High-strength steel thin-wall piece vacuum thermal treatment process

A technology of vacuum heat treatment and thin-walled parts, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of small safety factor, high cost, high labor intensity, etc., and achieve increased solid solution strengthening effect and phase transformation strengthening effect. , Eliminate manual cooling operation and cleaning operation, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

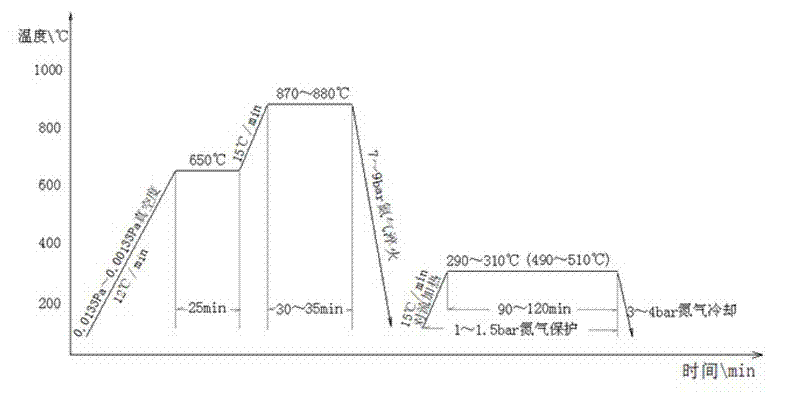

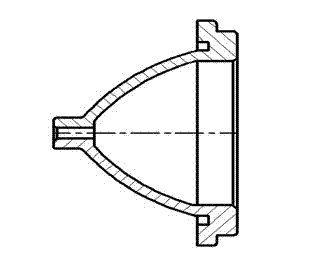

[0021] Example 1: Thin-walled parts made of high-strength steel: support cylinder, see attached figure 2 , The material is 35CrMnSiA, cleaned with aviation washing gasoline, and then vacuum heat treated after drying. When vacuum quenching, when the vacuum degree reaches 3.51×10 -3 After Pa, heat at 12°C / min to 650°C for 25 minutes, then heat at 15°C / min to 870°C for 35 minutes, then fill the furnace with 8.5bar high-purity nitrogen for pressure quenching, and cool to 60°C , and then conduct vacuum tempering directly; during vacuum tempering, when the vacuum degree reaches 3.32×10 -3 Pa, fill the furnace with 1bar high-purity nitrogen, and then heat at 15°C / min to 290°C-310°C for 2 hours, then fill the furnace with 3bar high-purity nitrogen for air pressure cooling, and cool to 50°C- Baked at 60°C. After the thin-walled parts are oiled and rust-proofed, the hardness and size are tested, and the furnace samples are subjected to tensile tests.

Embodiment 2

[0022] Example 2: Thin-walled parts made of high-strength steel: baffle, see attached image 3 , material 45CrNiMo1VA, when vacuum quenching, when the vacuum degree reaches 4.51×10 -3 After Pa, heat at 12°C / min to 650°C for 25 minutes, then heat at 15°C / min to 880°C for 30 minutes, then fill the furnace with 8bar high-purity nitrogen for pressure quenching, and cool to 60°C. Then carry out vacuum tempering directly; when vacuum tempering, when the vacuum degree reaches 4.32×10 -3 Pa, fill the furnace with 1bar high-purity nitrogen, then convectively heat at 15°C / min to 490°C-510°C for 1.5 hours, then fill the furnace with 3bar high-purity nitrogen for air pressure cooling, and cool to 50°C ~ 60 ℃ out of the oven. After the thin-walled parts are oiled and rust-proofed, the hardness and size are tested, and the furnace samples are subjected to tensile tests.

[0023] The following table lists the materials, specifications, furnace loading and vacuum heat treatment process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com