High-temperature-resistant silver-coated and nickel-coated copper conductive powder of core-shell structure and preparation method thereof

A technology of core-shell structure and conductive powder, applied in transportation and packaging, metal processing equipment, coating, etc. Complicated process and other issues, to achieve good industrialization prospects, improve electrical conductivity, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

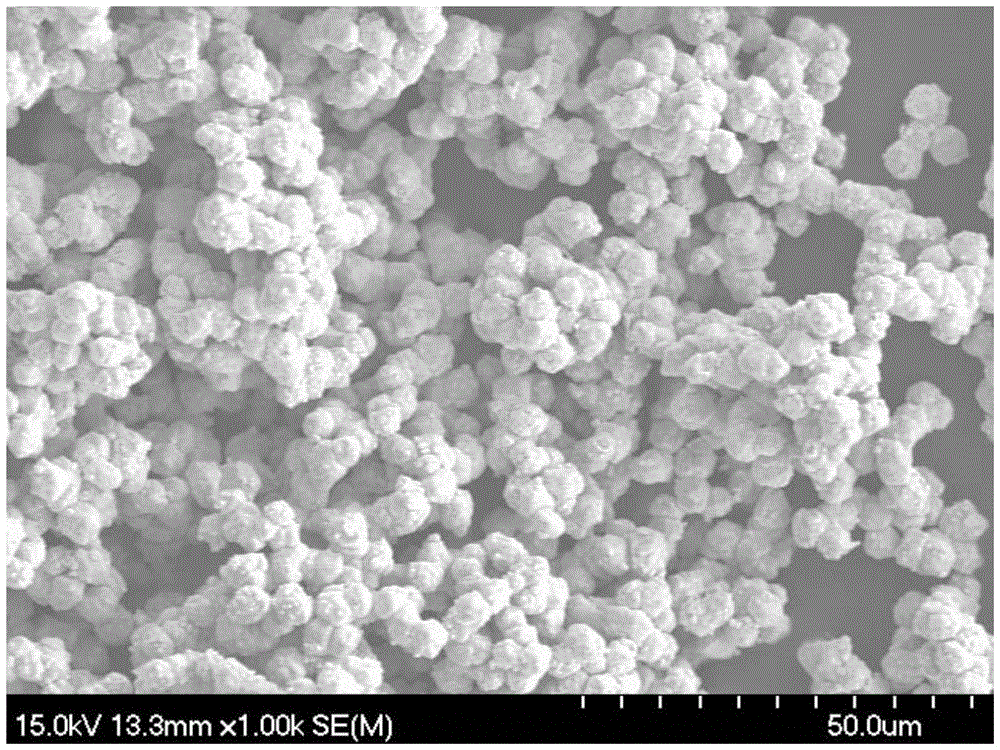

[0046] Take 250 g of spherical copper powder with a particle size of 2-3 μm and place it in 500 ml of 0.5 mol / L dilute sulfuric acid solution, stir and wash for 3-5 minutes to remove the oxide layer on the surface of the copper powder, and then wash twice with deionized water to remove the remaining Acid solution on the surface of copper powder, filter deionized water to obtain clean copper powder;

[0047] Add copper powder to 500ml of deionized water, then add 12.5g of PVP58000, stir well to make a copper powder suspension for use; dissolve 500g of nickel sulfate hexahydrate in 1.5L of deionized water to prepare a nickel sulfate solution for use;

[0048] Add the configured nickel sulfate solution to the copper powder suspension, place it in a water bath with a temperature of 55°C and stir it ultrasonically for 5 minutes, and add 110ml of 80% hydrazine hydrate and 250ml of 10mol / L of sodium hydroxide mixed solution, adjust the pH of the solution to 11 by 0.05mol / L sodium hy...

Embodiment 2

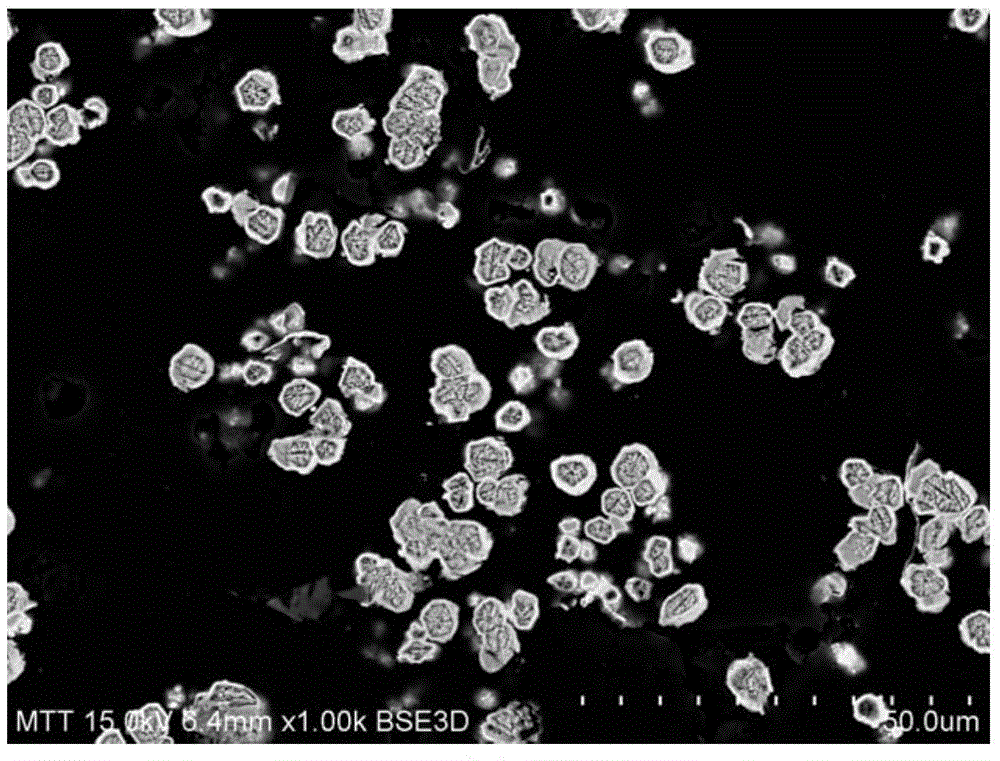

[0057] Take 50g of flake-shaped copper powder and place it in 100ml of 0.5mol / L dilute sulfuric acid solution, stir and wash for 3-5 minutes to remove the oxide layer on the surface of the copper powder, then wash twice with deionized water to remove the acid solution remaining on the surface of the copper powder , obtain clean copper powder after filtering deionized water;

[0058] Add copper powder to 100ml of deionized water, then add 2.5g of PVP58000, stir well to make a copper powder suspension for use; dissolve 28g of nickel sulfate hexahydrate in 100ml of deionized water to prepare a nickel sulfate solution for use;

[0059] Add the configured nickel sulfate solution to the copper powder suspension, place it in a water bath with a temperature of 55°C and stir it ultrasonically for 5 minutes, at an ultrasonic power of 500W and a stirring speed of 600rpm, add 6.5ml of 80% hydrazine hydrate and 14ml of 10mol / L of sodium hydroxide mixed solution, adjust the pH of the solut...

Embodiment 3

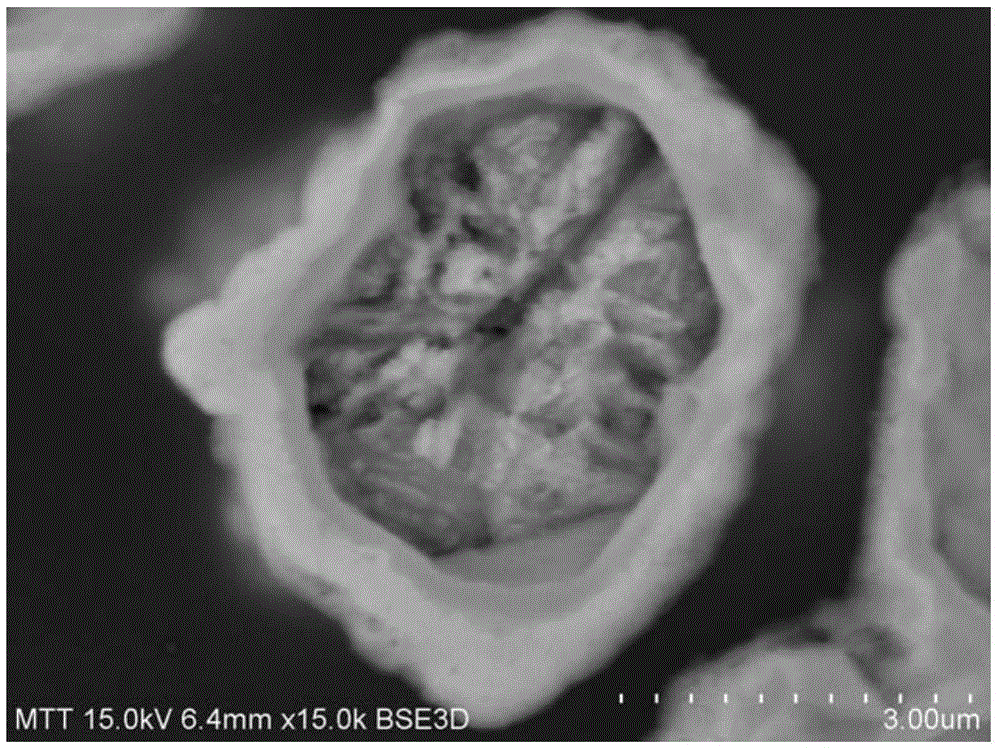

[0063] Take 50 g of spherical copper powder with a particle size of 5-7 μm and place it in 100 ml of 0.5 mol / L dilute sulfuric acid solution, stir and wash for 3-5 minutes to remove the oxide layer on the surface of the copper powder, and then wash twice with deionized water to remove the remaining Acid solution on the surface of copper powder, filter deionized water to obtain clean copper powder;

[0064] Add copper powder to 100ml of deionized water, then add 5g of PVP58000, stir well to make a copper powder suspension for use; dissolve 56g of nickel sulfate hexahydrate in 200ml of deionized water to prepare a nickel sulfate solution for use;

[0065] Add the configured nickel sulfate solution to the copper powder suspension, place it in a water bath with a temperature of 55°C and stir it ultrasonically for 5 minutes, at an ultrasonic power of 500W and a stirring speed of 600rpm, add 12.5ml of 80% hydrazine hydrate and 28ml of 10mol / L of sodium hydroxide mixed solution, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com