of the pre-heater (9) is connected to an inlet of the heater (3); an outlet of the heater (3) is connected to an inlet of the airflow dryer (5); the airflow dryer (5), the cyclone separator (6), the bag dust remover (7) and the induced draft fan (8) are connected with one another in sequence; an outlet of the induced draft fan (8) is simultaneously connected with the pre-heater (9) and the heater (3). The airflow energy-saving drying device and the airflow energy-saving drying method are capable of recycling the waste heat of the airflow drying tail gas to the maximum extent; the problem of accumulation of moisture in circulating air is solved; the operation load of the device is effectively reduced.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

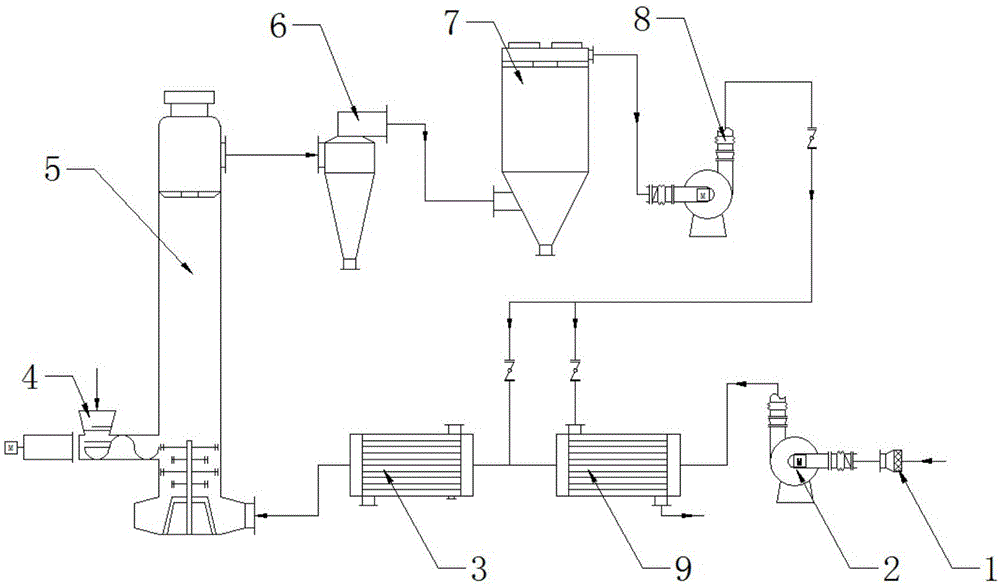

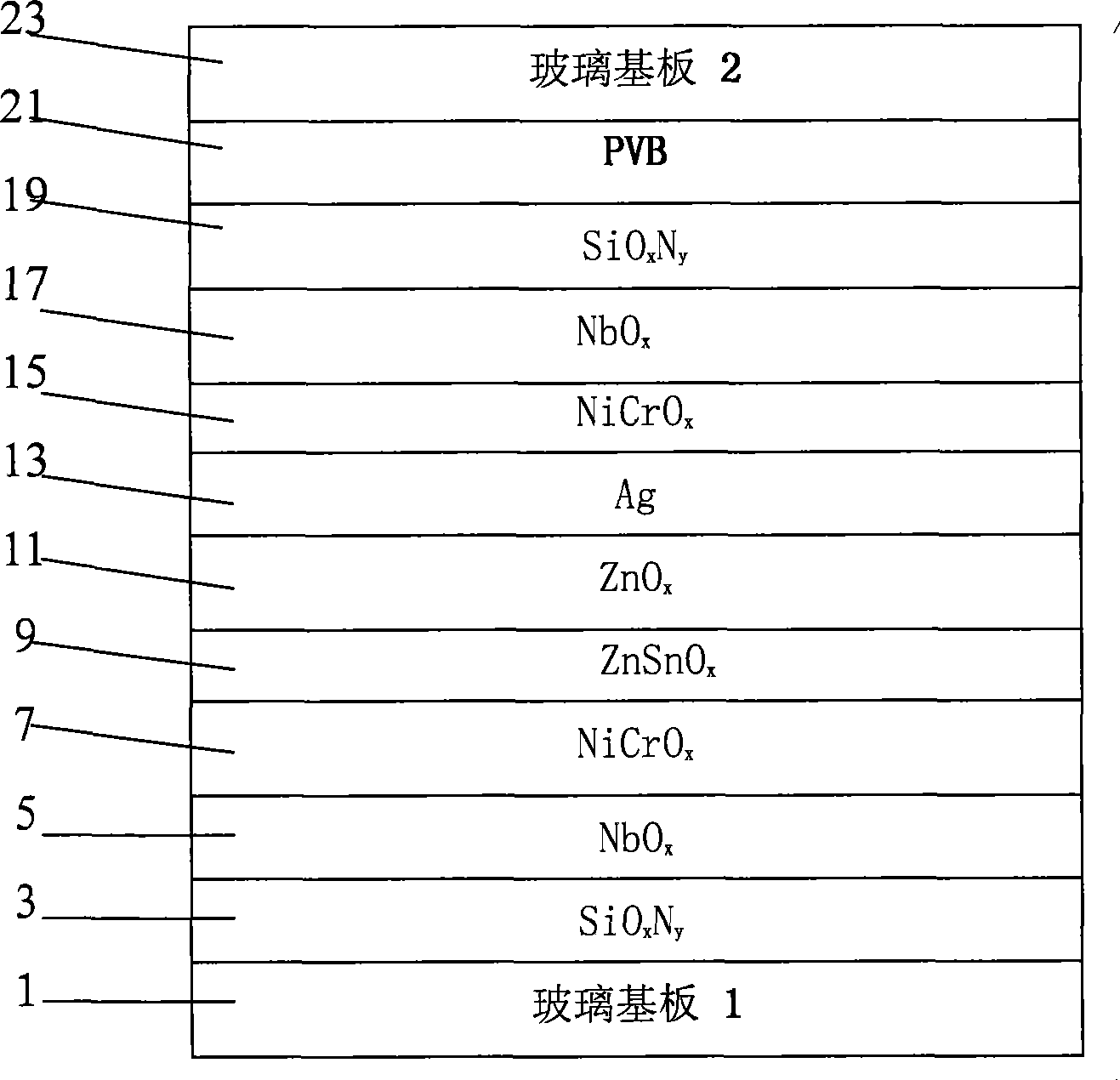

Bendable low radiation coated glass

The invention discloses low-emissivity coated glass which can be baked to be bent, relates to coated glass, in particular to the low-emissivity coated glass. The invention provides the low-emissivity coated glass and a sandwich heat-protecting glass formed by the low-emissivity coated glass. The low-emissivity coated glass is sequentially provided with a glass sheet, a first dielectric layer, a low-emissivity layer, a second dielectric layer and a protection layer, wherein, in a preferable embodiment, the coated glass is sequentially provided with glass substrate, SiOxNy, NbOx, NiCrOx, ZnSnOx, Ag, NiCrOx, NbOx and SiOxNy membranous layers. A polyvinyl butyral (PVB) layer and a glass sheet are sequentially overlapped outside the protection layer of the low-emissivity coated glass to form the sandwich heat-protecting glass. The visible light transmittance of the sandwich heat-protecting glass is at least 76%, and the solar energy transmittance is equal to or less than 48%; or the visible light transmittance is equal to or more than 70%, and the solar energy transmittance is equal to or less than 43%. The sandwich heat-protecting glass is particularly suitable for being used as the front windshield glass of an automobile.

Owner:FUYAO GLASS IND GROUP CO LTD

High-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as preparation method and welding method

InactiveCN104858570AEvenly meltedImprove wettingWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMechanical property

The invention discloses high-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as a preparation method and a welding method. The high-temperature Zr-based brazing filler metal comprises the following elements by weight: 10 to 12 percent of V, 3.0 to 9.0 percent of Nb, 3.0 to 4.0 percent of Si, 8.0 to 16 percent of Cu, 9.0 to 12 percent of Ni, 11 to 14 percent of Cr, 3.0 to 5.0 percent of Sn, and the balance of Zr. The brazing temperature of the brazing filler metal is 1010 to 1090 DEG C and moderate, so that the brazing filler metal is uniformly melted; tinsel made of the brazing filler metal can accelerate atomic diffusion and interface reaction in a high-temperature connection process, so that the wetting and spreading capabilities of the brazing filler metal are improved, the residual stress in a joint is reduced, and the mechanical property of the joint is improved. Through the adoption of the preparation method of the brazing filler metal, the preparation of the brazing filler metal can be reproduced repeatedly, so as to facilitate popularization and application; through the adoption of the brazing technology provided by the invention, sample pieces are connected through vacuum brazing, wherein the sample pieces are in a vacuum atmosphere while being heated, so that problems such as oxidation and pollution are solved, the surface wetting and spreading capabilities are relatively high, convenience is brought for filling of a brazing seam, the strength of the joint is improved, and the obtained welded joint can be stable and reliable.

Owner:江门市新会区华科电器制品有限公司

Preparation method of magnesium alloy corrosion resistant prevention coating

ActiveCN103255410ALow heating temperatureNo oxidationPressure inorganic powder coatingPorositySealant

The invention relates to a preparation method of a magnesium alloy corrosion resistant coating. The method is characterized in that spherical aluminum powder or spherical aluminum powder and SiC or Al2O3 powder are adopted, compressed air is used as an air source, and then a coating is prepared by a low-temperature pneumatic spraying method. The adopted powder comprises 100% of aluminum powder or 70-98wt% of aluminum powder and 30-2wt% of hard particles. After-treatment is performed by ceramic shot blasting or a 518 sealant produced by the Beijing Institute of Aeronautical Materials. Compared with the prior art, an aluminum coating prepared by the low-temperature pneumatic spraying method is dense with low porosity and high hardness, has good bonding strength with a base body, and has good corrosion resistance and wear resistance, thereby being a good protection coating for corrosion resistance of magnesium alloy.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Super particle size molybdenum powder preparing method

InactiveCN101224500AEasy to manufactureGuaranteed Chemical CompositionGranularityVolumetric Mass Density

The invention provides a preparation method of a molybdenum powder with ultra-large granularity, which relates to the preparation method used for an alloy powder with special physical performance and high melting point. The invention is characterized in that the preparation process comprises the following steps that: (1) a molybdenum powder is selected, with the Fisher particle size of 2.5-3.5 Mum, the loose density of 0.9 g / cm<3>-1.1 g / cm<3> and the oxygen content less than 0.08wt%; (2) the selected molybdenum powder is pressed into a blank under the pressure of 15MPa-30MPa; (3) the pressed blank is sintered for 1-5 hours under the temperature of 800-1200 DEG C; (4) the sintered blank is broken, ball milled and screened so as to prepare the molybdenum powder which consists of the grain groups with the average granularity of 100-200 Mum. By adopting the method of the invention, the molybdenum powder which consists of the grain groups with the average granularity of 100-200 Mum can be prepared and more than 80% of the yield can be realized.

Owner:JINDUICHENG MOLYBDENUM CO LTD

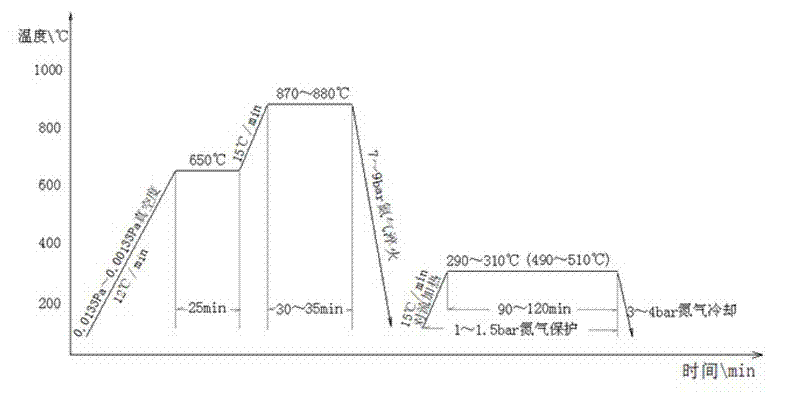

High-strength steel thin-wall piece vacuum thermal treatment process

InactiveCN102560037AHeating evenlyNo decarbonizationFurnace typesHeat treatment furnacesCounter flowHardness

The invention discloses a high-strength steel thin-wall piece vacuum thermal treatment process, which comprises vacuum quenching and vacuum tempering, wherein the vacuum quenching comprises the following specific steps of: heating to 650 DEG C at the vacuum degree between 1.33*10<-4> Pa and 1.33*10<-2> Pa; preserving heat for 25 minutes; heating to 870-880 DEG C; preserving heat for 30-35 minutes; charging 7-9 bar of high-purity nitrogen gas into a furnace for performing air pressure quenching; and cooling to 50-60 DEG C; and vacuum tempering comprises the following specific steps of: performing counter-flow heating to a tempering temperature under the protection of 1-1.5 bar of high-purity nitrogen gas; preserving heat for 1.5-2 hours; charging 3-4 bar of high-purity nitrogen gas into the furnace for performing air pressure cooling; and cooling to a low temperature for discharging. A high-strength steel thin-wall piece vacuum thermal treatment surface has the advantages of freeness from oxidation and decarburization, high size precision, uniform hardness, high strength and low cost.

Owner:HENAN BEIFANG HONGYANG IND

Isothermal normalizing technology of carburized gears steel forging

The invention discloses an isothermal normalizing process of a carburized gear steel forging stock, which relates to the technical field of metal heat treatment. The process is carried out on a bright isothermal normalizing production line under a preevacuated and fully electrically heated roller bottom protective atmosphere. The heating, heat preservation, fast cooling, isothermy and water cooling in the protective atmosphere are automatically completed by a PLC control. The normalizing heating temperature of the forging stock is Ac3 plus (100-150) DEG C, and the temperature is kept for 36-45min, and the forging stock is quickly cooled to 560-600 DEG C within 10min by high-purity nitrogen gas blown by an electric fan. The normalizing process has the advantages of normative operation, high production efficiency, and can ensure that the forging stock is not oxidized and decarburized in the heat treatment process, and austenite crystals in the forging stock are evenly distributed, which avoids the appearance of banded structures and causes the forging stock to have good and stable quality with small hardness fluctuation.

Owner:JIANGSU PACIFIC PRECISION FORGING

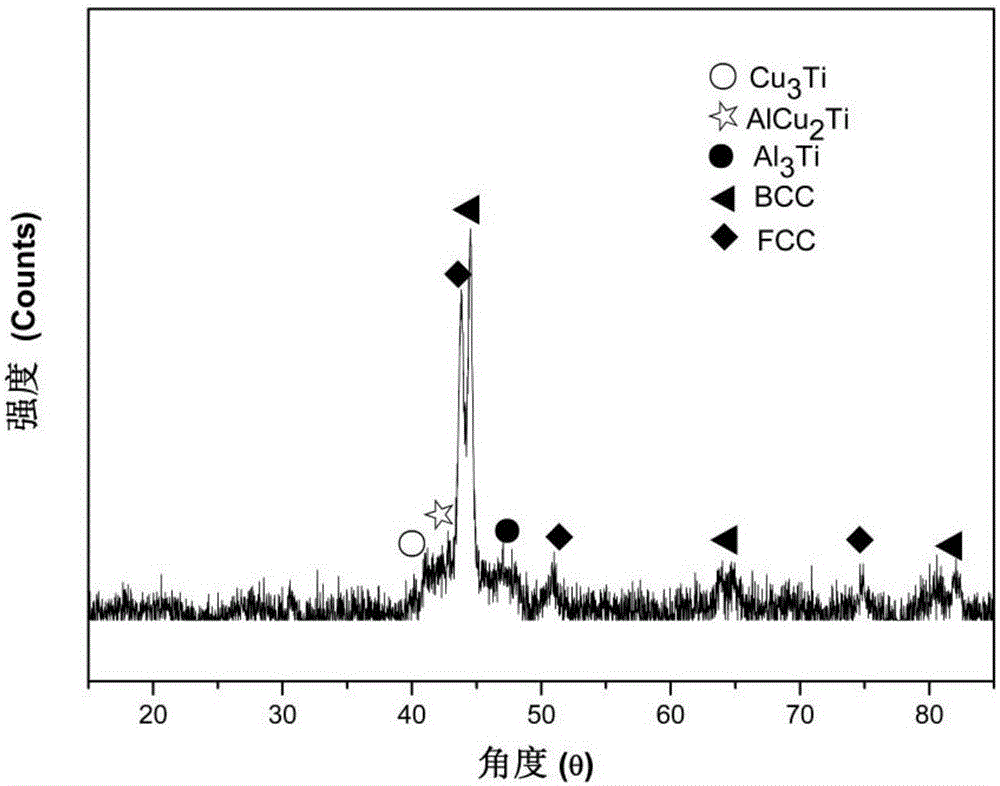

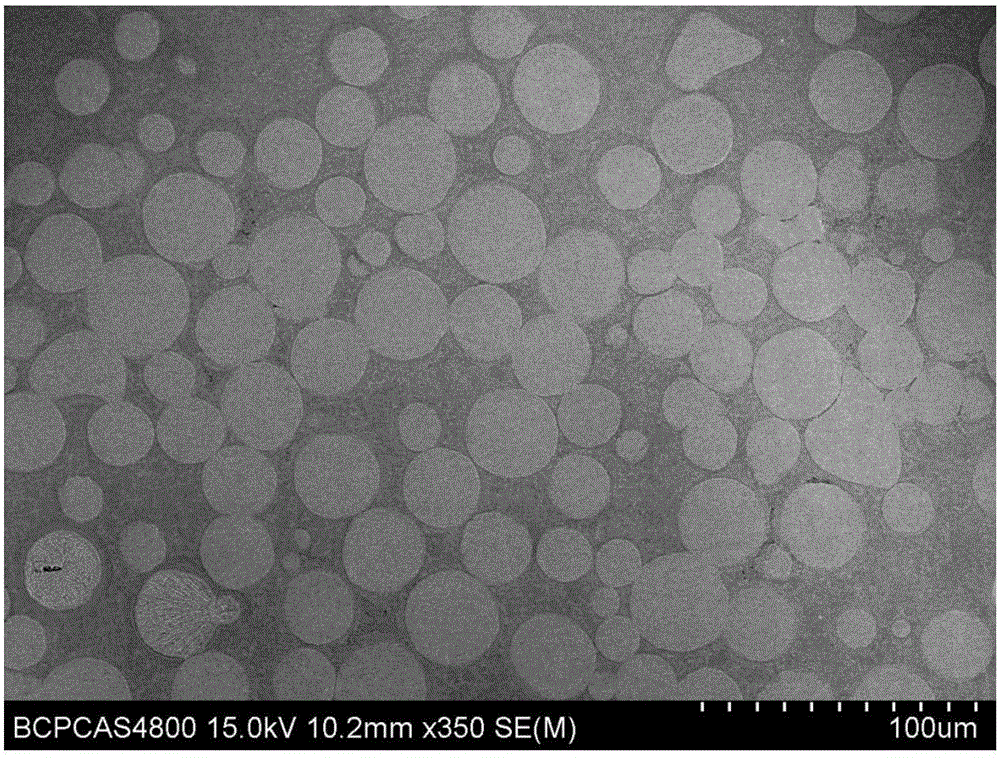

Aluminum-based amorphous/high-entropy alloy composite and preparation method thereof

The invention relates to an aluminum-based amorphous / high-entropy alloy composite and a preparation method thereof, belonging to the field of metal composites. The composite is relatively low in density and high in compressive strength and has certain deformability. The preparation method comprises the steps of placing metal powder of Al, Cu and Ti or Al, Fe and Ti or Al, Ni and Ti into a ball milling tank, injecting methylbenzene from a glove box with an Ar atmosphere to the ball milling tank, taking all the components out of the glove box after sealing the tank, and carrying out ball milling to obtain aluminum-based amorphous powder; preparing an original material from Al, Co, Cr, Fe and Ni metal blocks, and carrying out alloy smelting in vacuum by taking Ar as a protective gas to obtain a mother alloy ingot of AlCoCrFeNi high-entropy alloy; atomizing the obtained mother alloy ingot, and screening to obtain spherical high-entropy alloy powder with the particle size of 20-100mu m; and after carrying out ball milling and mixing on the obtained aluminum-based amorphous powder and the high-entropy alloy powder, placing the mixture into a hard alloy die to sinter to obtain the aluminum-based amorphous / high-entropy alloy composite.

Owner:北京中辰至刚科技有限公司

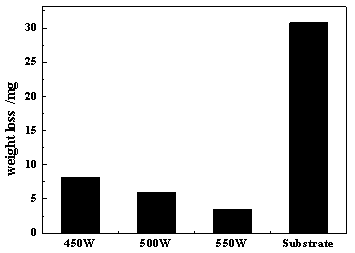

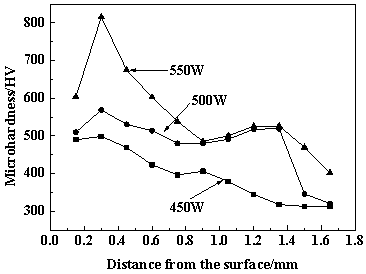

Preparation method for wear-resistant and corrosion-resistant composite coating layer

InactiveCN108611636AHigh hardnessAccelerated corrosionAdditive manufacturing apparatusMetallic material coating processesStellite alloySurface layer

The invention discloses a preparation method for a wear-resistant and corrosion-resistant composite coating layer. The preparation method specifically comprises the following steps: S1. carrying out pretreatment on a cladding matrix; S2. carrying out drying treatment on a cladding material; S3. melting the cladding material and the surface layer of the cladding matrix simultaneously through a laser device and in combination with a coaxial powder feeding method to form an alloy coating layer, that is, the high-hardness corrosion-resistant layer, wherein the cladding matrix in the step S1 is made from Q960 steel; and the cladding material in the step S2 is made from the mixture of tungsten carbide powder and Stellite 6 alloy powder. According to the preparation method disclosed by the invention, the composite coating layer is creatively prepared on the surface of the Q960 steel through a laser cladding technology; the tungsten carbide powder and the Stellite 6 alloy powder are mixed as the cladding material in a specific ratio; and the process parameters of the laser cladding technology are scientifically and reasonably designed, so that the problems of low hardness and short servicelife under the working condition of abrasive wear, of a laser cladding coating layer made from Stellite 6 cobalt alloy, are effectively solved.

Owner:HUNAN UNIV OF TECH +2

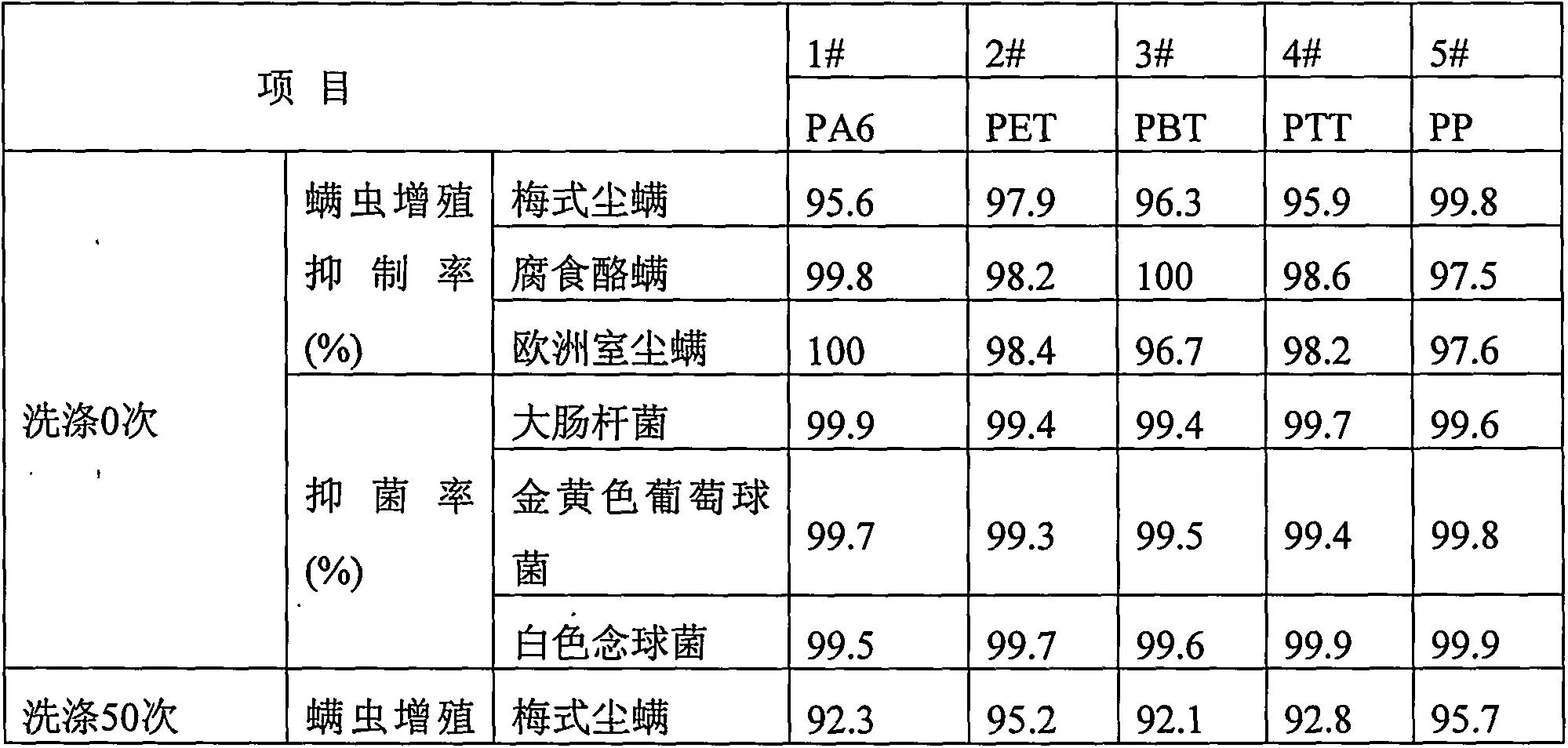

Anti-mite antibacterial thermoplastic polymer melt spun fiber and preparation method thereof

ActiveCN103882543AImprove durabilityAllergy freeSpinning head liquid feederArtificial filament heat treatmentHigh concentrationPolymer science

The invention relates to a thermoplastic polymer melt spun fiber with anti-mite and antibacterial functions and a preparation method thereof. The preparation method comprises the following steps: preparing a silver-loaded soda borosilicate ceramic powder which serves as an anti-mite and antibacterial component through a sol-gel method, performing surface modification on superfine ceramic powder through a coupling agent, granulating to prepare a high-concentration anti-mite and antibacterial master batch which takes a thermoplastic polymer as a matrix in a double-screw extruder, and finally, blending the anti-mite and antibacterial master batch with the thermoplastic polymer according to a certain ratio, and performing melt spinning to obtain the anti-mite and antibacterial fiber. The anti-mite and antibacterial fiber prepared by the method has obvious effects, is high in durability, high in washing resistance and high in safety.

Owner:上海市合成纤维研究所有限公司

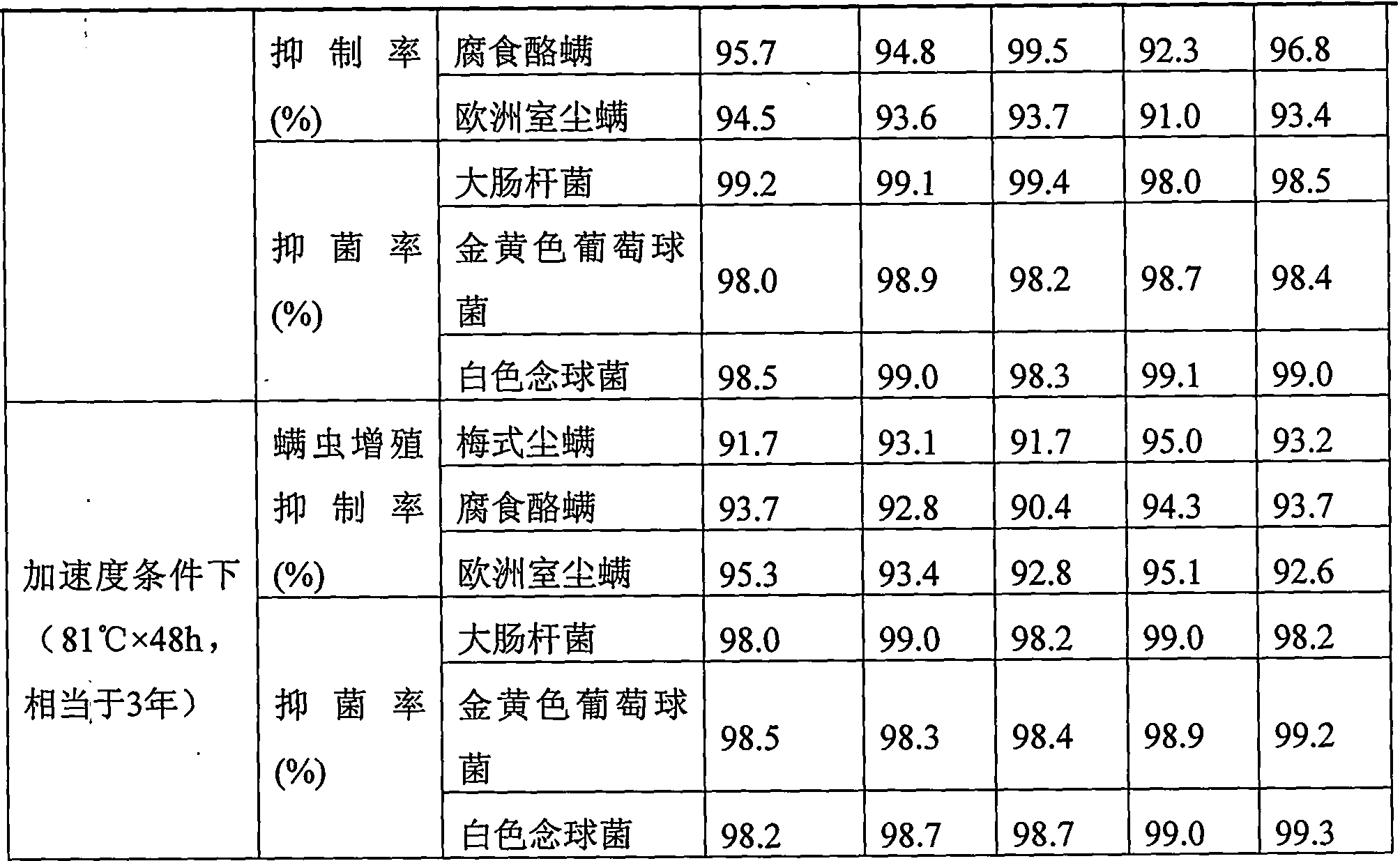

Automatic traceless fusion welding technology of thin-wall stainless steel clean pipeline

The invention discloses an automatic traceless fusion welding technology of a thin-wall stainless steel clean pipeline. The technology comprises the following steps of: step 1, treating a welding port: milling pipe end welding surfaces of two welded pipeline segments into planes; step 2: assembling welded junctions; step 3: carrying out point welding; step 4: carrying out fusion welding: carrying out fusion welding on the two pipeline segments by adopting an argon tungsten-arc welding machine, wherein the fusion welding process comprises the following steps of: introducing a protective gas before welding, welding the two welded pipeline segments by adopting the argon tungsten-arc welding machine, and introducing argon continuously during the welding process and introducing a protective gas continuously after welding; and step 5: sealing and protecting after welding. The automatic traceless fusion welding technology of the thin-wall stainless steel clean pipeline provided by the invention is reasonable in design, is simple and convenient to operate, is convenient to achieve, has a good pipeline cleanness control effect, is high in welding quality, and can effectively solve the problems of high labor intensity, low efficiency, high production cost, severe welding junction oxidation, poor formation inside and outside a welding line, difficulty in controlling cleanness in pipelines, poor cleanness control effect and the like in an existing welding method.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

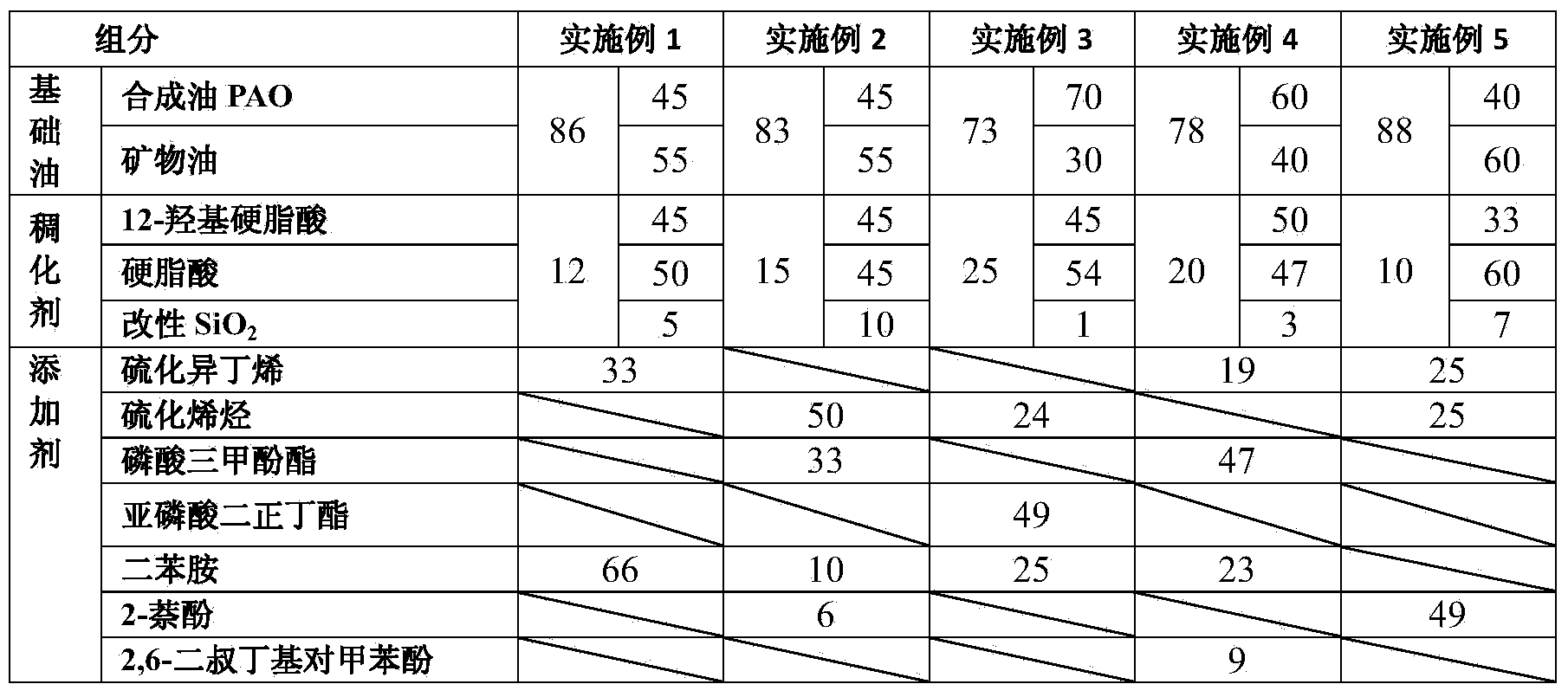

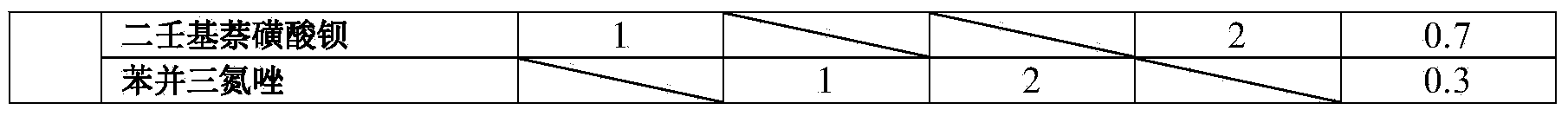

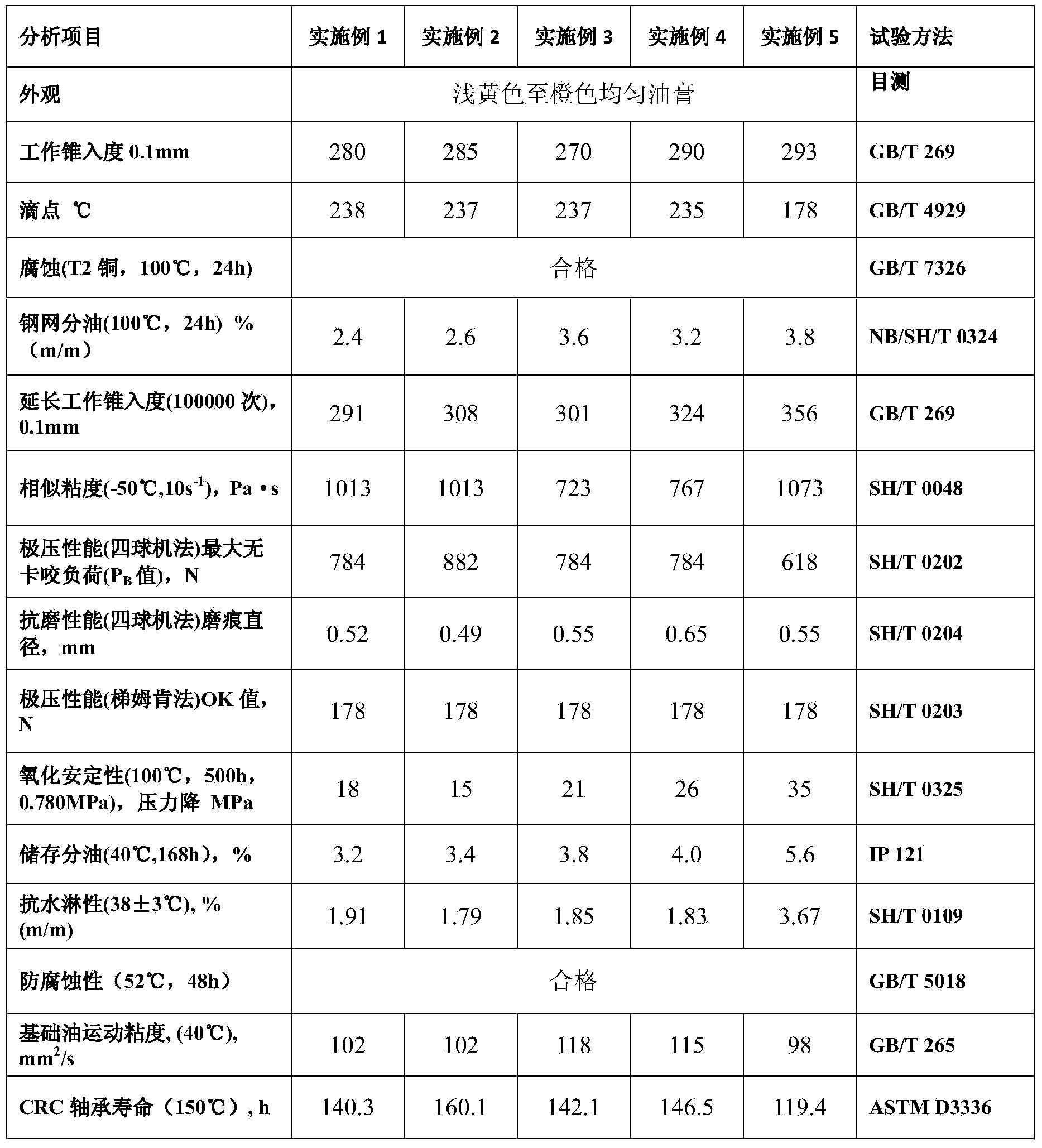

Lubricating grease containing modified silica component and preparation method of lubricating grease

ActiveCN103484204AImprove shear stabilityLittle change in cone penetrationPigment treatment with organosilicon compoundsLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to lubricating grease containing a modified silica component and a preparation method of the lubricating grease. The excellent properties of silicone grease and lithium lubricating grease are well combined through modified SiO2. With total weight of a composition as benchmark, the lubricating grease provided by the invention comprises the following components: a thickening agent accounting for 10-25% of the total weight and including 12-hydroxystearic acid, stearic acid and the modified SiO2; base oil accounting for 73-88% of the total weight and consisting of synthetic oil and mineral oil; and additives mainly including the following three types: (a) 0.6-1.8% of anti-wear reagent at extreme pressure, (b) 0.32-1.32% of antioxidant, and (c) 0.02-0.04% of antirust preservative. The novel lubricating grease containing modified SiO2 has excellent shear stability and storage stability and is a kind of SiO2-containing lithium lubricating grease in which high and low temperature, colloid stability and water resistance are greatly improved. The lubricating grease is especially suitable for application under harsh environmental conditions of high temperature and heavy load.

Owner:CHINA PETROLEUM & CHEM CORP

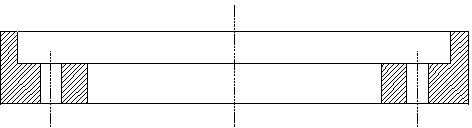

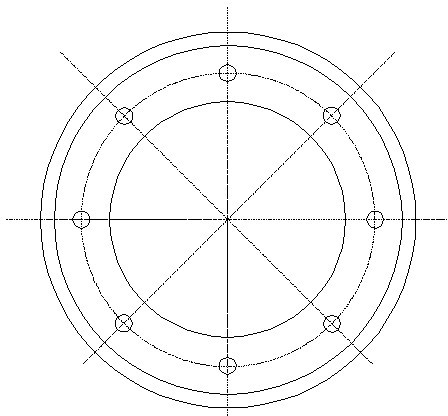

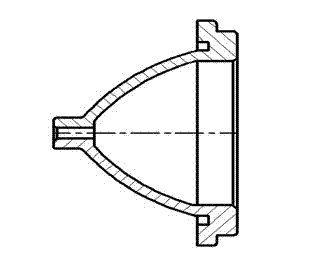

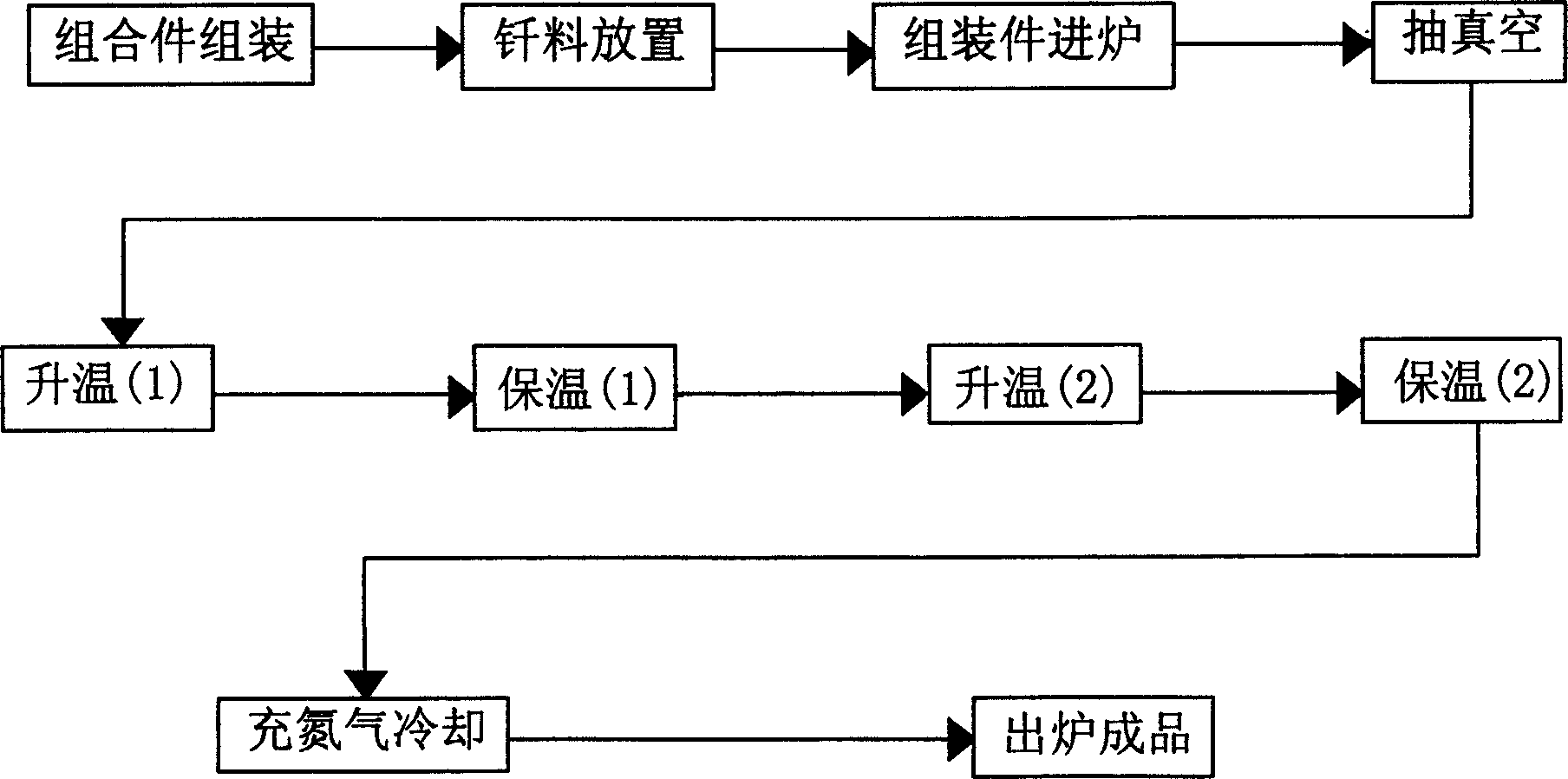

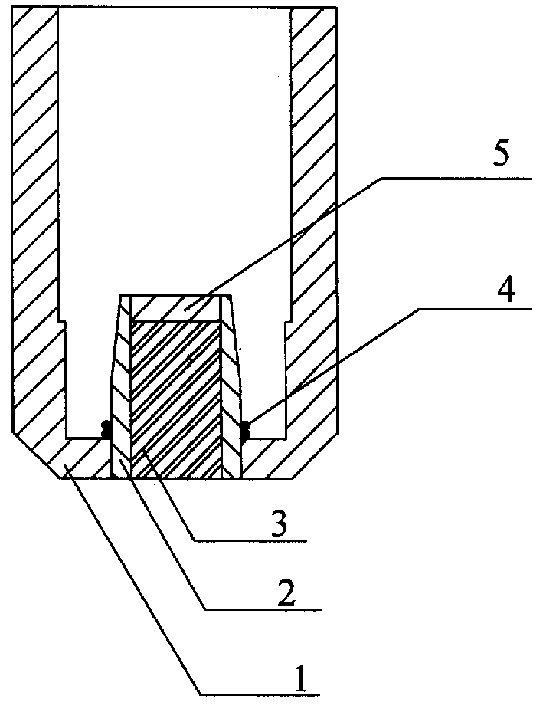

Plasma cutting electrode vacuum soldering method

InactiveCN1493430AImprove liquidityImprove surface qualityPlasma welding apparatusSheet steelSoldering

A vacuum soldering technology for the plasma cutting electrode includes assembling the non-oxygen copper sleeve, silver body and wire feeding coaxial core together, arranging solder, putting the assembly in vacuum furnace, vacuumizing to 1-5X10 to the power -1 - -2 Pa, heating and holding the temp twice at 820-880 deg.C, filling N2, and cooling. The resultant electrode features high quality and long service life (500 m for cutting steel plate).

Owner:上海市机械制造工艺研究所有限公司

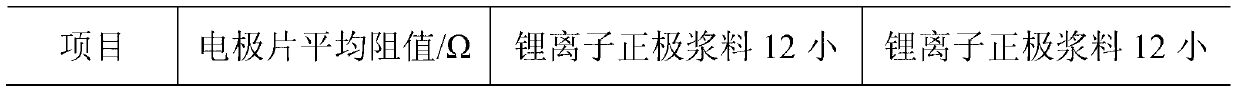

Li-ion positive electrode slurry and preparation method thereof

InactiveCN103346318AEvenly dispersedSolve the defect of easy reunionCell electrodesLithium iron phosphatePyrrolidinones

The invention provides a Li-ion positive electrode slurry and a preparation method thereof. The preparation method comprises the following steps of: mixing lithium iron phosphate and dry inorganic conductive agent powder, wherein uniform mixing is judged by randomly sampling and measuring the resistance value of the powder, and is considered to be achieved when the difference of the resistance value of each sample powder is less than 5%; then adding PVDF (Polyvinylidene Fluoride) colloidal fluid into the mixture step by step; finally regulating the viscosity of the slurry by utilizing 1-Methyl-2-pyrrolidinone, thereby obtaining the Li-ion positive electrode slurry. The viscosity of the Li-ion positive electrode slurry is 3000-5000cps, and the Li-ion positive electrode slurry comprises 1-methyl-2-pyrrolidinone, as well as lithium iron phosphate, polyvinylidene fluoride and the inorganic conductive agent which are at a mass ratio of (85-95):(3-8):(2-10). According to the preparation method, whether the inorganic conductive agent is uniformly dispersed in lithium iron phosphate is determined by a method of randomly sampling dry powder, mixing samples and measuring the resistance values, and meanwhile, the PVDF colloidal fluid is added step by step in a substep slurry preparation process, so that the conventional thought of firstly mixing solid materials and adding the colloidal fluid in one step in a slurry preparation process in the field is broken through, and a favorable slurry preparation effect is achieved.

Owner:IRICO

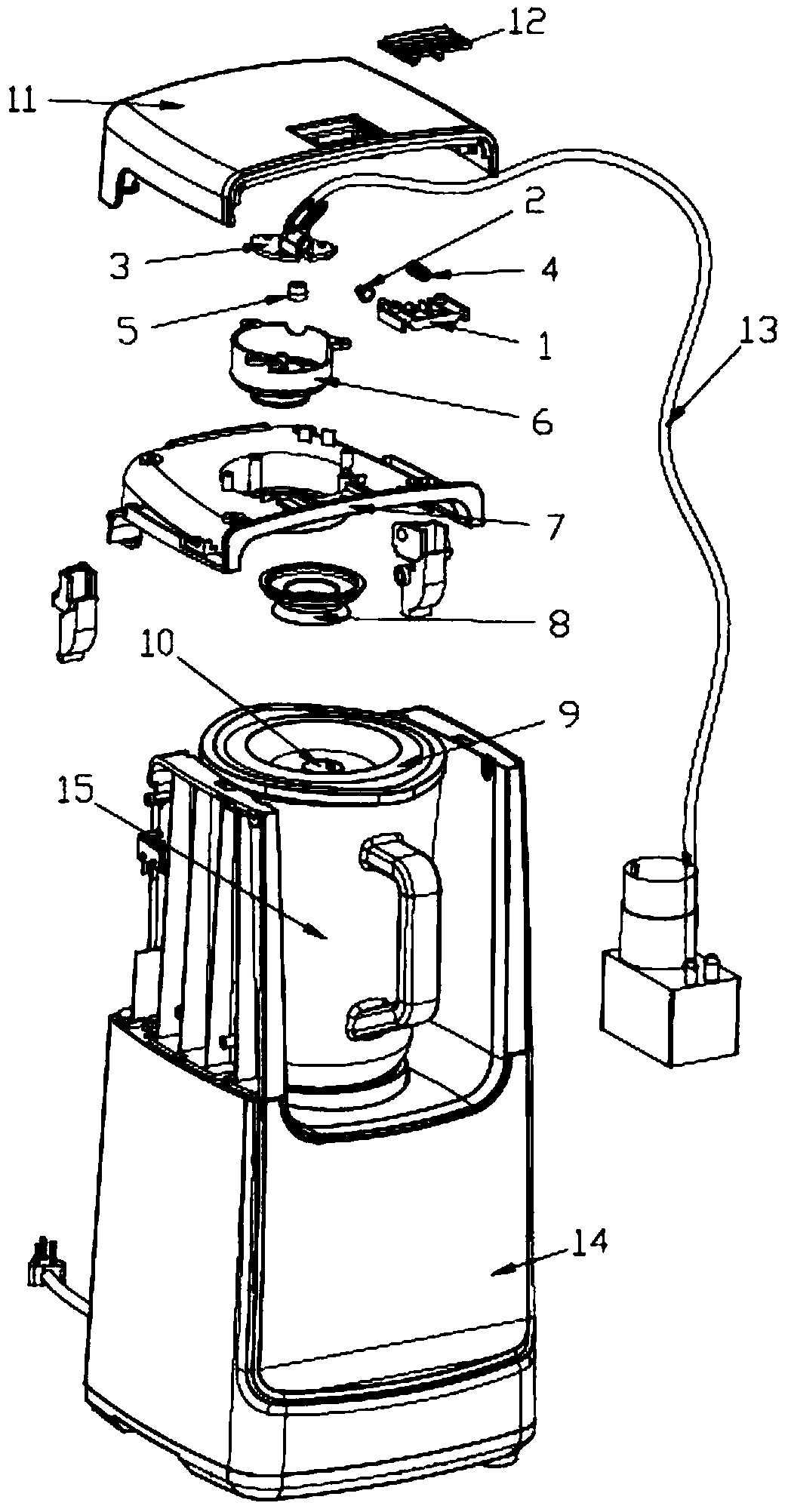

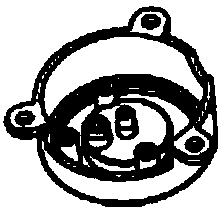

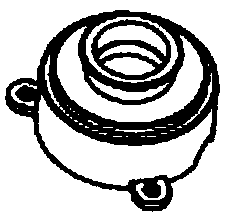

Vacuumizing cover opening device with air leakage function and high speed blender

The invention discloses a vacuumizing cover opening device with an air leakage function and a high speed blender. The vacuumizing cover opening device comprises a cup cover, a cup cover plug valve, avacuum nozzle, a vacuum nozzle sealing ring, an inner cover, a rubber cushion, a pressing plate, an air leakage sealing plug, a vacuum pump, a vacuum pipe, an air leakage switch, and others; the top part of the cup cover is provided with a cover hole, and the cup cover plug valve is arranged in the cover hole; the outer wall of the cup cover plug valve is connected with the cover hole in a sealingmanner; the inside of the cup cover plug valve is a unidirectional air valve opening; the upper part of the vacuum nozzle is a shell body structure with an inner cavity, an air leaking hole for leaking air and an air pumping hole for pumping air are arranged in the inner cavity of the vacuum nozzle; the upper part of the vacuum nozzle is provided with an annular buckle position. Compared with theprior art, the vacuumizing cover opening device with the air leakage function can be matched with a cup body of the high speed blender, and can vaccumize the cup body of the high speed blender, thusthe defects that the high speed blender is easy to blister and oxidize in mixing process, and cannot store food for a long time after blending, and easy to 'layer' and flare' are solved.

Owner:中山市德电电器科技有限公司

Method for preparing through-type composite strip embedded with silver copper

ActiveCN102896150AHigh bonding strengthIncrease productivityMetal rolling arrangementsIngotUltimate tensile strength

The application discloses a method for preparing a through-type composite strip embedded with silver copper. The method comprises the steps of: extruding silver and copper ingots into profiled strips according to a design shape, respectively cleaning the surfaces of the profiled silver strip and the purchased profiled copper strip, removing a greasy dirt, an impurity and oxide on the surface; mutually embedding the silver strip and the copper strip into a whole; reinforcing and welding two heads to prepare a pre-composite material; continuously rolling and hot rolling to form a silver copper composite material from the pre-composite material under a complete-atmosphere protection state; dragging and receiving materials by a receiving machine, and then annealing in a diffusion manner, rolling and cutting to obtain the product. The method disclosed by the application is high in bonding strength, low in demand on manufacturing device, easy to process, long in length of strip, and convenient to automatically process, and manufacturing on a large scale can be carried out, thus, the cost is greatly reduced.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Gas protecting system of metal powder laser quick forming machine

InactiveCN104550951AReduce consumptionGuarantee the oxygen content of the environmentWater filterEngineering

The invention discloses a gas protecting system of a metal powder laser quick forming machine. The metal powder laser quick forming machine comprises a sealing forming bin, the gas protecting system comprises a gas circulating purifying mechanism, the gas circulating purifying mechanism comprises an explosive-proof and smoke dust-removal purifier, the explosive-proof and smoke dust-removal purifier is connected with the sealing forming bin through a gas inlet pipe and a gas outlet pipe to form the gas circulating purifying, and is sequentially provided with a water filtering device, a filtering element device, a circulating fan device and a drying machine from an inlet to an exit, and electric valve switches are respectively arranged on the gas inlet pipe and the air outlet pipe. The gas protecting system has the advantages that the oxygen content of the forming environment is controlled to be less than 100ppm, the smoke dust produced in the forming process can be filtered to balance the gas pressure of the forming bin, and the compactness of the formed part reaches 100%; the bright metal luster is realized, and the oxidizing is avoided; the consumption amount of inert gas is saved, the consumption amount of gas is only equal to 2 / 100 of the consumption amount of gas of the prior art, and the economic benefit is higher.

Owner:GUANGDONG HANBANG 3D TECH CO LTD

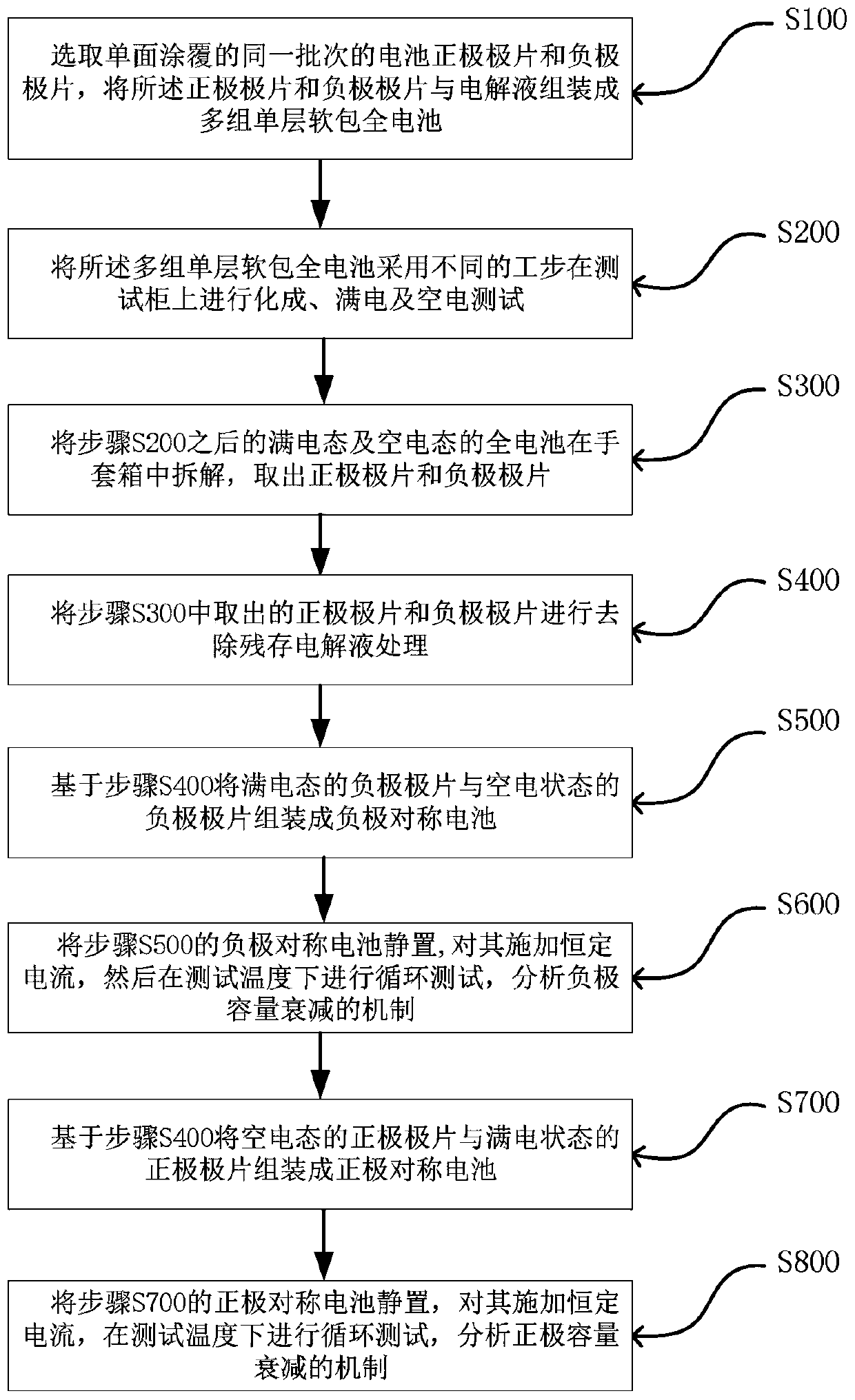

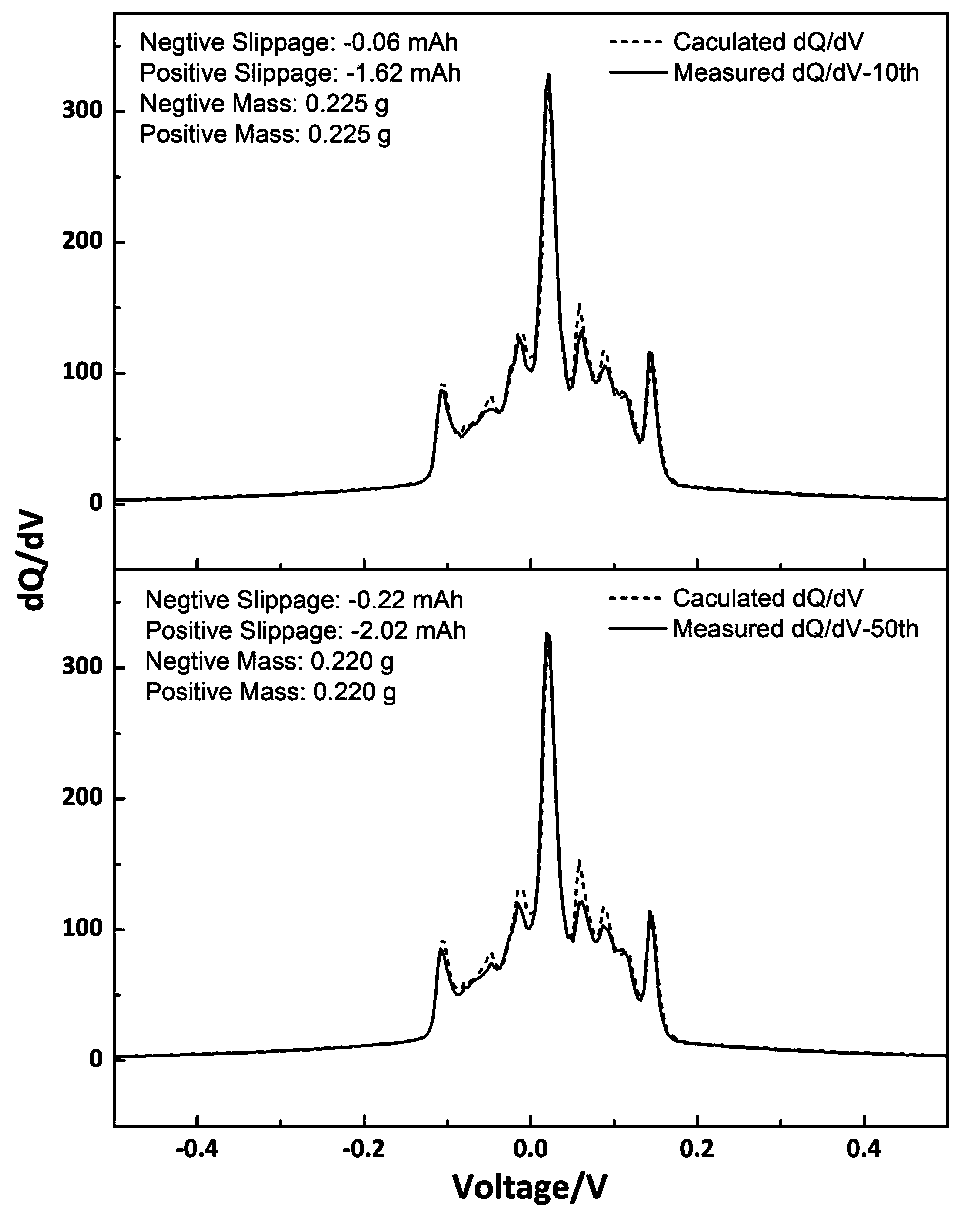

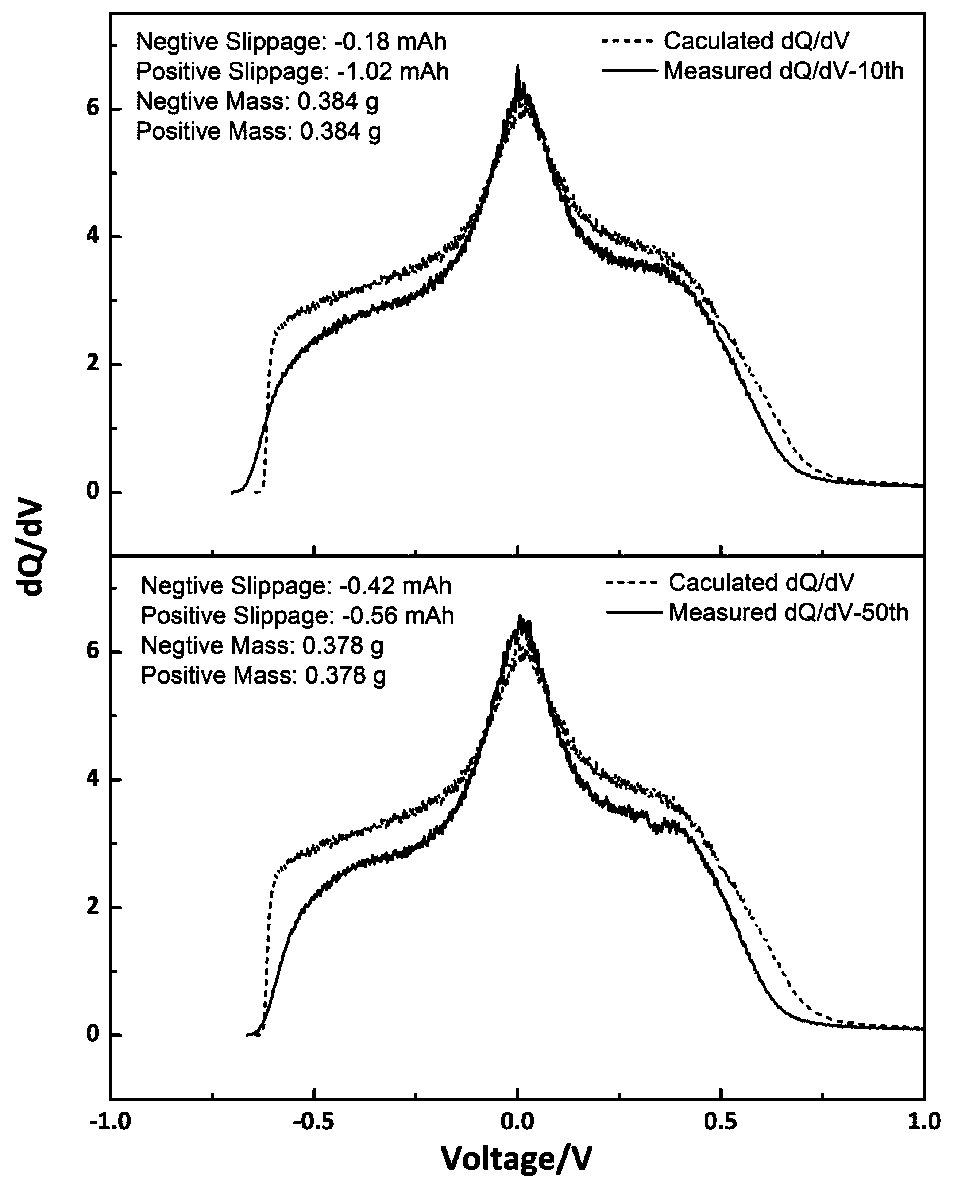

Lithium ion battery electrode cyclic attenuation mechanism evaluating method

ActiveCN109856549AAvoid side effectsNarrow test voltage rangeElectrical testingVoltage rangeSide reaction

The invention relates to a lithium ion battery electrode cyclic attenuation mechanism evaluating method. With the method adopted, the technical problem that the various failure mechanisms of an integrated battery system are difficult to completely separate can be solved. According to the lithium ion battery electrode cyclic attenuation mechanism evaluating method, anode polar sheets, cathode polarsheets and electrolyte are assembled, so that a plurality of sets of single-layer soft-package integrated batteries can be formed; after formation is performed, empty electricity and full electricitytesting is performed; the anode polar sheets and the cathode polar sheets are taken out, and residual electrolyte is removed; and the anode polar sheets and the cathode polar sheets are assembled into soft-package laminated symmetrical batteries, and the attenuation mechanisms of the symmetrical batteries are cyclically tested and analyzed. A symmetrical battery system is adopted, the failure mechanisms of the anodes or and cathodes are separately studied, the generation of the side reactions of the anodes or cathodes is avoided, a test voltage range is narrow, and electrolyte oxidation is avoided. Compared with a half-battery system, the symmetrical battery system is limited in lithium transmission, and has no extra lithium (lithium sheet) participating in side reactions; compared with abutton-type symmetrical battery system, the soft-package symmetrical battery system ensures the sealing of a whole device and enables long-term cyclic testing.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nano-silver aqueous solution and application method for applying nano-silver aqueous solution to technical wood

ActiveCN103817348AImprove stabilityGood dispersionWood treatment detailsNanotechnologyMicrowave frequency rangeAcrylic resin

The invention relates to the field of nano materials, in particular to a nano-silver aqueous solution and an application method for applying the nano-silver aqueous solution to technical wood. According to the aqueous solution, deionized water is used as a solvent, nano-silver is used as a solute and dissolves in the deionized water, acrylic resin is used as a complexing agent and a stabilizing agent and dissolves in the deionized water, meanwhile a dispersing agent and a first reducing agent are added to the deionized water, and then the solution is formed, wherein the dispersing agent is triethanolamine, the first reducing agent is a hydrous ammonia aqueous solution, the concentration of nano-silver ranges from 50 ppm to 150 ppm, and the mass content of acrylic resin in the solution ranges from 1% to 10%. The application method includes the steps that the technical wood is fed to a vacuum tank filled with the nano-silver aqueous solution, and the vacuum tank is pumped until the vacuum degree ranges from -0.05 MPa to -0.01 MPa for 15 min to 20 min; pressure application is conducted, and pressure is applied to 0.2 MPa to 0.5 MPa for 18 min to 28 min; eventually, microwave processing is conducted for 1 min to 3 min, the microwave frequency ranges from 300 MHz to 950 MHz, and then the technical wood is taken out for drying. The nano-silver aqueous solution is good in stability and dispersibility, nano-silver can be more effectively permeated into the technical wood, and mold is fully defended.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for sintering neodymium iron boron magnets

ActiveCN103506624APrevent oxidationSmall machining allowanceInductances/transformers/magnets manufactureMagnetic materialsMachiningNeodymium iron boron

The invention discloses a method for sintering neodymium iron boron magnets. The method for sintering the neodymium iron boron magnets is characterized by comprising the following steps of (1) preparation, wherein neodymium iron boron green bodies are buried in high-temperature resisting powder to enable the neodymium iron boron green bodies to be isolated from air, and the sintering temperature of the high-temperature resisting powder is higher than that of the neodymium iron boron magnets; (2) furnace feeding, wherein the neodymium iron boron green bodies and the high-temperature resisting powder are fed into a sintering space in the furnace together; (3) sintering, wherein the neodymium iron boron green bodies are sintered to form the neodymium iron boron magnets. The method can reduce the oxidation of the neodymium iron boron green bodies before the neodymium iron boron green bodies are fed into the furnace, therefore, sintering deformation is reduced, reserved allowance for the machining of the neodymium iron boron green bodies is reduced, and subsequent machining is made to be convenient.

Owner:SINO MAGNETICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com